Impact Analysis

advertisement

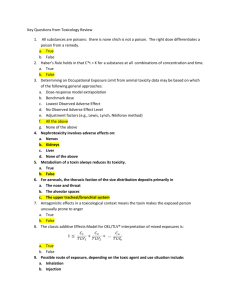

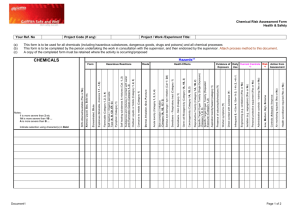

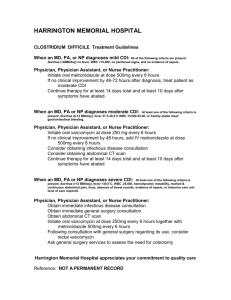

Project Scope Review • What’s your product/process? • What are your important limiting assumptions? • What impact categories will you focus on? LCA Process (review) Define Scope Inventory Analysis Impact Analysis Feedback Manufacture Improvement Analysis RERP Where RERP is the “Environmentally Responsible Product Rating” LCA Impact Assessment Impact Analysis • A very challenging step • Relates system outputs to impacts on the external world • Based extensively on Risk Assessment • The metric for “impact” is necessarily complex because these impacts are neither co-linear nor orthogonal Impact Assessment: Prioritizing Options • An interesting Canadian study of paper vs. polystyrene foam drinking cups – Martin Hocking, Univ. of British Columbia: “Paper vs. Styrene: A complex choice”. Science, 251 (1991): 504-505 and 252 (1991): 1361-1362. • A later study says both are better than ceramic! – Ministry of Housing, Physical Planning, and Environment. Integrated Substance Chain Management, Pub. VROM 91387/b/4-92. ‘s-Gravenhage, the Netherlands, 1991. Matrix Concept for Materials and Process Audits • In IE we often compare alternative designs • This requires the comprehension of large amounts of information • An industrial ecology matrix template can help • Four “Primary Matrices” are prepared: – Manufacturing: Manufacturing activity itself – Environmental: Traditional issues, but not single-media focused – Toxicity/Exposure: Health related issues – Social/Political: Non-technical aspects of produce/process • Matrix for each design shows Life Stages vs. Issues Categories Matrix Concept (continued) • Special symbols are used to label each cell • A summary table can be developed to compare various options on each of the four dimensions: manufacturing, environmental, toxicity/exposure, and social/political Auditing by Life Stage • Using checklists • For each life stage, one uses these checklists to complete ellipses where – Four-level scale for comparison to ideal product (excellent, good, fair, poor) – Texture indicates degree of confidence (black = high confidence, shade = medium, blank = low) • Then density of “blackness” indicates degree of environmental quality (darker is worse) Impact Analysis => Risk Assessment • In order to evaluate the impact of aspects of a product or process lifecycle, we have to be able to assess risk Risk Assessment Methodology • Typically decomposed into four steps: – – – – Hazard Identification Dose-Response Assessment Exposure Assessment Risk Characterization Hazard Identification • Determine the nature of the hazard: – Exposure pathways of concern, e.g. • • • • Ingestion Inhalation Dermal contact Puncture – Toxic endpoints, e.g. • Lethal vs. non-lethal • Chronic vs. Acute Acute Toxicity • Acute toxins result in observed endpoints after few exposures, in short timeframe • For lethal endpoints, toxicity is a measure of the amount of exposure required to produce death – Example endpoints: chemical poisoning, radiation sickness Chronic Toxicity • Chronic toxins produce observed endpoints only after repeated exposures and/or considerable elapsed time • Like acute toxicity, may be lethal or non-lethal • Toxicity may be cumulative or not (e.g. mercury vs. carbon monoxide) – Example endpoints: cancer, birth defects Measuring Toxicity • Need measures of dose which causes toxic endpoint • Measurements for ingested toxins ordinarily normalized for body weight (e.g. mg/kg) • Must generalize from populations of experimental subjects • For lethal endpoints can use LD50 But LD50 is limited! e.g.: here A is always more toxic than B but A can be less toxic than C, even with lower LD50 Toxicology vs. Epidemiology • Toxicology answers the wrong question well • Epidemiology answers the right question poorly Toxicology • Controlled laboratory experimental conditions but • Surrogate subjects (usually animals) • Exaggerated doses Extrapolating High to Low Dose • Experimental studies produce minimum detectable responses on order of a percent • Desire information on order of 10-6 • It’s virtually impossible to perform lab studies with N large enough (e.g. megarat) • We need a mathematical model to perform extrapolation Designing Toxicology Experiments • Selection of subject species • Control design • Multiple dose levels (at high levels to produce observable effect in relatively small number of subjects) Epidemiology • Human subjects • Realistic doses but • Uncontrolled experimental conditions Dose-Response Assessment • Relating Dose to (adverse) response • “Response” typically described as a probability (unitless fraction or percent) • Dose-Response Curve – Dose on the abscissa – Response on the ordinate – Intercept with abscissa is “threshold dose” Potency Factors (a.k.a. Slope Factors) • For chronic chemical toxicity (e.g. cancer), Potency Factor slope of the low dose DR curve Incrementa l Lifetime Cancer Risk PF Chronic Daily Intake where Chronic Daily Intake (CDI) is measured in units of mg/kg/day Potency Factors (cont’d) • Re-arranging, Incremental Lifetime Cancer Risk = CDI PF • Potency Factors are available from EPA’s Integrated Risk Information System (IRIS): http://www.epa.gov/iris Exposure Assessment • Risk has two components: – Toxicity of the substance – Exposure of humans to substance • Exposure often forgotten (see, for example, the Scientific American article comparing indoor pollution to outdoor pollution) Exposure Pathways • The route by which a toxin or hazard reaches the human influences its impact • Internal factors would include the human contact route (e.g. inhalation, ingestion, &c) • External factors would include the physical transport (e.g. distance and travel time in air or water, &c) Exposure Routes and Effects • Principle routes for chemicals: – Ingestion – Dermal – Inhalation • Other routes for hazard exposure: – Puncture – Eyes – Ears Gastrointestinal Exposures • Chemicals gain direct access to mucous membranes in stomach and intestines, allowing transfer of chemical to bloodstream • Digestive processes can transform chemicals into others • Physical hazard endpoints can apply (e.g. with ingested acids) Dermal Exposure • Epidermis consists of former living cells – Removed from blood vessels to some extent – Acts as barrier to loss of fluids and entry of contaminants • Some materials are able to pass this barrier – Solvents which can be absorbed into the skin – Pores and hair follicles Inhalation • Rapid route of entry to bloodstream • Alveoli designed to facilitate transfer of gases (oxygen and carbon dioxide) – Effectively transfer other materials too Distribution of Toxicants • Two factors govern transport: – Protein binding • Toxicants can bind to proteins in the blood, thus preventing their access to surrounding cells through capillary walls • But access to kidneys (for removal) is also inhibited – Polarity • Polar toxicants obstructed by non-polar membranes • Nonpolar toxicants dissolve through readily and can be stored in body fat Metabolism • Conversion of materials through reaction • For toxicants, tendency is to increase polarization (and therefore reduce bio-uptake) • In some cases chemicals can be converted into more toxic materials Pollution Control in the Body • Kidneys • Liver Kidney Function • Blood flowing through kidneys is exposed to porous membrane – the (relatively) small molecules of toxins pass – substantial quantities of water also pass • Aqueous solution passes along tubes which selectively retrieve desirable nutrients, water &c • Concentrated aqueous toxins expelled as urine Liver Function • Metabolize toxicants into more polar structures • Some substances removed from blood and transformed into bile, stored in gall bladder • Gall bladder sends bile into small intestine to assist with digestion • Toxins therefore eliminated with feces (unless resorbed by intestinal walls) Lifetime Exposure Average Daily Dose CDI Body Weigh t Concentrat ion Intake Rate CDI Body Weigh t where a 70-year lifetime is assumed Risk Characterization • Bring Dose-Response together with Exposure assessment to estimate risk Example: Chloroform in Drinking Water • Suppose your drinking water has 0.10 mg/L concentration of chloroform (CHCl3) • From IRIS, PF = 6.1x10-3 (mg/kg/day)-1 0.10 mg/L 2 L/day CDI 0.00286 mg/kg/day 70 kg • So incremental lifetime cancer risk is CDI PF 0.00286 mg/kg/day 6.110 3 (mg/kg/day ) 1 CDI PF 17.4 10 6 Chloroform Example (cont’d) • In a city of 500,000 people: 17.4 cancers 1 500,000 people 6 0.12 cancers/yr 10 people 70 yr General Exposure Conc Intake Rate Exposure (days) CDI Body Weigh t Lifespan (yrs) 365 days/yr Example: Occupational Exposure • A 60 kg person works 5 days/week, 50 weeks/yr, for 25 years • Each workday they breath 20 m3 of air containing 0.05 mg/m3 of toxin mg m3 days weeks 0.05 3 20 5 50 25 yrs m day week year CDI 60 kg 70 years 365 days/yr CDI 0.0041 mg/kg/day Example (cont’d) • If the Potency Factor is 0.02 (mg/kg/day)-1: Incr Risk CDI PF Incr Risk 0.0041 mg/kg/day 0.02 (mg/kg/day ) Incr Risk 8110 6 1 Non-carcinogenic Doses • Metrics from toxicity experiments include – – – – Lowest Observed Effect Level (LOEL) Lowest Observed Adverse Effect Level (LOAEL) No Observed Effect Level (NOEL) No Observed Adverse Effect Level (NOAEL) • Note: NOEL and NOAEL are the highest experimental doses at which no (adverse) effect was seen Reference Dose • The Reference Dose (RfD) is taken from the NOAEL: NOAEL RfD Uncertaint y Factors • Where Uncertainty Factors are 10 each for differences across population using animal data to estimate human endpoints using only a single species of animal Hazard Quotient • Compares exposure to Reference Dose: Average Daily Dose During Exposure HQ Reference Dose • HQ < 1 should be free if significant risk of toxicity Hazard Index • Considers multiple risks (e.g. from multiple chemical toxins) • The sum of the Hazard Quotients: HI HQ Other Factors in Risk Characterization • Also consider – Statistical uncertainties – Biological uncertainties – Selection of applicable dose-response and exposure data – Selection of population groups toward which the risk assessment should be targeted Occupational Standards revisited • The standards set by OSHA (and ACGIH and NIOSH) are based upon such risk assessment analyses Occupational Standards: TWA • The Time-Weighted Average (TWA) assumes an 8-hour day and 40-hour week Ct TWA t i i i i i TWA Example Exposure (ppm) 2 Time (hr) 10 Product (ppm*hr) 20 3 20 60 4 10 40 40 120 So TWA = 120 ppm / 40 hours = 3 ppm Occupational Standards: STEL • Short Term Exposure Level • Calculated as a 15-minute TWA • Allowed no more than four such exposure periods per day, separated by at least 1 hour Occupational Standards: Ceiling • Concentration which must not be exceeded, regardless of duration of exposure.