IPL and Logistics - Center for Integrated Operations in the Petroleum

advertisement

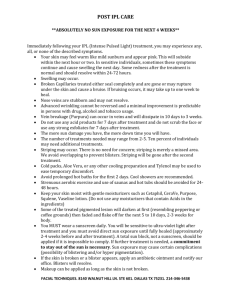

CENTER FOR INTEGRATED OPERATIONS IN THE PETROLEUM INDUSTRY TECHNICAL COMMITTEE MEETING May 7TH-8TH, 2013 at Trondheim Airport Agenda Participants Status report October 2012 - April 2013 1 CONTENTS Page AGENDA 3 PARTICIPANTS 4 STATUS REPORT OCTOBER 2012 – APRIL 2013 6 IO 1 IO TEAMWORK AND CAPABILITIES 7 IO2 INTEGRATED PLANNING AND LOGISTICS 10 IO3 PROACTIVE MANAGEMENT OF SAFETY AND ENVIRONMENT 14 IO4 PRODUCTION AND PERFORMANCE OPTIMIZATION 16 T3 SYSTEM INTEGRITY AND DYNAMIC RISK ASSESSMENT 18 TELEMEDICINE 20 2 AGENDA Location: Hotel Radisson Blu, Værnes Start: May 7th at 09.30 End: May 8th at 14.30 Suggested air flights, domestic To Trondheim May 7th Departure - Arrival From Trondheim May 8th Departure – Arrival Stavanger Bergen Oslo 06:40 - 08:35 07.35 – 08.35 08.00 – 08.55 or 07.00 – 07.55 15:30 - 17:25 15.30 – 16.30 15.30 – 16.25 DAY 1, TUESDAY MAY 7th 09.30-10.00 10.00-10.45 Welcome, presentation of program and participants Highlights from on-going projects Telemedicine IO1 IO Teamwork and Capability IO2 Integrated Planning and Logistics 10.45-11.15 Break 11.15-12.00 Highlights from on-going projects cont’d. T3 System Integrity and Dynamic Risk Assessment IO3 Proactive Management of Safety and Environment IO4 Production Optimization and Subsurface IO 12.00 - 13.00 Lunch 13.00 – 17.00 Parallel sessions (Including breaks) Presentation of status and results, feedback from industry partners and academic collaboration partners IO1 - IO IO2 - Integrated IO3 - Proactive IO4 - Production T3 - System Teamwork and Planning and Management of Optimization and Integrity and Capability Logistics Safety and Subsurface IO Dynamic Risk Environment Assessment 18.45 19.30 “Discovery session from Antarctic Expedition and other places”, Mike Herbert, ConocoPhillips. Dinner DAY 2, WEDNESDAY MAY 8th 08.30 – 09.30 Presentation of Knowledge Dissemination System, Jon Lippe 09.30 - 10.00 Break 10.00 – 11.30 Parallel sessions, continued from Day 1 IO1 IO2 IO3 IO4 11.30-12.30 Lunch 12.30-14.30 Plenary session Experience with cooperation between industry partners and IO Center Short presentations by industry partners on selected projects. Discussion. T3 3 PARTICIPANTS IO CENTER PARTNER NAME EMAIL TC INDUSTRY REPRESENTATIVES Aker Solutions Aker Solutions Aker Solutions Aker Solutions Aker Solutions BP BP BP BP BP BP ConocoPhillips ConocoPhillips DNV DNV DNV Eni Eni FMC FMC GDF SUEZ IBM IBM IBM IBM IBM Kongsberg (KOGT) Kongsberg (KOGT) Kongsberg (KOGT) Petrobras Petrobras Petrobras Petrobras Shell Shell SKF SKF Statoil Statoil Statoil Rohit Singh Rune Folstad Øystein Bjaanes Jonas Paulen Erik Walle Mikkelsen Paul Hocking Malcolm Woodman Greg Hickey Asbjørn Tansø Espen Arild Berge Tore Tjøstheim Mike Herbert Tor Cranner Erik Østby Bjørn Tore Hellesøy Sandra Hogenboom Gregar Haugen Eirik Holand Knut Vannes Bent Helge Nystad Kjell Ola Jørgensen Øystein Haaland Frode Myren Ulisses Melo David Echeverria Ciaurri Morten Dalsmo Angela Myhre Helge Didriksen Roar Nilsen Alex Furtado Teixeira Francisco Sant Anna Paulo Viana Silva Francisco Mei Choate Rolf Einar Sæter Jean-Luc Montesano Geraint Jones Øyvind Fevang Trond Lilleng Vidar Hepsø rohit.singh@akersolutions.com rune.folstad@akersolutions.com oystein.bjaanes@akersolutions.com jonas.paulen@akersolutions.com erik.walle.mikkelsen@akersolutions.com Paul.hocking@no.bp.com malcolm.woodman@uk.bp.com greg.hickey@uk.bp.com asbjorn.tansoe@no.bp.com espen-arild.berge@no.bp.com tore.tjoestheim@no.bp.com mike.herbert@conoccophillips.com Tor.Cranner@conocophillips.com Erik.Ostby@dnv.com Bjorn.Tore.Hellesoy@dnv.com sandra.hogenboom@dnv.com gregar.haugen@eninorge.com Eirik.Holand@eninorge.com knut.vannes@fmcti.com benthelge.nystad@fmcti.com kjell-ola.jorgensen@gdfsuezep.no oystein.haaland@no.ibm.com MYREN@no.ibm.com ulissesm@us.ibm.com decheve@us.ibm.com morten.dalsmo@no.ibm.com Angela.myhre@kongsberg.com hd@kdms.no Roar.nilsen@kongsberg.com alex.teixeira@petrobras.com.br jlrangel@petrobras.com.br pviana@petrobras.com.br franciscocss@petrobras.com.br mei.choate@shell.com rolfeinar.saeter@shell.com Jean-Luc.Montesano@skf.com Geraint.Jones@skf.com ofe@statoil.com TRLIL@statoil.com VIHE@statoil.com 4 IO CENTER PARTNER TC INDUSTRY REPRESENTATIVES, CONT’D Statoil Statoil Statoil Statoil Total Total Total IO CENTER STAFF SINTEF NTNU Petromanagement IFE Marintek NTNU Sintef SINTEF SINTEF Marintek NTNU NTNU NTNU NTNU NTNU NTNU IO CENTER, OTHER TEAM MEMBERS IFE IFE IFE IFE Marintek Marintek NTNU NTNU NAME EMAIL Gisle Nygård Tor Tønnessen Oskar Morten Fredagsvik Vidar Olaf Eriksen Ying Guo Ida-Marie Kastrud Åge Engen Pedersen giny@statoil.com torto@statoil.com ofr@statoil.com voer@statoil.com Ying.Guo@ep.total.no ida-marie.kastrud@ep.total.no aage-engen.pedersen@ep.total.no Lars Bodsberg Bjarne Foss Arild Nystad Grete Rindahl Lone Sletbak Ramstad Vidar Gunnerud Knut Steinar Bjørkevoll Stein Hauge Nicola Paltrinieri Per Kristian Norddal Eric Monteiro Ingrid Bouwer Utne Per Morten Schiefloe Stein Haugen Torgeir Haavik Curtis Whitson lars.bodsberg@sintef.no Bjarne.Foss@itk.ntnu.no arild.nystad@petromanagement.com grete.rindahl@hrp.no LoneSletbakk.Ramstad@marintek.sintef.no vidar.gunnerud@itk.ntnu.no KnutSteinar.Bjorkevoll@sintef.no stein.hauge@sintef.no nicola.paltrinieri@sintef.no PerKristian.Norddal@marintek.sintef.no Eric.Monteiro@idi.ntnu.no ingrid.b.utne@ntnu.no perms@svt.ntnu.no stein.haugen@ntnu.no torgeir.haavik@samfunn.ntnu.no whitson@pera.no Claire Taylor Espen Nystad Asgeir Droivoldsmo Sizarta Sarshar Even Ambros Holte Grethe Ose Harald Rødseth Aleksander Juell claire.taylor@hrp.no espen.nystad@hrp.no Asgeir.Droivoldsmo@hrp.no Sizarta.Sarshar@hrp.no EvenAmbros.Holte@marintek.sintef.no Grethe.Ose@marintek.sintef.no harald.rodseth@ntnu.no aleksander.juell@ntnu.no 5 STATUS REPORT OCTOBER 2012 – APRIL 2013 6 IO1 IO TEAMWORK AND CAPABILITIES The activities on Leadership, Teamwork and Capability development are working close together. The key industry pilot for Capability development is Eni Norge’s development of the Goliat field. Focus areas for capability research are Fleshing out and operationalizing the capability framework Development of methodology for practical utilization of a capability framework The project works to establish practical guidance for use of the capabilities concept in a scalable IO implementation model. The current phase of the pilot work covers the whole framework model (figure below), but is specifically aimed at the identification and development of cross organisation resources to support next generation IO. In order to understand the challenges faced by leaders, it is first important to identify a level of leadership and an area of collaboration to focus on. We have so far decided to focus on leadership within and between operational Distributed Collaboration Structures (DCSs) as these are probably the most visible example of a collaborative work environment. From Assessing the Quality of Collaboration in an Integrated Operations Organization. A. B. Skjerve, E. Nystad, G. Rindahl and S. Sarshar. 2013. 7 Two ongoing case studies of the IO 1 project have as main purpose of investigating teamwork challenges and lessons learned from teamwork in IO. A case study of a production optimization meeting was initiated at Sleipner (Statoil) in 2012. Another case study of a production optimization meeting at Gjøa (GDF) has started this year. A first round of data collection has been finished at Sleipner, and results have been described in a paper that has been delivered to the ESREL 2013 conference: " Assessing the Quality of collaboration in an Integrated Operations Organization" by A.B. Skjerve, E. Nystad, G. Rindahl and S. Sarshar. The paper describes the development of a method for assessing quality of collaboration in distributed collaboration structures (DCS). The concept of DCS was introduced because within IO it makes more sense to look at teamwork in a larger context than an isolated IO team. It is also a problem to define what constitutes an IO team. A DCS can be defined as the organization of a set of distinct, interdependent collaborative activities, which are all required to achieve an operational goal that: (1) cannot be achieved by co-located people on their own, and (2) cannot be achieved through a single joint collaboration session. 8 9 IO2 INTEGRATED PLANNING AND LOGISTICS IPL and Logistics A key activity has been to develop an understanding of logistics role in integrated planning in offshore operations and how new design of logistics planning processes can facilitate improvement of IPL. Further, an interesting topic is how principles from Lean and Agile can benefit offshore integrated planning and logistics. This is described in the white paper Integrated Planning and Logistics under stable and unstable conditions. Central in the work is the distinction between Lean and Agile capabilities which are important for handling both stable and unstable logistical conditions and Supply Chain Management in planning of offshore logistics. In this work the Statoil and the Petrobras pilot have both been very useful. The Statoil pilot has been connected to the internal LERC (Logistics and Emergency Response Center) project, focusing on how logistics can be implemented in the Planning Hierarchy and the integrated planning processes. In further work it is important to conduct some experiments/action research togheter with the industry partners to test how planning principles from Lean and Agile can conribute to more efficient planning practices across boundaries. It is expected that the white paper will be updated during the project, due to collaboration with industry partners and researchers from UC Berkeley who have years of experiences with Lean and implementation of Lean in the construction industry. IPL from a Subcontractor’s perspective IO2 has just started a pilot with Aker Solutions where the objective is to identify challenges in Maintenance and Modification (M&M) planning, improvement areas and assist in implementation of improvements. We are now conducting a survey including interviews and questionnaires for identifying planning challenges across internal boundaries and in the interfaces with Statoil, M&M Gullfaks. The IPL framework and tools are (or will be) used, including the new web based version of the IPL screening tool for assessing IPL maturity in the organization. UC Berkeley will participate in a workshop in June to plan the next phase of the pilot, where they plan to conduct an action research experiment including planning principles of Lean philosophy. It is expected that this work will contribute with valuable insight on how to improve integrated planning practices based on their extensive experiences from planning across boundaries in the construction industry. It is important that we manage to transfer this knowledge to the other industry partners especially when it comes to possible improvements of integrated planning between operators and sub-contractors. We propose to use the IPL Laboratory as an arena for sharing and further developing this knowledge. IPL Laboratory Concept including "IPL-Apps" This spring we have started the development of a concept named The IPL laboratory. This is a client focused and module-based training arena/tool supporting development and implementation of IPL. It is an arena where knowledge, tools and methods generated by IO2 can be tailored to the specific needs of a company, and thereby support development of IPL practices. The specific content of the different modules depends on the "IPL maturity" of the respective organization. Thus, the IPL Lab aims to support the mutual exchange of knowledge and experience between the R&D sector and the industry in a user friendly way. The concept includes actively use of interactive applications, "Apps", for strengthening the transfer of knowledge and learning experience. The Laboratory is organized in 5 different modules. A draft concept has recently been presented to Petrobras. Provided that we achieve positive response, the IO2-team would like to get the other industry partners on-board. The TC – meeting is an important arena to get this feedback. 10 - Module O Definition of main objectives The IPL App Introduction to IPL Module 1 - Introduction to IPL - Definition of AS-IS Module 2 - Description of To-Be Interactive IPL Module 3 De-brief/ evaluation Module 4 Follow- up The IPL Laboratory - a client focused and module-based training arena/ tool supporting development and implementation of Integrated Planning and Logistics 11 Milestone diagram 2013 PROJECT: IO 2 - INTEGRATED PLANNING AND LOGISTICS Jan – March Activity Theme 1. KPIs for IPL processes and plans PhD work: Theme 2. Optimization of logistics operations PhD work: April - June July - September October - December Paper 2 Paper 1 Field work/ Industry collaboration (IC) Theory study Field work / IC Paper 1 2Master thesis Theme 3. Decision Making in Cross-Professional Team PhD thesis completed Work shop IO Conf. Theme 4 The IPL-Model /Concept Case 1 Statoil Paper 2 Paper M6 work document Continue Field work with Statoil- LERC focusing on logistics & collaboration Master thesis M6 work document Paper Postponed Decision Gate Ongoing activity Workshop or seminar Completion Technical report or paper Decision Gate Work document or collected data Input KDS Planned Completed Delayed 12 Milestone diagram 2013 PROJECT: IO 2 - INTEGRATED PLANNING AND LOGISTICS Jan – March Activity April - June July - September To-be analysis Case 2 Petrobras Case 3 Aker Solutions October - December New solutions & testing Master thesis Field work Aker Solutions M6 work document M12 work document Testing web based "Readiness assessment tool" Industry Collaboration KDS/WikiO IPL Screening tool Version 3 Version 3 Draft version 3 for review to partners IPL Handbook Version 2 App & WikiO Book: Different Perspectives on integrated planning First draft & Status report Field work BP GAP analysis Case 4 BP Delayed because of reorganization in BP Ongoing activity Input KDS Workshop or seminar Technical report or paper Completion Decision Gate Work document or collected data Completed Planned Delayed 13 IO3 PROACTIVE MANAGEMENT OF SAFETY AND ENVIRONMENT The main objectives are to improve proactive management of safety and environment by applying IO-related solutions to prevent major accidents, including new methods and work processes for monitoring and anomaly detection during drilling and productions. Main industry partners involved in case studies are BP, ConocoPhillips, DNV and Statoil. Simplified risk management framework in an IO context Online monitoring of the risk picture In the last period a report has been published on: "Proactive indicators for managing major accident risk in integrated operations". The report presents a method that better utilizes "on-line" data to assess the impact on the risk level for daily HSE management decision support. The case study has focused on process related risk and a set of barrier indicators have been suggested as a means of monitoring the risk continuously. To visualise the risk, a "risk barometer" has been proposed as shown below. This barometer can be used as a qualitative aid to say something about the estimated risk level at a given point in time (instantaneous risk) and whether it is above or below the average risk over the last period. Beyond this it can also be applied to support certain decision criteria or rules. E.g. when the total risk indicator is exceeding a certain value, no more work permits related to work on HC-systems is allowed in that area, or when the indicator is exceeding another values all work on HC-systems in that area is stopped. Facilitating sensemaking process and collective learning Three reports have been published which documents results from case studies at Statoil and ConocoPhillips. We have analyzed the dilemmas personnel face during drilling operations when personnel must employ actions and strategies beyond the confines of the plan. The case study report suggests measures such as alternative models, more hands-on involvement, better utilisation of existing real-time data and explicit training on interpretation work. Another case study report explores the concept of collective learning as a primary capability in facilitating sense making. Main recommendations refer to: 1) Collective learning as a capability in drilling, 2) The value of learning-by-doing for drilling safety and performance, 3) Exploitation of document repositories for experience transfer and dashboard development, 4) Robust sense making and attention management for capturing “weak signals”. Anomaly detection during drilling With final versions of 2012 reports finished, work on more operational deliveries like guidelines and operational recommendations has started. The work on refinement of mathematical methods to make it more robust and fit for purpose has continued. We envision a "smart" alarm system which helps employ the human resources onshore in investigating alarms and let the driller "talk back" to the computer. Recommendations will include description of how mathematical methods should be adapted and further developed to better meet the needs seen in the interaction with humans and alarm systems. Work on developing and testing prototypes accordingly is planned. 14 15 IO4 PRODUCTION OPTIMIZATION AND SUBSURFACE IO The two programs IO4 Production and performance optimization and T2 Subsurface IO were merged 2013-01-01. The reason is to exploit the boundary between short term production optimization and reservoir management. Several activities within the earlier separate programs were also merged so IO4 now consists of seven separate activities as shown in the attached milestone diagram. All of the seven activities are run in cooperation with IO center partners. Some selected results are presented below. The selection is made to complement earlier reports and is hence not based on any prioritization of results. Based on feedback from the IO center board and the last TC-meeting more emphasis is currently placed on dissemination of results. 1. SmartX – a method for well monitoring A new approach to testing of oil and gas wells by means of sinusoidal oscillations in flow and pressure instead of the traditional build-up test has been developed. This approach allows faster and simultaneous testing of several wells, with no need for a dedicated test header; it can also be adjusted to strike an appropriate compromise between measurement precision and production loss. A SmartX video is developed to illustrate the method’s potential, and field tests are performed in an associated project. Further, the SmartX method is patented by NTNU and SINTEF. 2. IO center and SPE workshop on Norne data The IO center has developed and supports a portal that makes Norne field data available for research. The Norne data provide users with the ability to develop new knowledge on the integration of data sources (in particular 4D seismics and production data) for rapid history matching and reservoir management. A 2nd benchmark case is currently studied by research groups who will come together at a IO center / SPE Advanced Technology Workshop in June 2013 in Trondheim to discuss and compare methods and approaches. We expect 80 participants to this 2nd Norne workshop. 3. Production optimization in shale gas systems The shale gas (and oil) industry is developing rapidly. We have developed a new approach for dynamic production scheduling. The method uses a cyclic shut-in scheme once the well gas rate hits a lower critical rate, i.e., when liquid starts to accumulate in the wells, and is based on mathematical optimization. The method provides a systematic approach to production scheduling to for instance honor contractual obligations. Discussions are currently underway with IO center partners to test the approach in a realistic environment. 4. Education account The IO4 program (including earlier T2 program) has supported fully, or partially, 8 completed PhD theses, and is currently supporting 6 on-going PhD projects. Moreover, the program has been involved in 10-12 master student theses per year. The bulk of these students are currently employed by IO center partner companies. 16 17 T3 SYSTEM INTEGRITY AND DYNAMIC RISK ASSESSMENT Project T3 is working on 3 different cases; Case 1 System integrity and holistic risk understanding, Case 2 Experience transfer on usefulness of automation and monitoring systems for IO, and Case 3 Estimation of remaining useful life for turbo generators. Case 1 is in the start-up phase while Case 2 and 3 are well under way. The case studies conducted in T3 are related to collection and utilisation of data from technical systems, and how this can be transformed into valuable information in the decision making process. Experience transfer on usefulness of automation and monitoring systems for IO Case 2 was performed in collaboration with GDF SUEZ, where condition monitoring (CM) systems on the platform Gjøa was examined with regards to how well they performed. The main findings from the study were as follows: 1. Sharing of information – The CM solutions are to a various degree adapted to the IT infrastructure that permits sharing of information across the organization. CM solutions that require on-site logon, or where the communication is not based on a standard interface (e.g. OPC), tend to be less successful in an IO perspective. 2. Flexibility – The users require flexible solutions for grouping of data streams and displaying results. However, there is also a need for a set of standardized data set-ups for specific personnel categories and disciplines. 3. Make decisions – Many of the CM systems generate large quantities of data, which do not necessarily support the decision-making. When CM systems are being acquired, more emphasis needs to be placed on how the data should be processed to support the decision-making process. The last point is an area where organisations should put more emphasis both in the project phase and in operations in order to utilise the investments in CM solutions. Estimation of remaining useful life for turbo generators In the end of 2012 there was conducted a workshop for Petrobras in Rio de Janeiro for case 3. The case revealed a need for more detailed technical information in order to approach the RUL modelling. Petrobras has since the workshop been working on these issues. When their work is completed in May 2013, the RUL study will continue. 18 19 TELEMEDICINE The pre-project `Telemedicine of the Future in O&G` 2012 was the predecessor to the next step of `Telemedicine of the future in O&G 2013`. The kick off for next step was on February 28`th 2013. The demonstration of optimal workflow between HSE personnel offshore and medical experts onshore is the focus for the next step Telemedicine project. We have a governance structure in place and the scope of the project is acknowledged among the partners. The next step Telemedicine project involves ConocoPhillips, Petrobras, IBM, The Operating Room of the Future St. Olavs Hospital and the IO Center. We are looking at a very user driven innovation process. ConocoPhillips, Petrobras and St.Olavs Hospital represent the users, and we work to optimize the workflow and demonstrate decision support systems between medics onshore and offshore. There are three key activities; 1) design of optimal workflow and 2) prototype and 3) demonstration of solution. As we run demonstrations we bring the experiences back to the design of the workflow, which makes this an ongoing process. Milestone diagram 2013 PROJECT: TELEMEDICINE FOR THE FUTURE IN OIL AND GAS Jan – March Activit yy April June July September October December Project start - Next step Future of telemedicine in O&G Startup workshop NTNU/St.Olavs, IBM and ConocoPhillips Optimal work-flow design: Future of telemedicine in O&G Development of medical iPad application with IBM Demonstration of medical application with the partners Workshops St.Olavs IBM, Petrobras and ConocoPhillips Knowledge (Stavanger/Trondheim) (Rio de Janeiro) SPE IE 2014 Paper Short Video Web page & WikIO dissemination and publications Evaluation and next step decisions for bringing the solutions to the market Ongo ing activi ty Meeti ng Worksh op Work document Decision Gate Completi on Plan ned Comple ted Dela yed 20 What we want to achieve is a decision support system that supports an optimal workflow and collaboration, between medics onshore and offshore. The decision support system is primarily to be used when the medic offshore request decision support for matters of diagnostics or treatment/evacuation. The goal is to make better and faster medical decisions, and improve the quality of healthcare offshore. State of the art telemedicine in O&G is decision support systems, particularly focusing the diagnostics of patients, using High Density (HD) video conferencing systems and workflow. HD quality, preferably in real time, is essential as quality of images is containing important medical information. As there has been a huge development in the use of video consultation we believe the future of telemedicine in O&G will add to his workflow transmission of visual medical data between “non-experts” and experts to improve diagnostics. The Vscan handheld ultrasound device is a strong evidence of miniaturization of advanced medical technology that makes it well suited for use in remote locations. We have learned so far that the telemedicine work process at ConocoPhillips and Petrobras has a lot of similarities. They have much of the same structure and same challenges. As they acknowledge the status of their work process today we have been investigating how an optimal workflow may work and how technology can support a new telemedicine work process. Our approach is to understand the telemedicine work processes of today and investigate the optimal workflow of `tomorrow`. Key questions for the offshore medics at ConocoPhillips and Petrobras and medical experts at St.Olavs Hospital have been; What are the telemedicine work processes today? What are inputs and outputs in the work process? How are decisions made? What are the weaknesses of today`s decision making process? What are the needs/visions of the medics workers offshore and onshore? What is the optimal workflow and collaboration? We are looking at all medical data obtained to monitor the patient offshore. We are aiming for a Generic platform that can use any instrument. We shall not constraint ourselves to special instruments – but make the system open to any instruments that are needed. As the partners acknowledge the telemedicine work process of today and have agreed on the scope of the project we see a common understanding among the partners. We see a big motivation in the group, and this is very important to make a good progress. We have a progress plan and a governance structure in place – so with enthusiastic people and user organizations in place we hope to make successful achievements during 2013. 21