Figure 1. Gartner Supply Chain Masters for 2015

advertisement

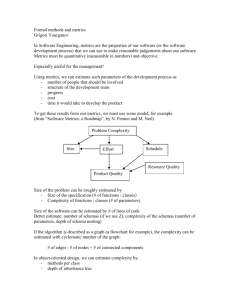

Summary This research unveils the 11th annual global Supply Chain Top 25, identifying global supply chain leaders and highlighting their best practices for heads of supply chain and strategy organizations. Overview Key Findings Three key trends emerged among the leaders: bimodal supply chain strategies, increased customer intimacy and emerging digital business models. The top five include three from last year — Amazon, McDonald's and Unilever — one returning leader, Intel, and a newcomer to this elite group, Inditex. Apple and P&G are the two inaugural companies joining a new Masters category recognizing sustained leadership over the last 10 years. Three companies rejoined the list this year after a lengthy hiatus: L'Oréal, Toyota and Home Depot. Recommendations Tailor your supply chain capabilities and align them to support both growth and cost efficiency where they are needed most by the business. Make customer experience a first-tier metric in your supply chain organization. Explore and adopt digital business capabilities in the areas best suited to your industry, business model and supply chain maturity level. Table of Contents Analysis o The Notable Trends o Bimodal Supply Chain Strategies Increased Customer Intimacy Emerging Digital Business Models Inside the Numbers o Introducing the Supply Chain "Masters" The Top Five Movers and Shakers: No. 6 Through No. 15 Rounding Out the List: No. 16 Through No. 25 Honorable Mentions What Is Demand-Driven Excellence? o Operational Excellence and Innovation Excellence o Measuring Demand-Driven Excellence o The Metrics We Wish We Had Supply Chain Top 25 Methodology Financial Component o Opinion Component Polling Procedure Composite Score New "Social Vote" Pilot Looking Ahead Gartner Recommended Reading Tables Table 1. The Gartner Supply Chain Top 25 for 2015 Table 2. Metrics for Operational Excellence and Innovation Excellence Table 3. Industries Not Included in the Supply Chain Top 25 Figures Figure 1. Gartner Supply Chain Masters for 2015 Figure 2. The DDVN Maturity Journey Figure 3. The Hierarchy of Supply Chain Metrics: Operational Excellence Figure 4. The Hierarchy of Product Metrics: Innovation Excellence Figure 5. 2015 Peer Opinion Panel Composition: Region Figure 6. 2015 Peer Opinion Panel Composition: Industry Figure 7. 2015 Peer Opinion Panel Composition: Role Figure 8. 2015 Peer Opinion Panel Composition: Revenue Analysis In our 11th edition of the Supply Chain Top 25, we have several longtime leaders with new lessons to share and a number of more recent entrants from the high-tech, consumer products (CP), retail and industrial sectors. A key aspect of the Supply Chain Top 25 ranking is the demonstration of demand-driven leadership. We've been researching and writing about demand-driven practices since 2003, highlighting the journey companies are taking — from inward-focused supply management functions to supply chains that orchestrate a profitable response to demand. One of our goals is to foster the celebration and sharing of best practices as a way to raise the bar of performance for everyone. Another objective of the Supply Chain Top 25 is to shine a light on the importance of the function and profession — within our community certainly, but also for corporate executives outside of supply chain and the investment community, at large. Last year, the CEO's mantra was the need to accelerate growth, and supply chain did its part to contribute. In the face of an uneven global economy, the approximately 300 large corporations we track in our survey managed to boost average annual revenue growth from 3.1% to 4.7%. This came despite slowing emerging markets and significant currency fluctuations. No one predicted the crash in oil prices over the second half of 2014, though most in supply chain reaped the benefits of lower fuel and input costs. Generally, we heard less about supplier risk management in the past year. Our hypothesis is that companies have either attacked their major risks with enhanced upstream visibility and flexible capacity or have struggled with a lack of management support to mitigate them. Of course, there will always be a crisis unfolding somewhere each year and one that did so in slow motion was the U.S. West Coast port closures that peaked earlier in 2015. The Notable Trends Each year, our analysts research the supply chains of hundreds of companies. Through this work, we note the trends: What are the leaders focusing on, where are they investing time and effort and what can be applied broadly? Three key trends stand out this year for these leaders that are accelerating their capabilities and further separating them from the rest of the pack. Bimodal Supply Chain Strategies Chief supply chain officers (CSCOs) and their teams face an environment where business models must change quickly, where the expectation is that they will spend as much or more time growing and innovating as they will streamlining and promoting efficiency. Gartner has termed this reality "bimodal." Traditionally, supply chain executives have been successful because they were good at driving down costs. The leaders now realize they will be judged on cost containment as well as the ability to promote and support the top line. In parts of the business with innovative products and solutions, these leaders help promote organic growth through timely supplier enablement, co-innovation and active participation in the phase gate release process to enable smooth new product launches. When growth comes from selling in new geographic markets, supply chain is a full partner with marketing, sales, finance and R&D, and plans for the required enablers well in advance. This often takes the form of local sourcing, manufacturing, order management and logistics capabilities. Moreover, leading supply chains have already developed deep partnerships with IT and HR to jointly deliver the systems and talent needed to implement these capabilities. Another pillar of growth that we've seen accelerate across most industries is the effective integration of mergers and acquisitions (M&As). The more mature supply chain organizations that we speak with have dedicated teams and established playbooks for assessing the current and required capabilities of new businesses and determining the best transition roadmap. The other mode for these leading supply chain teams is the continued pursuit of improvement and efficiency in mature and declining businesses. High-performance work systems are used to identify and pare out non-value-added complexity in product portfolios and operational processes to remove waste and improve profitability. Many of the companies at the top of the Supply Chain Top 25 are running integrated supply chains that can drive the appropriate trade-offs across individual functions for lowest end-to-end supply chain cost. They have also matured relationships with commercial and engineering teams in the business to drive standardization and reuse at the beginning of the product life cycle, and financial-based methods to evaluate which products need remediation or removal from the portfolio later in the cycle. Some leaders have strategies tailored to different business units, while others differentiate by major geography or individual markets. The common thread across them is a clear and cascading link between corporate and supply chain strategies, performance metric targets, business processes, technology and talent. Increased Customer Intimacy Another trend is a focus on customer experience as a measured priority in supply chain organizations. Some of the leading companies are tracking customer satisfaction measures, such as Net Promoter Score (NPS), as a first-tier metric for their organizations. Independent of the product being sold, leaders are focused on listening more closely to their customers and responding with innovative solutions. We see this happening not only in the CP/retail space, as expected, but also across the industrial manufacturing sectors. Global digital commerce now stands at north of one-trillion dollars, and push-of-a-button-type convenience has become an expectation, whether delivery is taken at home or at a physical store. Many of the more mature CP companies have regionalized customer service organizations to standardize and raise the overall quality of their interactions with customers. They have also built multilocal supply networks that enable agile responses to demand by staging capacity local to each region. This year, we heard from more companies extending visibility and insight beyond first-line customers and moving on to the end users of their products. Their supply chains are not just collecting data concerning the details of the sale, but also the patterns of usage and resulting sentiment of the end user. Consider that several leading PC and mobile device manufacturers are starting to think about product quality from both the perspective of performance-tospecification and performance-to-expectations. For instance, if a consumer is used to looking at high resolution screens on their smartphone and media tablet, they might think that the screen on their computer is functioning poorly if the clarity and brightness of the images are lower by comparison, despite performing to specifications. Mining of online sentiment data allows for these types of connections to be drawn and fed back to design teams for future product releases. Remote equipment monitoring is another popular mechanism for gathering end-user insights and for assisting with preventative maintenance. We see applications of this capability increasing at leading industrial machinery companies and high tech manufacturers, as well as in the consumer world of health monitoring products, home office equipment and others. Ultimately, delighting customers with strong operational supply chain performance, when combined with improved solution performance, will lead to measurable improvements in customer satisfaction and contributions to the top line. This is yet another way that leading supply chain organizations are becoming partners in growth with the business. Emerging Digital Business Models While still a nascent concept, the view on how supply chain can leverage digital capabilities to support new business models and improve broader value chain performance became clearer this year. Manufacturing is the center of many digital capabilities, including predictive quality, energy management and smart automation, all leveraging sensors and advanced analytics. Moreover, leading companies recognize that "the factory" is not just somewhere inside the four walls of the company or an outsource partner. Digital synchronization of manufacturing lines with upstream suppliers and other supply chain functions is where the business value starts to multiply. The automotive and chemical industries offer a leading vision of where digital manufacturing can go next in terms of these capabilities. The logistics function is not far behind manufacturing in terms of automation using sensors, gateways, tracking systems and business rules to predict and alert when there will be a variance to the current plan of record. For example, the rapid emergence of online ordering has forced retailers into the digital world of multichannel order management and fulfillment that requires increased visibility. Logistics control tower capabilities are not new, but when combined with more affordable sensors and computing power, they portend the democratization of deeper visibility that can reduce risk and improve both operating costs and customer-service levels for many companies. The use of big data and advanced analytics to improve demand visibility is somewhat commonplace among the top consumer-facing supply chains, though some are taking it to a higher level. Some smartphone manufacturers are replenishing supply and offering additional services based on device activations. A handful of consumer goods companies are using hourly SKU-shelf-level visibility to surgically manage supply during critical promotional and seasonal events. 3D printing is yet another digital-based technology having transformative effects on select processes at leading companies. Many industrial and high-tech companies are leveraging it to manage their equipment spares. Consumer-facing companies are using 3D printing to quickly prototype and manufacture high-mix, low-volume packages and containers for their products. Human organs, food, building materials — the list of potential applications is long and, as the variety of "printable" materials increases, more industries will add this form of instant agility to their toolkit of supply chain capabilities. One final impact of these digital business models is that they create a new growth opportunity for the technology companies that sell the hardware, software and talent to support not only themselves, but the rest of the industry. Bimodal supply chain strategies, increased customer intimacy and emerging digital business models are this year's most common trends among supply chain leaders. Inside the Numbers Introducing the Supply Chain "Masters" This year we are introducing a new category to highlight the accomplishments and capabilities of long-term leaders. At the same time, we want to create room for growth and visibility of even more newcomers. We are, therefore, recognizing those companies that have consistently had top-five composite scores for at least seven out of the last 10 years and placing them into a "masters" category, separate from the overall Supply Chain Top 25 list. In this inaugural year for supply chain masters, we want to recognize two companies demonstrating sustained leadership: Apple and P&G (see Figure 1). Figure 1. Gartner Supply Chain Masters for 2015 SOURCE: GARTNER (MAY 2015) Like a bolt out of the blue, Apple appeared at No. 2 on the 2007 Supply Chain Top 25 ranking, having not passed our revenue threshold during the prior two years. From 2008 through 2014, Apple sat at the pinnacle of the ranking, pulling far ahead of the pack on every component score, including all financials and opinion polls. There were a few one-word reasons for this sudden and sustained dominance: iPhone, ecosystem and solutions. The fact that many of us now begin and end our days with smartphone in hand is directly related to the sheer amount of functions they offer, and Apple has been a crucial driver behind this phenomenon. While there were mobile devices that previously provided parts of the current solution, no company, up until that time, brought it all together with beautiful hardware, intuitive software, hundreds (if not thousands) of useful applications and entertaining content. Skeptics point to the fact that for the most part, Apple's products are mainly "designed in California" and "assembled in China," but the reality is that it takes skill and, in some cases, sheer will to orchestrate the design, development and high-volume launch of highly integrated products across a network of hardware, software, manufacturing and logistics suppliers. Apple has chosen to mostly insource areas that it deems strategic, such as specialty microprocessor and OS design, as well as retail and customer service operations. In more recent years, it has become more vertically integrated and acquired additional suppliers of specialized hardware components and software solutions to further its competitive advantage. The company has always recognized the value of the digital ecosystems it creates. This started with the iTunes and the App Store catalogs that kept consumer purchases within a walled garden. It continues with the more recent launch of its digital wallet service, Apple Pay. Tomes have been written on the good, bad and ugly aspects of the Apple story, but one thing is clear, a resurgent Apple has captured the imagination of the entertainment, communication and computing markets with the introduction of each of its devices or services. This high tech leader demonstrates the spirit of the Supply Chain Top 25 through the integration of innovation and operations excellence. In stark contrast to the relatively young Apple is CP juggernaut P&G, which was founded in 1837 as a soap and candle maker. The perennial supply chain and product leader has appeared on the top five of our ranking for nine out of the last 10 years. P&G has a long-standing history of innovative supply chain practices, starting with the Efficient Consumer Response (ECR) capability it built with Walmart in the early 1990s, which evolved into modern-day collaborative planning forecasting and replenishment (CPFR) capability. Today's P&G is redefining customer-centricity in how it measures service by adopting differentiated performance metrics representative of the top customers in the channels it serves. The company's global product supply officer has reported directly to the CEO for several years, and many in the C-suite have had past stints in product supply leadership. The company has also blended its supply chain and product R&D organizations for a seamless approach to new product development and launch (NPDL). In the last year, the CP leader announced a decision to shed more than half of its brand count to improve profitability and accelerate the turnover of its customers' shelves. The 60 to 70 brands that will remain represent more than 90% of today's profits, and P&G will focus on standard formulations with a small number of regional variations off of a common menu. The company's Integrated Work Systems approach in manufacturing leverages best-in-class quality and efficiency techniques and tools to deliver progressively improved capabilities that are eventually extended out to both customers and suppliers. P&G is also using big data analytics to remove waste from its distribution network. This work dovetails into its commitment to improve the environment in areas such as reduced emissions, energy and water usage, and shifting toward sustainable inputs for its products. Both Apple and P&G have made major contributions to the supply chain profession over the years. P&G was one of the first to characterize and embed the concept of a consumer-driven supply chain, and Apple, defining the very notion of a "solution" supply chain, blazed new trails with its demand creation capabilities. We're excited to introduce this new Masters category to the ranking, and will revisit it each year as companies enter and exit it. Along with the Masters category, the Supply Chain Top 25 continues to offer a platform for debate, insights, learning and contribution to the rising influence of supply chain practices on the global economy (see Table 1). Table 1. The Gartner Supply Chain Top 25 for 2015 Rank 1 Company Amazon Peer Opinion1 (200 voters) (25%) Gartner Opinion1 (35 voters) (25%) ThreeYear Weighted ROA 2 (25%) 3,394 468 0.0% Inventory Turns 3 (15%) ThreeYear Weighted Revenue Growth 4 (10%) Composite Score 5 8.7 21.7% 5.32 Table 1. The Gartner Supply Chain Top 25 for 2015 Inventory Turns 3 (15%) ThreeYear Weighted Revenue Growth 4 (10%) Composite Score 5 14.6% 157.3 -0.2% 5.23 619 11.3% 6.7 -0.2% 5.15 1,064 481 12.1% 5.0 2.4% 4.09 Inditex 1,003 297 17.0% 3.8 8.8% 4.04 6 Cisco Systems 1,147 500 8.4% 12.6 1.5% 4.01 7 H&M 809 89 26.6% 3.7 12.8% 4.01 8 Samsung Electronics 1,568 330 10.5% 17.7 0.5% 3.91 9 ColgatePalmolive 1,034 318 17.8% 5.0 0.6% 3.91 10 Nike 1,369 214 14.5% 4.1 10.7% 3.78 11 The Coca Cola Co. 1,938 287 8.9% 5.4 -1.0% 3.49 12 Starbucks 1,215 174 13.0% 6.8 11.6% 3.48 13 Walmart 1,794 259 8.4% 7.8 2.5% 3.39 14 3M 1,161 150 14.9% 4.2 2.7% 3.09 15 PepsiCo 890 330 8.9% 8.3 0.3% 3.04 16 Seagate Technology 176 114 19.9% 10.8 3.9% 2.99 Company Peer Opinion1 (200 voters) (25%) Gartner Opinion1 (35 voters) (25%) ThreeYear Weighted ROA 2 (25%) 2 McDonald's 1,626 283 3 Unilever 1,996 4 Intel 5 Rank Table 1. The Gartner Supply Chain Top 25 for 2015 Rank Company Peer Opinion1 (200 voters) (25%) Gartner Opinion1 (35 voters) (25%) ThreeYear Weighted ROA 2 (25%) Inventory Turns 3 (15%) ThreeYear Weighted Revenue Growth 4 (10%) Composite Score 5 17 Nestlé 1,123 244 9.9% 5.1 2.0% 2.93 18 Lenovo Group 771 218 3.9% 12.8 18.9% 2.89 19 Qualcomm 218 50 15.5% 8.8 17.8% 2.85 20 KimberlyClark 819 243 10.5% 5.9 0.8% 2.76 21 Johnson & Johnson 1,192 139 11.1% 2.8 4.6% 2.73 22 L'Oréal 749 118 12.5% 2.9 2.9% 2.41 23 Cummins 148 149 11.5% 5.2 4.7% 2.16 24 Toyota 1,322 23 3.6% 10.6 13.4% 2.16 25 Home Depot 268 44 14.1% 4.6 5.6% 2.11 Notes: 1. Gartner Opinion and Peer Opinion: Based on each panel's forced-rank ordering against the definition of "DDVN orchestrator" 2. ROA: ((2014 net income / 2014 total assets) * 50%) + ((2013 net income / 2013 total assets) * 30%) + ((2012 net income / 2012 total assets) * 20%) 3. Inventory Turns: 2014 cost of goods sold / 2014 quarterly average inventory 4. Revenue Growth: ((change in revenue 2014-2013) * 50%) + ((change in revenue 2013-2012) * 30%) + ((change in revenue 2012-2011) * 20%) 5. Composite Score: (Peer Opinion * 25%) + (Gartner Research Opinion * 25%) + (ROA * 25%) + (Inventory Turns * 15%) + (Revenue Growth * 10%) 2014 data used where available. Where unavailable, latest available full-year data used. All raw data normalized to a 10-point scale prior to composite calculation. "Ranks" for tied composite scores are determined using next decimal point comparison. SOURCE: GARTNER (MAY 2015) The Top Five Amazon claims the No. 1 spot on the ranking this year and makes its fifth appearance in the top five. As a serial innovator, it posted a three-year weighted average revenue growth rate of more than 20%. Conversely, its average return on assets (ROA) was 0% over the same time frame due to continued heavy investment in future products and capabilities. Amazon's track record for introducing widely-adopted new products and services has been impressive. On the product side of its business, Amazon Kindle Fire tablets continue to sell well and act as a platform for delivering content. Its phone launch did not go as well, though a future version might gain traction in the marketplace if consumers' value proposition shifts further toward content and away from hardware-based features. On the service side, Amazon's cloud services are the most successful in that market by an order of magnitude. The e-commerce giant has also demonstrated its ability to successfully launch new supply chain services, such as same-day delivery, now available in 54 U.S. metro areas. There was a lot of buzz last year when Amazon started testing drones for package delivery. One year later, it's looking like that will happen in Europe and some Asian countries with more accommodating regulatory environments than the U.S. In another out-of-the-box move, Amazon recently announced a pilot with German automaker Audi to deliver packages directly to the trunks of customer's automobiles, following a similar announcement with Volvo. Finally, last year, Amazon released a series of instant ordering devices under the brand Amazon Dash, which enable consumers to push a button on a small, product-branded fob when they need to reorder common household items like laundry detergent, instant coffee cups and diapers. Where will Amazon go next? Amazon opened up its first brick-and-mortar store this year on a college campus. Regardless of how that experiment goes, its competitors will be watching closely. McDonald's, No. 2 on the ranking, is facing significant headwinds this year — new competition from specialty restaurants, innovative products from existing players, changing consumer tastes and a tightening labor market with increasing wages. Internally, it has had some challenges managing a menu that has grown more diverse over the last few years. All of these factors led to its first negative three-year revenue growth measure since joining the ranking in 2010. The company recently installed a new CEO that is focused on returning the restaurant giant to growth, and supply chain is central to the success of this strategy. In March, McDonald's announced that over the next two years, its U.S.-based stores will only serve chicken raised without antibiotics. Given the volumes it buys, this will create a sea change in the poultry business. It is also exploring the removal of preservatives from its food, in line with trends in consumer preference for fresh foods. McDonald's is rolling out a custom ordering menu called, "Create Your Taste." This service will slow down order times, so at the same time, it is removing lower volume and velocity items from its menu, to balance the portfolio. With an understanding of the cost-to-serve items from its menu, the supply chain, in partnership with outsource partners, is positioned to help the company make data-driven decisions. Supply chain operations have deepened involvement in the product life cycle to drive profitability and can help the business strike the delicate balance between reigniting growth and stoking complexity that detracts from profitability. CP leader Unilever is No. 3 on the list. As part of the broader Sustainable Living Plan it launched in 2010 to double revenue and halve its environmental impact by 2020, the company recently announced that it had achieved its goal of sending zero waste from all factories to the landfill, a year ahead of schedule. A big part of the company's success comes from its partnership with suppliers. Borrowing a page from the automotive and A&D playbook, it is now forging multicompany relationships between suppliers to foster deeper collaborative innovation on ingredient design and manufacturing processes. Unilever is rolling out regional centers of excellence (COEs) for customer service and logistics. Pilot results are showing improved speed-to-response and more efficient teams as a result of the colocation of these functions. The more centralized structure has also improved end-to-end visibility through the adoption of logistics control towers and enabled network optimization across a broader scope. Unilever's supply chain is viewed as a partner in growth and one example of that comes through its low-cost business model, which is focused on smarter formulations and packaging, material specifications, sourcing, portfolio deployment and pricing, all in partnership with suppliers. With collaboration in its corporate DNA, Unilever's supply chain team has also embraced a broader role in spreading best practices across the entire community. Intel, at No. 4, is another company whose supply chain has risen quickly up our ranking over the years. Its supply chain vision includes delivering on five key vectors that drive Intel's competitive advantage in the marketplace: technology leadership, manufacturing scale, agility, responsiveness and social responsibility. Intel's supply chain has taken on an expanded partnership role as an enabler of growth in new product markets. In recent times, that has meant media tablets and solutions that leverage the "Internet of Things" (IoT). In 2014, Intel went from selling almost no media tablet chips to over 40 million of them. Beyond the ability to successfully supply and ramp new products, this is a story about building a new ecosystem of hardware and software suppliers and contract manufacturers to work with in China. Another business where Intel's supply chain is part of the go-to-market approach is the IoT, which includes market verticals around transportation, smart buildings and industrial manufacturing applications. The supply chain group has successfully piloted the use of this technology for inbound factory capital installation and capacity management, as well as for transportation security through the use of geofencing, tracking and connections into local law enforcement. Jumping six slots to No. 5 this year is Spanish clothing retailer, Inditex. The owner of eight brands, including flagship Zara, sports a 17.0% three-year weighted average ROA and leverages a common operational approach across its portfolio. It also continues to grow through new store openings and expanded e-commerce offerings in all existing and new markets. Inditex is rolling out a reusable item-level RFID tracking system for all garments sold in its Zara stores. This system allows for more efficient inventory counts, quick, precision stock replenishment, enhanced security control and, ultimately, better service for customers looking for specific products within physical stores and online. Its supply chain continues to prioritize social responsibility and was recently recognized by the Dutch Association of Investors for Sustainable Development. In its appraisal, the jury emphasized Inditex's work in ensuring living wages for the textile workers comprising its supply chain and gave it the highest score of any retailer. Movers and Shakers: No. 6 Through No. 15 This section of the ranking offers an impressive array of blue chips, with notable contributions to the discipline of supply chain management (SCM). Leading off this group and up one slot this year is Cisco at No. 6. The networking leader is well down the path of selling integrated solutions. Value engineering work with customers has brought the realization that hardware is the commodity and software is the key differentiator in a solution's ability to effectively move data and workloads around a network. Supply chain's role in software has evolved in line with this shift, and it has stepped up to manage hardware and software quality, as part of new product release process. Cisco's supply chain has also invested in improving customer intimacy. Each director and above is a customer champion aligned with specific end customers and sales teams. These leaders are analyzing feedback, and being personally connected and invested has changed how the supply chain organization responds to customer requests. Cisco is another technology company using IoT, or the "Internet of Everything" as it's branded it, to both improve its supply chain operations and support the company in bringing these solutions to market. H&M made another large jump this year to No. 7 on the ranking. Its financial performance is spectacular, with three-year weighted average ROA and revenue metrics at 26.6% and 12.8%, respectively. The Swedish retail chain expanded its e-commerce business this year and rolled into nine new markets, including China. H&M's supply chain is strong at managing the product life cycle with designers and suppliers. Its next challenge will be reinventing the ability to capture demand and fulfill across all channels, given the recent expansion into e-commerce. H&M has received multiple awards for sustainability and social responsibility. The company was recognized as the 2015 World's Most Ethical Company by the Ethisphere Institute, a global leader in defining and advancing the standards of ethical business practices. Samsung Electronics was ranked No. 8 this year. This perennial leader is well-respected in the peer community and continues to post strong inventory turns at 17.7, complemented by a threeyear weighted-average ROA above 10%. While growth has recently flattened, the hope is that products such as the new sixth-generation Galaxy smartphone can pull back share from Apple. Operational excellence at Samsung Electronics centers on two key factors driving flexibility and profitability. The first is visibility in end-to-end supply chain, which it defines as R&D, procurement, manufacturing, logistics, marketing, sales and service. The second is the capability of its people, organization, process and IT infrastructure. Recent focus areas in supply chain include Collaborative Planning, Forecasting and Replenishment (CPFR) with mobile suppliers, supporting expansion into new markets such as large-scale printers and medical devices for businesses and online sales for Chinese consumers. Other priorities include improving demand/supply planning for mature markets and channel partners and continuous improvement in customer logistics. Colgate-Palmolive retained its No. 9 rank. Its supply chain team is testing the use and integration of leading-edge systems, utilizing the latest in-memory computing technology. This will allow it to gain end-to-end visibility and to take real-time actions in the planning and execution horizons. The vision, for this well-respected CP company is to have transparent business information, collaboration tools, what-if simulations and real-time analytics utilized by the supply chain and cross-functional partners all sitting at the same table — true integrated business planning. Colgate continues to fund the company's growth through close management of all investments in capital and capabilities. This growth has tapered due to slowing emerging markets and a strong dollar, but Colgate-Palmolive's three-year weighted average ROA continues to be a bright spot at 17.8%. Up two slots to No. 10 is perennial footwear and apparel leader, Nike. Despite intense competition, the company continues to deliver consistently superior financial performance, with a three-year weighted-average ROA of 14.5% and growth rate of 10.7%. Nike's supply chain has strong foundational capabilities in product life cycle and supply network management and is expanding the use of Lean techniques from the manufacturing environment to other supply chain functions. On the innovation front, it has unveiled products using a new ColorDry technology that dyes fabric with recycled CO 2 and zero water versus traditional water-intensive dyeing methods. This technology also saves energy and eliminates the need for added chemicals in the fabric dyeing process. Nike is also actively building prototypes for football cleats using 3D printing technology and exploring 4D printing technology for materials that can adapt to different environments over time. At No. 11, The Coca Cola Co. is consistently well regarded by the supply chain community. It faced some pressure on growth this year, reflected by a three-year weighted average revenue trend that was negative for the first time since the inception of our ranking. The Coca Cola Co.'s supply chain is focused on a handful of key objectives this year. In the upstream supply network, it is about quality at the source, with leading metrics and process controls that support its safety culture. Within its manufacturing and distribution environments it is automation that will increase productivity faster than the top line. Customer-facing initiatives are aimed at improving on-time and in-full rates through improved forecast collaboration, value-based product and packaging portfolio management and tailoring customer service models so that there is a picture of success for each channel type. Finally, the beverage leader is focused on continuous capability improvement in its people through professional development courses and experiential learning. Starbucks jumped five slots to land at No. 12. The world's largest coffee retailer continued its strong performance heading into 2015 with both a three-year weighted average ROA and growth rate well above 10%. Starbucks runs a broad-spanning supply chain, which includes new product development, customer service and strategy. Talent development is a core focus within the organization, as reflected by its training and rotational programs. Starbucks is still the only retailer to offer no-strings-attached reimbursement for employees pursuing an online undergraduate degree. It continues to innovate and will be expanding its advance mobile order and pay program to the entire U.S. in 2015. In the second half of 2015, Starbucks will also pilot two types of food and beverage delivery systems. One, in Seattle, Washington, will allow consumers to order products through an online app linked to a large, on-demand delivery service. Sustainability is another priority for Starbucks, as evidenced by its recent verification that 99% of the coffee it buys is ethically sourced. Supply chain pioneer Walmart is No. 13. The megaretailer has continued its push into ecommerce and has expanded investment in multichannel drive-thru pick-up centers, including one at its headquarters-based distribution center and a "click-and-collect" grocery service offered at some of its stores in Arizona. Walmart is also leveraging its expertise in supply network design and optimization in a drive to recapture the low-cost crown from its competition. At roughly 2.2 million employees, it is the largest private employer in the U.S. and often finds itself the subject of debate on labor and wage standards. The company is running multiple social responsibility programs focused on increasing sustainability at suppliers and in its own network, support for women-owned businesses and the broader communities it serves. Diverse industrial 3M climbed four to No. 14. Senior leadership in its supply chain recognize that complexity limits the long-term growth potential of the company and are on a mission to optimize operations through lean extended value streams. The lean work is clearly paying off as the company boasts an industry-leading three-year weighted average ROA of 14.9%, up more than a percentage point from last year. The engineering-savvy company actively engages with customers to develop innovative solutions to their problems and works closely with key suppliers early in the ideation process for new products with a focus on joint cost reduction and accelerated cycle times. 3M is also focused on increasing vertical integration through the acquisition of technologies and operational capabilities. Rounding out the middle section of the list is another perennial leader, PepsiCo at No. 15. The food and beverage company is unique in running an integrated distribution network that does direct store delivery through retail teams managing shelves around the globe. Its new demand signal repository tools are driving significant results based on the ability to do real-time promotion display management at the SKU level. PepsiCo's supply chain is also making significant automation investments in manufacturing and its distribution centers. The results are significant in terms of cost savings and sustainability benefits through the reuse of packaging materials. PepsiCo is cultivating a booming e-commerce business and driving innovations in shipping package design to accommodate its fragile snack products. This channel is accelerating product co-purchase behavior, whether through a Superbowl party pack in the United States or a Chinese New Year Box ordered on Alibaba. The PepsiCo team has continued its focus on social responsibility and sustainability with programs aimed at environmental quality, ethical sourcing and community improvement, including its innovative PepsiCorp program. Rounding Out the List: No. 16 Through No. 25 Seagate Technology is up four slots at No. 16, this year. The supply chain team at this leading high-tech storage company has developed a global network of customer value centers to provide more efficient fulfillment and deliver customer-specific solutions. It has also established a detailed value-at-risk methodology and applied it to determine and mitigate trouble spots in Seagate Technology's supply base. This capability, coupled with operational visibility at strategic suppliers, enables a fast time to recovery when supply disruptions occur. Seagate Technology has spent the last few years developing a cross-functional supply chain transformation office focused on landing new capabilities, developing talent and rolling out metrics for improved visibility. This group has also staffed "tiger teams" of subject matter experts (SMEs) that collaboratively develop improved supply chain processes at suppliers for better inventory and product quality performance. At No. 17, Nestlé runs one of the largest and most complex consumer foods supply chains in the world. The company processes 10% of both the coffee and cocoa sold globally, as well as significant levels of other agricultural commodities, so it is mindful that a lot of the world's farmers rely on it. Last year, Nestlé was recognized by community-based organization, Oxfam, as a topranked company for responsible sourcing. Nestlé's supply chain culture centers on decentralized, locally-empowered teams. Capital efficiency is a focus area since its level of local investment is high compared to competitors. E-commerce is a growth driver and divided into three distinct areas: clicks and mortar with big retailers, pure players in markets such as China and branded dot-com for its Nespresso line of espresso makers and accessories. Another major priority is upstream product traceability to ensure consumer trust, with a longer-term goal of tracking 100% of products back to source. Lenovo Group returns to the ranking at No. 18, this year. The Chinese technology company's supply chain strategy cascades from its continuing corporate strategy to protect PC-based businesses and attack mobile, enterprise, computing ecosystem and cloud services businesses. It's 18.9% three-year weighted average growth rate reflects significant acquisitions in the last two years. The supply chain team continues to drive new capabilities, while ensuring the smooth integration of large mobile and enterprise computing businesses. For instance, a major project for the network planning and manufacturing teams was migrating an acquired business to an existing Lenovo plant in China to improve efficiency and spread expertise on configure-to-ordertype products. The PC supply chain group has created an advanced analytical solution for inventory and order support visibility. It also has an extensive program to improve customer experience that includes new sensing tools, root cause analysis and a feedback loop on actual and perceived customer quality issues. Wireless telecommunications chipmaker, Qualcomm, landed at No. 19 again, riding a wave of growth in the mobile phone market over the past few years that generated a 17.8% three-year weighted average revenue growth rate in their business. Previous investments in supply capacity optimization and inventory management will be critical for it this year, on the heels of Samsung's announcement that it will use internally designed and manufactured chips for the next generation of its flagship Galaxy line of mobile devices. Meanwhile, Qualcomm is making continued investments in new applications for its products. The company's investment fund is seeding startups that leverage smartphone technologies for new consumer robotics applications. These include 3D mapping of building interiors for automated cleaning and the use of GPS and machine vision to guide delivery drones. The chipmaker is also making a push into the connected car market. Kimberly-Clark returns to the list, up one slot at No. 20. The purveyor of personal care and paper products continues to make progress on a multiyear journey to improve its supply chain organization and capabilities. It is extending lean expertise out in partnership with customers to improve collaborative processes for joint value. The company also runs a supply chain fund that shares value back with customers that choose to order and take delivery using efficient standards. Underpinning this program is a cost-service trade-off model built and leveraged by the supply chain organization. Another recent project is focused on standardizing integrated production scheduling, capacity planning and deployment planning tools. The supply chain in partnership with the business has established a standard product portfolio governance process aimed at improving overall SKU health. This work, along with effective demand shaping capability, has enabled a relatively high forecast accuracy for the company. Perennial healthcare leader Johnson & Johnson is ranked No. 21. J&J's supply chain has a legacy of decentralized decision making, but has become more center-led over the years as a COE formed to drive cross-business unit improvements. One of these programs is focused on complexity management and data-driven governance of the company's diverse product portfolios. The COE team is also working to better understand the voice of the customer in the pharmaceutical business. Following a method of immersion, innovation and connection, the team starts with patients and their unmet needs, then walks back through the supply chain process by which they get their drugs through intermediaries to identify potential improvements. For one product line, the packaging and instructions were simplified to improve patient adherence to their prescriptions. The COE is also delivering enhanced track-and-trace capabilities in support of global brand protection. It's been a decade since L'Oréal was on the global Supply Chain Top 25 list, and this year it lands at No. 22. The supply chain team has a dedicated effort in partnership with the business to improve demand forecast accuracy. It is also leveraging optimization techniques in supply planning to improve customer service levels, while holding less inventory. This required foundational investments in clean master product data to enable more agile planning. L'Oréal is using a collaborative supplier platform with its top strategic upstream partners to feed them weekly demand forecasts and pull through consumption requirements. Outside of acquisitions, the supply chain team has been able to maintain SKU counts with the business based on a simple, but powerful, "one in, one out" rule. Cummins returns to the list at No. 23. The vertically integrated engine and power equipment leader has a strong COE organization. Its COE is partnered with operations to evolve to end-toend differentiated SCM and, eventually, the orchestration of the extended supply chain through collaborative governance. Cummins' analytics team is starting to move beyond basic descriptive reporting of operational performance to more predictive applications such as network, inventory, transportation and warehouse optimization modeling. Its supply chain operations teams are also experimenting with the use of an inventory quality ratio (IQR) to identify areas of over and undercoverage across the product portfolio. Toyota rejoins our ranking at No. 24, based on improved ROA, growth and peer vote performance. It last appeared in 2009 at No. 10. Prior to that time, it was a perennial on the list since the inception of the ranking. Toyota's eponymous production system, which it pioneered leveraging lean principles, has been emulated by the rest of industry and beyond. Its supply chain team is focused on building logistics control towers and mitigation plans to avoid repeating supply disruptions experienced over the last several years. The organization has also worked through some challenges as it expanded from centralized design to region-based design. As a part of its digital strategy, Toyota is building its next-generation customer service model on a cloud-based platform where vehicle owners, dealers and service agents can exchange information about vehicle location, performance parameters and service status. Closing out this year's list is Home Depot at No. 25. The world's largest hardware retailer last appeared on the global Supply Chain Top 25 in 2005. Home Depot's CFO recently cited its supply chain as the enabler to improving gross margins. Its three-year weighted average ROA certainly reflects this result, coming in at just over 14% this year. Home Depot's supply chain team is reaping the rewards of a multiyear improvement journey. It is introducing direct fulfillment centers that will be able to ship to 90% of U.S. households within 48 hours. E-commerce, while a small portion of its total business, spans a wide variety of products and one-third of the volume is "click and collect" at its brick-and-mortar stores. Upstream, Home Depot has set up a vendor source program tapping into vendor-managed inventory (VMI) stocks. Honorable Mentions Every year, there are companies that demonstrate strong leadership in demand-driven principles, but do not make the list. This year, we recognize Caterpillar, HP, Schneider Electric, BASF and Nokia. Caterpillar dropped three slots to No. 26, this year, reflecting a market challenged by macroeconomic factors. The industrial leader has taken a disciplined approach, building upon a foundation in lean techniques to engineer integrated value chains. It is attacking configuration complexity and lead times in its product portfolio and is tailoring supply chains for different customer requirements. Caterpillar has also built logistics control tower capabilities for its own network and external customers. HP, empowered by supply chain operations, has rekindled innovation in products and services such as 3D printing workstations, advanced enterprise servers and digital printer ink replenishment. It is also demonstrating operational excellence in how it runs its enterprise server factories under a lean production system. HP's financials had suffered as a result of a secular decline in PC growth and large M&A write-offs, but those impacts are waning and it is back within shooting distance of the Top 25 at No. 30, this year. Schneider Electric jumped an amazing 33 slots this year to No. 34, based on higher opinion vote scores. Under its "Tailored Supply Chain" (TSC) transformation, Schneider Electric has segmented its supply chain into four types, helping it better align with customer needs and providing a differentiated manufacturing and delivery model for each customer segment. Schneider's TSC strategy, with S&OP as the decision-making forum supported by end-to-end supply chain visibility, is seen as the "nervous system" for its extended value chain, helping it bring predictability to its business results. BASF, the world's largest chemical company, finished up four slots at No. 36 overall in the Gartner rankings. The company has restructured its approach to supply chain in the past few years, having the CIO and CSCO roles under a single leader and aligning processes and IT systems to orchestrate end-to-end material flow, including both inbound and outbound deliveries across a complex global network of factories and storage locations. The supply chain team is exploring predictive analytics in areas such as preventative maintenance and weather-based forecasting for agrichemicals. Nokia was No. 1 on our ranking back in 2007 before it met fierce competition in the smartphone business from Apple and Samsung. After selling its mobile handset business to Microsoft, it shifted its focus to the telecom equipment business that was originally created as a joint venture with Siemens. Its disciplined SCM team is driving an impressive turnaround at the company. All of these companies exhibit leadership characteristics and have compelling lessons for the broader supply chain community. We look forward to sharing lessons from them and many others in the year ahead. What Is Demand-Driven Excellence? The concept of being demand-driven is at the heart of the Supply Chain Top 25 ranking. We have published hundreds of documents on the topic for more than a decade, including a maturity model to help companies move along the transformation curve (see "Introducing the Five-Stage Demand-Driven Maturity Model for Supply Chain Leaders" ). Because it's so critical to the Supply Chain Top 25 analysis, here's a brief synopsis of what it means to have a demand-driven value chain. The DDVN model is characterized by an understanding of customer value and enabled by processes and metrics that enable business trade-offs to deliver products and services profitably. Companies that work toward the DDVN ideal use demand management as a key differentiating capability, so they can plan, sense and shape in a way that brings profitable balance to the business. They also design supply networks to be more closely aligned with the development of product platforms that enable innovation, agility and responsiveness. We find that companies that continually secure spots on the Supply Chain Top 25 have successfully shifted from the traditional disconnected approach to managing supply, demand and product to an integrated approach to coordinating plan, source, make and deliver functions across the end-to-end supply chain. Companies typically make this shift as they advance along the DDVN maturity journey, which represents a long-term commitment to doing business in a customer-value-centric way (see Figure 2). Figure 2. The DDVN Maturity Journey SOURCE: GARTNER (MAY 2015) The seven dimensions of the Gartner DDVN maturity model (see "Assess Your Supply Chain Maturity Using the Seven Dimensions of DDVN Excellence" ) establish a clear definition for each aspect of the supply chain, as it matures and integrates with focus on customer value. Operational Excellence and Innovation Excellence Two basic dimensions of measurement capture the totality of the best-in-class, demand-driven, global supply chain: operational excellence and innovation excellence. To measure operations, including delivering as promised to customers and keeping costs under control, we recommend a hierarchy of metrics, with perfect order performance and total supply chain costs at the top (see "The Hierarchy of Supply Chain Metrics: Diagnosing Your Supply Chain Health" ). Of course, operational excellence has value only if customers want what's being made and shipped. To address this, we look at innovation excellence. Although far harder to measure reliably, this dimension can also be managed with a hierarchy of metrics, in this case, topped by time to value and return on NPDL. The key is to find the right balance on both these dimensions. Too much emphasis on one at the expense of the other either squashes innovation or hampers growth. It's important to recognize the business life cycle aspect to this balance that our methodology also attempts to reflect. Each year, we see examples of previously successful businesses struggling with the competitiveness of their products, while still possessing very advanced supply chain capabilities. This condition can exist for a period of time before both resynchronize and either return to high performance or spiral into decline. Since the opinion poll portion of our methodology is based on the relative capability and leadership of a supply chain at a given point in time, it is possible for a company's supply chain to score well on the polls, while also posting a less-competitive financial performance in the near term. Measuring Demand-Driven Excellence The Metrics We Wish We Had For the Supply Chain Top 25 ranking, our ideal would be to have metrics that perfectly describe the two basic dimensions of performance: operational and innovation excellence. These are the dimensions that point meaningfully to the better value chain, identifying which business is faster, stronger and smarter. Betting on next year or next quarter is a matter of knowing who the better "athlete" is, not merely who won last time. Our premise is that the better athlete is more likely to win markets and profits in the future. Therefore, the companies that can demonstrate superior performance against these dimensions merit a higher share price multiple on a dollar of current earnings. In our ongoing supply chain research, we've identified the metrics that map to these dimensions, which, if we had them, would clearly convey the organizations that have the healthiest value chains (see Table 2). Table 2. Metrics for Operational Excellence and Innovation Excellence Performance Dimension Key Metrics Operational Excellence Perfect order rates Total supply chain costs Innovation Excellence Time to value Table 2. Metrics for Operational Excellence and Innovation Excellence Performance Dimension Key Metrics Return on new product launch SOURCE: GARTNER (MAY 2015) For each of these performance dimensions, we've published a full hierarchy of metrics that allows management to assess overall performance at the highest level, diagnose problems via process decomposition and make corrections at the tactical work level (see Figure 3 and Figure 4). We have also published hierarchies for each of the functions that make up the supply chain: a hierarchy of supply management metrics (see "Use the Hierarchy of Supply Management Metrics for Strategic Alignment and Enhanced Performance" ) , a hierarchy of manufacturing metrics (see "Aligning Manufacturing and Supply Chain Performance, Part 2: The Hierarchy of Manufacturing Metrics" ), and a hierarchy of logistics metrics (see "Align Supply Chain and Logistics Performance With the Hierarchy of Logistics Metrics" ). Figure 3. The Hierarchy of Supply Chain Metrics: Operational Excellence AP = accounts payable; AR = accounts receivable; FG = finished goods; SCM = supply chain management; WIP = work in process SOURCE: GARTNER (MAY 2015) Figure 4. The Hierarchy of Product Metrics: Innovation Excellence SOURCE: GARTNER (MAY 2015) However, from our work with companies and our benchmarking studies, we're all too aware of how inaccessible this data is in most companies, particularly within a realistic time frame. Moreover, although some companies may have some of the data we seek, there are vast inconsistencies in how these metrics are calculated from company to company. Therefore, for the Supply Chain Top 25 ranking, we look to publicly available, audited financial data to find the closest possible proxies. We know the limitations inherent in these metrics. Existing financial accounting principles were developed in the hard-asset, factory-intensive economy of the early 1900s. For example, the balance sheet treatment of inventory as a valuable asset rings false for the many short-cycle businesses today that see inventory as more of a liability. Similarly, soft assets like brands and IP, which are essential to demand creation, are difficult for standard accounting practices to handle. Even income statements can obscure real costs with sneaky capitalization rules. Because of these issues, our methodology isn't limited to financial metrics. Instead, we see the financials as one important component that provides a baseline, an anchor and an objective foundation on top of which we place the group intelligence of a vote, precisely because no combination of income statement or balance sheet financial metrics will tell us which companies are furthest along toward the demand-driven ideal of supply chain excellence. For this reason, we look to craft a methodology that combines enough, but not too many, of the right metrics — both quantitative and qualitative — to achieve our goals. Supply Chain Top 25 Methodology The Supply Chain Top 25 ranking comprises two main components: financial and opinion. Public financial data provides a view into how companies have performed in the past, while the opinion component offers an eye to future potential and reflects leadership in the supply chain community. These two components are combined into a total composite score. We derive a master list of companies from a combination of the Fortune Global 500 and the Forbes Global 2000. Over the past 10 years, the revenue threshold for inclusion in the overall company list has been 10 billion U.S. dollars. In an effort to maintain the list of companies evaluated at a manageable level and in recognition of the inflation and growth these larger companies have experienced, we increased the general revenue threshold to $12 billion this year. We then pare the combined list down to the manufacturing, retail and distribution sectors, thus eliminating certain industries, such as financial services and insurance (see Table 3 for a full list of excluded industries). Table 3. Industries Not Included in the Supply Chain Top 25 Airlines Insurance Services Banks Mail, Package and Freight Delivery Shipbuilding Metals Software Development Diversified Financials Mining Telecommunications Energy Petroleum Refining Temporary Help Engineering/Construction Pipelines Trading Entertainment Railroads Utilities Healthcare: Insurance, Managed Care, Services, Providers Real Estate Information Technology/Computer Services Shipping Crude Oil Production SOURCE: GARTNER (MAY 2015) Each year, we examine the methodology used to develop the ranking, with two sometimesconflicting goals in mind: consistency and improvement. We want to improve the methods and procedures we use, but, for the sake of consistency, in a way that builds on what we've done in previous years. We are open to feedback from the broader supply chain community on the methodology we use and have made some changes this year related to corporate social responsibility and a new "masters" category recognizing sustained leadership. Indeed, the Supply Chain Top 25 at its core is intended to be a lightning rod and foundation for vigorous debate about what constitutes leadership and supply chain excellence. At the same time, we continually look for ways to enhance the explanatory power, applicability and extensibility of the overall ranking. The impact of brand recognition on the vote, industry variations in inventory and inequalities between more versus less asset-intensive industries are all challenges with which we grapple. These issues are multifaceted. By analyzing them, we've been able to make incremental changes that have allowed us to painstakingly chip away at some of the problems, while maintaining consistency from year to year at the same time. Similar to last year, we used a 50/50 overall weighting for this year's ranking: 50% for the financial component and 50% for the opinion component. Financial Component Three financial metrics are used in the ranking: ROA — Net income/total assets Inventory turns — Cost of goods sold/inventory Revenue growth — Change in revenue from prior year ROA was weighted at 25%, inventory turns 15% and growth 10%. Inventory offers some indication of cost, and ROA provides a general proxy for overall operational efficiency and productivity. Revenue growth, while clearly reflecting myriad market and organizational factors, offers some clues to innovation. Financial data is taken from each company's individual, publicly available financial statements. The weighting within the financials is the same as last year. Prior to 2010, inventory was weighted at 25%. We had considered dropping it altogether. As much as inventory is a timehonored supply chain metric — one of the few "real" supply chain metrics on a company's balance sheet — there have always been issues with it, not the least of which is that higher turns don't always point to the better supply chain. At the same time, it's a metric that's widely known and understood, both inside and outside the supply chain community. Despite the issues, it's not entirely invalid as an indicator, particularly if combined with other metrics. Therefore, we decided to leave it in, but reduce its weighting. Since 2009, we've used a three-year weighted average for the ROA and revenue growth metrics (rather than the one-year numbers we had previously used), and a one-year quarterly average for inventory (rather than the end-of-year number we had previously used). The yearly weightings are as follows: 50% for 2014, 30% for 2013 and 20% for 2012. The shift to three-year averages was put in place to accomplish two goals. The first was to smooth the spikes and valleys in annual metrics, which often aren't truly reflective of supply chain health, that result from events such as acquisitions or divestitures. It also accomplishes a second, equally important goal: to better capture the lag between when a supply chain initiative is put in place (a network redesign or a new demand planning and forecasting system, for example) and when the impact can be expected to show up in financial statement metrics, such as ROA and growth. Inventory, on the other hand, is a metric that's much closer to supply chain activity, and we expect it to reflect initiatives within the same year. The reason we moved to a quarterly average was to get a better picture of actual inventory holdings throughout the year, rather than the snapshot, end-of-year view provided on the balance sheet in a company's annual report. Opinion Component The opinion component of the ranking is designed to provide a forward-looking view that reflects the progress companies are making, and the extent to which they demonstrate leadership through visibility in the supply chain community. It's made up of two components, each of which is equally weighted: a Gartner analyst expert panel and a peer panel. The goal of the peer panel is to draw on the extensive knowledge of the professionals that, as customers and/or suppliers, interact and have direct experience with the companies being ranked. Any supply chain professional working for a manufacturer or retailer is eligible to be on the panel, and only one panelist per company is accepted. Excluded from the panel are consultants, technology vendors and people who don't work in supply chain roles (such as public relations, marketing or finance). We accepted 231 applicants for the peer panel this year, with 200 completing the voting process. Participants came from the most senior levels of the supply chain organization across a broad range of industries. There were 35 Gartner panelists across industry and functional specialties, each of whom drew on their primary field research and continuous study of companies in their coverage area. Organizations must surpass a base threshold of votes from both panels to be included in the ranking. Therefore, a company that had a composite score fall within the Supply Chain Top 25 solely based on the financial metrics would not be included in the ranking. The figures below provide a breakdown of the peer vote on the dimensions of region, industry, role and revenue. The regional breakdown of voters continued to be a particular emphasis for us, and we continued to make progress this year. Until 2010, North American voters made up 80% of the total. Since that time, we have made progress in achieving better balance regionally to provide a more balanced global view of supply chain leadership (see Figure 5). Figure 5. 2015 Peer Opinion Panel Composition: Region SOURCE: GARTNER (MAY 2015) Figure 6. 2015 Peer Opinion Panel Composition: Industry SOURCE: GARTNER (MAY 2015) Figure 7. 2015 Peer Opinion Panel Composition: Role SOURCE: GARTNER (MAY 2015) Figure 8. 2015 Peer Opinion Panel Composition: Revenue SOURCE: GARTNER (MAY 2015) Polling Procedure Peer panel polling was conducted in April 2015 via a Web-based, structured voting process identical to previous years. Panelists are taken through a four-page system to get to their final selection of leaders that come closest to the demand-driven ideal, which is provided in the instructions on the voting website for the convenience of the voters. We included consideration of corporate social responsibility (CSR) practices in this year's opinion poll voting criteria. We are now using more explicit language referencing CSR on our peer voting website and within the Gartner analyst evaluation process that influences our opinion poll. We specified that peer voters consider each company's commitment to running a supply chain that addresses social, environmental, ethical human rights and consumer concerns in its operations and core strategy. Many companies are proud of their CSR initiatives, and have observed that supply chain leadership includes running a responsible, sustainable business, and that our ranking should explicitly reflect this dimension. We have always recognized and often written that CSR is an important aspect of leadership, and wholeheartedly agree that it should be a consideration for how high or low they rate on the annual ranking. Here's a breakdown of the voting system: The first page provides instructions and a description of the demand-driven ideal. The second page asks for demographic information. The third page provides panelists with a complete list of the companies to be considered. We ask them to choose 30 to 50 that, in their opinion, most closely fit the demand-driven ideal. After the subset of leaders is chosen, the form refreshes, bringing just the chosen companies to a list. Panelists are then asked to force-rank the companies from No. 1 to No. 25, with No. 1 being the company most closely fitting the ideal. Individual votes are tallied across the entire panel, with 25 points earned for a No. 1 ranking, 24 points for a No. 2 ranking and so on. The Gartner analyst panel and the peer panel use the exact same polling procedure. By definition, each peer voter's expertise is deep in some areas and limited in others. Despite that, peer voters aren't expected to conduct external research to place their votes. The polling system is designed to accommodate differences in knowledge, relying on what author James Surowiecki calls the "wisdom of crowds" to provide the mechanism that taps into each person's core kernel of knowledge and aggregates it into a larger whole. Composite Score All this information — the three financials and two opinion votes — is normalized onto a 10-point scale and then aggregated, using the aforementioned weighting, into a total composite score. The composite scores are then sorted in descending order to arrive at the final Supply Chain Top 25 ranking. New "Social Vote" Pilot This year, for the first time, we tested the concept of a "social vote" as a complement to the Supply Chain Top 25 global ranking. The purpose of this social vote is to get a perspective for comparison from a broader portion of the supply chain community. The results from the social vote were not used in the scoring of the Supply Chain Top 25 ranking this year, rather we plan on using the results as complementary to the Supply Chain Top 25 ranking, which will still be determined using our traditional methodology. The social vote is very similar in appearance to the survey the peer voters complete; however, we asked that the social voters only pick their top 10 supply chain leaders. The intent is to see if different patterns emerge out of this more open, public vote versus our current invitation-only peer panel vote. The Supply Chain Top 25 social vote is open to any and all supply chain professionals. Unlike the peer vote, there is not a limit of only one voter per company. We leveraged a variety of social media channels and supply chain publications to inform the community of this new approach. The level of response was positive and we look forward to growing the social voter base next year. Looking Ahead Supply chain as a profession and practice has advanced dramatically over the years and now plays a central strategic role for companies with global aspirations. As we look forward to the future of the Supply Chain Top 25, we are excited to share the latest and greatest stories of the supply chain profession with the community and to a continued dialogue with you all on the definition of leadership. The Healthcare Supply Chain Top 25 lies ahead for the rest of 2015, as well as a steady cadence of publications that offer various analytical lenses on the full 2015 global ranking. These include industry cuts that examine how the companies in a particular industry stack up against each other and what the industry can learn from them, as well as regional cuts for Asia/Pacific and Europe, which do the same for companies headquartered in each region. These cuts will be published throughout the year and we will pull them all together in a special report toward the end of the year for ease of reference. We plan to publish a report after our 2015 supply chain executive conference that provides a "what if" scenario, comparing each company's performance against their specific industry, or a combination of industry and business model. Based on the results of this study and internal analysis and feedback from the broader community, we may choose to make further changes in the 2016 cycle and beyond. We will also continue to investigate new metrics, including the ROA metric on the physical supply chain, as well as other ways to define and measure supply chain excellence. For instance, we are investigating the incorporation of an externally published CSR index, such as the Dow Jones Sustainability Index, into the quantitative metric portion of Supply Chain Top 25 ranking methodology in 2016. In our engagement with supply chain leaders over the past year, it is evident that the bar of performance has risen considerably for the top of the group. As Gartner's supply chain research organization, we remain committed to providing a platform for informed and provocative debate about supply chain leadership. We look forward to leveraging this research to share the lessons, best practices and characteristics of leaders to inspire and challenge the entire supply chain community to new levels of performance and contribution.