RPS 20.17 Critical Planning Preparation & Delivery of

advertisement

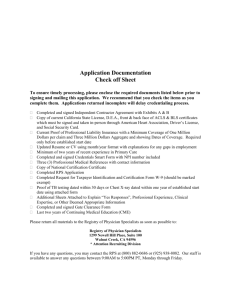

RPS 20.17 Critical Planning Preparation & Delivery of Critical Parts Goodrich Aerostructures Group 1 Outline • Definition of Critical Parts • How do you distinguish a critical part from other parts? • How are Critical Parts handled differently from other parts? • Controlled manufacturing plans • Recent revision to RPS 20.17 • Where and How to submit changes • Other key changes made in Rev. N 2 Definition of Critical Parts • “A critical part is a component (either a part or an assembly) that because of design or manufacturing process considerations, must be controlled to assure that it is produced to strict engineering requirements on a highly uniform and consistent basis”. • At a minimum, engine mounts designed by Goodrich/Rohr are critical parts. 3 Definition of Critical Parts • Critical parts are key structural elements whose integrity is crucial to the safety of the aircraft • For this reason, critical hardware undergoes extensive testing to insure its reliability • Any change to the design or manufacturing processes are carefully evaluated 4 How do you distinguish a critical part from other parts? • A critical part is any part designated as such per RPS 20.17, RPS 20.17-2 Critical Assembly, or RPS 20.17-4 Critical Extrusion. • The following note (or one very similar) will be specified on the drawing and specified for each affected part number “CRITICAL PART PER RPS 20.17”. 5 How are Critical Parts handled? • A Critical Part requires special control of planning. • The specific requirements of this planning are specified in RPS 20.17. • This planning is referred to as “frozen” or controlled planning. 6 Controlled Manufacturing Plans • RPS 20.17 requires that manufacturing plans for critical parts be submitted to GR/AG Quality and M&P Engineering for approval. • This plan is then considered “frozen” and all changes must be processed per the requirements of RPS 20.17 prior to being incorporated. 7 Controlled Manufacturing Plans • Parts manufactured or processed to a plan other than the approved plan on file at GR/AG are done so at the supplier’s risk! • Hardware manufactured at risk can not be delivered to GR/AG until the plan has been approved by GR/AG and the supplier has received written confirmation of that approval. 8 Controlled Manufacturing Plans • Recent revisions to RPS 20.17 have significantly affected the approval process required for critical parts. • Each part number shall have Serial Number Traceability per Para. 3.3.1.8 Sub-Para. a thru e. 9 What is a “Critical Operation”? •Critical Operation (CR) - any operation that, if removed, revised, or changed in sequence, may affect the quality or integrity of the final product. 10 What are some examples of Critical Operations? • • • • • • Forging operations Heat treatment Starting stock material specification Non-destructive testing of finished part Traceability requirements Ref. par. 5.3.1 in Revision N for a complete list of critical operations 11 How are Critical Operations identified on the planning? • When a plan is submitted, the letters (CR) should precede each operation that is a “critical operation”. • If no operations are identified with a (CR), all operations will be considered “critical” and all changes will require GR/AG approval prior to implementation. 12 Changes to Critical Operations • Any change to the content or sequencing of Critical Operations shall require approval from GR/AG M&P Engineering and Materiel Quality Engineer (MQE) or Program Quality Engineer (PQE) prior to their implementation. 13 Changes to Critical Operations •When production planning is submitted to GR/AG for approval, a “Critical Planning Revision Sheet” will accompany the plan. All relevant blocks should be completed. An incomplete form will be returned to the supplier and result in a delay of the planning approval. 14 What if “Critical Operations” are not changed? • Changes to planning that do not affect “Critical Operations” must be submitted to GR/AG M&P Engr and GR/AG MQE or PQE within 10 working days. • As before, any change to the plan will require a change to the approved planning date and (where applicable), a change to the planning revision letter. 15 What if “Critical Operations” are not changed? • Changes to operations that are not “Critical Operations” do NOT require GR/AG approval. Hence, these changes can be made and immediately implemented by the supplier. As stated before, a copy of this revised plan must be submitted to GR/AG within 10 days. 16 Control of Planning Revisions • During the annual RPS 20.17 audit, the ‘working’ shop travelers (job instructions) will be audited for conformance to the approved planning on file at GR/AG. The planning dates/ revision letters must match as well as the content and sequencing of all “critical operations”. 17 Control of Planning Revisions • Failure of the supplier to comply with these requirements will result in the supplier being put on probation and/or may lead GR/AG to require that ALL planning changes have prior GR/AG approval. 18 Where and How changes are to be submitted • If at all possible, changes are to be e-mailed to M&P Engineer and a MQE / PQE - Patricia Adams, M&PE, e-mail address patricia.adams@goodrich.com - Dave Hollings, MQE, e-mail address, dave.hollings@goodrich.com - Ed Bernad, PQE, CFM56 & PW4000 Engine Mount Program, e-mail address ed.bernad@goodrich.com 19 Where and How changes are to be submitted • If e-mail is not possible, all plans should be faxed to Patricia Adams at (619) 691-3781 (this is both her phone and fax number) • Do NOT fax a copy to the buyer / subcontract administrator UNLESS you have first sent a copy to the cognizant engineers 20 Other Key Changes • Engineering takes precedence over the approved plan. – 1- 1.3.4 “Where a conflict exists between the engineering requirements and the approved planning, the engineering requirements shall take precedence.” 21 Other Key Changes • Failure to strictly comply to the requirements of Rev. N could lead to probation and the loss of privileges – 1- 1.3.3 “At the discretion of RM&PE or RQA, Rohr may require that all revisions to the planning (whether critical operations or noncritical operations) may be submitted to RM&PE and RQA for approval prior to the delivery of the affected hardware.” 22 Other Key Changes • Raw material must be traceable to the point of manufacture and ALL raw material sources (mills) are controlled by the GR/AG QSD – 3- 3.1.15.1 “Raw material shall be traceable to approved raw material manufacturers specified in the Qualified Suppliers Document.” 23 RPS 20.17 Training Record • Date of Training ________________ • Attendee’s of Training ____________ ____________ ____________ ____________ ____________ ____________ • Instructor: David Hollings 24