Passive, Semi-Active and Active Suspension System

advertisement

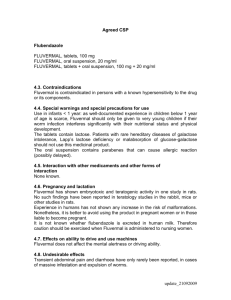

Passive, Semi-Active and Active Suspension System Definition: Suspension system: a mechanical system of springs and shock absorbers that connect the wheels and axles to the chassis of a wheeled vehicle The Function of suspension system: The job of a car suspension are: - to carry the static weight of the vehicle - to maximize the friction between the tires and the road surface, - to provide steering stability with good handling (minimize body roll) - to ensure the comfort of the passengers (ability to smooth out a bumpy road). The Function of Spring and Shock Absorber The Function of Spring: to absorb shock energy from road bump and convert it into potential energy of spring The Function of Shock Absorber: to dissipate shock energy from road bump without causing undue oscillation in the vehicle. Classification of Suspension System • Passive • Semi-Active - Orifice Based Damper - MR fluid based Damper • Active – Slow Active – Active – Fully Active Passive Suspension The damping value (Cs) of a passive damper is determined by the total orifice area (the number of hole) in the piston head. Orifice based Semi-Active Suspension MR fluid based Semi-Active Suspension MR Fluid - Magnetorheological fluid is composed of oil and varying percentages of ferrous particles (20-50 microns in diameter) that have been coated with an anti-coagulant material. - Varying the magnetic field strength has the effect of changing the viscosity of the magnetorheological fluid. Force – velocity relationship Active Suspension System Active suspension system uses hydraulic actuator to reduce the amount of external power necessary to achieve the desired performance characteristics and is able to exert an independent force on the suspension to improve the riding characteristics. Schematic Diagram and Basic Configuration of Hydraulically Actuated Active Suspension System Pneumatically Actuated Active Suspension System Developed in Autotronics Lab - UTeM Active VS Semi-Active • Semi-Active: – Lower implementation cost – Lower power consumption – Easier to control – Simpler design – Easy to install Disadvantage: damper constraint, the force range is limited, performance is not as good as active system Active VS Semi-Active • Active System: – Wider range of force – No force-velocity constraint – Can achieve better performance (vehicle dynamics) Disadvantages: power consumption is high, higher weight to power ratio, expensive, major modification should be made before installing active system into the existing vehicle