ЗАО «ИнТа

advertisement

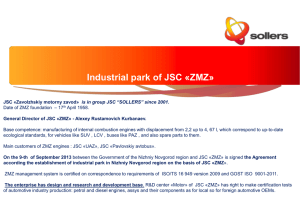

Company profile Head Office 150049, Russia, Yaroslavl, Magistralnaya st. 20a Phone: +7 (4852) 48-64-19 Fax: +7 (4852) 48-64-20 Established in 1991 Production Site 1 Production Site 2 (New) Russia, Yaroslavl, Magistralnaya st. 20a (1 500 sq. meters) Russia, Yaroslavl Municipal District, Ivnyaki Village, Nechernozemye 6 (2 500 sq. meters) Employees 70 General director REBROV Evgeniy, MBA Activity R&D, Production of fuel supply equipment (pumps, nozzles, valves) for various types of vehicle heaters, brake booster vacuum pumps, pumps and nozzels for DPF regeneration and SCR system Turnover in 2013 5 000 000 USD Products Products Products ZMZ-514 Diesel Engine Major Manufacturing Equipment: Poly GIM Swiss-type CNC Lathe / 4 machines / Production Site Max turning diameter Ø 26 (32) mm Leadwell 4-Axis CNC Vertical Machining Center / 8 machines / Table size 890x500 mm, Max workpiece mass 300 kg, Tool storage capacity 24 pcs Grinding Machines: Flat Surface Grinder / 3 machines / Rotary Surface Grinder / 1 machine / Cylindrical Grinder / 2 machines / Internal Cylindrical Grinder / 1 machine / Centerless External Grinder / 1 machine / MIKRON Haesler SA Rotary transfer Machine / 4 machines / Various types of Customized Machine Tools (Vetterly Engineering AG) for nozzles manufacturing Flat Surface Lapping Machine / 1 machine / Production Site New Production Site Input electrical power - 800 kVA Gas boiler house - 780 kW Utility lines – ready to use Total Area – 2567 m2 Height – 8 m Distance to M8 Federal road – 2 km R&D INTA-Center Research and Development is: - Process Approach to Management - Factual Approach to Decision Making - Over 40 years experience of design and development automotive parts and production processes - Over 10 years experience of APQP project management - Over 5 years of ISO/TS Core Tools usage - 10 issued patents - Robust product and process designs Quality Management Quality Management - Our QM System has certified according to ISO 9001 since 2003 - 8 years ago we have started ISO/TS 16949 implementation - 2008 FIAT has evaluated INTA-Center QMS by auditing and recognized as FPT potential supplier - 2012 INTA-Center QMS has been prepared to ISO/TS Certification - 2013 Ford-Sollers has recognized INTA-Center as potential supplier Our team attains high-quality level (0..50 ppm) by involving each employee into Continual Improvement Process Evgeniy REBROV Our Team General Director, MBA Education: Yaroslavl Polytechnic Institute / 1982 / Diploma in Engineering Deutsches Institut für Betriebswirtschaft GmbH /1992/ The Open University (United Kingdom) / 1996 / Professional Diploma in Management Lucas Automotive GmbH / 1998 / Management trainee job The Grenoble Graduate School of Business / 2004 / MBA in Technology Management Professional Experience: JSC "INTA-Center" / 2010-present / General Director JV "Sollers" and "Fiat Powertrain Technologies" / 2007-2010 / Director of the Project on F1A Diesel engine manufacturing plant establishing JSC "Zavolzhye Motor Plant" the member of "Sollers" Group / 2004-2007 / Executive Director JSC "Yaroslavl Fuel Equipment Plant" / 1997-2004 / Technical Director. Board of Directors Member JSC "RusPromAuto" / 2003 / The Head of "Heavy Duty Trucks" Business Restructuring (JSC “AZ Ural”) JSC “Yaroslavl Fuel Equipment Plant” / 1982-1997 / Designer, test-engineer, chief of the projects, chief of bureau… Our Team Maya KOMISSAROVA Alexey KLIMENKO Andrey SHADRUNOV Tatyana SMIRNOVA Deputy General Director Finance Manager Head of Production Department Head of R&D Department Senior Accountant Olga KARASEVA Dmitry SMIRNOV Timofey PELEVIN Senior Economist Head of Sales and Purchasing Department Head of Quality Assurance Department Customer Focus INTA-Center meets all customer requirements, keeping to terms of a Contract INTA-Center offers an acceptable price, because of good cost management (Lean process improvement and KAIZEN) JUST-IN-TIME is our Purchasing, Production and Supplying processes Philosophy. We are doing Risks assessment to guarantee meeting delivery schedule: - We have a Contingency plan; - We can provide reserve stocks; - We can deliver goods by various ways: corporate vehicle, cargo company, railway service - We have well-developed traffic networks, the distance to Moscow is 280 km We are ready to invest in new automotive parts production plant, which would be able to satisfy any Automotive Manufacturer Thank you!