Chp. 2

advertisement

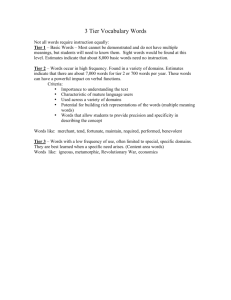

CHAPTER 2 Supply Chain Management SCM vs Logistics • Logistics – deals with the management of material, service and information flow across the SC • SCM – formerly, integrating logistics across the SC – integrating and managing key business processes across the SC SCM vs Logistics • The integration of key business processes from end user through original suppliers, that provides products, services, and information that add value for customers and other stakeholders. • Logistics is a part of supply chain process that plans, implements and controls the efficient, cost-effective flow and storage of goods, services, and related information from point of origin to point of consumption in order to meet customers’ requirements. SUPPLY CHAIN MANAGEMENT Integrating and Managing Processes Across the Supply Chain Information Flow Tier 2 Supplier Manufacturer Tier 1 Supplier Customer Logistics Marketing & Sales Purchasing Production Consumer/ End-user PRODUCT FLOW Finance R&D Supply Chain Business Processes CUSTOMER RELATIONSHIP MANAGEMENT CUSTOMER SERVICE MANAGEMENT DEMAND MANAGEMENT ORDER FULFILLMENT MANUFACTURING FLOW MANAGEMENT PROCUREMENT PRODUCT DEVELOPMENT AND COMMERCIALIZATION RETURNS Source: Douglas M. Lambert, Martha C. Cooper, Janus D. Pagh, “Supply Chain Management: Implementation Issues and Research Opportunities”, The International Journal of Logistics Management, Vol. 9, No. 2, 1998, p. 2. Figure 2-1 IMPLEMENTATION OF SUPPLY CHAIN MANAGEMENT Typical Functions Silos Business Processes S U P P L I E R S Customer Relationship Management Sales & Marketing Account Management Account Customer Service Management Administration Technical Logistics Requirements Requirements Definition Definition Sourcing Strategy Customer Profitability Priority Assessment Cost To Serve Tradeoff Analysis Coordinated Execution Capability Planning Sourcing Plant Direct Selected Supplier(s) Distribution Cost Production Planning Integrated Supply Manufacturing Cost Integrated Planning Supplier Management Materials Cost Process Specifications Material Specifications R & D Cost Process Requirements Network Planning Fulfillment Special Orders Environmental Requirements Distribution Management Product Development and Commercialization Manufacturing Strategy Performance Specifications Demand Planning Procurement Finance & Purchasing Accounting Technical Service Demand Management Manufacturing Flow Packaging Management Specifications Manufacturing Process Stability Order Booking Material Specifications Business Plan Product Design Prioritization Criteria Inbound Flow Movement Requirements C U S T O M E R S Information Architecture, Data Base Strategy, Information Visibility Note: Process sponsorship and ownership must be established to drive the attainment of the supply chain vision and eliminate the functional barriers that artificially separate the process flows. Customer Relationship Management • Customer service teams develop and implement customer partnering programs. • New customer interfaces lead to improved communication and better predictions of customer demand and improve the way customers are serviced. • Teams identify and eliminate sources of production variability. • Key performance evaluation criteria (both level of service and customer profitability) are used to measure results. Customer Service Management • Provides a single source of customer information, a point of contact for administration of the product/service agreement. • Conveys real-time information through interface with product and distribution operations. • Requires an on-line/real-time product and pricing information to assist customers with inquiries, order placement, and after-sales service. • Includes front line technical service that assists customers with product applications and recommendations. Supply Chain Network Structure Tier 1 Suppliers Tier 1 Customers Tier 2 Customers 1 1 2 2 n 1 1 2 2 Tier 3 to Consumers/ End-Customers n 1 n n 1 2 3 n 3 n 1 2 n n 1 n Focal Company 1 Members of the Focal Company’s Supply Chain Figure 2-2 Consumers / End-Customers Tier 2 Suppliers Tier 3 to n customers Tier 3 to n suppliers Initial Suppliers Tier 3 to Initial suppliers The SCM Framework Elements and Key Decisions 2. What processes should be linked with each of these key supply chain members? Supply chain business processes Supply chain management components Supply chain network structure 3. What level of integration and management should be applied or each process link? 1. Who are the key supply chain members with whom to link processes? Figure 2-3 Supply Chain Network Structure • Members of SC – Primary members: retailers,… – Supporting members: banks,… – Distinction may not be obvious Supply Chain Network Structure • Three structural dimensions – Horizontal structure: number of tiers across the SC • Long with many tiers (or short...) – Vertical structure: number of firms in a tier • Narrow if there are only a few firms – Horizontal position: Position of focal company-can be positioned at or near initial source of supply or the end users Issues Affecting Channel Structure • Make versus buy: outsourcing • Postponement: shifting the risk - Postponing changes in the form and identity of the product to the last possible point in the marketing process - Postponing inventory location to the last possible point in time Issues Affecting Channel Structure • Risk -economies of large scale production -reduction in logistics costs -reduction of stockouts -reduction of uncertainty • Local laws • Social and behavioral variables • Physical factors: geography, size of market, concentration of markets • Technological factors Issues Affecting Channel Structure • Type of distribution -Intensive distribution: chewing gum… -Selective distribution -Exclusive distribution • Seasonality Issues Affecting Channel Structure Product characteristics • • • • • • Value Technicality Market acceptance Substitutability Bulk Perishability Customer service objectives • Availability • Order cycle • Communication Types of Business Process Links Types of business process links • • • • Managed Process Links Monitored Process Links Not-Managed Process Links Nonmember Process Links Types of Inter-company Business Process Links Tier 1 Suppliers Tier 1 Customers Tier 2 Customers 1 1 2 2 n 1 1 2 2 Tier 3 to Consumers/ End-Customers n n n 1 2 3 3 n 1 n Managed Process Links Monitor Process Links Not-Managed Process Links Non-Member Process Links 1 n 1 n 1 2 n n Tier 3 to n customers 1 Consumers / End-Customers Tier 2 Suppliers Tier 3 to n suppliers Initial Suppliers Tier 3 to Initial suppliers 1 n Focal Company Members of the Focal Company’s Supply Chain Non-Members of the Focal Company’s Supply Chain Source: Douglas M. Lambert, Martha C. Cooper and Janus D. Pagh, "Supply Chain Management: Implementation Issues and Research Opportunities,” The International Journal of Logistics Management, Vol. 9, No. 2 (1998), p.7. Underlying Process Vision Supply Chain Management Vision The key to achieving an integrated flow of product and information throughout the supply chain is to create a focused customer interface, a focused supplier interface, and an integrated, process-oriented, supply chain which is driven by the customer. Customer Relationship Management Customer Service Management Fulfillment Customer Demand Management Procurement Manufacturing Flow Management Source: 3M