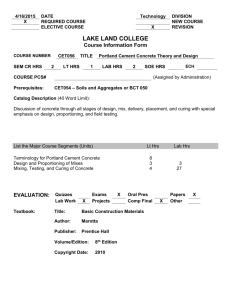

DT1410 - Materials and Processes in Design

advertisement

Global, Human, and Ethical Impacts of Product Design INVESTIGATING PRODUCT LIFECYCLES Impacts Human Throughout time, humanity has used natural resources, animals, plants and inanimate materials, for its survival, consumption, and enjoyment. It is often taken for granted things and resources will always be here. Many times short term monetary gain is considered a priority. Impacts Continued… Global Population: - is growing at an exponential rate. - shows a continual change in human needs and wants. Energy: non-renewable resources are becoming more and more scarce. Ethics A set of moral principles or values; a theory or system of moral values. The discipline dealing with what is good and bad and with moral duty and obligation. Ethical Design Dilemmas Situations in which decisions you make are in conflict with what may or may not be morally correct. Sometimes this is obvious right away, and other times it is not. Solutions to open-ended design problems have dilemmas that designers face when creating the product. Let’s look at some pictures of products or things and discuss the ethics involved. Steps in resolving ethical design decisions 1. Moral Clarity- identify the relevant moral values. 2. Conceptual clarity- clarify key concepts. 3. Just the facts- obtain all relevant information. 4. Informed about options- Consider all genuine options and alternative solutions. 5. Well-reasoned- Make a reasonable decision. Design Analogy Engineering design as a metaphor or model for thinking about moral decision making- in general, not just within engineering. Like design, moral choice often involves alternative permissible solutions to dilemmas. Product Lifecycle Definition is the succession of strategies used by business management as a product goes through its life-cycle. The conditions in which a product is sold (advertising, saturation) changes over time and must be managed as it moves through its succession of stages. The goals of Product Life Cycle (PLC) are to reduce time to market, improve product quality, reduce prototyping costs, identify potential sales opportunities and revenue contributions, and reduce environmental impacts at end-of-life. To create successful new products the company must understand its customers, markets and competitors. 1. Raise and Extract All consumer products begin their lifecycle with a dependence on the natural environment. Some form of energy is always required to extract the natural resources from the earth or its atmosphere. 2. Process Raw materials are processed or refined. Energy is required for the processing and refining. 3. Manufacture Manufacture Additional energy is required as the processed or refined materials move through the manufacturing and assembly process. 4. Use Use Consumer products are transported to stores (consuming additional energy) and are ready for purchase. Products remain at this stage as long as they are usable or repairable. 5. Dispose Dispose When the product is no longer of use to us and we “get rid” of it. EPA Guidelines EPA: Environmental Protection Agency. This organization’s mission is to protect human health and the environment. EPA Guidelines The EPA works to develop and enforce regulations that implement environmental laws enacted by Congress. EPA Guidelines The EPA is responsible for researching and setting national standards for a variety of environmental programs. The EPA delegates to states and tribes the responsibility for issuing permits and monitoring and enforcing compliance. OSHA Guidelines OSHA-Occupational Safety and Health Administration OSHA's mission is to assure the safety and health of America's workers by setting and enforcing standards; providing training, outreach, and education; establishing partnerships; and encouraging continual improvement in workplace safety and health. OSHA Guidelines To establish and maintain safe workplace environments, OSHA enforces standards and reaches out to employers and employees through technical assistance and consultation programs. Construction Materials Concrete Made by combining four materials into a mixture of two parts: portland cement aggregate Portland cement A finely pulverized material made up of compounds of silica, lime, alumina, and iron. Portland cement is created by mixing limestone with clay, slag, or shale and then burning the mixture in a rotary kiln. The setting and hardening is the result of a chemical reaction between the portland cement and water called hydration. Alternatives to Portland Cement Slag cement and Fly-ash cement are green alternatives. Formwork Creating concrete objects such as slabs, walls, footings, and columns with the use of a mold or form. Concrete reinforcement Placing a reinforcing material, such as steel bars, in a concrete structure to resist tensile, shear, and bending forces. Concrete joints Permits movement and volume changes to encourage cracks at the joint instead of other areas. Masonry Stone, clay masonry units, and concrete masonry units used for construction material Mortar A combination of portland cement, lime, or masonry cement and an aggregate that forms a workable paste. Grout Pourable construction materials used to fill voids in reinforced and unreinforced masonry, tile, and stone paving. Clay masonry units Burned clay units used in construction such as bricks, architectural terra cotta, and hollow clay tile. Molded concrete units used in the construction industries as structures, walls, and facing. Precast concrete Concrete products that have been precast in molds and then removed and transported to construction sites. An example is precast concrete walls for building, which are often prestressed. Dimensional Lumber is a collective term for harvested wood that has been manufactured into boards and planks. This process is part of something called wood production. Lumber is predominantly used for structural purposes but has many other uses as well. Lumber is classified as hardwood or softwood. Lumber is supplied either rough or finished. Besides pulpwood, rough lumber is the raw material for furniture-making and other items requiring additional cutting and shaping. It is available in many species, usually hardwoods, but it is also readily available in softwoods such as white pine and red pine because of their low cost. Finished lumber is supplied in standard sizes, mostly for the construction industry, primarily softwood from coniferous species includingpine, fir and spruce (collectively known as Spruce-pine-fir), cedar, and hemlock, but also some hardwood, for high-grade flooring. Sheathing Oriented strand board (OSB) is an engineered wood particle board formed by layering strands (flakes) of wood in specific orientations. It may have a rough and variegated surface with the individual strips of around 2.5 × 15 cm (1" x 6"), lying unevenly across each other. OSB is a material with high mechanical properties that make it particularly suitable for load-bearing applications in construction.[1] The most common uses are as sheathing in walls, flooring, and roof decking. For exterior wall applications, panels are available with a radiant-barrier layer prelaminated to one side; this eases installation and increases energy performance of the building envelope. OSB also sees some use in furniture production. Water Membranes In building construction, a structure needs waterproofing since concrete itself will not be watertight on its own (but note concrete is easily waterproofed with additives). The conventional system of waterproofing involves 'membranes'. This relies on the application of one or more layers of membrane (available in various materials: e.g., bitumen, silicate, PVC, EPDM etc.) that act as a barrier between the water and the building structure, preventing the passage of water. However, the membrane system relies on exacting application, presenting difficulties. Problems with application or adherence to the substrate can lead to leakage. In the UK these membranes are rarely allowed below ground below the water table. Asphalt Shingles An asphalt shingle is a type of wall or roof shingle. They are one of the most widely used roofing covers in North America because they have a relatively inexpensive up-front cost and are fairly simple to install. Gypsum Board (Drywall) Drywall (also known as plasterboard, wallboard, gypsum board, sheetrock, or gyprock) is a panel made of gypsum plaster pressed between two thick sheets of paper. It is used to make interior walls and ceilings. Drywall construction became prevalent as a speedier alternative to traditional lath and plaster. In many places, the product is sold under the trademarks Sheetrock or Gyproc. In New Zealand the category is known as plasterboard or gib board (originally "Gibraltar board"), the latter being a proprietary brand name but now largely a genericised trademark Finish Carpentry Carpentry that involves the installation of finish woods, (and trim made of plastic or molded polyurethane materials) to provide a finished appearance to installed doors, windows, stairs, and other features of a building's interior. Elements include casing, baseboard, railings, mantels, louvers, paneling, and shelving. Paints Paint is any liquid, liquefiable, or mastic composition that, after application to a substrate in a thin layer, converts to a solid film. It is most commonly used to protect, color, or provide texture to objects. Paint can be made or purchased in many colors—and in many different types, such as watercolor, artificial, etc. Paint is typically stored, sold, and applied as a liquid, but dries into a solid. Carpets A carpet is a textile floor covering consisting of an upper layer of "pile" attached to a backing. The pile is generally either made from wool or a manmade fiber such as polypropylene, nylon or polyester a nd usually consists of twisted tufts which are often heat-treated to maintain their structure.