07.Coarse Dispersions

advertisement

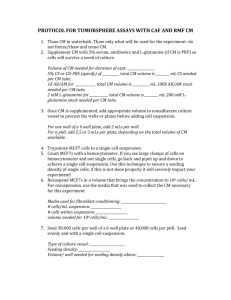

Coarse Dispersions PhD Halina Falfushynska 2 Definition • A Pharmaceutical suspension is a coarse dispersion in which internal phase is dispersed uniformly throughout the external phase. • The internal phase consisting of insoluble solid particles. • The external phase (suspending medium) is generally aqueous in some instance, may be an organic or oily liquid for non oral use. Suspensions Dispersions containing coarse particles, usually 10 to 50 um in size, are referred to as coarse dispersion. Dispersions containing particles of smaller size are termed fine dispersions (0.5 to 10 um) Suspensions Classification • Based On General Classes Oral suspension Externally applied suspension Parenteral suspension • Based On Proportion Of Solid Particles Dilute suspension (2 to10%w/v solid) Concentrated suspension (50%w/v solid) • Based On Electrokinetic Nature Of Solid Particles Flocculated suspension Deflocculated suspension • Based On Size Of Solid Particles Colloidal suspension (< 1 micron) Coarse suspension (>1 micron) Nano suspension (10 ng) 5 • Advantages and Disadvantages due to viscosity of medium 312 PHT Advantages • High viscosity inhibits the crystal growth. • High viscosity prevents the transformation of metastable crystal to stable crystal. • High viscosity enhances the physical stability. Disadvantages • High viscosity hinders the re-dispersibility of the sediments • High viscosity retards the absorption of the drug. • High viscosity creates problems in handling of the material during manufacturing. Physical Features of the Dispersed Phase of a Suspension Good pharmaceutical suspensions, the particle diameter is between 1 to 50. Particle size reduction is generally accomplished by dry-milling prior to the incorporation of the dispersed phase into the dispersion medium. One of the methods of producing fine drug powders of about 10 to 50 um size is micropulverization. For still finer particles, under 10 um, the process of fluid energy grinding, sometimes referred to as jet-milling or micronizing. Dispersion Medium The amount of the suspending agent must not be such to render the suspension too viscous to agitate (to distribute the suspensoid) or to pour. The study of the flow characteristics is termed rheology Rheological properties • Viscosity - is a measure of the resistance of a fluid which is being deformed by either tensile stress • Flexibility- the ability to recover the form of matter (volume) after deformation. Flexibility causes the alignment marks of finger pressure on the surface of plastiline. • Plasticity - the opposite of the elastic properties of the substance taken and permanent deformation after removing the load. Due to the plasticity of plastiline retain fashioned. • Elasticity - the property of matter experience significant deformation without destroying the structure. Standard laboratory viscometers for liquids Ostwald viscometers measure the viscosity of a fluid with a known density. Falling Piston Viscometer Suspensions quantified by sedimentation volume (f) Degree of flocculation (β) Sedimentation volume is a ratio of the final or ultimate volume of sediment (Vu) to the original volume of sediment (VO) before settling. Sustained-Release Suspension • In liquid preparations (suspensions) of the coated particles, the drug remains adsorbed onto resin, but slowly released by the ion-exchange process when taken into gastrointestinal tract. The use of a combination of ion-exchange resins complex and particle coating is called Pennkinetic system. • Examples: ▫ Hydrocodone polistirex =Tussionex Pennkinetic Extended-Release Suspension Characteristics of Oral Suspension • Particles should be small uniform sizes that do not settle rapidly • The particles that do settle to the bottom of the container should not pack in to a hard cake and should be re-dispersed completely and evenly with a minimum amount of agitation Characteristic of Suspensions Should not be too viscous to pour freely from the mouth of the bottle Should have an agreeable odor, color and taste and must not decomposed or support mold growth during storage Must have therapeutic efficacy Characteristic of Suspensions •Suspensions for injections must contain particles size such that they can pass freely through the syringe needle called “syringeability”. Characteristic of Suspensions Ophthalmic suspension should be formulated such that the particles do not exceed 10 microns. Below this size, the patient experiences no pain when instilled into the eyes. Dispersion Medium • Suspending agents are added to the dispersion medium to lend its structure to assist in the suspension of the dispersed phase • Examples: Carboxymethylcelulose Methylcellulose Microcrystalline cellulose Polyvinyl pyrolidone, Xanthan gum Bentonite Example of Preparation Aluminum Hydroxide Compressed Gel 326.8 g Sorbitol Solution 282.0 mL Syrup 93.0 mL Glycerin 25.0 m Methylparaben 0.9 g Propylparaben 0.3 g Flavor q.s Purified water, to make 1000.0 mL USE: ANTACID Examples of Oral Suspensions by Category Antacids Alumina, Magnesia and Simethicone - Mylanta liquid Magaldrate Oral Suspension - Riopan Oral Suspension Magnesia and Alumina Oral - Maalox Suspension Aluminum Hydroxide and Magnesium Carbonate - Gaviscon liquid Anthelminitics Pyrantel Pamoate - Antiminth Oral Suspension Thiabenzadole Oral Suspension - Mintezol Oral Suspension Antibacterial (Antibiotics) Chloramphenicol Palmitate - Chloromycetin Palmitae Oral Suspen. Ertythromycin Estolate - Ilosone Oral Suspension Antibacterial (non- Methenamine Mandelate - Mandelamine Suspension/Forte antibiotic Anti- Sulfamethoxazole and Trimethoprim - Bactrim, Septra Suspension infectives) Sulfamethoxazole - Gantanol Suspension Sulfisoxazole Acetyl Oral Suspension- Gantrisin Syrup/Pedia Anticonvulsants Pimidone Oral Suspension - Mysoline Suspension Antidiarrheal Bismuth Subsalicylate - Pepto-Bismol liquid Examples of Oral Suspensions by Category Antiflatulent Simethicone Oral Suspension - Mylicone Drop Antifungals Nystatin Oral Suspension - Nystatin Oral Suspension Griseofulvin Oral Suspension -Grifulvin Oral Suspension Antihypertensive Methyldopa Oral Suspension - Aldomet Oral Suspension Antipsychotics, Sedatives, Antiemetic Hydroxyzine Pamoate Oral Suspension - Vistaril Oral Suspension Thioridazine Oral Suspension - MellarilS Oral Suspension Diuretic Chlorothiazide Oral Suspension - Diuril Oral Suspension Nonsteroidal Anti-inflammatory Indomethacin Oral Suspension - Indocin Oral Suspension Sample Products CEFIXIME TERGECEF GRANULES FOR SUSPENSION PARACETAMOL BIOGESIC SUSPENSION CARBOCISTEINE SOLMUX FORTE SUSPENSION EMULSIONS • The word emulsion, came from emulgio, “meaning to milk out”. • Is a dispersion in which the dispersed phase is composed of small globules of a liquid distributed throughout a vehicle in which it is immiscible. Emulsion terminology • The dispersed phase is referred to as the Internal phase • The dispersion medium as the External or Continuous phase • Emulsions having an oleaginous internal phase and aqueous external phase are referred to as oil-in-water (o/w) emulsions • Emulsions having an aqueous internal phase and an oleaginous external phase are termed water-in- oil (w/o) emulsions. Theories of Emulsification 1. 2. 3. 4. Surface Tension Theory Oriented-Wedge Theory Plastic or Internal Film Theory Viscosity Theory Oriented-wedge Theory • Assumes monomolecular layers of emulsifying agent curved around a droplet of the internal phase of the emulsion. • It is based on the presumption that certain emulsifying agents orient themselves about and within a liquid in a manner reflective of their solubility in that particular liquid. • An emulsifying agent having a greater hydrophilic character than hydrophobic character will promote an O/w emulsion and a W/O emulsion results through use of more hydrophobic than hydrophilic emulsifiers. Plastic or Interfacial-Film Theory • Places the emulsifying agent at the interface between the oil and water, surrounding the droplets of the internal phase as a thin layer of film adsorbed on the surface of the drops. • The film prevents the contact and the coalescence of the dispersed phase, the tougher and more pliable the film, the greater the stability of the emulsion. Viscosity Theory • States that the viscosity of an emulsion aids emulsification by the mechanical hindrance to coalescence of the globules although it is not the cause of emulsification. Emulsifying Agents These materials form hydrophilic colloids when added to water and generally produced O/W emulsions. Acacia is most frequently use. Tragacanth and Agar - thickening agents in Acacia emulsified products. These substances produce O/W emulsions. The disadvantage of gelatin is that the emulsion prepared from it are too fluid. Natural Emulsifying Agents High Molecular Weight alcohols These materials employed primarily as thickening and stabilizing agents for O/W emulsions such as lotion and ointments Cholesterol may also be employed in externally used emulsion and promote W/O emulsions. Carbohydrates: acacia, tragacanth agar, chondrus, pectin Proteins gelatin, egg yolk, casein stearyl alcohol, cetyl alcohol, glyceryl monostearate Emulsifying Agents Finely Divided Solids These materials generally form O/W emulsions when the insoluble material is added to the aqueous phase if there is greater volume of the aqueous phase than of the oleaginous phase Colloidal clays including Bentonite, Magnesium hydroxide Aluminum hydroxide Synthetic (wetting agents), which may be Anionic, Cationic, Nonionic Anionic: triethanolamine oleate and sodium lauryl sulfate Cationic: benzalkonium chloride Nonionic: sorbitan esters (span); polyethylene glycol 400 monostearate; polyoxyethylene sorbitan esters (Tweens) Qualities Required for Emulsifiers ▫ ▫ ▫ ▫ ▫ ▫ Must be compatible with other ingredients in the formula Must not interfere with the stability and efficacy of the therapeutic agent Must be stable to microorganisms Must be non-toxic Must possess little or no odor, taste or color Must promote emulsification and maintain stability of the emulsion for intended shelf-life The HLB or Hydrophilic- Lipophile Balance • Each emulsifying agents has a hydrophilic portion (water-loving) and a lipophilic portion (oil-loving) with one or other being more or less predominant and influencing • A method indicative of the substances polarity devised and lead to the assigning of an HLB value for each agent. The usual range is between 1 to 20. • Materials that are highly polar or hydrophilic have assigned higher numbers than materials that are less polar and were lipophilic. Methods of Preparation 1. 2. 3. 4. 5. 6. Continental or Dry gum method English or wet gum method Bottle or Forbes bottle method Auxiliary method In SITU soap method Microemulsions Continental or Dry gum method +O+W) (G • The method is also referred to as the “4:2:1” method because for every 4 parts (volumes) of oil, 2 parts of water and 1 part of gum are added in preparing the initial or primary emulsion. • For instance, if 40 mL of oil are to be emulsified, 20 mL of water and 10 g of gum would be employed, with additional water or other formulation ingredients being added afterward to the primary emulsion Bottle or Forbes Bottle Method (G+O+W) • For the extemporaneous preparation of emulsions from volatile oils or oleaginous substances of low viscosities, the bottle method is used. (2:2:1) Auxiliary Methods An emulsion by either the wet gum or dry gum methods can generally be increased in quality by passing it through a hand homogenizer. In this apparatus, the pumping action of the handle forces the emulsion through a very small orifices which reduces the globules of the internal phase to about 5 um and sometime less In SITU Soap Method • Two types of soap developed by this method are Calcium soaps and Soft soaps. • Calcium soaps water - in - oil emulsions which contain certain vegetable oil (e.g. Oleic acid) in combination with lime water ( Syn: Calcium Hydroxide Solution USP) and prepared by mixing equal volumes of the oil and lime water Microemulsions • • • Thermodynamically stable, optically transparent, isotropic mixtures of a biphasic oil-water system stabilized with surfactants. The diameter of droplets in a microemulsion may be in the range of 100 A (10 microns) to 1000 A whereas in a microemulsion the droplets may be 5000 angstroms in diameter. Both O/W and W/O microemulsions may be formed spontaneously by agitating the oil and water phases with carefully selected surfactant. Terminology Flocculation - is the joining together of globules to form large clumps or floccules which rise or settle in the emulsion more rapidly than do the individual particles Creaming is the rising (upward creaming) or settling (downward creaming) of globules or floccules to form a concentrated layer at the surface or to the bottom of the emulsion Coalescence and breaking unlike creaming, the coalescence of globules and the subsequent breaking of an emulsion are irreversible processes. In creaming, the globules are still surrounded by a protective coating or sheath of emulsifying agent and may redispersed simply by agitating the product. Deterioration by Microorganism Molds, yeast and bacteria may bring about decomposition and contamination of the emulsion. Preservatives should be more fungistatics than bacteriostatic Miscellaneous Physical and Chemical Change Light and rancidity affect the color and the odor of oils and may destroy their vitamin content. Freezing and thawing and high temperature result in the coarseness and breaking of an emulsion. Terminology Related To Gels Imbibition is taking up of a certain amount of liquid without a measurable increase by a gel with an increase volume. Swelling is the taking up of a liquid by a gel with an increase in volume. Only those liquid that solvate a gel can cause swelling. The swelling of protein gels is influenced by pH and thepresence of electrolytes. Syneresis is when the interaction between particles of the dispersed phase becomes so great than on standing, the dispersing medium is squeezed out in droplets and the gel shrinks. Syneresis is a form of instability in aqueous and nonaqueous gels Thixotrophy is a reversible gel-sol formation with no change in volume or temperature-a type of non-Newtonian flow. Xerogel is formed when the liquid is removed from a gel and only the framewok remains. Examples: gelatin sheet, tragacanth ribbons and acacia tears