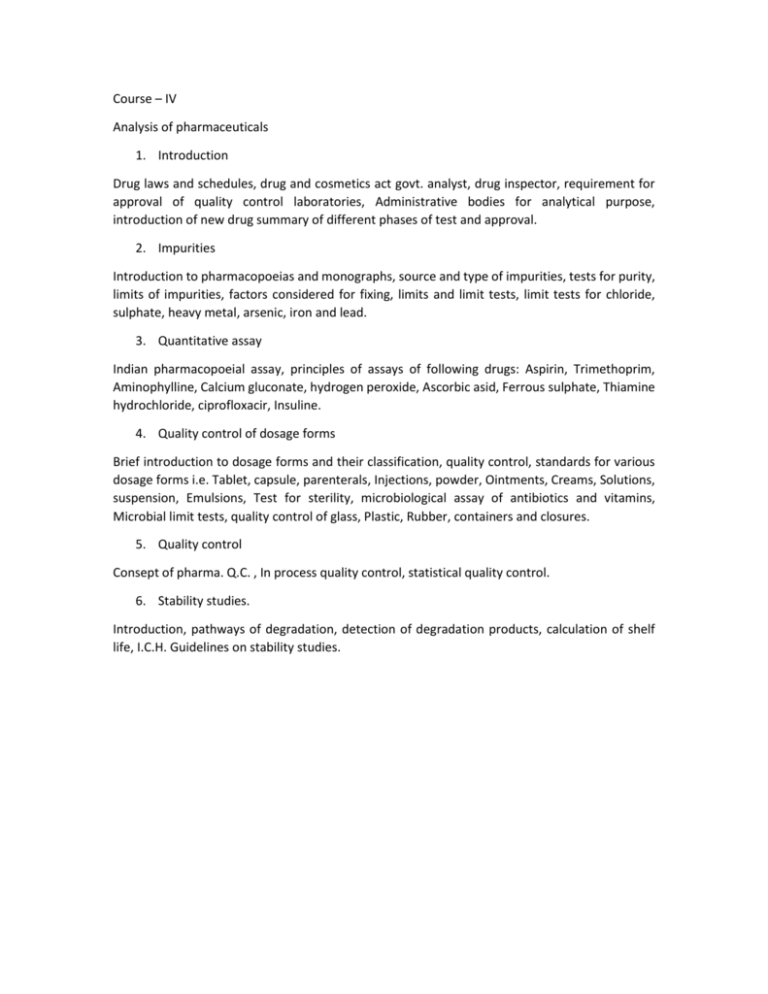

Course – IV Analysis of pharmaceuticals Introduction Drug laws and

advertisement