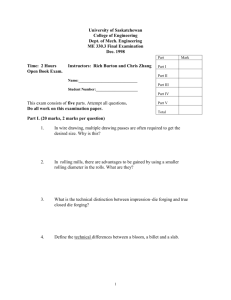

Mechanical Engineering Design Chapter 2

advertisement

Chapter 1 Tolerances and Fits Department of Mechanical Engineering Middle East Technical University ME307 Machine Elements I Fall 2006-2007 Dr. Serkan Dağ Tolerances and Fits Deviations from the exact dimensions are inavoidable due to the nature of manufacturing processes. These deviations must not be so large that the part is useless. Designer specifies upper and lower limits to the dimensions Tolerance is the difference between the maximum and minimum size limits of a part: d d max d min dmin dmax d Too tight tolerance High manufacturing cost Too large tolerance Part may not function as expected Dr. Serkan Dağ Fits Dr. Serkan Dağ Tolerances Application, Process Tolerance (mm) Slip blocks, reference gages 1-2 High quality gages, plus gages 2-3 Good quality gages, gap gages 3-5 Fits produced by lapping 4-10 Ball bearings, Diamond or fine boring, fine grinding 5-12 Grinding, fine honing 6-20 High quality turning, broaching 12-35 Center lathe turning and boring, reaming 14-50 Horizontal or vertical boring machine 30-80 Milling, slotting, planing, metal rolling or extrusion 50-100 Drilling, rough turning and boring, precision tubing 70-140 Light press work, tube drawing 120-240 Press work, tube rolling 150-500 Die casting or molding, rubber moulding 250-1000 Stamping 400-1400 Sand casting, flame cutting 500-2000 Dr. Serkan Dağ Basic Systems for Fit Specification In order to standardize dimensioning of fits, two basic systems are used 1) Basic Hole System (BHS) Minimum hole diameter is taken as the basis. Lower deviation for the hole is equal to zero. Dmax is prescribed according to the specified tolerance. 2) Basic Shaft System (BSS) Maximum shaft diameter is taken as the basis. Upper deviation for the Shaft is equal to zero. dmin is prescribed according to the specified tolerance. Dr. Serkan Dağ Basic Systems for Fit Specification tolerance zone Fund. Dev. BHS tolerance zone hole basic size BSS Fund. Dev. hole basic size shaft shaft tolerance zone Dr. Serkan Dağ International Tolerance Grade Numbers • In order to establish a preferred fit we need 1) The magnitude of the tolerance zone for the shaft and the hole 2) Fundamental deviation for the shaft (in BHS) Fundamental deviation for the hole (in BSS) • International tolerance grade numbers (IT numbers) designate groups of tolerances such that tolerances for a particular IT number have the same relative level of accuracy but vary depending on the basic size. • The magnitude of the tolerance zone is the variation in part size. The tolerance zones are specified in international tolerance grade numbers called IT numbers. • These numbers range from IT0 to IT16. The smaller grade numbers specify a smaller tolerance zone. • IT numbers are given in Tables A-11 and A-13 in the textbook. Dr. Serkan Dağ International Tolerance Grade Numbers Application,Process Tolerance (mm) IT Grade Slip blocks, reference gages 1-2 1 High quality gages, plus gages 2-3 2 Good quality gages, gap gages 3-5 3 Fits produced by lapping 4-10 4 Ball bearings, Diomand or fine boring, fine grinding 5-12 5 Grinding, fine honing 6-20 6 High quality turning, broaching 12-35 7 Center lathe turning and boring, reaming 14-50 8 Horizontal or vertical boring machine 30-80 9 Milling, slotting, planing, metal rolling or extrusion 50-100 10 Drilling, rough turning and boring, precision tubing 70-140 11 Light press work, tube drawing 120-240 12 Press work, tube rolling 150-500 13 Die casting or molding, rubber moulding 250-1000 14 Stamping 400-1400 15 Sand casting, flame cutting 500-2000 16 Dr. Serkan Dağ International Tolerance Grade Numbers Example: A shaft of nominal diameter 25 mm is going to be manufactured. IT grade is required to be IT7. Determine the tolerance on the shaft. Use Table A-11 (tolerance grades, metric series) Basic size 18-30 (Consider the 1st appearance) Ts d d max d min 0.021 mm • Tables can be used for both shafts and the holes. • Tolerance on a shaft or a hole can be calculated by using the formulas provided by ISO. Dr. Serkan Dağ Tolerance Designation (ISO R286) Tolerance on a shaft or a hole can also be calculated by using the formulas provided by ISO. T K i where, T is the tolerance (in mm) i 0.453 D 0.001D (unit tolerance, in mm) D D1 D2 (D1 and D2 are the nominal sizes marking the beginning and the end of a range of sizes, in mm) K 101.6 ITn IT 6 Dr. Serkan Dağ International Tolerance Grade Numbers Example: Consider the previous example (D = 25 mm and IT grade of IT7) and calculate the tolerance on the shaft using the formulas given in ISO standards. i 0.453 D 0.001D Note: When the nominal sized marking the beginning and end of a range of sizes are not available, nominal size can be directly used to calculate i. i = 1.341 mm K 101.6 7 6 16 Ts K i 21.45 mm 0.021mm Same result is obtained using Table A-11 Dr. Serkan Dağ Fit Types There are three types of fits a) Clearence Fits b) Interference Fits c) Transition Fits Clearence Fits The mating parts have such upper and lower limits that a clearence always results when the mating parts are assembled. hole d max 25.95 mm Cmin d min 25.93 mm Dmax 26.03 mm shaft Dmin 26.00 mm Ts 0.02 mm Th 0.03 mm Allowance of the fit corresponds to maximum material condition (Cmin). Allowance can be calculated by considering tightest fit. Dr. Serkan Dağ Fit Types There are three types of fits a) Clearence Fits b) Interference Fits c) Transition Fits Interference Fits The mating parts have such limits that the lowest shaft diameter is larger than the largest hole diameter. hole shaft d max 25.04 mm I max Dmax 25.01 mm d min 25.02 mm Dmin 25.00 mm Ts 0.02 mm Th 0.01 mm Allowance of the fit corresponds to maximum material condition (Imax). Dr. Serkan Dağ Fit Types There are three types of fits a) Clearence Fits b) Interference Fits c) Transition Fits Transition Fits Either a clearance or an interference may result depending on the exact value of the dimensions of the machined shaft and hole within the specified tolerance zones d max 25.04 mm shaft hole I max d min 25.02 mm Dmax 25.03 mm Dmin 25.00 mm Ts 0.02 mm Th 0.03 mm Allowance of the fit corresponds to maximum material condition (Imax). Dr. Serkan Dağ Fundamental Deviation tolerance zone Fund. Dev. BHS Tolerance zones for the hole and the shaft are prescribed by IT numbers. Note that we also need the fundamental deviation for the shaft to completely specify the fit. ISO standard uses tolerance position letters with capital letters for the holes and lowercase letters for the shafts. • Letters are combined with tolerance grades to establish a preferred fit. • Specification for the holes: H7, D8, J6 • Specification for the shafts: h6, b8, k7 Dr. Serkan Dağ Specification for the Fits tolerance zone 25 H7/g6 Fund. Dev. BHS basic size fund. dev. for the hole IT grade for the hole IT grade for the shaft fund. dev. for the shaft • H…/(a-z)… BHS (fund. dev. for the hole is zero) • (A-Z)…/h… BSS (fund. dev. for the shaft is zero) • Letters I, L, O, Q, W, i, l, o, q, w are not used. Dr. Serkan Dağ Specification for the Fits, Example. + 34 H11/c11 Basic Size (Datum) H11 Th fund. dev. - Ts (BHS) c11 What are the max. and min. limits for the hole and the shaft for the given fit spec.? Table A-12 (Fund. devs. for shafts (BHS)). D 34 mm, for c, F 0.12 mm. D 34 mm, IT11, T 0.16 mm. (Table A-11) Dmin 34 mm. Dmax 34.16 mm. d max 34 0.12 33.88 mm. d min 34 0.12 0.16 33.72 mm. Dr. Serkan Dağ Specification for the Fits In Basic Shaft System (BSS), fund. dev. of the shaft is given by h and it is equal to zero. (Upper limit of the shaft is on datum line). + B Datum Line (A-Z)…/h…, h + - H shaft Datum Line h Ex: B8/h8 H…/h…, snug fit. shaft Note: Fund. dev. table for BSS is not given in the textbook. Dr. Serkan Dağ Fundamental Deviations (Letter Specification) + A BSS: (A-G)…/h… (positive) BHS: H…/(a-g)… (negative) (J-K)…/h… (depends on size) H…/(j-k)… (depends on size) (M-Z)…/h… (negative) H…/(m-z)… (positive) z BC DE F F G p mn H JK MN P HOLE rs v u t RS TU VX F b YZ cd e f j gh y F basic size F x k SHAFT a - Dr. Serkan Dağ Tolerance on the Fit Tolerance on the fit is defined as the sum of the tolerance on the hole and tolerance on the shaft. T f Th Ts Dmax Dmin d max d min clearence Cmin interference Imin Cmax Imax T f I max I min T f Cmax Cmin Cmax Imax transition T f I max Cmax Dr. Serkan Dağ Example For a nominal diameter of 25 mm and for a fit specification of H7/j5 determine the following: a) b) c) d) e) f) g) h) Type of the tolerancing system Tolerance on the hole Tolerance on the shaft Upper and lower limits of the hole (Dmax, Dmin) Upper and lower limits of the shaft (dmax, dmin) Type of the fit Tolerance on the fit Allowance Dr. Serkan Dağ Example a) H7/j5 Basic Hole System b) D = 25 mm, from the given table: H7 21 mm 0 mm + - j5 5 mm - 4 mm nominal size H7 j5 Th 21 mm c) Ts 9 mm Dr. Serkan Dağ Example d) Dmin 0, (Basic Hole System) Dmax 25 0.021 25.021 mm e) dmin 25 0.004 24.996 mm dmax 25 0.005 25.005 mm f) Interference fit. g) Tolerance on the fit: T f Th Ts 21 9 30 mm or, I max 5 mm, Cmax 21 4 25 mm. T f I max Cmax 30 mm. h) Allowance = Imax= 5 mm. Dr. Serkan Dağ Fits, Interference and Clearence Values In the second table, interference and clearence values for commonly used fits are given. For example, consider G7/h6, D = 20 mm. From the table we read: Cmax 41 mm clearence fit. Cmin 7 mm G7 Cmin 28 mm 7 mm h6 0 mm 13 mm G7 Cmax h6 Dr. Serkan Dağ Fits, Interference and Clearence Values Consider H7/m6, D = 20 mm. From the table we read: Cmax 13 mm interference fit. I max 21 mm H7 H7 21 mm 0 m6 m6 21mm 8 mm nominal size Dr. Serkan Dağ