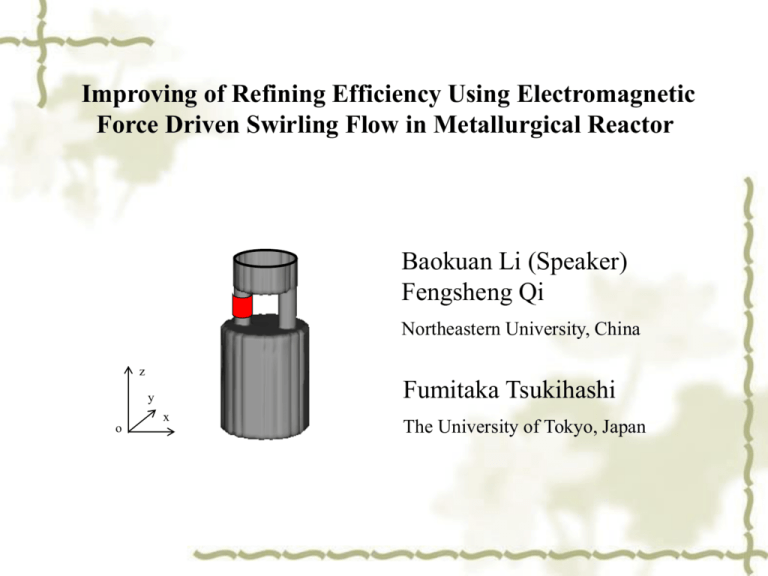

Improving of Refining Efficiency Using Electromagnetic

advertisement

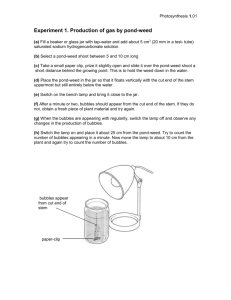

Improving of Refining Efficiency Using Electromagnetic Force Driven Swirling Flow in Metallurgical Reactor Baokuan Li (Speaker) Fengsheng Qi Northeastern University, China z Fumitaka Tsukihashi y x o The University of Tokyo, Japan Research background Vacuum Pump Inclusions are mainly removed by attachment of argon gas bubbles in molten steel. Argon gas bubbles Removal rate of inclusions depend on the number, size, shape, selfmotion and distribution of gas bubbles in melt. θ r Air A optimum behavior of argon gas bubbles for refining efficiency is very important. z Molten steel +inclusions y o x life of RH equipment is also affected by attachment and action of gas bubbles near wall. Innovative Steelmaking Application of Swirling Flow • Swirling flow is produced by the application of rotating magnetic field, and effect of swirling flow included: • Efficient mixing and • Efficient separation of inclusions by improving probability of attachment, collisions and coalescence with dispersed gas bubbles in Refining processes. Vacuum Pump Argon gas bubbles θ r Air z Molten steel + inclusions y o x Water model experiments examine the research ideas Manometer Impeller Gas distributor Rotameter Nozzle distribution RH degassing vessel Ultrasonic flowmeter (a) (b) (c) (d) Effect of impeller input power on gas bubbles distribution, shutter speed is 1/125 second. Q=0.25 m3/h. (a) 0, (b) 20 W, (c) 25 W and (d) 35 W 9 8 7 6 Circulation flow rate, 10-5 m3/s 10 6.944×10-5m3/s 11.111×10-5m3/s 16.667×10-5m3/s 40 35 30 25 20 15 10 5 0 Input power, W Effect of plane blade impeller on circulation flow rate of RH vessel 2w Swirl number 3u u Q downleg A upleg W nD (Yokoya et al ) Nozzle diameter is 2 mm, gas flow rate is 0.25 m3/h, strobe light speed is 1/2000s. swirl number is 0, 0.23, 0.53, 0.68, respectively. Averaged gas bubble diameter at outlet of nozzle, mm Effect of swirl number on the gas bubble diameter at outlet of nozzle 6 5 4 3 2 Nozzle diameter is 2 mm Gas flow rate 0.25 l/h 1 0 0 0.1 0.2 0.3 0.4 Swirl number 0.5 0.6 0.7 Mathematical model Vacuum Pump Argon gas bubbles • A homogeneous model for the twophase turbulent flow in the RH vessel with the rotating magnetic field in the up-leg. θ r • The momentum equation for gas phase is ignored. Air • The previous model is only valid for bottom blown reactors. z Molten steel + inclusions y o x Formulation ( V ) 0 2 V ( V ) e V p F g Spitzer et al. [1] v 1 Fr B02 ( ) 2 2 m r 3 8 r v 1 F B02 ( )r 2 r Fx Fr cos F sin F y Fr sin F cos k turbulence model = g (1 ) Liq (u u in u slip ) (v v in v slip ) ( w wslip ) ( e ) ( e ) ( e ) x y z x x y y z z Penetrating velocity and slip velocity Horizontal penetrating velocity: uin v in Up-leg 1 2 y nA Qg : total argon gas flow rate, n :nozzle number A : cross nozzle inlet area Nozzle z Qg Gas jet zone α : gas volume fraction (at inlet α0) x Centripetal force and horizontal slip velocity caused by rotating magnetic field Fr r ( L g ) 2 R 2 2 r Vr 2( L g ) 9 u slip Vr cos , v slip Vr sin Vertical slip velocity wslip exp( a0 ) exp( a1 ln d g ) exp[ a2 (ln d g )2 ] Boundary conditions and solution method Blackage technique Flow field 1, for fluid 1, for fluid Volume factor f V , Area factor f A 0, for solid 0, for solid 0 n Near wall: The wall law function is used to calculate e , k , and Free surface and symmetrical sections:Vin 0, Gas volume fraction Inlet: in is calculated by Thermodynamic equation of gas Other sections: 0 n Self-developed computer code in Fortran language Vacuum Pump θ r Air z water y o x B0 = 0.1 mT Frequency = 50 Hz B0 = 0.1 mT Frequency = 50 Hz (d) (c) (b) (a) (a) (b) (c) (d) Calculated flow velocities at horizontal sections of RH degassing vessels, (a) up-leg, (b) bottom of vacuum chamber, (c) middle of vacuum chamber, and (d) surface of vacuum chamber. B0 = 0.1 mT Frequency = 50 Hz 0.7 0.7 0.6 0.6 0.6 0.5 0.5 0.5 0.4 0.4 0.4 0.3 0.3 0.3 0.2 0.2 0.2 0.1 0.1 0.1 0 0 0 0.1 0.2 0.3 (a) 0.4 0.5 0 0 0.1 0.2 0.3 0.4 0.5 (b) Computed gas volume fraction at main sections of RH degassing vessels, (a) no swirling flow (b) with swirling flow. 0.8 0.5 Vertical velocity, m/s Gas volume fraction 0.7 0.4 0.3 0.2 0.1 No swirling flow With swirling flow -0.04 0 0.6 0.5 0.4 0.3 No swirling flow With swirling flow 0.2 0.1 0.04 -0.04 Diameter of up-leg, m Gas volume distribution of RH degassing vessel 0 0.04 Diameter of up-leg, m Velocity distribution of RH degassing vessel CONCLUSIONS Water model experiments showed that the gas bubbles may be moved toward the central zone in up-leg in RH vessel under the swirling flow. the size of gas bubbles produced from nozzle become small and number of gas bubbles increases. the gas bubbles are dispersed in the whole up-leg. Residence time and journey of gas bubbles in up-leg is prolonged. The numerical results showed that a swirling flow may be produced and extended into the vacuum chamber in case that rotating magnetic field is applied in up-leg. The maximum of gas volume fraction moves toward the center zone of the upleg. The upward velocity distribution in up-leg changes from M type to parabolic type. The future works --- application of swirling flow Vacuum Pump Argon gas bubbles θ Control of size, shape and distribution of argon gas bubbles r Change of collisions, coalescence and attachment of the inclusions Air z Molten steel + inclusions y o x