Contracting

advertisement

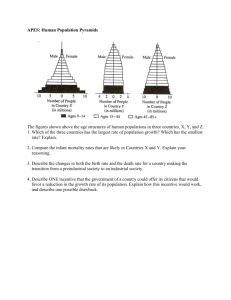

SE503 Advanced Project Management Dr. Ahmed Sameh, Ph.D. Professor, CS & IS Managing Contractors and Consultants What is a Contract? Offer to do business (Request for Proposals) Acceptance of offer (Formal Proposal) Agreement on consideration (Pay/Incentives) Constraints – – Owners scope of work must be legal activity Contractor must be legally able to perform the scope of work Contract Procedure Definition of Needs (Bid package) Invitation to Bid Pre-bid meeting Solicitation Period Bid Opening Post-Bid Discussion/Negotiation Bid Award Bid Package Detailed Scope of Work Detailed Drawings (list) Detailed Specifications (materials and methods) Acceptance of Work by Owner Financial Arrangements (contract type, fee formula, multipliers, payment schedules) Materials Supplied by Owner Materials Supplied by Contractor Project/Work Schedule Sealed Bids to be Delivered to ___ by ___ Technical Questions to be Directed to ___ at ___ Legal “boilerplate” – reserve the right to reject any and all bids Procedures... Invitation to Bid (RFP) – – – Send to known contractors (how many?) Publish if necessary Dates/times/locations Pre-Bid Meeting – – Information, clarification Site tour Procedures… Solicitation period – – How long? Student’s syndrome Bid opening – – – – Late bids not accepted All bids sealed Witnessed opening Note exceptions Bid Problems Late Bids Low Bids High Bids Not Enough Bids Sandbagging Unfairness & Unethical Behavior Procedures… Bid Award – – – Discussion/Negotiation Final documents + changes to successful bidder “Dear John” letter to unsuccessful bidders How much do you tell them? Contract Types Fixed Price – – Incentive fee Fixed fee (hidden) – – – Cost Plus – – – Incentive fee Fixed fee Percentage fee Time & Material Established labor rates Material mark-up Not to exceed Do Not Combine Contract Types with a Single Contractor Change Order Change to the scope of work or specifications during contract execution Additional compensation and time for the contractor Some contractors rely on these for profit Have a well-documented procedure Which is Best? Contractors and owners often have different objectives Many contract types are possible How do we find out which is best without actually executing the project? – – Simulated environment Intelligent agents Objectives of The Parties Owner – – – Contractor – – Budget Schedule Quality Profit margin Future business Objectives often conflict Intelligent Agents React to environment Autonomous control of actions Goal oriented Communication with other agents Learning ability Believable behavior One Possible Approach Intelligent agents can be used to model the owner-contractor relationship The model can be used to determine which contract will lead to the best outcomes for a given situation A Lot of Assumptions Owner – – Single task… Done by a single contractor Item Crew size (workers) Labor required (worker-hours) Duration (8-hour days) Estimate 5 400 10 Labor cost (400 hr. @ $56/hr.) $22,400 Material cost $30,000 Contractor fees (15%) Total project cost $7,860 $60,260 Economic Assumptions 10-year life No salvage value Benefits of $12,000 per year IRR 15% Year 0 Costs Benefits $60,260 Cash Flow -$60,260 1 $12,000 $12,000 2 $12,000 $12,000 3 $12,000 $12,000 4 $12,000 $12,000 5 $12,000 $12,000 6 $12,000 $12,000 7 $12,000 $12,000 8 $12,000 $12,000 9 $12,000 $12,000 10 $12,000 $12,000 Contractor Assumptions Adequate crew size Fixed overhead of $6000 Target profit margin 6% Labor rate – – – – $40/hour base $16/hour load $56/hour total No overtime Contractor Parameters Labor productivity – Labor quality – 0.8 to 1.2 0.8 to 1.0 Material quality – 0.8 to 1.0 Simulated Task Estimated labor hours, material cost, crew size Target – – – – – Labor productivity 1.0 Labor quality 1.0 Material quality 1.0 Budget: labor+material+15% Duration based on estimated hours, crew size Simulated Contracts Fixed bid Time and material (15% markup) Fixed labor (15% on material) Fixed fee ($10,000) Budget incentive ($7500+50% of savings) Schedule incentive ($7500+$1500/day) Quality incentive ($7500+ $150/% point) Contractor Bidding Bids were submitted to match the contract type Bidding rule was 10% over expected variable cost Contractor Learning Maximize profit margin inv mat lab oh p inv By adjusting – – – Labor productivity Labor quality Material quality Simulated Annealing - Iterations Parameters initialized to 1.0 Step size set at 0.05 One of three parameters chosen at random Direction of change chosen at random Change made if within limits Execute contract and check profit Keep the change if profit improves Repeat 60 times at each step size Simulated Annealing Convergence Reduce step size by 0.80 multiplier Do 60 more iterations at new step size Repeat until step size is below 0.0001 Typical Learning Performance Learning Progress, Fixed Bid Contract 10.00% Profit Margin 5.00% 0.00% -5.00% -10.00% -15.00% 1 6 11 16 21 26 31 36 41 46 51 56 61 66 71 Iteration Current Best 76 81 86 91 96 101 106 111 116 Task Outcomes Contract Type Quality Duration (Days) Labor Cost ($) Material Cost ($) Fees ($) Total Cost ($) Fixed Bid 0.8 10.4 $23,330 $24,000 $10,288 $57,640 Time and Material 0.8 15.6 $35,000 $37,500 $10,880 $83,380 Fixed Labor 1.0 8.3 $18,670 $30,000 $10,470 $59,140 Fixed Fee 0.8 10.4 $23,330 $24,000 $10,000 $57,330 Budget Incentive 0.8 10.4 $23,330 $24,000 $10,040 $57,370 Schedule Incentive 1.0 8.3 $18,670 $30,000 $10,000 $58,670 Quality Incentive 1.0 8.3 $18,670 $30,000 $10,000 $58,670 Target 1.0 10.0 $22,400 $30,000 $7,860 $60,260 Contractor Outcomes Contract Type Labor Productivity Labor Quality Material Quality Profit Margin (%) Fixed Bid 1.2 1.0 0.8 7.5% Time and Material 0.8 0.8 1.0 5.9% Fixed Labor 1.2 1.0 1.0 7.6% Fixed Fee 1.2 1.0 0.8 7.0% Budget Incentive 1.2 1.0 0.8 7.0% Schedule Incentive 1.2 1.0 1.0 6.8% Quality Incentive 1.2 1.0 1.0 6.8% Target 1.0 1.0 1.0 6.0% Owner Outcomes - Economics Quality factor (labor quality x material quality) Benefit values multiplied by QF First-year benefits adjusted up (or down) $48 per day that job was ahead of (or behind) schedule Cost set to actual invoice amount IRR (%) calculated based on adjusted cash flows Owner Outcomes Contract Type Quality Duration (Days) Total Cost ($) Benefit Year 1 Benefit Years 2-10 Return (IRR%) Fixed Bid 0.8 10.4 $57,640 $9580 $9600 10.5% Time and Material 0.8 15.6 $83,380 $9331 $9600 2.6% Fixed Labor 1.0 8.3 $59,140 $12081 $12000 15.5% Fixed Fee 0.8 10.4 $57,330 $9580 $9600 10.7% Budget Incentive 0.8 10.4 $57,370 $9580 $9600 10.6% Schedule Incentive 1.0 8.3 $58,670 $12081 $12000 15.7% Quality Incentive 1.0 8.3 $58,670 $12081 $12000 15.7% Target 1.0 10.0 $60,260 $12000 $12000 15.0% Owner Perspective Fixed Labor, Schedule Incentive, and Quality Incentive contracts best – Fixed Bid, Fixed Fee, and Budget Incentive contracts next – High quality, high IRR, ahead of schedule On time, lower quality, lower IRR Time and Material contract worst – Low quality, very late, very low IRR Contractor Perspective Fixed Labor, Fixed Bid best (7.5-7.6%) Fixed Fee and Incentive contracts next (6.87.0%) Time and Material good for keeping people busy and maintaining profit margin (5.9%) Contractor needs access to high quality, productive labor pool to exceed target profit margin Risk Allocation Risk/Reward tradeoff Contractor – – – Fixed Bid highest Fixed Labor and Incentive contracts moderate Fixed Fee and Time and Material lowest Owner – – – Fixed Bid, Budget Incentive, and Fixed fee limited budget risk Fixed Labor, Schedule Incentive, and Quality Incentive balanced the priorities Time and Material was highest risk (no reward) Personal Experience Believable contractor behavior Fixed Bid Time and Material Fixed Labor Penalties and incentives What Contract is Best for the Owner? It depends… The level of detail possible or desirable in the bid package The relative priorities of budget, schedule, and quality The willingness of the owner to assume risk Decision Process Limitations Simple bid process No change orders Single task/single contractor Many assumptions Multiple Contractors Common situation – – Individual incentives clash – – Engineer-Procure-Construct (EPC) Multiple trades or specialties Owner objectives Contractors may make money at the expense of others or the project Proposed Contract: Incentive fee pool Incentive Contract Types Firm Fixed Price Const Plus Fixed Fee Cost Plus Incentive Fee – – – High owner risk (cost plus fixed fee) High contractor risk (firm fixed price) Risk sharing Risk sharing contracts work! Risk Sharing Formula Single Contractor F mo B Where: F is fee due contractor m0 is original contractor profit margin B is original budgeted cost of the work ρ is risk sharing fraction Δ is deviation from original budget (over-run being positive) Incentive Fee Formula B1 1 F1 mo Bt t Bt t where : Bt B1 B2 B3 t 1 2 3 Profit Margin mo Bt t m1 m2 m3 Bt t Some Scenarios Over-run – – One or more contractors exceed budget Profit margin for each contractor drops Under-run – – One or more contractors come in under budget Profit margin for each contractor increases More Scenarios Bad trade-off – – One contractor saves money at the expense of the other contractors, increasing project cost Profit margin for each contractor drops Good trade-off – – One contractor spends more money but the others are able to save as a result, decreasing project cost Profit margin for each contractor increases Contractor Profit and Owner Cost 16.50 Contractor Profit Margin (%) 16.00 15.50 15.00 14.50 14.00 13.50 102.5 102.0 101.5 101.0 100.5 100.0 99.5 99.0 Owners Final Cost (Thousands) 98.5 98.0 97.5 Variations Different sharing fractions Different profit margins Quality incentives Schedule incentives Conclusions CPIF works well for single contractors Cost Plus Pooled Incentive Fee (CPPIF) works for multiple contractors Holistic behavior – – – All parties work toward common goals Cooperation encouraged All contractors have same profit margin Contract Management Head Counts Material Verification Work Quality, Schedule, and Cost Control Document All Changes in Writing Close Out ASAP Be Hard Nosed (They are!) Engineering Consultants Need for Consultants – – Specific skills Size of project Consultant Responsible For... – – – Design Construction/Start-up Contracting Evaluating Consultants Reputation (Talk to other clients) Size/Success Appropriate Skills People Available for YOUR Job Location Cost Consulting Agreements Hours & Expenses Maximum (not to exceed) Fixed Fee On-Site or Off-Site Define Expenses – – Office/copies/fax/phone/secretarial Travel Consultants Are... Professionals Design-Oriented (less concerned with budget and schedule) Expensive Obtaining Bids from Consultants Scope of Work Poorly Defined Work Difficult to Estimate People are Dynamic (Other Jobs) Not to Exceed Figure Incentive Formula Clearly Identify Deliverables & Dates Expect Deviation from Estimate Managing Consultants Monitor Progress and Deliverables Monitor Quality of Design/Specs/Drawings Verify Hours and Expenses Control Travel Document Change Requests in Writing Terminate Agreement ASAP Be Professional (If they are!) Summary Contract management has been called the “Keystone of project management” Contract and consultant management is difficult Good contract and consultant management is a huge step toward good project management