Attachment 8 – Permit Certificates AH

advertisement

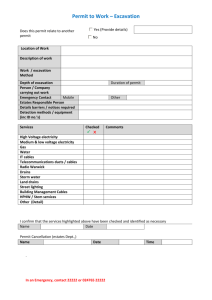

Attachment 8 – Permit Certificates A-H Certificate A – Hot Work Certificate Certificate B – Confined Space Certificate Certificate C – Work At Height - roofs, canopies and temporary structures Certificate D – Excavation Certificate Certificate E – Isolation Certificate Certificate F – Tank Removal / Installation Certificate Certificate G – Demolition Certificate Certificate H – Overhead Crane Certificate Last updated13 May 2014 A Corresponding permit to work No. HOT WORK CERTIFICATE (Only to be completed by authorised persons) Specify location: Specify likely ignition sources: OPERATIONAL INFORMATION I have checked the workplace and reviewed the hazardous areas, and; It is free of flammable materials Sewer and drain systems, and other low lying areas are protected against sparks The working area is defined with barriers/ signs Additional fire fighting materials are present and close by ready for use. Personnel are trained in their use; (e.g. 2 x 9kg fire extinguishers) Fire retardant blankets have been used to contain all sparks An Emergency Response plan is in place and personnel inducted into it. Continuous gas monitoring is present GAS TEST (Only to be completed by an AGT) Test frequency: Once before commencement of the work Yes No Tick if applicable (minute/hourly repeat frequency) Test while work is in progress, at specified frequency The following working area has been tested for flammable gases/vapours: Gas test acceptable results: Acceptable results have to be agreed with the AGT and PI: Substance Hydrocarbon Oxygen Other, specify when measured Maximum 0 % of the LEL 23.5 % Vol Methane 0 % Minimum N/A 19.5 %Vol Hydrogen Sulphide 10ppm Gas tests performed I confirm that I have tested for gas and/or oxygen and that the results are within the specified acceptance levels, and that the measured concentration of explosive gases/vapours is 0% LEL Date Time AGT Signature Validity of the Hot Work Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Hot work certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014 B Confined Space Certificate Corresponding Permit to Work No. (Only to be completed by authorised persons) Activity: Maximum duration in the confined space: Describe the confined space Personal Protective Clothing (compulsory) Tick where required Location: Description: Contents: Access/ egress: Number of open entrances: Other entrances: Diameter: Height: How were the residue vapour removed from the confined space? Fresh air breathing set Respiratory equipment Eye protection, Rescue line & 5 point harness Special clothing, Gloves Equipment and emergency arrangements Is the confined space now free of residue vapour? Cathodic protection disconnected? Which instruments have been made safe? Access/ egress ladder Scaffold Crane Method of communication (intrinsically safe) Continuous ventilation Which instruments/equipment are isolated? How was the confined space cleaned? Tick if applicable Purged with air: Tick where required Fire extinguisher Temperature: <30 degrees Celsius Safety guardrail/cover at manhole Flushed with water: Emergency plan - & understood by all Purged with inert gas: Specify cleansing agent used: Emergency plans practiced Emergency recovery equipment Warning signals understood by all Measurements before entering Method of measurement Result AGT Name: Oxygen Explosive vapour/gas, specify Asphyxiant vapour/gas, specify Poisonous vapour/gas, specify Signature Date/time: Measurements during work Gas test acceptable results Oxygen Maximum Minimum 23.5 % 19.5 % Name: Explosive vapour/gas specify <1% of the LEL N/A Asphyxiant vapour/gas; <50% WES ( C i r c l e t o specify) WES= CO 25ppm, H2S10ppm, Ammonia 25ppm ppm ppm ppm ppm Max people to enter space Max time of entry; specify persons Signature PI/AGT: Rest time between entries minutes minutes Date / Time: Tests performed: I confirm that I have tested the confined space for gas and/or oxygen and that the results are within the specified acceptance levels, and that the measured concentration of explosive gases/vapours is below the 1% LEL Date Time AGT Signature Validity of the Confined Space Permit Permit Issuer: Permit Issuer: Confined space work certificate and Permit to Work are withdrawn Permit Holder From: Until: Name: Signature: Date/Time: Reason: Name: Signature: Date/Time: Date: I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. Signature: Date: Last updated13 May 2014 C Work At Height Certificate Corresponding Permit to Work No. roofs, canopies, temporary structures (Only to be completed by authorised persons) Specify location: Maximum fall height: Type(s) of fall protection used: Emergency rescue means: Access/egress means: Equipment / signs / barricades / emergency devices used: OPERATIONAL INFORMATION Yes I have checked the workplace and reviewed the hazards to workers, and; No It is compliant with the Z Work at Height Policy The working area is defined with barriers / signs The work will not impact neighbouring areas and increase any current risk level If there any of the following hazards in the work area, or an equivalent hazard, the required controls to eliminate otherwise minimise the risk has been established - brittle surfaces, skylights, internal gutters, trip hazards, structural instability, single skin canopy, hazardous material/dust, overhead hazards Emergency rescue means is available Note: all equipment and HSSE control measures are to be onsite and established prior to work starting. Work at Height instructions to the permit applicant: Work at Height policy to be complied with; fall protection is required for potential fall distance of 1.8 metres or more, inclusive of whether it is at or below ground level or within 2.0 metres or less from an unguarded edge. The hierarchy of fall protection is to be used at all times to determine the reasonable and practicable control measure for the work; i.e. in order of application: 1. Eliminate work at height 2. Work from permanent guard rail 3. Work from temporary guard rail or elevating working platform (scissor lift/boom lift) 4. Work with fall restraint means 5. Work with fall arrest means. Scaffolds 4m and over must be erected by a competent person. Fall restraint is to be worn at all times in a boom lift/cherry picker. If a permanent anchor point is installed in a scissor lift fall restraint is also to be worn. Any time a worker is wearing fall restraint/arrest means an emergency recovery plan must be established and equipment for it available on site prior to the work starting. You may only work off a step ladder with the prior approval of the main managing contractor if the lowest part of the worker’s body is less than 1.8m and the work area is so restricted that prevents the use of a standard work platform. A suitable ladder shall only be used for access to and from a suitable working at height platform with no more than 6 metres potential fall distance. The ladder must be secured and protected/isolated at the base. Access to the retail shop canopy is to only be via an elevating work platform or scaffold. When a worker is working within 2 metres of the unguarded edge fall protection must be established and maintained 2 metres either side of the workers work area at all times. Direct transit between the access platform/ladder to and from a work area at height must be done in a safe manner. Last updated13 May 2014 Brittle surfaces, sky lights, gutters, among others are to be isolated from the workers work area or additional structural support to these areas established and maintained. Working on sloped surfaces are to comply with the Guidelines for the Prevention of Falls and Best Practice Guidelines for Working on Roofs. If erecting a fall protection guard rail its height is to include the worker’s height standing 2 metres from the edge on the slope plus 900mm to1100mm. The area below the work at height is to be isolated and protected from falling objects. When closing a fuel pump lane ensure both ends of the lane are barricaded fully to prevent motorists entering the work area. Mechanical plant operator’s competencies are to be verified prior to work starting. Mechanical plant risk assessments and prestart inspections are to be completed and recorded to ensure they are safe to operate. Fall restraint/arrest and recovery equipment must be checked prior to use, have been inspected 6 monthly by a competent person and be less than 10 years old. Check weather conditions are suitable for the entire works completion. Firmly secure equipment and materials in strong winds at all times. Validity of the Work At Height Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Work at Height certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014 D Excavation Certificate Valid only when attached to Permit to Work No. (Only to be completed by authorised persons) Specify location: Maximum excavation depth: Type(s) of plant used: Emergency rescue means: Access/egress means: Equipment / signs / barricades / emergency devices used: OPERATIONAL INFORMATION Yes No Is the excavation in a hazardous zone? If yes an Isolation Certificate and Hot Work Certificate are also required Is the excavation potentially exposed to gases from soil type during the works? If yes a Confined Space Certificate may also be required and/or appropriate control measures Is there a fall risk of 1.8m or more? If yes a Work at Height Certificate is also required Does the work involve a Tank Removal / Installation? If yes a Tank Removal / Installation Certificate is also required Does the work involve Demolition? If yes a Demolition Certificate is also required Does the work require working on a road? If yes a Traffic Management Plan is also required Are there any resource consent conditions that require actioning? If yes include in the Safe Work Method Statement and implement Note: all equipment and HSSE control measures are to be onsite and established prior to work starting Excavation instructions to the permit applicant: Contact the local authorities for the services (Dial Before You Dig) and obtain drawings if required Piping and electrical/instruments must be localised by hand digging (with spades) within 1-meter radius around piping and cabling. Identified cabling and piping must be marked with wooden pegs or spray paint. Piping and Cabling may have moved from its original location, as indicated on as-built drawings, due to soil settlement. Excavation adjacent to buildings or structures must not be excavated below the foundation or inside the safe slope without precautions advised from a chartered professional engineer, and established for the building/structure and the excavation face. Exposed piping and cabling is to be assessed for support requirements. Workers are to maintain safe distance while equipment is in operation; guide 2m radius for swing radius and drop zones. Work at Height policy to be complied with; fall protection is required for potential fall distance of 1.8 metres or more, inclusive of whether it is at or below ground level or within 2.0 metres or less from an unguarded edge. Last updated13 May 2014 Install and maintain a 2m clear cordoned area around the excavation to prevent falls. Confirm mechanical plant SWL, position and access, including operator safe access to cab: e.g. on ramps/slopes and inside cordon. Protection from falling objects must be provided for the public and workers. A 1m high barrier/fencing or cover to be erected around all open excavations left unattended overnight at any time. This is in addition to construction site fencing where other works are also conducted on site. Excavations deeper than 1.5 metres require slopes as shown below side supporting structures to prevent collapse. Mechanical plant, vehicles and or heavy loads including spoil piles must be a minimum of 600mm from the edge of the excavation unless the excavation face is shored to allow for the load. Disengaged buckets are not to be stored on top of spoil piles. Water pumping from the excavation may cause subsidence of adjacent structures. Expert advice and precautions are to be taken. Excavations 6 metres or deeper require the services of a specialised chartered professional engineer and a detailed emergency response plan with access/egress No blasting or use of explosives is allowed. The handling of contaminated soil requires the use of additional PPE as defined in the Permit Removal of contaminated soil and dewatering must comply with the Z Environmental Management Plan and/or the environmental monitoring consultant’s instruction. Removing spoil from site: vehicle wheels must be clean of spoil prior to leaving site; the load is to be secured; dust and water runoff is to be controlled. Hazard warning notices must be placed at all exits and entrances to the work area, including the afterhours contact details. Emergency Response Plan must be established specific to the excavation and all workers inducted into it. Access/egress ladders to be established. If ramps are used: slope, cleating, and pedestrian/plant separation must be established as per the Excavation Approved Code of Practice. Mechanical plant operator’s competencies are to be verified prior to work starting. Mechanical plant and equipment risk assessments and prestart inspections are to be completed and recorded to ensure they are safe to operate. Noise, dust and vibration controls must be established and maintained. Daily inspection of the structural integrity of the excavation is to be conducted prior to work starting, and after rain or other event that would affect the stability of the face. Inspections are to be recorded and any new hazards identified controlled prior to work starting. Last updated13 May 2014 I have checked the site / studied the layout drawings and certify that the excavation proposed under Permit to Work number dated can be carried out: a) * Without risk of damage to any underground services b) * Provided that the following additional controls are taken to prevent damages to the equipment/services specified below: Situation Sketch / Indication of Hazards: Validity of the Excavation Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Excavation work certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014 Isolation Certificate E Corresponding Permit to Work No. Location: (Only to be completed by authorised persons) Identify equipment being worked on, including identity number Specify energy being isolated (electrical, hydraulic, pneumatic, mechanical, chemical, thermal, radiation, gravitational, other) Specify exact location of isolation point Person(s) completing the isolation Name Company Job Signature Accidental reconnection of this equipment has been prevented by the following means: Isolation Point: Isolation Point: Safe Position: On / Off (circle one) Safe Position: On / Off (circle one) Lock/Tag No: Lock/Tag No: Applied by (Name): Applied by (Name): De-energised Test applied - specify: De-energised Test applied - specify: Results: Results: Lock out until Lock out until am/pm (time) (date) am/pm (time) (date) Validity of the Isolation Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Isolation work certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Name: Signature: Signature: Signature: Date/Time: Date: Date: Reconnection I the Permit Holder have personally checked the equipment isolated above and confirm that work on it is completed and said equipment has been re-connected and is in a safe working condition. Name: Signature: Date/time: Permit Holder Last updated13 May 2014 F Tank Removal / Installation Certificate Corresponding Permit to Work No. Location: (Only to be completed by authorised persons) Requirements for Tank Removal and/or Installation: Yes No An Excavation Certificate is also required. Has one been completed? A Confined Space Certificate may also be required. Has one been completed? An Overhead Crane Certificate is also required. Has one been completed? A Traffic Management Plan must be established. Has one been completed? Is an oversized vehicle permit required for tank removal from site to destination? If so has one been obtained? Have the neighbours been notified? OPERATIONAL INFORMATION Instructions to the permit applicant: The geotechnical report is to be reviewed where available and any hazard and risk control measure requirements are to be included in the works SWMS All existing pipe work, including vent rises and cathodic protection to be disconnected prior to tank removal. Check weather conditions are suitable for the entire works completion Establish Emergency Response Plan requirements for the whole works e.g. falls, crushing, structure collapse, subsidence, confined space entry, suspended load falls, vehicle/pedestrian collision, among others. For tank installations ensure optical equipment is available on site to enable remote reading of deflection gauges e.g. dumpy level sight or binoculars. Confirm crane SWL, position and access when lifting, including operator safe access to cab: e.g. on ramps/slopes and inside cordon. Toolbox talk all parties involved in the works as a prestart meeting to co-ordinate crane operation, excavation and traffic management tasks, communication means, and responsibilities. Where ground instability adjacent to the tank is of concern, ensure no persons enter the cordon area without the required control measures identified established. The Work at Heights Policy is to be complied with. Fall Protection is required over 1.8 metres and within 2 metres of an unguarded edge. This includes all works involving slings and rigging. Ensure the Excavation Certificate controls are implemented, in particular: cordon, fall protection, fencing and cover for open tank pit. Check complete setup of tank preparation for safe lift prior to lift for removal and/or installation. Confirm any back fill requirement situations that may arise during the works. Confirm any tank pit reinstatement requirements. Ensure workers are clear of overhead loads, mechanical plant swing arcs and fall risks during all tasks undertaken as part of the complete works. Validity of the Tank Removal/Installation Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Tank Removal work certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014 G Demolition Corresponding Permit to Work No. Location: (Only to be completed by authorised persons) Requirements for demolition works: Yes No Is the demolition in a hazardous zone? If yes and Isolation Certificate and Hot Work Certificate are also required Is the structure known to have Asbestos? If yes and Isolation Certificate and Hot Work Certificate are also required Does the demolition include working in a confined space? If yes a Confined Space Certificate is also be required Is there a fall risk of 1.8m or more? If yes a Work at Height Certificate is also required Does the work involve an overhead crane? If yes an Overhead Crane Certificate is also required Does the work require working on a road? If yes a Traffic Management Plan is also required Have the neighbours been notified? OPERATIONAL INFORMATION Instructions to the permit applicant: No blasting or use of explosives is allowed. All services underground or above ground within the demolition area must be located and disconnected. As built building plans are to be reviewed and the structure inspected prior to any works starting. If there is potential for asbestos to be present in the structure an asbestos survey is required prior to works starting. If asbestos is present an approved asbestos removalist is to be engaged and an isolation certificate completed as part of this permit. Identify other common hazardous substances likely to be encountered and arrange procedures for safe containment or removal where applicable. The handling of contaminated soil requires the use of additional PPE as defined in the Permit Identify and ensue safe disposal of PCB’s as per regulatory requirements. Ensure the safe disposal of PCB’s as per regulative requirements and appropriate PPE is used during the handling processes. Recycling the clean waste material from the demolition works is encouraged. Check weather conditions are suitable for the entire works completion. Precautions should be taken to ensure that sudden weather changes do not affect the stability of the structure. Barricade or perimeter fencing is to be erected. Barricade and signs to be erected to prevent persons from entering demolition area before work starts. A demolition plan is to be developed and where required a structural engineers report obtained to verify structural stability if it is of concern. This includes any impact risk to adjacent buildings or structures. Debris should not be allowed to accumulate in areas that impact structural stability. The Work at Heights Policy is to be complied with. Work at Height policy to be complied with; fall protection is required for potential fall distance of 1.8 metres or more, inclusive of whether it is at or below ground level or within 2.0 metres or less from an unguarded edge. This includes all works involving slings and rigging. Removal of roof trusses/structure should be from safe work platforms. Care should be taken that removal of trusses does not cause instability of walls. Removal of hazardous materials must comply with the Z Environmental Management Plan and/or the specialist consultant’s instruction. Last updated13 May 2014 Removing spoil from site: vehicle wheels must be clean of spoil prior to leaving site; the load is to be secured; dust and water runoff is to be controlled. Hazard warning notices must be placed at all exits and entrances to the work area, including the afterhours contact details. Emergency Response Plan must be established specific to the demolition and all workers inducted into it. Emergency exits are to be established. Fire protection means is to be available onsite. Confirm SWL of mechanical plant, position and access when lifting, including operator safe access/egress inside cordon. Mechanical plant operator’s competencies are to be verified prior to work starting. Mechanical plant and equipment risk assessments and prestart inspections are to be completed and recorded to ensure they are safe to operate. Noise, dust and vibration controls must be established and maintained. Toolbox talk all parties involved in the works as a prestart meeting to co-ordinate the demolition, and other tasks, communication means, and responsibilities. Daily inspection of the structural integrity of the demolition is to be conducted prior to work starting, and after any non-routine event that would affect the stability of the structure. Inspections are to be recorded and any new hazards identified controlled prior to work starting. Validity of the Demolition Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Demolition certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014 H Overhead Crane Corresponding Permit to Work No. Location: (Only to be completed by authorised persons) Lift Weight: Crane SWL: Lift Radius: Crane Certification No: Crane Model: Lift Supervisor: Crane Operator’s Name : Dogman/Rigger’s Name: SWL of crane attachments /slings: Equipment / signs / barricades / emergency devices used: Requirements for overhead crane works Yes No Is the excavation in a hazardous zone? If yes and Isolation Certificate and Hot Work Certificate are also required Is an internal /external Traffic Management Plan required? Is an oversized vehicle permit required for the crane to/from site to destination? If so has one been obtained? OPERATIONAL INFORMATION Note: all equipment and HSSE control measures are to be onsite and established prior to work starting. Instructions to the permit applicant: Check the ground stability for the combined crane and load weight, underground services impact, and include any hazard and risk control measure requirements in the works SWMS. Confirm crane SWL, position and access when lifting, including operator safe access to cab: e.g. on ramps/slopes and inside cordon, any impact on neighbouring structures/public areas. Check the crane lift and swing arc is outside overhead services permissible distances and other overhead hazards. The crane, slings, shackles and other lifting equipment must have their SWL identified. All lifting equipment must have a tag of the current date of last load test carried out by a competent person Check weather conditions are suitable for the entire works completion. Work is not to proceed in excessive winds, lightning strikes, poor visibility, or other event that may endanger the stability of the crane. The Work at Heights Policy is to be complied with. Fall Protection is required over 1.8 metres which includes all works involving slings and rigging. When the crane is unattended the operator must ensure that no load is suspended, the crane is shut down and locked. Establish Emergency Response Plan requirements for the whole works e.g. falls, crushing, structure collapse, subsidence, suspended load falls, vehicle/pedestrian collision, among others. Establish a lift plan (if over 70% of lift capacity) and attach to permit. Communications between the Crane Driver and the Dogman is to be via a dedicated frequency via 2 way radios. The radios are to be checked prior to use. Toolbox talk all parties involved in the works as a prestart meeting to co-ordinate crane operation, with other teams/personnel involved in the works, including communication means, and responsibilities. Crane operator’s competency is to be verified prior to work starting. The Crane, attachments and lifting equipment are to have plant and equipment risk assessment and prestart inspections completed and recorded to ensure they are safe to operate. Check complete setup of crane and attachments for safe lift prior to lift. Ensure tie lines on the load are secure and workers are clear of suspended load falls. Ensure workers are clear of overhead loads, swing arcs and fall risks prior to and during the lift. Install and maintain a 2m clear cordoned area around the lift area. Last updated13 May 2014 I’ve checked the site / studied the layout drawings and certify that the crane lift proposed under Permit to Work number dated can be carried out: c) * Without risk of damage to any structure d) * Provided that the following additional controls are taken to prevent damages to the equipment/services specified below: Situation Sketch / Indication of Hazards: Validity of the Overhead Crane Permit Permit Issuer: Permit Issuer: Permit Holder I certify that I have reviewed the proposed work and I am satisfied that it is adequately described on the Permit to Work documents and that the controls detailed in this certificate are adequate and clearly defined. The Permit to Work is allowed between: Overhead Crane certificate and Permit to Work are withdrawn I certify that I am aware of the planned work and the controls detailed on the Permit documents and will ensure that work only proceeds when the conditions set out in the documentation are met. From: Date/Time: Name: Until: Reason: Signature: Name: Signature: Signature: Date/Time: Date: Date: Last updated13 May 2014