OWSO - WEFNET.org

advertisement

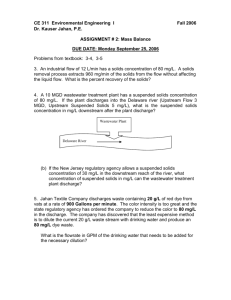

WERF’s OWSO Research Challenge Optimization of Wastewater & Solids Operations (a.k.a. OWSO) WEF / WERF Workshop 103 WEFTEC 2007, San Diego, CA October 13, 2007 Optimization of Wastewater and Solids Operations (OWSO) Energy Management Process Optimization Resource Recovery Solids Volume Reduction Background to Challenges “Energy Develop strategies, methods, processes, and tools for cost-effective management of energy used in wastewater operations “Solids Management” Volume Reduction” Cost-effective methods to minimize the volume and quantity of wastewater treatment solids generated, without sacrificing product value and quality “Resource Recovery” Identify new resource recovery opportunities for wastewater solids, including biosolids Why combine the challenges? Energy use accounts for about 35% of WWTF’s total cost to provide wastewater service – 2nd only to labor costs Solids treatment operations and sludge handling, transport, and disposal account for a significant portion of energy use at these facilities Disposal of biosolids offsite require transportation and land availability Each one impacts or influences the others Common element – energy and costs “OWSO” Goal To develop and demonstrate economical and environmentally responsible processes that improve wastewater and solids treatment operations efficiencies and costs by at least 20% Focus Areas & Desired Outcomes – Short Term Encourage collaboration and knowledge exchange with other organizations Leverage related existing research Analyze the economics of facility performance Provide benchmarking measures of facility performance Focus Areas & Desired Outcomes – Long Term Reduce environmental footprint of WWTFs and solids management practices Facilitate RD&D and breakthroughs of innovative and emerging technologies Explore innovative uses for solids Improve resource recovery across entire facility Minimize and conserve energy use Reduce solids volume OWSO Agency Liaisons WERF’s “sister organizations” that share mutual goals and objectives related to OWSO initiative Potential partners/collaborators/co-funders Help leverage resources and avoid duplication Help ensure “knowledge exchange” Includes: -AwwaRF -GWRC -NYSERDA -CEE -NACWA -USEPA -CEC -WEF -Global Energy Partners -ENERGY STAR IAT (Issue Area Team) members Municipal Utilities Shabir Choudhary, PWD, PA David Cooley, HRSD, VA Hsiao-Ting Ong & David Tucker, City of San Jose, CA Ali Oskouie, MWRDG Chicago, IL Steve Rogowski*, Metro Denver, CO Dariush Vosooghi, City of Los Angeles, CA Academic William Boyle*, University of Wisconsin Industry / Equipment Steve Constable & Melanie Masek, DuPont John Barber & Art Meyers, Eastman Chemical Robert Kelly, Infilco Degremont, Inc. Regulatory Jim Wheeler, US EPA Consulting Glen Daigger*, CH2M-Hill Rob Simm, Stantec Consulting John Willis, Brown and Caldwell Milind Wable, CDM Agency Liaisons Bob Bastian, US EPA OWM Bob Dominak, NACWA (and NEORSD, OH) Katy Hatcher, EPA Energy Star Ted Jones, CEE Kathleen O’Connor, NYSERDA Linda Reekie, AwwaRF Peter Brady, WEF RBC WERF staff Lauren Fillmore, IAT Chair Amit Pramanik, Alan Hais, Roy Ramani State Agency Shahid Chaudhry, CEC, CA * WERF Research Council liaisons OWSO Long Term Program Four Key Cross Cutting Functions Knowledge Exchange Research Demonstrations Tools & Products Where are we now? RFPP released in January 2007 18 respondents 7 short-listed (3 for Core team, 4 on specific research opportunities) 3 selected, one for core team, and 2 more Core team: led by George Crawford, CH2M-Hill, and various other agencies, individuals Second team led by David Parry, CDM + others – focus on Co-Digestion Third team led by SAIC (includes NYSERDA funding) Others: pursuing “low-hanging fruit” opportunities Additional beta testing of LCAMER tool State of science report on Resource recovery with GWRC Continue to work with other agencies (WEF, EPA, NYSERDA, CEE, CEC, etc.) on collaborative efforts OWSO How can You become involved? George Crawford, P.E. CH2M HILL Our Organization is Dynamic – because Research Needs will Evolve Our Work Plan is also Dynamic – Research will be Prioritized Annually 16 Immediate Action Plan Suggestions (Templates, Initial Workshop) 17 Research Task Item Suggestions Some examples: Example A Energy Management: Strass WWTP Benchmark Plant Demonstration 250.000 3.250.000 3.000.000 2.877.427 3.082.216 3.223.514 3.080.841 3.052.723 2.889.701 3.003.670 3.113.518 2.873.476 2.682.322 2.200.510 1.730.790 1.571.795 1.571.385 1.628.185 500.000 818.712 750.000 1.402.264 1.250.000 2.006.305 1.500.000 1.000.000 3.500.000 2.750.000 2.500.000 2.250.000 2.000.000 2.486.470 1.750.000 2.437.779 2.000.000 E-Energie Verbra uch /Eigenerzeugung 2.770.170 2.250.000 2.278.812 2.500.000 2.684.464 2.750.000 2.598.855 3.000.000 2.717.025 3.250.000 2.854.465 Gesamtverbrauch ARA Generator Polynomisch (Generator) Polynomisch (Verbrauch) 3.500.000 1.750.000 1.500.000 1.250.000 1.000.000 750.000 500.000 250.000 2005 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 0 1994 0 1993 2.137.292 669.032 100% energy selfsufficient Key European benchmark Modeling to show carbon and energy relationship Lead researchers: Dimitri Katehis (CH2M HILL); Mark Van Loosdrecht (Delft University) ); Bernhard Wett/ Conrad Buchaer (ARA Consultants) 1992 Example B Energy Management Research Approach feedback Review Energy Literature and Related Research Projects Research Gap Workshop Review Recommendations feedback Improve Energy Toolkit Develop Energy Management Framework Pilot and Bench Scale Demonstration Projects Update Toolkit and Final Report Draft Energy Toolkit Framework Tool Pilot Results Final Deliverables Communicate Results Example B Improve Energy Toolkit • Objective – Develop Comprehensive Toolkit to Evaluate Plants, Processes, Equipment, and Operational Strategies Related Programs: - Energy Index developed by AWWARF/CEC - Life Cycle Analysis Model for Energy Recover developed by WERF Benefits: Tool to Evaluate Alternatives and Progress at a Facility Example B Energy Management Framework • Objective – Develop Comprehensive Framework of an Energy Audit Using the Toolkit and Best Practices Related Tasks: - Research Gap Workshop - Energy Toolkit - Best Energy Management Practices Benefits: A Process to Evaluate Alternatives and Progress at a Facility Example C Scope of LCAMER Tool Current WERF Study 01-CTS-18- UR addresses anaerobic digestion and energy recovery processes Some form of energy is required for the operation The LCAMER model is limited in scope, and does not address all energy management issues Electrical Energy Recovery Anaer. Dig’n Thermal Mechanical Natural Gas Example C ECEP Biosolids Disposal Air 1o Total Facility Energy Management! 2o aeration Filter Disinfect RAS Thicken Electrical Energy Recovery Dewater Anaer. Dig’n Thermal Mechanical Natural Gas Example C Energy Consumption Evaluation and Planning Tool (ECEP) Development of an energy management model that will: Provide an inventory all major energy consuming devices at POTW Estimate energy consumption through all stages of liquid and solids processing Integrate energy demand with on-site energy production Permit allocation of purchased energy in optimum manner Estimate onsite emissions of air contaminant and greenhouse gas reductions Example D 05-CTS3 Evaluation of Processes to Reduce Activated Sludge Generation and Disposal Develop evaluation methodology for WAS reduction technologies. Project awarded to CH2M HILL-led team. Dr. Julian Sandino, principal investigator 2-year assignment, started Spring 2007 Included under OWSO “umbrella” Example E Energy and Resource Recovery Example E Effect of Sludge Contaminant Levels on Energy/Resource Recovery Options ISSUE: Contaminant levels may limit non-agricultural use of biosolids for energy or resource recovery OBJECTIVE: identify limits of trace substances that restrict uses of biosolids; identify research opportunities to reduce contaminant levels for wider opportunities BENEFIT: greater choice for recovering value from residual solids; improved economics of operation FOCUS AREAS: Solids Reduction; Resource Recovery Example F An Integrated Approach to Solids Volume Reduction Novak, Higgins & Murthy Specific objectives of this research are to determine: I. The impacts of influent wastewater characteristics and metal additions within a plant on: A. solids quantities and characteristics; B. downstream solids digestion; C. dewatering and cake quality. II. The impact of upstream process type and operation on: A. solids quantities and characteristics; B. downstream solids digestion; C. dewatering and cake quality. III. How conditioning and dewatering can be optimized by utilities to minimize solids volume. Lab digestion processes at Virginia Tech Example F Centrifuge Testing at Bucknell University Our Organization is Dynamic – Your Involvement is Welcome! For additional information, please contact: Lauren Fillmore, P.E. Conveyance Systems lfillmore@werf.org Amit Pramanik, Ph.D. Wastewater Treatment & Reuse apramanik@werf.org Phone: (703) 684-2470 Fax: (703) 299-0742 635 Slaters Lane Suite 300 Alexandria, VA 22314 www.werf.org George Crawford, P.E., BCEE CH2M-Hill George.Crawford@ch2m.com