Superpave Powerpoint

advertisement

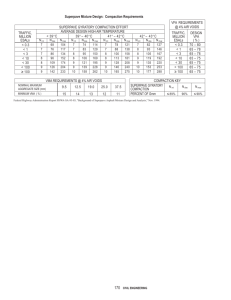

SUPERPAVE FHWA Condensed Superpave Asphalt Specifications Lecture Series What is Superpave • Final product of the 1987-1993 FHWA Strategic Highway Research Program to investigate better pavement materials & design methods. • Superior Performing Asphalt Pavements = Superpave • Produced new standards for aggregates and bituminous binders used in paving as well as mix design changes. Aggregates Usually refers to a soil that has in some way been processed or sorted. 100 100 90 72 65 48 36 22 15 9 4 Aggregate Size Definitions • Nominal Maximum Aggregate Size – one size larger than the first sieve to retain more than 10% • Maximum Aggregate Size – one size larger than nominal maximum size 100 99 89 72 65 48 36 22 15 9 4 Percent Passing 100 max density line restricted zone control point 0 .075 .3 2.36 4.75 9.5 nom max size max size 12.5 Sieve Size (mm) Raised to 0.45 Power 19.0 Superpave Aggregate Gradation Percent Passing 100 Design Aggregate Structure 0 .075 .3 2.36 12.5 19.0 Sieve Size (mm) Raised to 0.45 Power Superpave Mix Size Designations Superpave Designation 37.5 mm 25 mm 19 mm 12.5 mm 9.5 mm Nom Max Size (mm) 37.5 25 19 12.5 9.5 Max Size (mm) 50 37.5 25 19 12.5 Gradations * Considerations: - Max. size < 1/2 AC lift thickness - Larger max size + Increases strength + Improves skid resistance + Increases volume and surface area of agg which decreases required AC content + Improves rut resistance + Increases problem with segregation of particles - Smaller max size + Reduces segregation + Reduces road noise + Decreases tire wear Percent Crushed Fragments in Gravels • Quarried materials always 100% crushed • Minimum values depended upon traffic level and layer (lift) • Defined as % mass with one or more fractured faces Rounded Aggregates in Pavement • Crushed face aggregates help to reduce shear plane slides and mass deformation of the pavement structure. Percent Crushed Fragments in Gravels 0% Crushed 100% with 2 or More Crushed Faces Coarse Aggregate Angularity Criteria Traffic Depth from Surface Millions of ESALs < 100 mm > 100 mm < 0.3 --/-55/-<1 --/-65/-<3 50/-75/-< 10 60/-85/80 < 30 80/75 95/90 < 100 95/90 100/100 100/100 100/100 >100 First number denotes % with one or more fractured faces Second number denotes % with two or more fractured faces Asphalt Cements Background History of Specifications Background • Asphalt – Soluble in petroleum products – Generally a by-product of petroleum distillation process – Can be naturally occurring • Tar – Resistant to petroleum products – Generally by-product of coke (from coal) production Penetration Testing • Sewing machine needle • Specified load, time, temperature 100 g Initial Penetration in 0.1 mm After 5 seconds Penetration Specification • Five Grades • • • • • 40 - 50 60 - 70 85 - 100 120 - 150 200 - 300 Ductility Typical Penetration Specifications Penetration 40 - 50 200 - 300 Flash Point, C Ductility, cm 450+ 100+ 350+ 100+ Solubility, % 99.0+ 99.0+ Retained Pen., % 55+ 37+ Ductility, cm NA 100+ Viscosity Graded Specifications Types of Viscosity Tubes Asphalt Institute Tube Zietfuchs Cross-Arm Tube Table 1 Example AC 2.5 Visc, 60C 250 + 50 Visc, 135C Penetration 80+ 200+ Visc, 60C <1,250 Ductility 100+ AC 40 4,000 + 800 300+ 20+ <20,000 10+ Penetration Grades Viscosity, 60C (140F) AC 40 100 50 40 50 AC 20 60 70 AC 10 85 100 AC 5 120 150 10 5 200 300 AC 2.5 Asphalt Cements New Superpave Performance Graded Specification PG Specifications • Fundamental properties related to pavement performance • Environmental factors • In-service & construction temperatures • Short and long term aging High Temperature Behavior • High in-service temperature – Desert climates – Summer temperatures • Sustained loads – Slow moving trucks – Intersections Viscous Liquid Pavement Behavior (Warm Temperatures) • Permanent deformation (rutting) • Mixture is plastic • Depends on asphalt source, additives, and aggregate properties Permanent Deformation Courtesy of FHWA Function of warm weather and traffic Low Temperature Behavior • Low Temperature – Cold climates – Winter • Rapid Loads – Fast moving trucks Elastic Solid Pavement Behavior (Low Temperatures) • Thermal cracks – Stress generated by contraction due to drop in temperature – Crack forms when thermal stresses exceed ability of material to relieve stress through deformation • Material is brittle • Depends on source of asphalt and aggregate properties Thermal Cracking Courtesy of FHWA Superpave Asphalt Binder Specification The grading system is based on Climate PG 64 - 22 Performance Grade Min pavement temperature Average 7-day max pavement temperature Pavement Temperatures are Calculated • Calculated by Superpave software • High temperature – 20 mm below the surface of mixture • Low temperature – at surface of mixture Pave temp = f (air temp, depth, latitude) Concentric Cylinder Rheometers Concentric Cylinder t Rq = Mi 2 p Ri2 L g= WR Ro - Ri Dynamic Shear Rheometer (DSR) • Parallel Plate Shear flow varies with gap height and radius Non-homogeneous flow 2M tR = p R3 RQ gR = h Short Term Binder Aging • Rolling Thin Film Oven – Simulates aging from hot mixing and construction Pressure Aging Vessel (Long Term Aging) • Simulates aging of an asphalt binder for 7 to 10 years • 50 gram sample is aged for 20 hours • Pressure of 2,070 kPa (300 psi) • At 90, 100 or 110 C Bending Beam Rheometer Deflection Transducer Computer Air Bearing Load Cell Fluid Bath Direct Tension Test Load Stress = s = P / A DL sf D Le Strain ef Summary Construction Rutting Fatigue Cracking Low Temp Cracking [DTT] [RV] No aging [DSR] [BBR] RTFO Short Term Aging PAV Long Term Aging Superpave Binder Purchase Specification Superpave Asphalt Binder Specification The grading system is based on Climate PG 64 - 22 Performance Grade Min pavement temperature Average 7-day max pavement temperature Performance Grades CEC Avg 7-day Max, oC 1-day Min, oC PG 46 PG 52 PG 58 PG 64 PG 70 PG 76 PG 82 -34 -40 -46 -10 -16 -22 -28 -34 -40 -46 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -10 -16 -22 -28 -34 ORIGINAL > 230 oC < 3 Pa.s @ 135 oC (Flash Point) (Rotational Viscosity) (Dynamic Shear Rheometer) > 1.00 kPa 46 52 52 90 < 5000 kPa 10 7 S < 300 MPa 4 25 22 19 m > 0.300 100 64 100 0 -6 Report Value 28 22 19 16 13 31 -12 -18 -24 -30 -36 -6 -12 -18 -24 -30 0 (Bending Beam Rheometer) > 1.00 % (Direct Tension) -24 -30 -36 -18 -24 0 -6 100 (110) 16 25 -12 -18 -24 -30 -36 -6 -12 -18 -24 -30 0 76 82 PAV 100 (110) ( Bending Beam Rheometer) -24 -30 -36 18 -24 70 DSR G* sin 7 82 Mass Loss < 1.00 % (Dynamic Shear Rheometer) 13 10 76 DSR G*/sin 58 90 70 RTFO (PRESSURE AGING VESSEL) 20 Hours, 2.07 MPa DSR G*/sin 64 (Dynamic Shear Rheometer) 46 RV 58 (ROLLING THIN FILM OVEN) > 2.20 kPa FP 25 22 19 16 34 31 28 BBR “S” Stiffness -6 -12 -18 -24 -30 BBR 0 -6 25 110 (110) 22 19 37 34 31 28 25 40 37 28 31 34 & “m”- value -12 -18 -24 -30 0 -6 -12 -18 -24 0 -6 -12 - 0 -6 -12 -18 -24 0 -6 -12 Physical Hardening DT -6 -12 -18 -24 -30 0 -6 -12 -18 -24 -30 How the PG Spec Works CEC Spec Requirement 1-day Min, C Remains Constant Avg 7-day Max, oC o PG 46 PG 52 PG 58 PG 64 PG 70 PG 76 PG 82 -34 -40 -46 -10 -16 -22 -28 -34 -40 -46 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -40 -10 -16 -22 -28 -34 -10 -16 -22 -28 -34 ORIGINAL > 230 oC < 3 Pa.s @ 135 oC (Flash Point) (Rotational Viscosity) (Dynamic Shear Rheometer) > 1.00 kPa 46 64 RTFO 52 90 58 90 100 10 7 S < 300 MPa 4 25 22 19 m > 0.300 16 28 25 22 19 16 13 31 0 -6 Report Value -12 -18 -24 -30 -36 -6 -12 -18 -24 -30 0 (Bending Beam Rheometer) > 1.00 % (Direct Tension) -24 -30 -36 -18 -24 0 -6 -12 -18 -24 -30 -36 -6 -12 -18 -24 -30 0 76 100 (110) DSR G* sin 7 82 82 PAV 100 (110) ( Bending Beam Rheometer) -24 -30 -36 18 -24 70 (Dynamic Shear Rheometer) 13 10 76 Mass Loss < 1.00 % 64 100 Test Temperature < 5000 kPa Changes 70 DSR G*/sin (Dynamic Shear Rheometer) (PRESSURE AGING VESSEL) 20 Hours, 2.07 MPa DSR G*/sin 64 (ROLLING THIN FILM OVEN) 46 RV 5858 52 > 2.20 kPa FP 25 22 19 16 34 31 28 BBR “S” Stiffness -6 -12 -18 -24 -30 BBR 0 -6 25 110 (110) 22 19 37 34 31 28 25 40 37 28 31 34 & “m”- value -12 -18 -24 -30 0 -6 -12 -18 -24 0 -6 -12 - 0 -6 -12 -18 -24 0 -6 -12 Physical Hardening DT -6 -12 -18 -24 -30 0 -6 -12 -18 -24 -30 PG Binder Selection PG 52-28 PG 58-22 > Many agencies have established zones PG 58-16 PG 64-10 Summary of How to Use PG Specification • Determine – 7-day max pavement temperatures – 1-day minimum pavement temperature • Use specification tables to select test temperatures • Determine asphalt cement properties and compare to specification limits Asphalt Concrete Mix Design History Hot Mix Asphalt Concrete (HMA) Mix Designs • Objective: – Develop an economical blend of aggregates and asphalt that meet design requirements • Historical mix design methods – Marshall – Hveem • New – Superpave gyratory Requirements in Common • Sufficient asphalt to ensure a durable pavement • Sufficient stability under traffic loads • Sufficient air voids – Upper limit to prevent excessive environmental damage – Lower limit to allow room for initial densification due to traffic • Sufficient workability MARSHALL MIX DESIGN Marshall Mix Design • Developed by Bruce Marshall for the Mississippi Highway Department in the late 30’s • WES began to study it in 1943 for WWII – Evaluated compaction effort • No. of blows, foot design, etc. • Decided on 10 lb.. Hammer, 50 blows/side • 4% voids after traffic • Initial criteria were established and upgraded for increased tire pressures and loads Marshall Mix Design • Select and test aggregate • Select and test asphalt cement – Establish mixing and compaction temperatures • Develop trial blends – Heat and mix asphalt cement and aggregates – Compact specimen (100 mm diameter) Marshall Design Criteria Light Traffic ESAL < 104 Compaction Stability N (lb.) Medium Traffic 10 4 < ESAL< 10 Heavy Traffic ESAL > 106 35 50 75 3336 (750) 5338 (1200) 8006 (1800) Flow, 0.25 mm (0.1 in) 8 to 18 8 to 16 8 to 14 Air Voids, % 3 to 5 3 to 5 3 to 5 Voids in Mineral Agg. (VMA) Varies with aggregate size Asphalt Concrete Mix Design Superpave Superpave Volumetric Mix Design • Goals – Compaction method which simulates field conditions – Accommodates large size aggregates – Measure of compactibility – Able to use in field labs – Address durability issues • Film thickness • Environmental Compaction Key Components of Gyratory Compactor height measurement reaction frame tilt bar rotating base control and data acquisition panel loading ram mold Compaction • Gyratory compactor – Axial and shearing action – 150 mm diameter molds (6” vs. 4” Marshall) • Aggregate size up to 37.5 mm • Height measurement during compaction – Allows densification during compaction to be evaluated Ram pressure 600 kPa 1.25o Three Points on SGC Curve % Gmm Nmax Ndes Nini 10 100 Log Gyrations 1000 SGC Critical Point Comparison %Gmm= Gmb / Gmm Gmb = Bulk Mix Specific Gravity from compaction at N cycles Gmm = Max. Theoretical Specific Gravity Compare to allowable values at: NINI : %Gmm < 89% NDES: %Gmm < 96% NMAX: %Gmm < 98% Design Compaction % Gmm • Ndes based on – – average design high air temp traffic level • Log Nmax = 1.10 Log Ndes • Log Nini = 0.45 Log Ndes Nmax Ndes Nini 10 100 1000 Log Gyrations Superpave Testing • Specimen heights • Mixture volumetrics – – – – Air voids Voids in mineral aggregate (VMA) Voids filled with asphalt (VFA) Mixture density characteristics • Dust proportion • Moisture sensitivity Superpave Mix Design • Determine mix properties at NDesign and compare to criteria – – – – – – – Air voids VMA VFA %Gmm at Nini %Gmm at NDES %Gmmat Nmax Dust proportion 4% (or 96% Gmm) See table See table < 89% < 96% < 98% 0.6 to 1.2 Superpave Mix Design Gyratory Compaction Criteria