Two-stage batch adsorber design using pseudo-second

advertisement

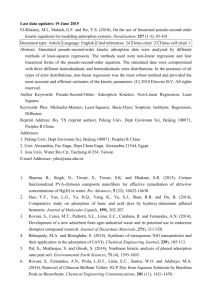

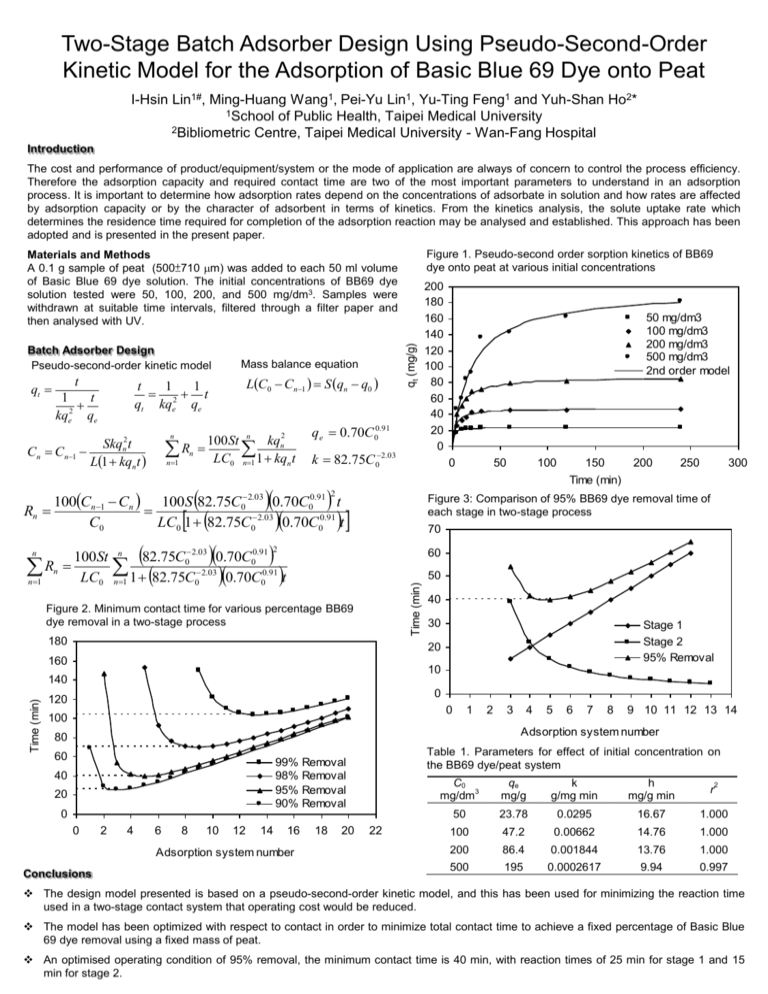

Two-Stage Batch Adsorber Design Using Pseudo-Second-Order Kinetic Model for the Adsorption of Basic Blue 69 Dye onto Peat I-Hsin Lin1#, Ming-Huang Wang1, Pei-Yu Lin1, Yu-Ting Feng1 and Yuh-Shan Ho2* 1School of Public Health, Taipei Medical University 2Bibliometric Centre, Taipei Medical University - Wan-Fang Hospital Introduction The cost and performance of product/equipment/system or the mode of application are always of concern to control the process efficiency. Therefore the adsorption capacity and required contact time are two of the most important parameters to understand in an adsorption process. It is important to determine how adsorption rates depend on the concentrations of adsorbate in solution and how rates are affected by adsorption capacity or by the character of adsorbent in terms of kinetics. From the kinetics analysis, the solute uptake rate which determines the residence time required for completion of the adsorption reaction may be analysed and established. This approach has been adopted and is presented in the present paper. Figure 1. Pseudo-second order sorption kinetics of BB69 dye onto peat at various initial concentrations Batch Adsorber Design Pseudo-second-order kinetic model qt t Mass balance equation LC0 Cn1 S qn q0 t 1 1 t qt kqe2 qe 1 t kqe2 qe 100 St n kqn2 Rn LC0 n1 1 kqn t n1 n Skqn2t Cn Cn1 L1 kqn t qt (mg/g) Materials and Methods A 0.1 g sample of peat (500±710 m) was added to each 50 ml volume of Basic Blue 69 dye solution. The initial concentrations of BB69 dye solution tested were 50, 100, 200, and 500 mg/dm3. Samples were withdrawn at suitable time intervals, filtered through a filter paper and then analysed with UV. qe 0.70C 00.91 k 82.75C 02.03 2 n 1 n 0 n 1 150 200 250 300 70 60 50 Figure 2. Minimum contact time for various percentage BB69 dye removal in a two-stage process 180 40 30 Stage 1 Stage 2 95% Removal 20 160 10 140 Time (min) 100 Figure 3: Comparison of 95% BB69 dye removal time of each stage in two-stage process 0.91 2 0 0.91 0 2.03 0 2.03 0 n 50 Time (min) Time (min) n 50 mg/dm3 100 mg/dm3 200 mg/dm3 500 mg/dm3 2nd order model 0 100Cn1 Cn 100S 82.75C02.03 0.70C00.91 t Rn C0 LC0 1 82.75C02.03 0.70C00.91 t 82.75C 0.70C 100St R LC 1 82.75C 0.70C t 200 180 160 140 120 100 80 60 40 20 0 0 120 0 100 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Adsorption system number 80 60 Table 1. Parameters for effect of initial concentration on the BB69 dye/peat system 99% Removal 98% Removal 95% Removal 90% Removal 40 20 0 0 2 4 6 8 10 12 14 16 Adsorption system number Conclusions 18 20 22 C0 mg/dm3 qe mg/g k g/mg min h mg/g min r2 50 23.78 0.0295 16.67 1.000 100 47.2 0.00662 14.76 1.000 200 86.4 0.001844 13.76 1.000 500 195 0.0002617 9.94 0.997 The design model presented is based on a pseudo-second-order kinetic model, and this has been used for minimizing the reaction time used in a two-stage contact system that operating cost would be reduced. The model has been optimized with respect to contact in order to minimize total contact time to achieve a fixed percentage of Basic Blue 69 dye removal using a fixed mass of peat. An optimised operating condition of 95% removal, the minimum contact time is 40 min, with reaction times of 25 min for stage 1 and 15 min for stage 2.