Presentatie Japan finaal - Third UN World Conference on Disaster

advertisement

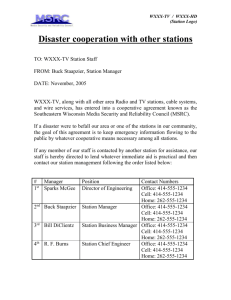

Triple Helix Disaster Approach building cooperation between government, companies and knowledge institutes within the Netherlands Marcel Michon Managing Partner Buck Consultants International marcel.michon@bciglobal.com 0031 (6) 53647131 1 Introduction 2 Project Approach 3 Project Partners 4 Results Summary A new approach concerning the readiness of natural disasters has been developed: Specific with regard to cross country supply chains (food) It brought partners together that weren’t aware of each others competences It combined preparation activities with execution Buck Consultants International, 2015 1 1 Introduction Famous system of Dyke-rings within the Netherlands A system of dykes and dams must be able to withstand a treat of an overflow of water Without this system half of the country would end up under water in case of a flood. Buck Consultants International, 2015 2 Imagine a Flood after a dyke breakthrough in the heart of the Netherlands t = +6h t = +12h But: Imagine a flood after dyke breakthrough in the heart of the Netherlands t = +48h t = +24h t = +4d t = +2w Buck Consultants International, 2015 3 Challenges which we are facing with in such a situation: Too much focus on ‘the first 48 hours’ Too little attention for public-private partnerships Underestimating cascading effects: mutual dependencies rise and vulnerabilities follow, we don’t have sufficient figures Worldwide supply chains are not taken into account in disaster management The Dutch Ministry of Economic Affairs is responsible for policy concerning scarcity at the system level and has initiated a project to address these issues Pilot: food distribution in case of a flood Buck Consultants International, 2015 4 2 Project Approach What is needed: Creating an operational framework How can partners in the triple helix help each other? Gain insight in to cascading effects Gain insight in to situational awareness Conditions: Compatible with international standards and useable in case of international aid such as Red Cross, UNOCHA and EU civil protection mechanism Scalable from a local into an international level Making use of available experience and know-how from governments, institutions and companies Comprising different levels of ‘readiness’ Buck Consultants International, 2015 5 Preparation levels (readiness) Readiness can be raised to several levels. The desired level is dependent on (perceived) risks and costs Omvang cluster Doorstart Intended level Current level in the Netherlands Neergang Limited subject knowledge Previous measures have either become obsolete or are forgotten A new reality demands new considerations Businesses are at the centre of current policy The government is a facilitator and initiator, without getting in the way 5 4 1 3 2 Standard Operating Consolidatiefase Procedures Clearly defined Groeifase Protocols Prepared Ontwikkelfase improvisation Awareness Startfase Unprepared Kiemfase Buck Consultants International, 2015 Fase 6 3 Project Partners Core partners Ministry of Economic Affairs Legislative. Roles: Initiation, coordination Ministry of Defense Participating as part of increased civil-military cooperation Roles: disaster and calamity expertise, scenario and exercise expertise, military equipment Connekt Independent network of companies and authorities. Links up parties to improve mobility in the Netherlands in a sustainable manner Roles: Project management, transport & logistics expertise Buck Consultants International Roles: Logistics expertise, supply chain expertise, economic policy expertise, project management Buck Consultants International, 2015 7 Companies (examples) Food industry Logistics Buck Consultants International, 2015 Retail Food sector representatives 8 Institutional partners TNO: TNO is an independent research organization that employs some 3,000 specialists. TNO focusses on transitions or changes in five social themes: Industry; Healthy Living; Defence, Safety & Security; Urbanisation and Energy. IFV: Institute for Physical Safety NGOs Dutch Red Cross Other governmental organizations Several “Safety Regions”: partnerships of multiple Dutch municipalities with joined police, fire brigade, ambulance and other public services Buck Consultants International, 2015 9 4 Project results Data Gathering phase Triple Helix building phase Testing phase Q2 2014 Q3 & Q4 2014 Q1 & Q2 2015 Buck Consultants International, 2015 10 Data Gathering Phase The preliminary phase called for insight into the analytical expertise in the Netherlands at: Universities and other knowledge institutions Logistics companies Retail companies Food industry The goal was to get a clear picture of the current capacity and network of the food value chain in the Netherlands Were are stockpiles kept? How long will these last? At any time, what part of stockpiles is on the road being delivered? What is the deployability of different types of goods? Fragmentation of supplies, number of stockpilers, Dutch or foreign owned? Can we build this picture for every region in our world? The next slides show some exercises we did Buck Consultants International, 2015 11 Distribution centres Top 10 Food Retailers Buck Consultants International, 2015 12 Production sites Top 30 Food manufacturers Buck Consultants International, 2015 13 Warehouses Top 50 Food wholesalers No Company name 31Zegro-Centrum Rotterdam B.V. 32Sourcing Unit Nassaukade 33Nutricia Nederland B.V. Nestlé Waters Direct 34 Netherlands B.V. 35Nature's Pride B.V. 36W. Heemskerk B.V. 37Vergeer Holland 38Haluco B.V. 39Boering Melkblok 40F. Wellink Lekkerkerk B.V. 41Vepo Cheese N.V. 42UNIVEG trade BENELUX B.V. 43Lunenburg Vlees B.V. 44A ware Lopik 45A-Ware Packaging 46Agrico 47Qizini Losser B.V. 48J.M. Levarht & Zonen B.V. 49Hilton Meats Zaandam B.V. 50Deen Distributie B.V. 51Klaas Puul B.V. 52Jos Slippens Vleeswaren 53Mead Johnson B.V. Buck Consultants International, 2015 Location ROTTERDAM ROTTERDAM ZOETERMEER ZOETERMEER MAASDIJK RIJNSBURG REEUWIJK BLEISWIJK VLEUTEN LEKKERKERK BODEGRAVEN WADDINXVEEN OUDEWATER LOPIK ZEEWOLDE EMMELOORD LOSSER DE KWAKEL ZAANDAM HOORN NH VOLENDAM OPMEER NIJMEGEN 14 Warehouses top 50 Food wholesalers Buck Consultants International, 2015 15 Triple Helix building phase The goal of this phase was to contact, mobilize and organize the partners needed to address the issues in a public-private partnership. Intended partners would have to be drawn from : Logistics companies Retail companies Food industry NGOs Local governments Knowledge institutions Buck Consultants International, 2015 16 Results so far: Awareness and a sense of urgency regarding the operation of the food supply chain in case of a disaster A strong community with representatives from key players and from every part of the triple helix (more than 20 parties) A useable framework to be internalized by all partners The problem solving capacity of companies is superior to that of the government. Tap in to that capacity and organize it to maximize impact outside the companies themselves All parties involved have the same motives following disasters: rebuilding Buck Consultants International, 2015 17 Testing phase The third phase of the project aims to bundle all the insights and contacts and let the partners participate in an exercise. In co operation with the ministry of Defense and other experts on disaster exercises, a scenario was being developed The goal of the exercise is: Strengthen the community and establish formalized contacts between companies, governments and NGOs Determine the position of actors in the food supply chain during a disaster in relation to traditional actors Evaluate actions, solutions and communication during the exercise Draw conclusions and recommendations from the exercise and shape these into a framework useable by all parties in the triple helix Buck Consultants International, 2015 18 Effects food supply chain Distribution centres Approx. 5 out of 60 distribution centres of the Top 10 supermarkets out of order (9%) Production sites Approx. 1 out of 34 production sites of the Top 30 food manufacturers out of order (3%) Warehouses Approx. 10 out of 50 warehouses out of the Top 50 wholesalers out of order (20%) Buck Consultants International, 2015 19 Recommendations Explore other supply chains (for instance medical supplies) A lessons learned approach with other regions all over the world Build systematic but feasible exercises of all partners involved Buck Consultants International, 2015 20