Safety Stocks

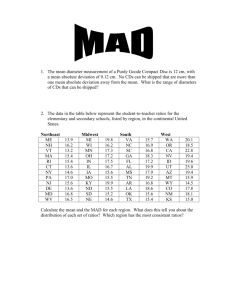

advertisement

Stock is held either because it is convenient to buy in bulk, or because the item is required faster than the supply can provide it. The Amount of Safety stock held in an organization depends upon three main factors: • the variability of demand •the reliability of supply • the dependability of transport The general approach to this situation is to set stock levels to cover the normal variability of demand and to adjust the other two variables so that they are relatively insignificant. Quality initiatives have improved the supply situation but it is usually found that the major uncertainly is caused by customers and their unpredictable requirements. Store records show the movement of stock in and out of the warehouse and such historical information is essential for evaluating what level of stock to hold. Individual stock movements logged on the stock records to be analyzed into movements per time period, normally weekly, so that weekly usage statistics are produced for each stock item. The normal amount of stockholding can be determined by statistical methods which rely on history to predict the future, and assume no change in circumstances during periods ahead. Safety stock is primarily to cover random variations in demand, but it can also cover many other situations such as: •Supply failure •Production shortfall •Transport failure •slow, unreliable or inaccurate information •and any other source of disruption of service Risk measurement The reason for having to use SDs and MADs is that they are the only sensible ways to work out stock levels. Additional Safety stock Safety stock is normally calculated on the basis of unknown demand. The quality of supply from the manufacturers may also prompt an increase in safety stock, either because the lead time for an item may vary between placing one order and the next, necessitating extra stockholding, or because the supplier’s delivery performance against the lead time is unreliable and delivery is more often late than early. Stock availability The need to cover for changeability of demand is a central task of inventory control. Unexpected demand requires a level of safety stock to cover for it. In fact using the normal distribution, the unexpected demand can be anticipated, or at least taken into account. Standard deviation -is theoretically the correct measurement. Standard deviation should be built into computer systems. The basic premise for safety stock is that the differences between the forecast and the actual demand are random. SD= √[(1/N) x exi²] Mean absolute deviation The MAD is a simple assessment of the variability of demand pattern. MAD is the basis from which stock is calculated. MAD = Sum of absolute deviations from mean Number of periods included in the sum Slow-moving items For a large number of stock items the usage rate is low. This includes obsolescent items, non-standard lines and spares. For these the ‘normal’ distribution is squashed against zero usage and is replaced by a skewed distribution. Demand for slow movers is a Poisson distribution. Standard Dev. = √Ave. demand Standard Dev. Of sales orders = √Ave. # of sales orders Excess and obsolete items Obsolete should be that there is no use for the item. This information is normally only available when the customer changes to a direct and improved substitute. In many instances, goods are classed as obsolete as a result of a long period with no demand; so the practical definition is usually that an item is obsolete if it is has not moved for months.