Clay - Ministry of Public Works

advertisement

Project Title: Chemical Stabilization of Clay

Design Department

Presenter: Stephan Cheong

Date: February 5,2015

Outline of Presentation

Introduction to Soil Stabilization

Chemical Admixtures

Application of Soil Stabilization

Environmental Impacts

Engineering Properties of Clay

Standard Engineering Tests

Project Limits

Results and Analysis

Discussion

Flexible Pavement Design

Economical Consideration of Flexible Pavement

Benefits of Soil Stabilization

Conclusion

Recommendations

Introduction to Soil Stabilization

Permanent physical and chemical alteration of soils to

enhance their physical properties.

To create an improved soil material possessing the

desired engineering properties.

Chemical stabilization relies on the use of an admixture to

alter the chemical properties of the soil.

Chemical Admixtures

The chemical additives used to modify the chemical

properties of a clay soil in this research are listed

below:

o Rice Husk Ash – Silicate Based

Chemical Admixtures

o Sodium Hydroxide – Sodium Based

o Lime – Calcium Based

Application of Soil Stabilization

Road Pavements

Foundations

Environmental Impacts

Environmental

Parameter

Sodium Hydroxide

Rice Husk

Lime

PHYSICAL

Air: Dust Control

measures when

transported

Not Required

Required

Required

Water Quality

Sodium

toxicity Water quality is Ionizes

to

results from

high not affected

Calcium cations

concentration

of

in water which is

Sodium in water but

beneficial

for

decreases acidity of

human and fish

water due to low pH

health

Social

Health and Safety

Severely Hazardous Harmless

Substance

Substance

Harmless

Substance

Engineering Properties of Clays

Their vulnerability to slow volume changes that can occur

independent of loading due to swelling or shrinkage.

The degree of weathering they have undergone

which leads to the destruction of interparticle bond.

Reductions in strength and elastic modulus with a general increase

in plasticity.

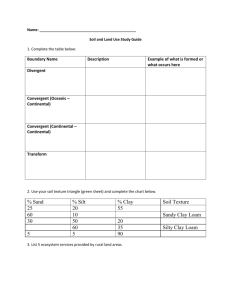

Standard Engineering Tests

Standard Tests

Key Engineering Properties

Liquid and Plastic Limit {ASTM D4318 00}

Plasticity Index

Shrinkage Limit {ASTM D4943 -02}

Shrinkage Potential

Specific Gravity {ASTM D854 -02}

Soil Density

Standard Engineering Tests

Standard Tests

Modified Proctor {ASTM D1557 -00}

California Bearing Ratio {ASTM

D1883 -99}

Key Engineering Properties

Compaction

Subgrade Strength

Settlement Potential of Cohesive Soils Soil Permeability and Percent

{ASTM D4546 -03}

Settlement

Project Limits

Location of Disturbed Tested Sample: University of Guyana

Selected Test Specimens: Soil mixed with 5%, 10%, 15%

NaOH, 3%, 5%, 8% Lime and 20%, 25% and 30% RHA.

Soil mixed with 8% Lime, 30% RHA and 10% NaOH was more

effective in stabilizing clay soils.

Results and Analysis

Soil Type

Specific

Gravity

Values

Plasticity

Index /%

Soil Type

*Plasticity

Chart

(ASTM D

2487)

Shrinkage

Limit/%

Untreated

Clay Soil

2.695

47.26

CH

13.62

Soil +

30% RHA

2.452

35.75

MH

3.90

Soil + 8%

Lime

2.504

26.87

MH

8.90

Soil +

10%

NaOH

2.956

24.09

MH

7.47

Results and Analysis

Soil Type

Maximum

Modified

Proctor Dry

Density /

lb/ft3

Untreated

Clay Soil

California

Bearing

Ratio

Subgrade Strength

*Based on

AASHTO

Pavement

Thickness Design

Guide

105

3.01

Low

Soil + 30%

RHA

87.0

3.23

Low

Soil + 8%

Lime

101.6

4.12

Low

Soil + 10%

NaOH

110.6

5.71

Medium

Results and Analysis

Soil Type

Settlement Potential of

Cohesive Soils

{Remolded Samples}

Hydraulic Conductivity, kz

(m/yr)

Untreated Clay Soil

0.05755

Soil + 30% RHA

0.80495

Soil + 8% Lime

0.72524

Soil + 10% NaOH

0.0938

Results and Analysis

Seating

Pressure σvo

(KPa)

384

-

24

Untreated

Clay Soil

Soil + 8% Lime

Soil + 30%

RHA

Soil + 10%

NaOH

Percent Settlement /% of Remolded Samples

-13.0

-6.1

-8.2

-7.4

Percent Rebound Settlement /% of Remolded Samples

-8.2

-4.3

-5.5

-4.7

Discussion

Increased Compaction

Increased Density

Stabilized Soil

% Variation

from Clay

Stabilized Soil

% Variation

from Clay

10% NaOH

5%

10% NaOH

10%

8%Lime

-3%

8%Lime

-7%

30% RHA

-17%

30% RHA

-9%

Discussion

Increased Load Bearing

Capacity (Subgrade Strength)

Increased Hydraulic

Conductivity

Stabilized Soil

% Variation

from Clay

Stabilized Soil

% Variation

from Clay

10% NaOH

90%

10% NaOH

60%

8%Lime

37%

8%Lime

1160%

30% RHA

7%

30% RHA

1300%

Discussion

Reduction in Settlement

and Rebound Settlement

Stabilized Soil

% Variation

from Clay (S)

% Variation

from Clay (R.S)

10% NaOH

43%

43%

8%Lime

53%

48%

30% RHA

37%

33%

Flexible Pavement Design

(AASHTO 1993)

Input Values for

Nomograph

•

•

•

•

•

•

•

Reliability (R)%=95

Overall Standard Deviation (So) =

0.40

Estimated Future traffic, 18 Kip

ESALs, w18= 10 × 106

m=1 (drainage provided)

Final Serviceability limit = 4.5

Initial Serviceability limit = 2.5

Design Serviceability loss = 2.0

Layer Coefficient

•

•

•

•

•

•

•

•

Asphaltic Concrete;

a1= 0.365, EAC = 300,000 psi

Aggregate base;

a2= 0.13, CBR = 70

White Sand/Sand Clay;

a3=0.11, CBR = 30

White Sand;

a4= 0.0925, CBR = 20

Structural Number and Layer

Thickness (AASHTO 1993)

Subgrade

Type

Design

Structural

Number

SN (DES)

d1

d2

d3

d4

Subgrade

Resilient

Modulus

/MPa

(AC)

(AB)

(WS/SC)

(WS)

Clay

148.2

100

250

350

450

31.1

Clay +

30%RHA

145.1

87.5

237.5

350

450

33.4

Clay +

8%Lime

134.2

75

225

350

450

42.6

Clay +

10%NaOH

119.6

50

150

350

450

59.1

Economical Considerations of

Flexible Pavement

o Lane Width = 12Ft; Stabilized Depth = 12in;

Road Length = 1mile

Subgrade

Cost of

Stabilized

Material/Mile

(GYD)

Cost of Road

Material / Mile

(GYD)

Total Road

Pavement

Cost per

Mile (GYD)

Clay

-

$133M

$133M

Clay + 30%RHA

0

$121.4M

$121.4M

Clay + 8%Lime

$10M

$100M

$110M

Clay +

10%NaOH

$27M

$79M

$106M

Economical Benefits of

Stabilization

From a financial point of view, Stabilization produces the following

relevant benefits:

1) Increased Long-term performance of pavement structures

2) Saving of significant amounts of non-renewable resources

3) Transforms inexpensive earth materials into effective construction

materials

Despite positive benefits of stabilization, the engineering properties

derived can vary widely due to heterogeneity in soil composition,

differences in micro and macro structure among soils.

Benefits of Soil Stabilization

Stabilization can:

o

increase the strength of a soil

o control the shrink-swell properties of a soil

o Replace mechanical methods of stabilization which can be

more costly.

o improve stress-strain properties, permeability, and durability.

Conclusion

All three admixture can potentially stabilize Guyana’s coastal clays.

The Sodium Hydroxide admixture proved to be the most effective

investigated admixture.

Lime was slightly more effective in

controlling settlement and

improving permeability.

Rice husk ash was more effective in controlling volume changes and

improving permeability.

Recommendations

A complete and thorough Environmental and Social Impact

Assessment will be required.

The following items which are not part of the scope of research are

recommended areas of further study;

1)

Correlation Between Laboratory Strength and In-situ Strength

2)

Impact of Subgrade Stabilization on Life-Cycle Cost of Pavements

3)

Mixing the Proportions of Two Stabilizers