ppt

advertisement

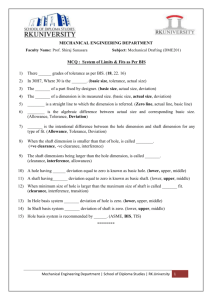

Tolerance • The replacement of parts should be easy. Dimensions are important for interchangeability. • Exact size is difficult to manufacture. • Exact size is not required. • To accept variation is size is called tolerances. Maximum & minimum allowable dimensions are called Limit Dimensions. The difference in limit dimensions is called tolerance. Shaft: A member which fit in another member Hole: A member in which external member fit. Clearance = Max Hole – Min Shaft Allowance = Min Hole – Max Shaft (MMC) Required to fit properly (not interchangeable) Size Designations • Nominal Size: Used for general identification. Calling name. • Basic Size: This is the size on which tolerances are applied. • Actual size: measured size of the finished parts. • Allowance: Minimum clearance (MMC) Fit between mating parts • Clearance fit: • Both allowance and Maximum clearance positive. Interference fit: Both allowance and maximum clearance are negative Max Clearance = 1.2506 – 1.2513 = -0.0007 Allowance = 1.2500 – 1.2519 = -0.0019 Transition fit: One negative and one positive Max Clearance = 1.2506 – 1.2503 = +0.003 Allowance = 1.2500 – 1.2509 = -0.0009 Line fit • Allowance is zero with positive maximum clearance. • This results in a surface contact. • Selective Assembly:Pars are so classified and grouped that small hoes matches with small shaft, medium with medium and large with large. Basic Hole system: When basic dimensions are for hole. Basic Shaft system: When basic dimensions are for shaft. Limit Dimensions: The maximum and minimum values are specified. Plus or minus dimensions: Basic size followed by plus or minus tolerance. Unilateral: variation in only one direction. One value should be zero, another may be all + or -. Bilateral tolerance: allows variation in both direction of basic size. Symmetry in bilateral dimension Single limit dimension: some time one limit for example 0.5R MAX Angular Tolerance: usually bilateral and in degree minute or in second. It is best to dimension to each surface so that it is affected by only one dimension. This can be done by referring all dimensions to a single datum surface. Decimal Inch system Metric system of tolerances and fit • Specified by International Organization for Standardization (ISO). • Basic Size: The size where limits are assigns. • Deviation: Different between the basic and hole or shaft size. Upper Deviation: Difference between the basic and maximum size. Lower Deviation: Difference between the basic and minimum size. Fundamental deviation • The deviation which is closest to the basic size. • For Shaft, upper deviation is the fundamental deviation • For Hole, Lower deviation is the fundamental deviation Basic Hole System • • • • • For Hole, Lower Deviation = Min Hole – basic size Upper Deviation = Max Hole – basic size Fundamental Deviation is Lower deviation Fundamental deviation represents in capital letters, A, B, C ,…..H, G, ……AA,…… • Each letter has its own number can be seen in hand books. H means zero. • If Fundamental deviation is H, it means minimum hole size is the basic size and the system is called basic hole system. Basic Shaft System • For shaft, • • • • Lower Deviation = basic size – min shaft Upper Deviation = basic size – max shaft Fundamental Deviation is upper deviation Fundamental deviation represents in small letters, a, b, c ,…..h, g, ……aa,…… • Each letter has its own number can be seen in hand books. h means zero. • If Fundamental deviation is h, it means maximum shaft size is the basic size and the system is called basic shaft system. IT Grade for Tolerances • Tolerances: Difference between maximum and minimum size. • International Tolerance Grade (IT) Set of tolerances that varies according to the basic size and provide uniform level of accuracy. • Total 18 IT grade, IT01, IT0, IT1,…IT16. Example of IT Grade (p-a33) • 40h6 shaft, basic size 40, Tolerance 0.016 • Max size = 40, Min size = 39.984 • 30H10 Hole, basic size 30, Tolerance 0.084 • Min size = 30, Max size = 30.084 Basic Size = 50, Basic Hole System Max Min Tol Hole 50.039 50.000 0.039 Shaft 49.975 49.950 0.025 Clearance = 0.089, Allowance = 0.025, Clearance fit. From Hand out, for hole, +39 & 0, for shaft, -25. -50. Another example, 45N7/h6 • Basic size = 45 and Basic shaft system. Max Min Tol Hole 44.992 44.967 0.025 Shaft 45.000 44.984 0.016 Clearance = 0.008 and allowance = -0.033 Transition fit From hand out, for hole, -8,and -33and for shaft, 0, and -16