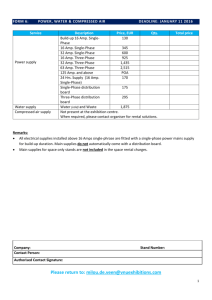

Power Systems

advertisement

Power Systems

Power Systems

Lesson Objectives

When you finish this lesson you will

understand:

• Control of the high electrical power

systems, transformer control

• Timing functions

• Calculation of the heat

• Troubleshooting

Learning Activities

1. View Slides;

2. Read Notes,

3. Listen to lecture

4. Do on-line

workbook

5. Do Homework

Keywords

Power Systems, Single Phase AC, Single Phase Rectified, Three

Phase, Three Phase Rectified, Frequency Changer, Inverter,

Transformer, Tap Switches, Saturation, Hysteresis, Reactance,

Inductance, Resistance, Impedance, Power Factor, Duty Cycle,

Timing Controls, Synchronous, Phase Shift Heat Control, SCR, half

wave rectified, Full Wave Rectified

Machines and Equipment

• Cooling System

• Mechanical System

– Force generation system

• Pneumatic/Hydraulic system

• Motor or foot-operated system

– Electrode application system

• Rocker arm or pinch type

• Press or direct action type

• Portable system

• Electrical System

– Single-phase system

– Single-phase rectified

system

– Three-phase rectified

system

– Frequency changer

system

– Frequency inverter

system

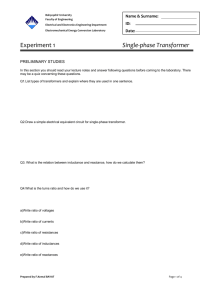

Block Diagram of Single-Phase

Spot Welder

Contactor

Main Power Line

Spot Weld

Configurations for Spot Welding

Transformers

(a) Stacked, Shell Type

(b) Stacked, Core Type

(c) Wound Type

W. Stanley, Resistance Welding

McGraw-Hill, 1950

N=np/ns

Vs= Vp/N

Is = Ip N

Parallel/Series Tap Switches

Es

(a) Parallel

S2

P2

S1

P1

Es

S1

P1

Vp

(b) Series

S2

P2

Es

Es

Vp

Transformer Tap Switch

Es

Vp

Induced Magnetic Filed

Saturation Induction

Remnant Induction

Coersive Force

Structure & Properties of Materials,

Wiley, 1967

Applied Magnetic

Field

Rp

X = reactance in Ohm

L = inductance in Henry

f = frequency in Hertz

Xs

Rs

Xp

X 2fL

Z R X

2

2

Z = impedance in Ohm

R = resistance in Ohm

Power Factor

DC Current

Ohm’s Law

V

I

R

I= Current

V= Voltage

R= Resistance

Power = VI

=KW (kilowatts)

AC Current

V

I

Z

Z X2 R2

Z= Impedance

X= Reactance

• Frequency of AC

• Geometry of Secondary

• Magnetic Material

Power = KVA

Power Factor

P

P

V

I

V

I

(a) Purely Resistive Load

(b) Resistive and Reactive Load

Pav = VavIav cos()

X=Reactance

Z=Impedance

R=Resistance

Power Factor = Cos

45 o

If: R=X

pf = 70.7%

If: I=10,000 amps Kva=100

V=10 volts

Kw=70.7

Variables Affecting Power Factor

• Machine Design

• Single-Phase versus Three-Phase Current

• Frequency

• Reactance/Resistance of the Secondary

Loop

• Magnetic Material in the Throat

Increased Throat Length

R 2K 2L

X KL

X

R

Increased Angle

Decreased Power Factor

Resistance Welding Manual,

RWMA, 1972

Ferrous Material in Throat

X

R

Reduced Power Factor

Resistance Welding Manual,

RWMA, 1972

Power Factor Correction Capacitors

AC Power

Supply

Contactors

(Switched Simultaneously)

High Impedance DC

Charging Circuit

(a) Shunt Capacitors

Welding

Contactor

AC Power

Supply

Normally-Closed

Contactor

Discharging

Resistor

Tuned Capacitor

(b) Series Capacitors

Duty Cycle

Percent Rated Load

is the power level at which a transformer can operate for

some fraction of time without overheating

kvamax

7.07kvarated

DutyCycle

DutyCycle

100%

50%

Percent Duty Cycle

TimeOn

TimeOn TimeOff

Timing Controls

At what point in time do we close the contactor

• Non-synchronous Controls

• Synchronous Controls

• Microprocessor Control = Synchronous

Synchronous Timing Accuracy

Electronic Control Res. Weld,

McGraw-Hill, 1943

Transient Currents with Non-Synchronous Timing

Electronic Control Res. Weld,

McGraw-Hill, 1943

Electronic Control Res. Weld,

McGraw-Hill, 1943

Control of Secondary Current

• Transformer Tap Setting (Turns Ratio)

• Phase Shift Heat Control

60 Cycle

AC

Gate

Cathode

Anode

Rules for SCR Conduction

• can conduct when anode is + with respect to cathode

• once initiated, can only be stopped by removal of anode voltage

• initiated by a pulse on ignitor

Welding Handbook

“Idealized” Phase Shift Heat Control

(a) Current Controlled by Tape Settings

In Actual Case,

Current can not

instantaneously

change

(b) Current Controlled by Phase Shift Setting

Actual

Condition

1

%Heat

Firing

Angle

Hangover Angle

Related to R/L ratio

Androvich “Resistance Welding Constant Current Heat Control”,

AWS Sheet Metal ConfV, 1992

IRN = Normalized Available

RMS Current

L

arctan

R

IRN

1

{

2

[sin( t ) sin( ) (R / L)( / t ) ]2 (t )} 1 / 2

Androvich “Resistance Welding Constant Current Heat Control”,

AWS Sheet Metal ConfV, 1992

Tsai, Experimental Study of Weld Nugget Expan,

Paper B1, Sheet Metal Welding Conf V, AWS, 1992

Link to:

Phase Shift Heat Control Demo

Portable Trans Guns

Transformer Integral with Gun Thus smaller in Size

Nedorezov, J “Using Portable Transguns for Resistance Spot

Welding”, Practical Welding Today, Nov-Dec 1997

Nedorezov, J “Using Portable Transguns for Resistance Spot

Welding”, Practical Welding Today, Nov-Dec 1997

Machines and Equipment

• Cooling System

• Mechanical System

– Force generation system

• Pneumatic/Hydraulic system

• Motor or foot-operated system

– Electrode application system

• Rocker arm or pinch type

• Press or direct action type

• Portable system

• Electrical System

– Single-phase system

– Single-phase rectified

system

– Three-phase rectified

system

– Frequency changer

system

– Frequency inverter

system

Single-Phase Rectified System

Center-Tapped Transformer

Bridge-Type Rectifier

Primary Current

Secondary Current

Single-Phase Rectified System

Advantages

• Higher Power Factor

Disadvantages

• Expensive

• More Uniform Heat Flow Pattern

• Less pf Loss by Material in Throat

• Need Heavy Duty Diodes

•One Electrode Wears Rapidly

• Load on one side of Three Phase Line

• Balanced 3 phase hook-up needed

A

B

C

a

b

b

c

a

Machines and Equipment

• Cooling System

• Mechanical System

– Force generation system

• Pneumatic/Hydraulic system

• Motor or foot-operated system

– Electrode application system

• Rocker arm or pinch type

• Press or direct action type

• Portable system

• Electrical System

– Single-phase system

– Single-phase rectified

system

– Three-phase rectified

system

– Frequency changer

system

– Frequency inverter

system

Three-Phase Rectified System

Half Wave

Full Wave

Primary Current

Primary Current

100% Heat

Secondary Current

10% Heat

Secondary Current

120°

*

*

*

*

Half Wave

120°

Full Wave

120°

Spinella, D., “Al RSW: Capital and Operating Costs”,

AWS Xsheet Metal Conf, 1996

Comparison of Two PF on Three Machines

Roth, “Alternating Current Vs DC in Resistance

Welding” AWS Sheet Metal Conf IV, 1990

High Ripple

Medium Ripple

Low Ripple

Comparison of Two PF on Three Machines

• Both Single Phase and 3 Phase DC is best in low

power factor (high inductive) circuits providing as

much smoothing as possible

• Phase shifting will increase ripple (more in single

phase). Operate on the highest phase shift and lowest

tap setting possible

Advantages

• High Power Factor

• Uniform Heat Flow

• No need to balance hook-up

• No pf loss by material in throat

Disadvantages

• Expensive

• Need Heavy Duty Diodes

• One Electrode Wears

Machines and Equipment

• Cooling System

• Mechanical System

– Force generation system

• Pneumatic/Hydraulic system

• Motor or foot-operated system

– Electrode application system

• Rocker arm or pinch type

• Press or direct action type

• Portable system

• Electrical System

– Single-phase system

– Single-phase rectified

system

– Three-phase rectified

system

– Frequency changer

system

– Frequency inverter

system

Frequency Converter

1

Controller A

2

Controller B

3

Controller C

Frequency Changer System

(a) Frequency-Changer

(b) Rectified

Advantages

• Power Factor > 98%

Disadvantages

• Cost

• Balanced Loading

• Balanced Electrode Wear

• Control Problems

Machines and Equipment

• Cooling System

• Mechanical System

– Force generation system

• Pneumatic/Hydraulic system

• Motor or foot-operated system

– Electrode application system

• Rocker arm or pinch type

• Press or direct action type

• Portable system

• Electrical System

– Single-phase system

– Single-phase rectified

system

– Three-phase rectified

system

– Frequency changer

system

– Frequency inverter

system

Frequency Inverter System

Oscillator

Rectifier

AC

60 Hz

DC

AC

HF

400, 600, or

1200 Hz

Advantages

• High Power Factor > 98%

• Less Core Material

• Lighter & Smaller –

suitable for robots

Disadvantages

• Cost

• Newer Process – Still

Under Development

Duty Cycle