Bio-Inspired wind energy harvester

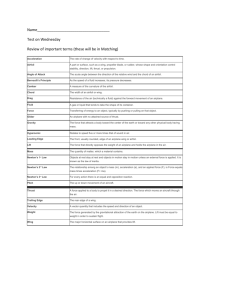

advertisement

Advisors: Dr. Manish Paliwal and Dr. Lisa Grega Kevin Hynes David Talarico • At the current time, we have used somewhere around half of the earth’s natural supply of fossil fuels • How will we continue to supply society with the energy it needs to function? 1 in 4 people in the world live without electricity This energy poverty is the biggest limitation to improving living conditions Need for a cheap open source design Blades spin a central shaft Shaft runs to a gearbox Gearbox steps up shaft speed to 60Hz in generator Use linear, oscillatory movement to improve wind energy capture technology in one or more of the following categories: Overall efficiency Energy produced per dollar input Energy produced per unit area of land used Design a system that exploits rather than mitigates vortex energy Make design as simple and modular as possible Lower shipping and maintenance costs Opening the door to ‘open source’ use Use vibrational modeling to widen range of resonant behavior Drucker E G , Lauder G V Integr. Comp. Biol. 2002;42:243-257 Forces exerted on cylinder only from vortex shedding Forces exerted on airfoil to due pressure differential (lift) as well as vortex formation and shedding ‘Synchronization’ of a vibrational system occurs where driving frequency approaches natural frequency Mass ratio defined as m* = mass of system/mass of displaced fluid Plot of oscillatory frequency vs. This occurs over a large range of flow speeds if the mass ratio is very low Low mass ratio allows the system to respond more quickly E. Swanton, B. Vanier, and K. Mohseni, Leading Edge Vortex Stability in a Flapping Model Hummingbird Wing, 38th Fluid Dynamics Conference and Exhibit, AIAA paper 2008-3718, Seattle, OR, June 23-26, 2008. ‘Delayed Stall’ Proves concept that a leading edge vortex (LEV) provides an additional lift force during the time that it remains in contact with the wing Kinsey and Dumas 2008 Pitching- rotational movement of wing Plungingtranslational movement of wing Coupling these two motions will allow the design of a system that can extract flow energy through lift and vortex formation Plunge Amplitude (Ho) Pitch Amplitude (θo) Effective angle of attack (α) Chord Length (c) Airfoil Thickness Pitching Center Frequency of Oscillation Flow Speed (U∞) Motion characteristics Vibration constants Reduced frequency = f* = fc/U∞ Thickness has a negligible effect on efficiency Our Design: More flexibility on selection of airfoil design Optimal pitching center location found to be 1/3 Efficiency increases with Reynolds number Our Design Re~30,000 Sine curve is position vs. time Slope is velocity Resultant of lift and drag resolved into X and Y components Power vs. Propulsion Effective angle of attack Y-component in phase with velocity Quasi-steady assumption Propulsion = High energy wake Power extraction = Low Energy wake Our Design: Must keep Y-component of force in phase with velocity “Energy Harvesting through Flow-Induced Oscillations of a Foil” A ‘Leading Edge Vortex’ (LEV) is formed at the leading edge of an airfoil that is about to undergo flow separation LEV energy can be recovered at the trailing edge – depends on LEV-foil interaction and timing This occurs over a large range of flow speeds at a low mass ratio Unsteady phenomenon Leading Edge Vortex Synchronization (LEVS) dependent on maximum pitching amplitude and reduced frequency Optimal pitching amplitude ~ 75° Optimal reduced frequency ~ 0.15 Our Design: Use as baseline What is the most efficient form of movement? - Power extraction dominated by vertical force in phase with vertical velocity - Square wave ensures that the movement of the wing spends the most time in the power stroke, highlighted below, where the Ycomponent of force and velocity are both at their maximum - ‘Power Strokes’ ended by rapid pitching of airfoil and change in vertical direction Sinusoidal vs. Non-Sinusoidal (Square Wave) Oscillation “Extracting Power from the Jet Stream: Pushing the Performance of Flapping Wing Technology” Platzer et. al. Mass ratio of wing must be very low Thickness has a negligible effect on efficiency Optimal pitching center location found to be 1/3 Efficiency increases with increasing Reynolds number Pitching amplitude and reduced frequency – extremely important parameters Strive for θ0 ≈ 75° and f*=0.15 for highest efficiency Optimal vertical motion of wing section is a square wave Exceptional complexity of the CFD modeling in this situation Beyond our scope of knowledge Use studies presented to create an adjustable experimental apparatus 1) 2) 3) For fully flow driven motion, three models were considered based off of relevant studies System whose pitching movement was allowed through a rotational spring System whose pitching movement was allowed to achieve a max value during ‘power stroke’ and used a mechanical lever arm to change angles of attack, and thus, direction System which utilized a mechanically prescribed motion While all three models have been confirmed to operate effectively with numerical simulations, the use of a mechanical lever arm was chosen on the basis of simplicity of design and higher efficiency Linear bearings needed to reduce friction and mechanical inefficiency Two wings attached to same track To apply as much force to the generator as possible, new system’s wing sections will stand vertically – weight will not counteract lift Use of one track cuts costs Use of two wing sections increases power, eliminates unwanted moments Lever arm responsible for pitch angle reversal by coming into contact with a stopper Mechanism by which ideal pitch reversal time will be approximated Design, Build, Test Small Scale Model Kinsey and Dumas 2008 θ≈73°, f*≈0.15, H/c≈1 Platzer et al. 2010 Lever Arm ΔTR = 0.3 28 Design Adjustability Power Transmission Wing Design Testing PIV Velocity Profile 29 The pitching amplitude will adjust by a series of holes on the bearing block Each pair of holes will allow for a different maximum pitch Pivot Bearing Holes Airfoil/ Lever Arm Block Pegs 30 Heaving amplitude - Adjusted by moving a pair of locking collars on track Fixed Supports Pivot Bearing Block Locking Collar Locking Collar Track Mechanical Stops Airfoil/ Lever Arm 31 Objective: Linear Movement Electrical Energy Power Transmission Linear Generator Pneumatic Piezoelectric DIY/Patents Extremely Inefficient Need Small Displacement Mechanical (Gear/Pulley) Many Options/High Efficiency 32 Method Linear Movement One-Way Rotation Flywheel Energy Storage Rotary Generator 33 Found that magnetic flux is directly related to rotor speed and efficiency Most PM Generators designed for use at a given rotor speed Use of a flywheel for constant speed “Dynamic modeling of transverse flux permanent magnet generator for wind turbines “ - Maurício B. C. SallesI; José R. CardosoI; Kay HameyerII 34 T Energy extracted flywheel = energy gained by airfoil + frictional losses each cycle θ0 𝐻 𝑇𝑑θ= 0 𝐿𝑑𝑦 0 θ0 T= Torque of generator θ0=angle passed through in one cycle L=lift force H=total linear distance traveled in one cycle 0.5*H 35 Very low mass Strong enough to withstand forces of lift and momentum change Durability – must withstand outdoor weather conditions Ease of manufacturing and assembly Inflatable Wing Styrofoam Composite Wing Sails Inflatable wing very light and cheap, but leaking may pose problems Composite wing is very strong and lightweight, but it is difficult to manufacture and repair ANSYS calculation for Styrofoam wing Stress levels too high at peak power output levels Styrofoam ruled out Sail is an attractive choice Cheapest option Most Durable Ease of manufacture, assembly and maintenance Reversible camber Lose some efficiency – lower CL Partially rigid ‘wingsail’ – best option Movement will be translated to generator by timing pulley-belt system First order vibration analysis of the system reveals its equation of motion, natural frequency and damping ratio PIV testing to be conducted on completed prototype Integration of the velocity fields around the airfoil can supply the vibrational model’s forcing function Algorithm inputs forcing function is used to optimize system Kutta-Joukowski theorem (ρ = free stream density, V = free stream velocity, and Γ = circulation) Definition of Cirulation (C is the curve enclosing the airfoil and Vcosθ is the velocity tangent to the curve) Optimize parameters in nonlinear system Need for algorithm that can input complex forcing function First order approximation Simple sinusoidal forcing function Amplitude determined from thin airfoil theory calculations MATLAB - Runge Kutta Approximation for vibrational analysis Used vibration hand calculations to supply governing equation