Stress Concentrations

advertisement

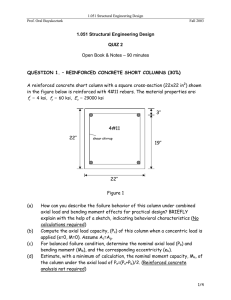

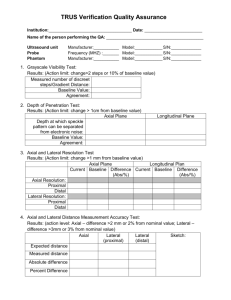

EGR 236 Properties and Mechanics of Materials Lecture 09: Stress Concentrations Spring 2014 Today: -- Homework questions: -- New Topics: -- Stress Concentrations -- Homework: Read Section 4.7 Work Problems from Chap 4: 93, 95, 100 Following today's class you should be able to: -- Understand what types of features and discontinuities cause stress level to increase. -- Calculate expected values of stress in the vicinity of discontinuous features. Stress Concentrations: The axial deformation equation that we have worked with so far is effective for determining stress in members with uniform shape and composition at locations in the body that are located sufficiently far enough away the point of load application. Directly around the point of load application, the stresses and strains can be considerably higher than the stress predicted by that of the axial load equation. The higher stresses at the point of an applied load are called stress concentration points. Stress concentrations also arise at locations along the axial member where the geometry undergoes a change in the cross sectional area or material composition. This is especially true if the change occurs very suddenly and abruptly. We have looked at the stress set up in one such example during the FEA lab 1. In lab one a model of a flat plate with a hole in the middle was subjected to an axial load. The maximum stress levels found to be near the hole. Examples of common stress concentration patterns: When designing a part we will be interested in determining the largest stress. This max stress will limit the maximum load that can be carried. The FEA tools are extremely useful to predict stresses that occur with changing geometry. The FEA tool offers a way to predict the maximum stress for whatever geometry of part is shown. Another method used to determine the maximum stress of some common geometry changes can be found using readily available graphical stress concentration tables. While limited to simple cases, the tables can be useful to predict the stress concentration factor in the vicinity of holes and internal fillets on flat plates subjected to axial loading. The stress concentration factor, K, may is defined as max K ave This value depends very heavily on the sharpness of the hole or corner. Very sharp corners amplify the stress. One of the most important general design rules you should always keep in mind when designing a part subjected to loads, is to avoid sharp internal corners. Example 1: ----------------------------------------------------------------------------------------------- Example 1: ----------------------------------------------------------------------------------------------Find Stress Concentration factor: D = 60 mm d = 40 mm t = 10 mm r = 8 mm Find: D/d and r/d D 60 1.5 d 40 and r 8 0.2 d 40 Reading the K value from the table for internal fillets: K ≈ 1.85 Find Average Stress: F P ave A td combining this with the stress concentration equation: KP max K ave td allows us to solve for the largest force P that can be held. td (165MPa)(10mm)(40mm N / mm2 P ) 35675 N K 1.85 MPa Example 2: The resulting stress distribution along the section AB for the bar is shown in the figure. a) From this distribution, determine the approximate resultant axial force P applied to the bar. b) What is the stress-concentration factor of this geometry. ----------------------------------------------------------------------------------------------- a) Approximate axial force, P P dA [Area Under Stress-Cross Section Diagram] By inspection: 25 28 33 29 ksi 3 A (0.75in)(6 0.4in) 1.8in2 ave Therefore: P ave A (29ksi )(1.8in2 ) 52.2 kip b) Stress Concentration: K max ave where ave 25 28 33 29 ksi and 3 so K 36ksi 1.24 29ksi max 36 ksi