Exploration of Airfoil Sections to Determine the

Optimal Airfoil for Remote Controlled Pylon Racing

by

Michael DeRosa

An Engineering Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

Major Subject: MECHANICAL ENGINEERING

Approved:

_________________________________________

Dr. Ernesto Gutierrez-Miravete, Project Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

April 2012

(For Graduation May 2012)

© Copyright 2012

by

Michael R. DeRosa

All Rights Reserved

ii

TABLE OF CONTENTS

LIST OF TABLES ............................................................................................................. iv

LIST OF FIGURES .............................................................................................................v

LIST OF SYMBOLS……………………………………………………………….…….vi

ACKNOWLEDGMENT.................................................................................................. viii

ABSTRACT. .................................................................................................................... xix

1. Introduction…………………………………………………………….……………...1

1.1 Background………………………...………………………………….……………...1

1.2 Problem Description……………………..…………………………….……………...3

1.3 Airfoil Selection Matrix………………………………………………….…………...4

1.4 Prior Work and Research on Pylon Race Simulations………………...……………...6

2. Methodology……………………………….………………………………………….7

2.1 Assumptions and Simplifications……………….……………………...…………….7

2.2 Reynolds Number Calculation…………….…….……………...………….………….9

2.3 Airfoil Drag Coefficient Calculation Using XFOIL…………………....…..……….11

2.4 Entire Plane Drag Coefficient Calculation………………..…………….….……….14

2.5 Governing Differential Equations………………………………….…….....……….16

2.6 Determination of Top Airfoil Candidates for Race Simulation…....……...…..…….20

2.7 Airfoil race simulation in Maple……………….……………………..……..…...….24

3. Results……………………………………………………………….….……...…….28

3.1 Maximum Speed and Maximum Loss of Speed in Turns………………...……...….28

3.2 Maple Race Simulation Results…………………………...……….………….....….29

3.3 Airfoil Polar Interpretations…………………………….………….…………….….31

3.4 XFOIL 𝐶𝑝 Plot Comparison……………………………….……….………….....….35

3.5 Validation of Results………….……………….…………………………….....…….36

3.6 Implications of Moment Coefficient……………………………….……...……..….38

4. Discussion and Conclusion…….….…………………………………..………….….40

4.1 Summary of High Level Results………………..…..………….……..………….….40

4.2 Recommendations for Further Results…………………..….….……..……………..40

5. References………………………………………………………...……..…..……….42

iii

6. Appendix……………….……………….………………………………..…….…….43

6.1 Email from Jett .40 Engine Manufacturer Concerning Actual Engine Power

Output…………………………………………………………………….….…….…….43

6.2 Email from Dr. Martin Hepperle on Calculating Thrust on Engine/Propeller

Combination…………………………………………………………………..….……....43

6.3 XFOIL Input Parameters…………….……………………………….…..………….44

6.4 Output of JavaProp Program on Engine/Propeller Combination…………..………..44

6.5 Screenshots of Maple Calculation of Maximum Possible Velocity and Maximum

Speed Loss in Turns for NACA 66-012 Airfoil…………………………………..……...44

6.6 Maple Screenshots of Maple Calculation of Time and Velocity for Start Line to Take

Off and Around First Turn for NACA 66-012 Airfoil………………………….…..…....47

6.7 XFOIL Polar Accumulation Results (PACC command) for NACA 66-012 Airfoil for

α from -1 to 5 Degrees…………………………………………………………..…..…...50

iv

LIST OF TABLES

Table1 Airfoil Selection Matrix……………………………………………..….……........5

Table 2 Tabulations of drag coefficients for top 12 performing airfoils………..…….....16

Table 3 Maximum possible speed and speed loss in turns for each airfoil candidate.......23

Table 4 Simulated race for NACA 66-012 airfoil…………………..…………….……..26

Table 5 Maximum possible speed and speed loss in turns for each airfoil candidate…...28

Table 6 Overall airfoil race simulation results…………………..……..…………….......30

v

LIST OF FIGURES

Figure 1 A typical Quickie 500 pylon racing airplane………………….………………....2

Figure 2 Pylon race course………………………………...…………….………………...2

Figure 3 NACA 66-012 Airfoil………………………………………….………………...3

Figure 4 Clark Y Airfoil…………………………………………………..…..………......4

Figure 5 Race course layout in dashed blue lines for race simulation.…….……………...7

Figure 6 The paneling of a NACA 66-012 airfoil………………………….………….....12

Figure 7 Coefficient of Lift Input into XFOIL………………………………..………....13

Figure 8 XFOIL output for NACA 66-012 airfoil at 𝐶𝐿 = 0.018776……….……….....13

Figure 9 Pressure coefficient distribution for NACA 66-012 airfoil at 𝐶𝐿 =

0.018776………………………………………………………………….………..……14

Figure 10 Estimation of drag contribution of components in Q-500 pylon racer…...…...15

Figure 11 Initial JavaProp inputs for engine/propeller…………………………….….....17

Figure 12 Estimation of an 8.8x8.75 in. propeller as JavaProp inputs……………..…....18

Figure 13 Thrust vs. Velocity Results as produced by JavaProp…………………..…….19

Figure 14 Maple output for top speed of NACA 66-012 airfoil at 60 seconds….............20

Figure 15 Maple plot for velocity vs. time for NACA 66-012 airfoil at 𝐶𝐿 =

0.018776…………………………………………………………………….……..…....21

Figure 16 Velocity of NACA 66-012 airfoil after 50 ft. radius turn at top speed….…....21

Figure 17 Velocity from start line to first turn for NACA 66-012 airfoil…………...…...24

Figure 18 Initial velocity for a particular portion of the race simulation…………..….....25

Figure 19 Velocity and time for first turn around pylon #1………………………..…….25

Figure 20 𝐶𝐿 as a function of angle of attack for 12 airfoils…………………………......32

Figure 21 Drag polars for al 12 airfoils…………………………………...…………......33

Figure 22 Laminar bucket of NACA 66-012 airfoil with flaps……………...………......34

Figure 23 Lift curve for flapped NACA 66-012 airfoil…………………………...……..35

Figure 24 𝐶𝑝 Plots for NACA 66-012 and MH-17 airfoils at 𝐶𝐿 = 0.563277………......36

Figure 25 NACA 66-012 Wind Tunnel Data from Theory of Wing Sections………...…36

Figure 26 Velocity vs. time result of race simulation by Dr. Hepperle…………...…......37

Figure 27 Velocity vs. time result of race simulation for NACA 66-012 airfoil…….…..38

vi

Figure 28 Airfoil pitching moment coefficients as a function of 𝐶𝐿 for the 12 airfoils......39

vii

LIST OF SYMBOLS

𝑅𝑒

dimensionless Reynolds number

𝜌∞

free stream air density (𝑚3 )

𝑉∞

free stream air velocity (𝑠𝑒𝑐)

𝑥

airfoil chord length (𝑚)

𝜇∞

free stream air absolute viscosity (𝑚∙𝑠𝑒𝑐)

𝐿

whole plane lift force (N)

𝑆

wing area (𝑚2 )

𝐶𝐿

dimensionless whole plane lift coefficient

𝑚

mass of airplane (kg)

𝑔

gravitational constant (𝑠𝑒𝑐 2 )

𝐴

centripetal acceleration around turns (𝑠𝑒𝑐 2 )

𝑟

turn radius (𝑚)

𝐶𝐷

dimensionless whole plane drag coefficient

𝐶𝑑

dimensionless airfoil drag coefficient

𝐶𝐷,𝑖

dimensionless wing induced drag coefficient

𝑒

dimensionless Oswald span efficiency factor

𝐴𝑅

dimensionless wing aspect ratio

𝑑𝑉

𝑘𝑔

𝑚

𝑘𝑔

𝑚

𝑚

𝑚

𝑑𝑡

change in velocity with respect to time (𝑠𝑒𝑐 2 )

𝐿

thrust from engine/propeller combination (N)

𝐷

whole plane drag force (N)

𝐷𝐶𝐿=0.018776

whole plane drag force at lift coefficient of 0.018776 (N)

𝐶𝐷,𝐶𝐿=0.018776

dimensionless whole plane drag coefficient of 0.018776

𝐷𝐶𝐿=0.563277

whole plane drag force at lift coefficient of 0.563277 (N)

𝐶𝐷,𝐶𝐿=0.563277

dimensionless whole plane drag coefficient of 0.563277

𝐶𝑃

dimensionless power coefficient of engine/propeller combination

𝑑

propeller diameter (𝑚)

𝑉

actual airplane velocity (𝑠𝑒𝑐)

𝑚

viii

𝐶𝑝

dimensionless pitching moment of airfoil

ix

ACKNOWLEDGMENT

I want to thank my grandfather for instilling a lifelong interest in model airplanes

when I was young, which ultimately put me on a path to pursuing an education and

employment in the aerospace engineering field. I also would like to thank my

grandmother for strongly encouraging me to pursue a Master’s in Engineering. Dr.

Ernesto Gutierrez- Miravete and Dr. Martin Hepperle provided invaluable assistance and

advice during the course of this project. Last, but not least, I want to thank my wonderful

girlfriend Liz for her encouragement during the times when this project seemed very

daunting.

x

ABSTRACT

In remote controlled pylon racing, the Quickie 500 class of airplanes has 500 square

inches of wing area, and with a Jett 0.40 cubic inch displacement methanol fueled engine,

has a top speed of about 150 miles per hour. They are flown 10 times around an oval

course marked by 3 pylons, for a total of 2 to 2.5 miles. These planes lose a significant

amount of speed in the 30 G’s turns. This project will explore several airfoils to find the

optimal airfoil that will minimize the loss of speed of turns while maximizing top speed

during straight and level flight. Airfoil selections include the popular NACA 66-012 and

airfoils designed by Martin Hepperle, Michael Selig, Clark, and Richard Eppler. XFOIL

airfoil analysis program will provide analytical drag coefficient data for each airfoil.

These airfoil drag coefficient will be used to calculate the finite wing drag for level and

turning flights. The blending of two airfoil sections to obtain the best of both will be

explored as well as flaps to increase lift during the turns. Finally, using Maple and Excel,

the airfoil sections will be run through a simulated race, and the one that completes the

race in the shortest amount of time is the optimal airfoil for Quickie 500 pylon racing.

xi

1. Introduction

1.1 Background

Radio controlled pylon racing has been around since the 1960’s, and now there are 3

distinct classes: sport Quickie 500 (120 mph), AMA Quickie 500 (150 mph), and

Quarter 40 (180-200 mph). The only difference between sport and AMA Quickie 500 is

that the former uses the 1.25 horsepower Thunder Tiger Pro .40 engine, while the latter

uses a 1.8 horsepower Jett .40 engine. Both are powered by methanol fuel. The .40

signifies the size of the engines, at 0.40 cubic inch total displacement. The Jett is able to

gain a 0.55 horsepower advantage through the use of advanced timing. This project

focuses pylon racers in the AMA Quickie 500 class powered by the Jett engine.

There is always a search for an edge to design these planes to fly as fast as possible,

while remaining within rules. The official rules posted on the Academy of Model

Aeronautics’ contest rules website [1] impose the restriction on Q-500 airplane wings:

Minimum projected wing area of 500 square inches

Wingspan range of 50-52 inches

Minimum wing thickness of 1.1875 inches

The purpose of these rules is to enforce equality among each racer. It also keeps the

speeds down which allows the planes to maintain structural integrity in turns. There are

also rules imposed on the fuselage size and tail thickness, but they have been mostly

optimized over the years. The tail is typically a V-tail configuration, and they have been

optimized for size and stability. Any further optimization on the tail and fuselage will

yield an insignificant speed benefit through the reduction of drag. Because the wing is

the largest contributor of drag during racing, there is room for improvement, particularly

in the airfoil section. Figure 1 below shows a typical Q-500 racer, a Viper 500, which is

sold by Great Planes. Note the constant chord wing and the V-tail.

1

Figure 1 A typical Quickie 500 pylon racing airplane

Hence, the Q-500 rules provide sufficient constraint on design that lends the airplane

to be an ideal airfoil test bed. The wing area is fixed at 500 square inches, and the

minimum span is 50 inches, which leads to an aspect ratio of 5. With an aspect ratio of 5,

the chord is 10 inches. With a minimum airfoil thickness of 1.1875 inches, the airfoil

thickness to chord ratio, t/c is fixed at 11.875%. The chord and t/c are important inputs

for the selection of airfoils.

In pylon racing, four racers take off at the same time, fly around a course ten times,

and the first plane that crosses the finish line wins. Pilot skill being equal, the fastest

plane wins, obviously. Being that this is not a perfect world, and pilot skill does vary,

having a fast plane certainly does help. A typical racing course layout and dimensions

are laid out below in Figure 2.

Figure 2 Pylon race course

2

As seen in Figure 2, a typical course has 3 pylons, with 2 being 100 feet apart, while

the third is 475.5 ft. from the centerline of the 2. The perimeter of the resultant triangle is

951 feet, which translates to 2 miles when flown for 10 laps in a counter clockwise

direction. It is an inefficient flight path to fly a triangular course as shown, but rather, an

oval flight path is more typical. The overall distance covered is closer to 2.5 miles. The

start/finish line is 100 ft. from the twin pylons. All planes take off within 0.5 seconds of

each other and immediately turn at the far pylon. The way the course is designed, there

are 2 turns per lap, for a total of 20 turns between straight and level flight. Because there

are significant penalties if planes turn inside the pylons, this scenario will not be

considered here.

1.2 Problem Description

While entering the 50 ft. radius turns at 150 mph, the airplane experiences 30G’s of

centripetal acceleration. This results in the wings having to adjust to a higher angle of

attack in order to create more lift to keep the plane in place while turning. An increase of

drag from a higher angle of attack will slow the plane down during turns. The most

popular airfoil for pylon racing, the laminar NACA 66-012, in Figure 3, typically loses

10-15 miles per hour in the turns, as exhibited in the radar gun tests. This airfoil is

desirable for low drag in straight and level flight, at the cost of high drag in the turns.

Figure 3 NACA 66-012 Airfoil

In contrast, a flat bottomed Clark Y airfoil, in Figure 4 below, has a higher lift to

drag ratio due to its higher camber. The high L/D ratio of the Clark Y reduces loss of

speed in the turns. However, its high form drag will not allow it to attain sufficient speed

in the straightway.

3

Figure 4 Clark Y Airfoil

There are several different newer airfoils created by Hepperle, Selig, and Eppler that

may have the benefits of both higher speeds in straight ways and lower speed loss in

turns. Particularly, Hepperle and Eppler have designed airfoils specifically for pylon

racing, and they are good candidates. A formal evaluation of all possible pylon racing

airfoils has not been done to this date. A wing comprised of two different types of

airfoils may have the best of both worlds, as well as flaps deflected at small angles during

the turns. Those configurations need to be assessed as well. The anticipated speed

benefit of using the optimal airfoil over the NACA 66-012 for this application will mostly

likely be small. Even 2-3 mph speed benefit coming out of the turns is helpful, which

will allow the plane to jump ahead of the competition.

1.3 Airfoil Selection Matrix

Table 1 below is the airfoil selection matrix. The first column is the airfoil name, the

second shows the actual shape as produced in XFOIL, and the third column is the percent

maximum thickness with respect to chord length. Even though the AMA contest rules

limit the minimum thickness to 11.875%, thinner airfoils, such as the Clark Y, are

included and tested for reference purposes. If the best performing airfoil is indeed too

thin, it will be disregarded, as it cannot be used in Quickie 500 pylon racers.

4

Airfoil

Airfoil Shape

Airfoil

Thickness

NACA 66-012 (Baseline)

12.000%

Clark Y

11.706%

NACA 64-012

11.962%

NACA 64-212

11.964%

MH-27

11.990%

E-220

11.469%

S-8064

12.338%

S-8052

11.895%

MH-16

12.127%

MH-17

12.127%

MH-18

11.145%

MH-18B

11.734%

Combination of NACA66-012 and

Clark Y (0.5 Interpolation)- MD1

Combination of Clark Y and

NACA66-012 (0.5 Interpolation)MD2

11.650%

11.654%

Combination of NACA66-012 and

Clark Y (0.25 Interpolation)- MD3

11.772%

Combination of NACA66-012 and

Clark Y (0.75 Interpolation)- MD4

11.612%

Combination of NACA66-012

and MH-18B (0.5 Interpolation)MD5

Combination of NACA66-012

and MH-17 (0.5 Interpolation)MD6

11.815%

12.062%

Table1 Airfoil Selection Matrix

5

The airfoil coordinates for the NACA 66-012, Clark Y, Selig S-8052, and the Eppler

E-220 airfoils were found in the University of Illinois Aerospace Engineering department

(UUIC Airfoil Database) [2]. Coordinates for airfoils designed by Dr. Martin Hepperle,

designated by “MH-XX” are located in the pylon racing page on his MH Aero Tools

website [3]. The Viper 500 pylon racer, shown in Figure 1 above, uses the Selig S-8064,

which Dr. Michael Selig personally designed for this plane alone. The coordinates were

found in a different page in the University of Illinois Aerospace Engineering department

website [4]. Finally, the “MD-X” airfoils are entirely new airfoils created in XFOIL by

interpolating shapes between 2 existing airfoils.

1.4 Prior Work and Research on Pylon Race Simulations

In his MH Aero Tools website [3], Dr. Hepperle performed race simulations for his

own airfoils, as well as existing airfoils of the time. He explored various aspects that

effect race times, such as retractable landing gear, tail plane layout, wing aspect ratio,

power of various racing engines, wing surface quality, and employing flaps in turns.

Various paths around a race course and the resultant race times were also explored by

him.

Dr. Hepperle has not performed any simulations on the popular NACA 66-012

airfoils, nor looked into the use of flaps to improve the turning performance of this

particular airfoil. Utilizing flaps for the NACA 66-012 in turns is one of the focuses of

this project. He also did not consider the effect a blended airfoil wing has on the

performance of a pylon racer. This project will attempt to fill in this knowledge gap in

the performance of blended airfoil wings, particularly to improve the race times of the

widely used NACA 66-012 airfoil.

6

2. Methodology

2.1 Assumptions and Simplifications

The dashed lines in blue in Figure 5 below are the chosen race course to be used for

the race simulation. Race course dimensions were obtained from the Academy of Model

Aeronautics contest rulebook for 426 level pylon racing [1]. The twin pylons (pylons #2

and 3) are 100 ft. apart and pylon #1 is 475.5 ft. from the midpoint of the twin pylons.

The start line (black dashed line) is 100 ft. (30.48 m.) from the twin pylons so that the

plane has to cover only 375.5 ft. (114.45 m.) to initiate a turn around pylon #1 on the first

lap. It assumes that the pylon racer flies just outside the pylons in turns. The racing

simulation takes into account the 475.5 ft. of straight and level flight between sets of

pylons and 50 ft. radii semicircular turning flight.

Figure 5 Race course layout in dashed blue lines for race simulation

For simplification, the race course simulation will be as follows:

Start line to first turn in 114.45 meters (375.5 ft.)

19 instances of 50 ft. radius turn in 47.88 meters (157.0796 ft.) preceding a

144.93 meter level flight (475.5 ft.)

7

Final 50 ft. radius turn in 47.88 meters (157.0796 ft.) during lap #10.

Back to start/finish line from previous turn in 30.48 meters (100 ft.)

For further simplification, sea level air conditions were used, namely air density of

𝑘𝑔

𝑘𝑔

1.2250 𝑚3 and absolute viscosity value of 1.7894𝑥10−5 𝑚∗𝑠𝑒𝑐 were taken from Anderson

[5].

Since the racing airfoils were later found to have maximum speeds in the range of

𝑚𝑖

146-157 ℎ𝑟 , 150

𝑚𝑖

ℎ𝑟

is an acceptable speed assumption for the Reynolds number and 𝐶𝐿

for all airfoils tested. This speed was obtained from radar gun data of a NACA66-012

pylon racer top velocity, which is set as our baseline airfoil. Reynolds number was

calculated for that speed only to obtain all airfoil data in XFOIL. Whole plane coefficient

of lift calculations for both flight regimes were based on the speed of 150

𝑚𝑖

ℎ𝑟

for all

airfoils.

In reality, Reynolds number does change with velocity, which has an effect on the

drag coefficient of airfoils. If you look at any wind tunnel data, you will see that drag

coefficients do decrease with increasing velocity due to the delaying of the laminar to

turbulent transition. Reynolds number will increase with velocity, especially during the

initial acceleration from zero speed to the first turn, but velocity changes will be much

smaller after this point. To be able to compare each airfoil on an equal basis, a constant

Reynolds number was used at all portions of the race. Also for the same reason, the

straight and level flight regime and turning flight regime lift coefficients are the same for

all airfoils.

The wing is treated as the sole contributor of lift since lift from tail surfaces and

fuselage is insignificant when compared to the wing. Also, this allows each wing to be

compared on an equal basis.

Since the minimum wing (airfoil) thickness is specified by the AMA rules to be

11.875%, any airfoils that are too thin will typically be rejected, with few exceptions for

comparison purposes. Some airfoils are required to be fixed at a certain angle of attack,

either positive or negative, to produce lift during straight and level. This is permissible

since one can easily set a wing incidence (angle of attack) to trim it for high speed flight.

This is true for cambered airfoils which have negative angles of attack at zero lift. At

8

very small lift coefficients required for high speed flight, it is necessary for the airfoils to

be at a negative angle of attack. For symmetrical airfoils, such as a NACA 66-012

airfoil, zero angles of attack produces zero lift.

Flaps dramatically increase airfoil camber, and lift as a result. For this reason,

flapped airfoils require less angle of attack to produce the same amount of lift as their

unflapped counterparts. For the higher lift regime of turning flight, flaps are beneficial in

increasing lift for a particular airfoil with a small gain of angle of attack. As long as the

angle of attack for turning flight for a flapped airfoil is greater than the straight and level

unflapped angle of attack, the flapped configuration is acceptable. In some cases, so

much lift is created with high angle of flap deflection, that the required angle of attack is

actually less than the unflapped airfoil in high speed flight. Such flap angles are rejected

since it does not make sense for a wing to lower its angle of attack while transitioning

from low to high lift regimes.

For flapped airfoils, the drag coefficient during high speed flight is assumed to be

equal to their unflapped counterparts, due to the assumption of similar airfoil shape when

flaps are fully retracted. Realistically, there will be a slight increase in drag due to gaps

and breaks in the airfoil contours where the flap hinges are located.

In his own airfoil simulations, Dr. Hepperle assumed a 10% increase in airfoil drag

for 0.25 seconds to account for the ¼ roll into and out of turns. Overall, the increase of

race time due to this effect is only 0.2 seconds [3]. Since it affects airfoils approximately

equally, and since it has a very slight influence on lap times, the drag increase during

rolling into and out of turns will be ignored.

The above assumptions are required for the simplification of race simulations and to

keep all airfoils on equal basis for the ease of performance comparisons.

2.2 Reynolds Number Calculation

Radar gun data for a pylon racer with a NACA 66-012 (or slight variation of) show a

maximum speed of 150

𝑚𝑖

ℎ𝑟

m

(67.056 sec). The 2011-2012 AMA contest rules specify a

minimum wing area of 500 𝑖𝑛2 (0.32258 𝑚2 ), and wingspan range of 50-52 inches [1].

As stated before in the introduction section, for a 500 square inch wing, a 50 in. span was

selected to set the chord to 10 inches (0.254 m). With the maximum wing thickness

allowable set to 1.1875 inches by AMA rules, this allows a broader selection of airfoils as

9

set by a maximum thickness of 11.875%. Standard sea level absolute viscosity value of

𝑘𝑔

𝑘𝑔

1.7894𝑥10−5 𝑚∙𝑠𝑒𝑐 and air density of 1.2250 𝑚3 [5] were selected for the Reynolds

number calculation. The Reynolds number equation was obtained from Anderson [5] as

follows:

𝜌∞ 𝑉∞ 𝑥

𝑅𝑒 =

(2.1)

𝜇∞

𝑘𝑔

𝑚

∗ 67.056 𝑠𝑒𝑐 ∗ 0.245𝑚

𝑚3

𝑘𝑔

1.7894𝑥10−5 𝑚 ∙ 𝑠𝑒𝑐

1.2250

𝑅𝑒 =

𝑅𝑒 = 1.17𝑥106

This value was used as the default Reynolds number in calculating the drag

coefficients and polars for each airfoil. Next, we must calculate the overall plane lift

coefficient for straight and level flight at 150

𝑚𝑖

ℎ𝑟

m

(67.056 sec). The equation for lift from

Anderson [5] is given here:

1

𝐿 = 2 𝜌∞ 𝑉∞2 𝑆𝐶𝐿

(2.2)

Rearranging:

𝐶𝐿 = 1

2

𝐿

(2.3)

𝜌∞ 𝑉∞2 𝑆

For steady, level flight, lift is equal to weight. Since the AMA rule book allows a

minimum weight of 3.75lbs (1.7009714 kg), this weight is used, since it reflects the ideal

weight of pylon racers. The final equation for the coefficient of lift during steady, level

flight at maximum speed is:

𝑚𝑔

𝐶𝐿 = 1

(2.4)

𝜌 𝑉2𝑆

2 ∞ ∞

1.7009714𝑘𝑔 ∗ 9.8067

𝐶𝐿 =

𝑚

𝑠𝑒𝑐 2

𝑘𝑔

1

𝑚 2

2

2 ∗ 1.2250 𝑚3 ∗ (67.056 𝑠𝑒𝑐 ) ∗ 0.32258𝑚

𝐶𝐿 = 0.018776

During turns, the wings (and the plane) undergo centripetal acceleration, which the

wing must counteract by creating more lift to oppose the centrifugal force in turns. It

does so by pitching itself to increase the angle of attack to create more lift in the direction

10

of the center of the turn. Equation 2.5 describes the centripetal acceleration which the

plane must counteract in 50 ft. (15.24 m) turns:

𝐴=

𝐴=

2

𝑉∞

(2.5)

𝑟

𝑚

(67.056 𝑠𝑒𝑐 )2

15.24𝑚

𝐴 = 295.0464

𝑚

𝑠𝑒𝑐 2

𝑚

With gravitational acceleration being 9.8067 𝑠𝑒𝑐 2, this shows that centripetal

acceleration is 30 times gravitational acceleration, or 30G’s. This comes down to the fact

that the plane is effectively 30 times heavier in the turns, so the wing must increase the

lift force to compensate. The plane creates this lift in the horizontal direction when the

wing is banked nearly 90 degrees during turns. The overall coefficient of lift in turns is

given in equation 2.6:

30∗𝑚𝑔

𝐶𝐿 = 1

(2.6)

𝜌 𝑉2𝑆

2 ∞ ∞

30 ∗ 1.7009714𝑘𝑔 ∗ 9.8067

𝐶𝐿 =

𝑚

𝑠𝑒𝑐 2

𝑘𝑔

1

𝑚 2

∗ 1.2250 3 ∗ (67.056

) ∗ 0.32258𝑚2

2

𝑠𝑒𝑐

𝑚

𝐶𝐿 = 0.563277

Of course there is lift opposing gravity to keep the plane in the air. This is ignored,

since it will be small compared to lift that counteracts the centripetal force in turns. In

actuality, the wing is not banked a full 90 degrees, so some vertical component of lift is

used to keep the plane in the air during turns. Also, the fuselage is shaped to produce a

lifting surface in the vertical direction, and the tail can be trimmed to pitch the plane’s

nose upwards in turns. For simplification, the coefficients of lift and drag are assumed to

be constant throughout the turns, even though speeds do decrease during turns.

2.3 Airfoil Drag Coefficient Calculation Using XFOIL

The XFOIL airfoil analysis program, designed by Dr. Mark Drela of MIT, was used

to calculate the drag coefficient of each airfoil at both lift coefficients. The program uses

viscous flow equations to estimate the coefficients of lift and drag of an airfoil based on

its shape. Next, the airfoil coordinate files were loaded into XFOIL, and paneled them

with 280 panels. The XFOIL instructions [6] recommended keeping the angles between

11

panels to less than 10 degrees, and that requirement was consistently met with 280

panels. Panels are analogous to a mesh, where viscous differential equations were solved

for. Figure 6 shows the paneling of a NACA 66-012 airfoil. The number of panels and

maximum angle between panels are shown in the upper left corner.

Figure 6 The paneling of a NACA 66-012 airfoil

Flaps are added to any airfoil in the geometry design menu by indicating the chord

station of the flap hinge, the vertical station of the flap hinge, and the flap deflection in

degrees. Creation of new airfoils that are interpolations of two existing airfoils is done in

the geometry design menu. This operation is performed by inputting the coordinate files

of two existing airfoils and the interpolation factor between 0 and 1. The higher the

interpolation factor, the closer the shape of the resulting airfoil is to the base airfoil,

which is the first airfoil input into XFOIL. Airfoils created using this operation is

designated with MD-x.

In the operation menu, the Reynolds number is set to1.17𝑥106 , the viscous

equations option turned on (visc command), the constant Re number option (type 1) is

turned on, and the number of iterations to solve for a lift coefficient is set to 200 or 300.

Ncrit, the laminar to turbulent transition criteria number is left to the default value of 9,

which Martin Hepperle used in the calculation of his airfoils [3]. Figure 7 shows how the

straight and level coefficient of lift of 0.018776 is input into XFOIL.

12

Figure 7 Coefficient of Lift Input into XFOIL

Figures 8 and 9 are XFOIL outputs for NACA 66-012 airfoil at 𝐶𝐿 = 0.018776.

The laminar to turbulent transition location for each side is show at “transition at x/c” in

the form of the normalized chord location. The angle of attack value is given after “a”,

CL is the input coefficient of lift, and Cm and CD are the corresponding moment and

total drag coefficient at that particular lift coefficient. This drag coefficient value is used

for calculating drag at straight and level flight between turns. Drag coefficient is further

broken down into drag due to skin friction coefficient (CDf), and pressure drag (CDp).

The plot in Figure 9 also reiterates the coefficient values and the angle of attack.

Most importantly, it shows the pressure coefficient distribution over both surfaces, which

is a function of air velocity over the wing. The dashed line is the invisicid (theoretical)

plot, and the solid lines are the plot from the viscous calculations.

Figure 8 XFOIL output for NACA 66-012 airfoil at 𝐶𝐿 = 0.018776

13

Figure 9 Pressure coefficient distribution for NACA 66-012 airfoil at 𝐶𝐿 = 0.018776

For each airfoil, corresponding drag coefficients are calculated and tabulated for

𝐶𝐿 = 0.018776 (straight and level flight between turns) and 𝐶𝐿 = 0.563277 (turning

flight).

2.4 Entire Plane Drag Coefficient Calculation

In order to calculate the whole plane drag at the two flight regimes, we must

calculate the whole wing 𝐶𝐷 then proceed to calculate the whole plane 𝐶𝐷 . Since turning

flight is dominated by induced drag, this drag must be included with the airfoil profile

drag. Equations 2.7 and 2.8 calculate the whole wing 𝐶𝐷 using equations from Anderson

[5].Hepperle [3] assumed the Oswald span efficiency factor, e, to be 0.9, which he felt

gave good results for induced drag calculations. With a 500 square inch rectangular wing

with chord of 10 inches, the wing aspect ratio (AR) is easily calculated to be 5.

𝐶𝐷 = 𝐶𝑑 + 𝐶𝐷,𝑖

𝐶𝐷 = 𝐶𝑑 +

𝐶𝐿2

𝜋𝑒𝐴𝑅

NACA 66-012 airfoil has 𝐶𝑑 = 0.00528 at 𝐶𝐿 = 0.018776 and 𝐶𝑑 =

0.01089 at 𝐶𝐿 = 0.563227, and the whole wing drag is calculated as follows:

14

(2.7)

(2.8)

𝐶𝐷,𝐶𝐿=0.018776

0.0187762

= 0.018776 +

𝜋 ∗ 0.9 ∗ 5

𝐶𝐷,𝐶𝐿=0.018776 = 0.005305

𝐶𝐷,𝐶𝐿=0.563277 = 0.01089 +

0.5632772

𝜋 ∗ 0.9 ∗ 5

𝐶𝐷,𝐶𝐿=0.563277 = 0.033333

Note that the turning flight 𝐶𝐷 is more than six times than the straight and level 𝐶𝐷 ,

even though the airfoil profile 𝐶𝑑 differs by only 2x. This indicates that induced drag

dominates the turning flight mode. Next, we must find the whole plane drag coefficients

for both regimes of flight. In his comparison of pylon racing airfoils, Hepperle [3]

estimated the wing drag to be 27% in level flight and 76% in turning flight as shown in

Figure 10 below. To calculate both whole plane 𝐶𝐷 ′𝑠, the wing 𝐶𝐷 is multiplied by the

inverse of each respective percentage. For NACA 66-012 airfoil, the whole plane drag

coefficients are 𝐶𝐷 = 0.019648 at 𝐶𝐿 = 0.018776 and 𝐶𝐷 = 0.043859 at 𝐶𝐿 =

0.563227. These drag coefficient values are inputs into the Maple routine that simulates

a race. Note that with the inclusion of drag from the fuselage, tail and landing gear, the

turning flight 𝐶𝐷 is 2.2 times the level flight 𝐶𝐷 .

Figure 10 Estimation of drag contribution of components in Q-500 pylon racer [3]

Table 2 is a tabulation of drag coefficient results for the top 12 airfoils. The whole

plane drag coefficients in the last two columns are used as inputs for the race simulation

created in Maple.

15

Airfoil

MH-17 @ 5 Degrees 15% Span Flaps

MH-17

MH-18B

S8064

NACA 66-012 @ 10 Degrees 15% Span

Flaps

Combination of NACA66-012 and MH-18B

(0.5 Interpolation)- MD5

Combination of NACA66-012 and MH-17

(0.5 Interpolation)- MD6

Combination of NACA66-012 and Clark Y

(0.5 Interpolation)- MD1

E-220

NACA 66-012 (Baseline)

MH-18

Clark Y

CD @ CL = CD @ CL =

0.018776 0.563277

Whole Wing Whole Wing Whole Plane

CD @ CL =

CD @ CL =

CD @ CL =

0.018776

0.563277

0.018776

0.004395

0.027513

0.016278

0.004395

0.029013

0.016278

0.004725

0.028383

0.017500

0.004995

0.028803

0.018500

Whole Plane

CD @ CL =

0.563277

0.00437

0.00437

0.00470

0.00497

0.00507

0.00657

0.00594

0.00636

0.036201

0.038175

0.037346

0.037899

0.00528

0.00602

0.005305

0.028463

0.019648

0.037451

0.00490

0.00964

0.004925

0.032083

0.018241

0.042215

0.00487

0.00994

0.004895

0.032383

0.018129

0.042609

0.00543

0.00568

0.00528

0.00637

0.00810

0.00558

0.00579

0.01089

0.00538

0.00538

0.005455

0.005705

0.005305

0.006395

0.008125

0.028023

0.028232

0.033333

0.027823

0.027823

0.020203

0.021129

0.019648

0.023685

0.030092

0.036872

0.037147

0.043859

0.036609

0.036609

Table 2 Tabulations of drag coefficients for top 12 performing airfoils

2.5 Governing Differential Equations

In order to calculate the maximum speed and speed loss in turns for each airfoil in

Maple, a differential equation describing the physics of flight must be created first.

Starting from F=ma, the following differential equation is derived:

𝑑𝑉

𝑚 𝑑𝑡 = 𝑇 − 𝐷

(2.9)

In its derivative form, the equation states that velocity is a function of forces acting

on the airplane. Velocity is constant when all forces (T-D) on the plane are zero, or when

the drag force equals the thrust from the engine/propeller combination. In equations 2.10

and 2.11, the equation for drag was obtained from Anderson [5] to calculate drag for both

regimes of flight for the all airfoils. Note that 𝐶𝐷 is the whole plane drag coefficient.

1

𝐷𝐶𝐿=0.018776 = 2 𝜌∞ 𝑉∞2 𝑆𝐶𝐷,𝐶𝐿=0.018776

1

𝐷𝐶𝐿=0.563277 = 2 𝜌∞ 𝑉∞2 𝑆𝐶𝐷,𝐶𝐿=0.563277

(2.10)

(2.11)

The other variable that must be accounted for is thrust from the engine/propeller

combination, which also varies as a function of velocity. Dub Jett, the sole producer of

AMA Quickie 500 engines, stated that the expected power of the Jett 0.40 cubic inch

displacement engine is 1.6-1.8 horse power [Appendix 6.1]. With a handheld optical

tachometer, it can spin an 8.8 in. diameter prop with an 8.75 in. pitch up to 18,000

revolutions per minute on the ground.

16

After an email exchange with Dr. Hepperle [Appendix 6.2], he determined the most

effective manner to obtain thrust as a function of velocity was to use his JavaProp

program on his MH Tools website. Initial engine/propeller inputs for JavaProp include

ground RPM of 18,000, 8.8 in. diameter propeller with a 1 inch diameter spinner, 1.8

horsepower, and near zero speed, as seen in Figure 11. Note that all units have been

converted to their respective metric units.

Figure 11 Initial JavaProp inputs for engine/propeller

The initial engine power value of 1.7 hp produced results that were too slow

compared to real life data, while 1.8 hp produced results that correlate with real life data

very well. The next step is to estimate the propeller airfoil and angle of attack that

produces results that matches real life data for a pylon racer equipped with a NACA 66012 airfoil. Figure 12 below is the estimation of propeller airfoils of an 8.8 in. diameter

and 8.75 in. pitch racing propeller.

17

Figure 12 Estimation of an 8.8x8.75 in. propeller as JavaProp inputs

After calculating the engine/propeller efficiency, power, thrust, and velocity,

JavaProp outputs data as shown in the Appendix. Dr. Hepperle advised to check the

coefficient of power, 𝐶𝑃 against a known velocity to ensure the result matches. Zero

speed (or close to zero) was used. Equation 2.12 is the 𝐶𝑃 formula provided by Dr.

Hepperle.

𝑃

𝐶𝑃 = 𝜌∗𝑛3 ∗𝑑5

𝐶𝑃 =

(2.12)

1,269.67𝑊

𝑘𝑔

𝑟𝑒𝑣

1.2250 3 ∗ (300 𝑠𝑒𝑐 )3 ∗ 0.22352𝑚5

𝑚

𝐶𝑃 = 0.06896

This power coefficient value matches very well with the JavaProp output power

coefficient of 0.073635 at zero speed. The reason for the difference is that one cannot

input zero velocity as input in the first page for JavaProp, so the lowest allowable value

of 0.5

𝑚

𝑠𝑒𝑐

was used. This validates the JavaProp results. JavaProp gave the thrust result

for each velocity, as seen in the plot in Figure 13.

18

Thrust vs. Velocity for 1.8 HP Engine and 8.8 x

8.75 in. Propeller

30

Thrust (N)

25

20

15

10

5

0

0

20

40

60

80

Velocity (m/sec)

-5

100

120

Figure 13 Thrust vs. Velocity Results as produced by JavaProp

The sixth order trend line seen in the plot above gives thrust as a function of

velocity, shown in equation 2.13 below.

𝑇 = −4.70258202𝑥10−11 ∗ 𝑉 6 + 4.71680931𝑥10−9 ∗ 𝑉 5 +

1.82170086𝑥10−6 ∗ 𝑉 4 − 3.42822861𝑥10−4 ∗ 𝑉 3 + 1.63054071𝑥10−2 ∗ 𝑉 2 −

0.231096635 ∗ 𝑉 + 23.7462140 (2.13)

Now, the complete governing differential equation can be constructed by

substituting 2.10, 2.11, and 2.13 into 2.9 to develop the governing equations for both

flight regimes. Equation 2.14 is the straight and level flight with 𝐶𝐿 = 0.018776 and

equation 2.15 is the governing equation for turning flight with 𝐶𝐿 = 0.563277.

𝑑𝑉

𝑚 𝑑𝑡 = 𝑇 − 𝐷𝐶𝐿=0.018766

(2.14)

𝑇 = −4.70258202𝑥10−11 ∗ 𝑉 6 + 4.71680931𝑥10−9 ∗ 𝑉 5 + 1.82170086𝑥10−6

∗ 𝑉 4 − 3.42822861𝑥10−4 ∗ 𝑉 3 + 1.63054071𝑥10−2 ∗ 𝑉 2

− 0.231096635 ∗ 𝑉 + 23.7462140

𝐷𝐶𝐿=0.018776 =

1

𝜌 𝑉 2 𝑆𝐶

2 ∞ ∞ 𝐷,𝐶𝐿=0.018776

𝐷𝐶𝐿=0.018776 = 0.003882056752𝑉 2

𝑑𝑉

𝑚 𝑑𝑡 = 𝑇 − 𝐷𝐶𝐿=0.563277

19

(2.15)

𝑇 = −4.70258202𝑥10−11 ∗ 𝑉 6 + 4.71680931𝑥10−9 ∗ 𝑉 5 + 1.82170086𝑥10−6

∗ 𝑉 4 − 3.42822861𝑥10−4 ∗ 𝑉 3 + 1.63054071𝑥10−2 ∗ 𝑉 2

− 0.231096635 ∗ 𝑉 + 23.7462140

𝐷𝐶𝐿=0.563277 =

1

𝜌 𝑉 2 𝑆𝐶

2 ∞ ∞ 𝐷,𝐶𝐿=0.563277

𝐷𝐶𝐿=0.563277 = 0.008696889865𝑉 2

𝑑𝑥

𝑑𝑡

=𝑉

(2.16)

The position of the plane, in meters, is the derivative of velocity, as shown in

Equation 2.16. For Equations 2.14 and 2.15, the initial condition of any starting velocity

is determined by the velocity at the end of the preceding stage of the race. For example,

the initial velocity is the speed at the end of the straightway before the plane turns, and is

the initial condition of the governing equation that describes velocity behavior at that

turn. At the start line, initial velocity is zero. The initial position condition is always

zero for each stage of the race, since we are concerned with only the distance covered by

that stage of the race. More details on this method will be covered in later sections.

2.6 Determination of Top Airfoil Candidates for Race Simulation

All of the above equations and drag coefficients are input into Maple for each airfoil

to determine the top speed of the plane and the maximum loss of speed in turns from top

speed. The top speed is determined by entering the whole plane drag coefficient for 𝐶𝐿 =

0.018776 with zero initial speed and applying equation 2.15 in Maple and querying the

output at 60 seconds. Figure 14 is the Maple output for the NACA 66-012 airfoil at 60

seconds, and Figure 15 is the velocity vs. time plot produced by Maple.

Figure 14 Maple output for top speed of NACA 66-012 airfoil at 60 seconds

20

Figure 15 Maple plot for velocity vs. time for NACA 66-012 airfoil at 𝐶𝐿 = 0.018776

At 60 seconds, a plane equipped with a NACA 66-012 airfoil will reach a top speed

𝑚

𝑚𝑖

𝑚𝑖

of 66.72 𝑠𝑒𝑐, or 149.25 ℎ𝑟 , which agrees with the radar gun data of 150 ℎ𝑟 . From the

plot, you will see that velocity stabilizes at 15-20 seconds and is constant at 60 seconds.

To determine the maximum speed loss in turns, Equation 6.15 was solved in Maple

with the initial velocity set to the top speed for this particular airfoil. In the case of the

𝑚

NACA 66-012 airfoil, the initial speed is 66.72 𝑠𝑒𝑐, and will decrease during the turn. The

distance covered in a 50 ft. (15.24m) radius turn, from zero initial distance, is 157.0796

ft. (47.88 m).

Figure 16 Velocity of NACA 66-012 airfoil after 50 ft. radius turn at top speed

21

The velocity after a 50 ft. radius turn is shown in Figure 16, and does not show the

exact metric equivalent, 47.88 meters, ordered by time. The closest distance is used,

since it is only off by 0.01 meters, or 0.39 inches, which is sufficiently accurate. From

𝑚

this distance, one can read the corresponding velocity, 59.73 𝑠𝑒𝑐, and time to complete the

turn, 0.762 sec. Since the actual distance is not available, the closest distance and

corresponding time and velocity are used. Time is within 0.001 seconds and velocity is

𝑚

𝑚𝑖

accurate within 0.01 𝑠𝑒𝑐, or 0.02 ℎ𝑟 , which is sufficiently accurate for this purpose. The

speed loss is simply the difference of the velocity going into the turn (maximum speed)

𝑚

𝑚𝑖

and the velocity after a 50 ft. radius turn, which is 6.99 𝑠𝑒𝑐, or 15.64 ℎ𝑟 . All maximum

velocities and speeds are tabulated for all 32 airfoil candidates in Table 3 below.

22

Maximum Possible

Speed (m/sec)

66.72

58.23

66.49

66.43

67.23

65.30

67.88

66.83

67.20

70.30

70.30

70.30

63.05

68.93

Speed After 50 ft.

radius turn (m/sec)

59.73

56.58

60.04

61.28

60.96

60.70

62.07

61.39

61.78

63.52

63.97

64.06

59.48

62.87

Maximum

Possible Speed

Loss in Turns

(m/sec)

6.99

1.65

6.45

5.15

6.27

4.60

5.81

5.44

5.42

6.78

6.33

6.24

3.57

6.06

66.72

59.85

6.87

149.25

15.37

NACA 66-012 @ 5 Degrees 10% Span Flaps

NACA 66-012 @ 7.5 Degrees 10% Span

Flaps

NACA 66-012 @ 10 Degrees 10% Span

Flaps

NACA 66-012 @ 2.5 Degrees 15% Span

Flaps

66.72

59.97

6.75

149.25

15.10

66.72

60.04

6.68

149.25

14.94

66.72

60.11

6.61

149.25

14.79

66.72

59.83

6.89

149.25

15.41

NACA 66-012 @ 5 Degrees 15% Span Flaps

NACA 66-012 @ 7.5 Degrees 15% Span

Flaps

NACA 66-012 @ 10 Degrees 15% Span

Flaps

NACA 66-012 @ 2.5 Degrees 20% Span

Flaps

66.72

59.95

6.77

149.25

15.14

66.72

60.02

6.70

149.25

14.99

66.72

61.46

5.26

149.25

11.77

66.72

59.78

6.94

149.25

15.52

NACA 66-012 @ 5 Degrees 20% Span Flaps

NACA 66-012 @ 7.5 Degrees 20% Span

Flaps

NACA 66-012 @ 10 Degrees 20% Span

Flaps

Combination of NACA66-012 and Clark Y

(0.5 Interpolation)- MD1

Combination of Clark Y and NACA66-012

(0.5 Interpolation)- MD2

Combination of NACA66-012 and Clark Y

(0.25 Interpolation)- MD3

Combination of NACA66-012 and Clark Y

(0.75 Interpolation)- MD4

Combination of NACA66-012 and MH-18B

(0.5 Interpolation)- MD5

Combination of NACA66-012 and MH-17

(0.5 Interpolation)- MD6

66.72

59.90

6.82

149.25

15.26

66.72

59.98

6.74

149.25

15.08

66.72

61.56

5.16

149.25

11.54

66.18

61.31

4.87

148.04

10.89

65.47

60.88

4.59

146.45

10.27

67.88

61.43

6.45

151.84

14.43

60.30

57.87

2.43

134.89

5.44

68.15

61.02

7.13

152.45

15.95

68.26

60.98

7.28

152.69

16.28

Airfoil

NACA 66-012 (Baseline)

Clark Y

NACA 64-012

NACA 64-212

MH-27

E-220

S8064

S8052

MH-16

MH-17

MH-17 @ 2.5 Degrees 15% Span Flaps

MH-17 @ 5 Degrees 15% Span Flaps

MH-18

MH-18B

NACA 66-012 @ 2.5 Degrees 10% Span

Flaps

Maximum

Possible Speed

(mi/hr)

149.25

130.26

148.73

148.60

150.39

146.07

151.84

149.49

150.32

157.26

157.26

157.26

141.04

154.19

Maximum Possible

Speed Loss in Turns

(mi/hr)

15.64

3.69

14.43

11.52

14.03

10.29

13.00

12.17

12.12

15.17

14.16

13.96

7.99

13.56

Table 3 Maximum possible speed and speed loss in turns for each airfoil candidate

23

2.7 Airfoil race simulation in Maple

Based on the highest attained velocities and minimal loss of velocity in turns, the top

12 airfoil candidates were selected for race simulations in Maple. The NACA66-012

airfoil was selected as the baseline airfoil for comparison purposes, as well as the Clark

Y.

Each portion of the race is measured in meters, for ease of use. To reiterate the race

simulation from section 2.1, the race simulation is as follows:

Start line to first turn in 114.45 meters (375.5 ft.)

19 instances of 50 ft. radius turn in 47.88 meters (157.0796 ft.) preceding a

144.93 meter level flight (475.5 ft.)

Final 50 ft. radius turn in 47.88 meters (157.0796 ft.) during lap #10.

Back to start/finish line from previous turn in 30.48 meters (100 ft.)

The total length covered in the race simulation outlined above is 3.856 km (12,651.6

ft. or 2.3691 miles). The perimeter of the triangle marked by the pylons over 10 laps is

exactly 2 miles; hence it is referred to as the 2 mile course. Since this is an impossible

flight path, the above race simulation is a much more realistic representation of a race.

The straight and level flight in between turns is governed by equation 2.14, and

turning flight is governed by equation 2.15., so there are two distinct equations and

solutions in a Maple worksheet. In Maple, each stage of the race simulation is calculated

for velocity and time for each corresponding length in a similar manner as calculating

velocity and time after a 50 ft. radius turn in Section 2.6. For example, in Figure 17

below, with zero initial velocity, it takes 4.273 seconds to reach the first pylon from the

start line, as seen in the box. The distance covered is 114.45 meters, but time and

velocity was read from the closest distance, 114.4295 meters.

Figure 17 Velocity from start line to first turn for NACA 66-012 airfoil

24

Velocity at the end of this portion of the race is set as the initial velocity into the

governing equation that describes turning flight around pylon #1, as seen in Figure 18

below. The first box shows where the velocity at the end of the preceding portion of the

race is entered as an initial condition (ic3). The second box is the Maple output which

validates the initial velocity, where time is zero, at the beginning of this portion of the

race.

Figure 18 Initial velocity for a particular portion of the race simulation

Since this portion of the race is a turn around pylon 1, equation 2.15 is used to

describe this flight regime, which covers a distance of 47.88 meters. Figure 19 below

shows the velocity and time at the end of the first turn. 47.885 meters is the closest to the

actual distance of 47.88 meters; therefore velocity and time is read from this distance.

The velocity a thousandth of a second before and after the velocity highlighted in the box

𝑚

is well within 0.001 𝑠𝑒𝑐 .

Figure 19 Velocity and time for first turn around pylon #1

This process continues until the velocities stabilize at about lap #4. Stabilization

occurs when the velocity at the beginning of a straight and level flight regime is equal to

the previous straight and level flight regime since the loss of speed in turns is now

constant. This can be seen in lap 3 in Table 4 below for a simulated race for a NACA66012 airfoil. Distance in meters is used to find the closest velocity at the end of this

25

portion of the race and the time it takes the plane to cover this distance. Velocity is then

converted into miles per hour.

Speed at the end of each piece of the race is recorded in Table 4 below, and the

change of speed in turns is the difference of speed going into and out of turns. From the

table, you can easily see that a plane equipped with a NACA 66-012 airfoil reaches a

𝑚𝑖

𝑚𝑖

maximum speed of 143.34 ℎ𝑟 at the end of straight and level flight and loses 13.29 ℎ𝑟 in

𝑚𝑖

turns. The maximum speed in a race is lower than the maximum speed of 149.25 ℎ𝑟 for a

plane with this airfoil because the race course is not sufficiently long enough to allow the

plane to reach a steady state velocity. The maximum speed loss in turns during a race is

𝑚𝑖

lower than the maximum possible 15.64 ℎ𝑟 because maximum possible speed has not

been attained.

Piece #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Lap #

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

10

10

10

10

10

Location

Start Line to Pylon 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to 1

Around Pylon 1

Pylon 1 to Pylon 2

Around Pylons 2 and 3

Pylon 3 to Finish Line

Distance (m)

114.45

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

144.93

47.88

30.48

Speed (m/sec)

49.39

49.91

61.74

56.83

63.69

57.96

64.03

58.15

64.08

58.18

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

64.09

58.19

60.09

Time (sec.)

4.273

0.964

2.549

0.811

2.380

0.791

2.355

0.788

2.351

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

2.350

0.787

0.515

Distance(ft.)

375.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

475.5000

157.0796

100.0000

Speed (mi/hr)

110.48

111.65

138.11

127.13

142.47

129.65

143.23

130.08

143.34

130.14

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

143.37

130.17

134.42

Table 4 Simulated race for NACA 66-012 airfoil

26

Speed Loss in

Turns (mi/hr)

10.98

12.82

13.15

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

13.20

The time for each piece of the race is summed to be the total race time. This

process is repeated for the top 12 airfoil candidates to obtain the total race time for each

for the overall airfoil performance comparison.

27

3. Results

3.1 Maximum Speed and Maximum Loss of Speed in Turns

Maximum Possible

Speed (m/sec)

66.72

58.23

66.49

66.43

67.23

65.30

67.88

66.83

67.20

70.30

70.30

70.30

63.05

68.93

Speed After 50 ft.

radius turn (m/sec)

59.73

56.58

60.04

61.28

60.96

60.70

62.07

61.39

61.78

63.52

63.97

64.06

59.48

62.87

Maximum

Possible Speed

Loss in Turns

(m/sec)

6.99

1.65

6.45

5.15

6.27

4.60

5.81

5.44

5.42

6.78

6.33

6.24

3.57

6.06

66.72

59.85

6.87

149.25

15.37

NACA 66-012 @ 5 Degrees 10% Span Flaps

NACA 66-012 @ 7.5 Degrees 10% Span

Flaps

NACA 66-012 @ 10 Degrees 10% Span

Flaps

NACA 66-012 @ 2.5 Degrees 15% Span

Flaps

66.72

59.97

6.75

149.25

15.10

66.72

60.04

6.68

149.25

14.94

66.72

60.11

6.61

149.25

14.79

66.72

59.83

6.89

149.25

15.41

NACA 66-012 @ 5 Degrees 15% Span Flaps

NACA 66-012 @ 7.5 Degrees 15% Span

Flaps

NACA 66-012 @ 10 Degrees 15% Span

Flaps

NACA 66-012 @ 2.5 Degrees 20% Span

Flaps

66.72

59.95

6.77

149.25

15.14

66.72

60.02

6.70

149.25

14.99

66.72

61.46

5.26

149.25

11.77

66.72

59.78

6.94

149.25

15.52

NACA 66-012 @ 5 Degrees 20% Span Flaps

NACA 66-012 @ 7.5 Degrees 20% Span

Flaps

NACA 66-012 @ 10 Degrees 20% Span

Flaps

Combination of NACA66-012 and Clark Y

(0.5 Interpolation)- MD1

Combination of Clark Y and NACA66-012

(0.5 Interpolation)- MD2

Combination of NACA66-012 and Clark Y

(0.25 Interpolation)- MD3

Combination of NACA66-012 and Clark Y

(0.75 Interpolation)- MD4

Combination of NACA66-012 and MH-18B

(0.5 Interpolation)- MD5

Combination of NACA66-012 and MH-17

(0.5 Interpolation)- MD6

66.72

59.90

6.82

149.25

15.26

66.72

59.98

6.74

149.25

15.08

66.72

61.56

5.16

149.25

11.54

66.18

61.31

4.87

148.04

10.89

65.47

60.88

4.59

146.45

10.27

67.88

61.43

6.45

151.84

14.43

60.30

57.87

2.43

134.89

5.44

68.15

61.02

7.13

152.45

15.95

68.26

60.98

7.28

152.69

16.28

Airfoil

NACA 66-012 (Baseline)

Clark Y

NACA 64-012

NACA 64-212

MH-27

E-220

S8064

S8052

MH-16

MH-17

MH-17 @ 2.5 Degrees 15% Span Flaps

MH-17 @ 5 Degrees 15% Span Flaps

MH-18

MH-18B

NACA 66-012 @ 2.5 Degrees 10% Span

Flaps

Maximum

Possible Speed

(mi/hr)

149.25

130.26

148.73

148.60

150.39

146.07

151.84

149.49

150.32

157.26

157.26

157.26

141.04

154.19

Maximum Possible

Speed Loss in Turns

(mi/hr)

15.64

3.69

14.43

11.52

14.03

10.29

13.00

12.17

12.12

15.17

14.16

13.96

7.99

13.56

Table 5 Maximum possible speed and speed loss in turns for each airfoil candidate

28

Table 5 is a reiteration of Table 3 from section 2.6. The NACA 66-012 airfoil is

selected as the baseline airfoil, as it is the most common airfoil used for racing today.

Since it is the lowest speed airfoil, the Clark Y was chosen as the high lift airfoil for the

race simulation in Maple for comparison purposes. As for the other 10 airfoils, the first

priority was given to the highest top speed, and the second priority was given to the

minimal loss of speed. Only 12 out of 32 airfoils were selected for the race simulation in

Maple, as simulating a race is a time consuming process that takes 20-30 minutes per

airfoil. Because the goal of this project is to determine the airfoils with the lowest race

times, airfoils that produce high race times were not incorporated. For example, the MD4 airfoil produced a top speed of only 135

𝑚𝑖

ℎ𝑟

. It is for this reason that it is not a

competitive airfoil. Conversely, even though the MH-18 airfoil has a top speed of

only 141

𝑚𝑖

ℎ𝑟

, it is a viable candidate due to its low maximum speed loss in turns of 8

𝑚𝑖

ℎ𝑟

second only to the Clark Y airfoil.

As with any selection process in the field of Engineering, one must find the best

compromise between two or more selection metrics. A balance between top speed and

minimal loss of speed in turns during the airfoil selection process must be found. Upon

completion of a various race simulations, it can be determined that airfoil top speed is a

greater driver of race times than maximum loss of speed in turns.

3.2 Maple Race Simulation Results

29

,

Cd @ CL =

0.018776

Cd @ CL =

0.563277

Max Race

Speed

(mi/hr)

Max Speed

Loss in Turns

(mi/hr)

Race Time

(sec)

MH-17 With 5 Degrees 15% Span Flaps

0.00437

0.00507

151.13

11.65

62.146

MH-17

0.00437

0.00648

150.66

12.64

62.509

MH-18B

0.00470

0.00594

148.55

11.39

63.567

S-8064

0.00497

0.00636

146.65

10.98

63.814

NACA 66-012 With 10 Degrees 15% Span

Flaps

0.00528

0.00602

144.75

9.95

64.396

MD5- Combination of NACA66-012 and

MH-18B (0.5 Interpolation)

0.00490

0.00964

146.12

13.38

64.484

MD6- Combination of NACA66-012 and

MH-17 (0.5 Interpolation)

0.00487

0.00994

146.21

13.65

64.485

MD1- Combination of NACA66-012 and

Clark Y (0.5 Interpolation)

0.00543

0.00558

143.95

9.28

64.607

E-220

0.00568

0.00579

142.34

8.84

65.203

NACA 66-012

0.00528

0.01089

143.37

13.20

65.619

MH-18

0.00637

0.00538

138.38

6.93

67.668

Clark Y

0.00810

0.00538

126.49

3.27

70.189

Airfoil

Airfoil Shape

Table 6 Overall airfoil race simulation results

Table 6 above shows the outcome of the Maple airfoil simulation results, ordered by

the lowest to highest race times for the 12 airfoil candidates selected. The MH-17 with

15% span flaps during turns is the clear winner in this simulation. Even the MH-17

airfoil without flaps is less than 0.4 seconds slower than its flapped counterpart, the

complexity of the flap installation alone is not worth the 0.4 second.

30

It is surprising to note that the NACA 66-012 baseline airfoil performance is near the

bottom, albeit slower by only 3.473 seconds than the MH-17 with 5 degrees 15% span

flaps. Another commonly used airfoil in pylon racing, the S-8064, outperformed the

NACA 66-012 airfoil by 1.8 seconds. The performance of the NACA 66-012 airfoil can

be improved by 1.2 seconds by including 15% span flaps at 10 degrees during turns. This

added benefit of flaps may not be worth the complexity of flap installation for some

airplane builders. Another way to improve the NACA 66-012 airfoil is by blending it

with a higher lift airfoil (MH-18B, Clark Y) to create a new airfoil. One can also

improve the 66-012 airfoil by incorporating a wing with 3 various airfoil sections

consisting of a smooth transition between them.

Raymer [7] suggested using washout for constant airfoil wings to lower the angle of

attack of outboard wings. Washout is the twist of the wing where the outboard sections

are set to lower angles of attack than the inboard section. Washout results in two things:

it prevents the wing tips from stalling first, which will cause a violent stall and to make a

more elliptical lift distribution. Such lift distribution allows lift to naturally decrease

towards the wing tips. With a more elliptical lift distribution, the effect of induced drag

is lower. Rather than reducing the angle of attack towards the wing tips, one can design

a blended airfoil wing with a higher lift airfoil, such as a MH-18B in the inner 1/3,

transition to a MD-5, and finally to NACA 66-012 in the following manner:

Inboard 1/3: MH-18B

Mid 1/3: MD-5 airfoil, which is a blend of NACA 66-012 and MH-18B

Outboard 1/3: NACA 66-012

The beauty of calculating the section 𝐶𝐷 of a wing blended in the above manner is

that the average 𝐶𝐷 of each airfoil will be very close to the drag coefficient of the airfoil

that is the 50% blend of the inner and outer airfoils. In other words, the 𝐶𝐷 of the blended

airfoil, MD-5, can represent a wing comprised of those 3 airfoils or of just the MD-5

airfoil only.

3.3 Airfoil Polar Interpretations

XFOIL has the capability to create polars for a given range of angles of attack and

lift coefficients through the polar accumulation command (pacc) in the operations menu.

31

The XFOIL output polar text file was read into an Excel spreadsheet and plotted. An

example of the XFOIL polar output file for the NACA 66-012 airfoil is found in section

6.7 in the Appendix.

NACA 66-012

Clark Y

MH-18

MH-18B

S-8064

E-220

MD-1

MD-5

MH-17

MD-6

CL = 0.018776

CL = 0.563277

1.40

Lift Coefficient

1.30

1.20

1.10

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

-4

-3

-2

-1-0.10 0

-0.20

-0.30

1

2

3

4

5

6

7

8

9

Angle of Attack (Degrees)

Figure 20 𝐶𝐿 as a function of angle of attack for 12 airfoils

Figure 20 above shows the coefficient of lift as a function of α for the top 11

performing airfoils and the Clark Y. It can be seen that the Clark Y airfoil produces

higher 𝐶𝑙 at all α than all airfoils. Even the Clark Y must be kept at a negative α during

the high speed 𝐶𝐿 , marked by purple dashed lines. Since it is at a higher absolute α at

low 𝐶𝐿 , its 𝐶𝑑 will be higher.

You will also see that the NACA 66-012 is a relatively low-lift airfoil, and requires

higher α than a majority of airfoils in turning flight regime, marked by a blue dashed line.

This is why its 𝐶𝐷 is higher in this flight regime than the other airfoils. Conversely, the

Clark Y airfoil requires low α during turning flights, which leads to lower 𝐶𝐷 in that

flight regime.

32

10

Since XFOIL is incapable of solving for coefficients at and near stall α, a sudden

drop in the 𝐶𝐿 curve at higher α will not be seen. You can see that the Clark Y, MH-17,

MH-18, and MH-18B lift slope flatten out at 9-10 degrees α as stall is being approached.

These high lift airfoils are excellent candidates for the inboard airfoil section of a blended

airfoil wing, since they will stall first. Since the NACA 66-012 is known to have

somewhat more abrupt stall behavior, it will be ideal for the outboard section of a

blended airfoil wing. The NACA 66-012 curve does not start to flatten out at 9-10

degrees α, since it is not yet close to stalling.

The next figure, 21, shows the drag polar for those 12 airfoils run through the race

simulation. It shows 𝐶𝑑 as a function of 𝐶𝑙 . 𝐶𝐿 for high speed flight is marked by blue

dashed lines on the left, and 𝐶𝐿 in turns is marked by orange dashed lines on the right.

NACA 66-012

Clark Y

MH-17

MH-18

MH-18B

S-8064

E-220

MD-1

MD-5

MD-6

CL = 0.018776

CL = 0.563277

Drag Coefficient

0.024

0.023

0.022

0.021

0.020

0.019

0.018

0.017

0.016

0.015

0.014

0.013

0.012

0.011

0.010

0.009

0.008

0.007

0.006

0.005

0.004

0.003

0.002

-0.3 -0.2 -0.1 0.0

Lift Coefficient

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Figure 21 Drag polars for al 12 airfoils

From the drag polar on the left, one can easily see why the Clark Y airfoil is the

slowest in high speed flight regime, but yet has the minimal loss of speed in turns. Its

33

1.4

1.5

𝐶𝑑 is the highest at high speed, and is lowest during turning flight. On the other hand, the

NACA 66-012 loses the most speed in turns because of high 𝐶𝑑 at the 𝐶𝐿 for turning

flight. From the plot, it can be observed that the MH-17 airfoil has the lowest 𝐶𝑑 at

low 𝐶𝐿 , and yet has significantly lower 𝐶𝑑 in the turns than the NACA 66-012 airfoil.

The NACA 66-012 airfoil has high 𝐶𝑑 at higher 𝐶𝑙 because of the airfoil’s inherent

laminar bucket. This laminar bucket is a 𝐶𝑙 range where 𝐶𝑑 does not increase due to

strong laminar flow attachment. The plot in Figure 22 below illustrates the laminar

bucket.

0 Degrees Flaps

2.5 Degrees Flaps

5 Degrees Flaps

7.5 Degrees Flaps

10 Degrees Flaps

-2.5 Degrees Flaps

CL = 0.563277

0.03500

Drag Coefficient

0.03000

0.02500

0.02000

0.01500

0.01000

0.00500

Lift Coefficient

-0.2

0.00000

-0.1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Figure 22 Laminar bucket of NACA 66-012 airfoil with flaps

The unflapped NACA 66-012 airfoil emerges out of the bucket at

approximately 𝐶𝐿 = 0.3, so it is out of the laminar bucket and into higher 𝐶𝐷 regime at

the turning flight regime 𝐶𝐿 = 0.563277, marked by the black dashed line. Increasing

flap angle shifts the laminar bucket to the right until the 10 degree flap is just inside the

laminar bucket at 𝐶𝐿 = 0.563277, which is why flaps minimize speed loss in turns. For

34

1.0

reference, the orange curve represents -2.5 degree flaps, which shifts the laminar bucket

to the left.

0 Degrees Flaps

2.5 Degrees Flaps

5 Degrees Flaps

7.5 Degrees Flaps

10 Degrees Flaps

-2.5 Degrees Flaps

CL = 0.563277

1.0

0.9

Lift Coefficient

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

-7

-6

-5

-4

-3

-2

0.0

-1

0

-0.1

1

2

3

4

5

6

7

8

9

10

Angle of Attack (Degrees)

-0.2

Figure 23 Lift curve for flapped NACA 66-012 airfoil

As seen in Figure 23 above, the reason flaps lower 𝐶𝑑 at 𝐶𝐿 = 0.563277 from

lowering α required to attain this lift coefficient. The unflapped NACA 66-012 airfoil

(dark blue) requires just over 5 degrees α to maintain turning flight, while the 10 degrees

flaps requires less than 1 degree. This lowers the amount of exposed surface area of the

airfoil relative to the free steam flow, and thus lowers 𝐶𝑑 during turns.

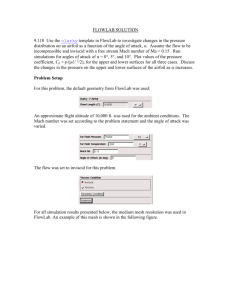

3.4 XFOIL 𝑪𝒑 Plot Comparison

At the turning flight regime 𝐶𝐿 = 0.563277, the MH-17 airfoil has lower 𝐶𝑑 than

the NACA 66-012. The plot in Figure 24 below offers an explanation for this difference

in 𝐶𝑑 .

35

11

Figure 24 𝐶𝑝 Plots for NACA 66-012 and MH-17 airfoils at 𝐶𝐿 = 0.563277

Since the coefficient of pressure is related to the local velocity of air over the airfoil,

the spike near the leading edge of the NACA 66-012 airfoil on the left indicates high

local velocity. This translates to higher drag coefficient at 𝐶𝐿 = 0.563277

3.5 Validation of Results

Figure 25 NACA 66-012 Wind Tunnel Data from Theory of Wing Sections [8]

36

Wind tunnel data for NACA 66-012 is found in pages 662-663 in [9], copied as

Figure 25 above. At Re = 3,000,000, 𝐶𝑑 ≈ 0.004 at 𝐶𝐿 = 0.018776. At this Reynolds

number and 𝐶𝐿 , XFOIL predicted 𝐶𝐷 = 0.00368, an 8.7% difference. XFOIL predicted

𝐶𝑑 = 0.00841 at 𝐶𝐿 = 0.563277, which is 7.0% lower than the published 𝐶𝑑 = 0.009

at the same 𝐶𝐿 . The difference could be due to some viscous effects not accounted for in

XFOIL or even in the wind tunnel data itself. The data was produced in the 1940’s, when

wind tunnel technology and measurement was not as advanced as modern methods. This

discrepancy between both sets of data is expected to be similar for all airfoils, which still

allow relative comparisons to be made using XFOIL results. There is relatively good

agreement between XFOIL and published wind tunnel data, thus validating XFOIL

results.

The lowest race time achieved with a NACA 66-012 airfoil (or a slight variation of)

is 63 seconds with a course layout similar to the one used in the airfoil simulations. The

Maple simulation predicted this airfoil to complete the race in 65.6 seconds, a good

agreement at 4.16% difference. In the race simulation, the plane initiates turns when

pylons are reached, but in reality, the turns are initiated before the pylons are reached.

This reduces the flight distance covered, and accounts for the 2.6 second difference. All

in all, the race simulation ensures the race course is similar between all airfoils for equal

comparison.

As posted in his pylon racing page of his MH Aero Tools website [3], Dr. Hepperle

also completed a similar race simulation, with results shown in Figure 26 below.

Figure 26 Velocity vs. time result of race simulation by Dr. Hepperle [3]

37

Figure 27 Velocity vs. time result of race simulation for NACA 66-012 airfoil

Velocity vs. time results between Figures 26 and 27 show similar trends, which

validates the race simulation. As mentioned before, the velocities stabilize after the 4th

lap, so the amplitude of the sine graphs are the same after the 4th lap.

3.6 Implications of Moment Coefficient

The airfoil pitching moment coefficient as a function of 𝐶𝐿 for each of the 12 airfoils

is plotted in Figure 28 below. The vertical dashed line represents the high speed flight