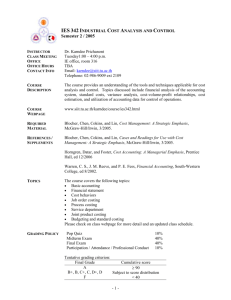

Cost Management and Strategy: An Overview

advertisement

Chapter Sixteen The Management & Control of Quality Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 2 Learning Objectives • Define accounting’s role in the management & control of quality • Define “quality” and the characteristics of total quality management (TQM) • Develop a comprehensive framework for the management & control of quality • Understand two different approaches for setting quality-related goals Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 3 Learning Objectives (continued) • Prepare and interpret relevant financial information to support TQM initiatives • Discuss the use of nonfinancial information to support TQM initiatives • Describe & understand techniques for detecting & correcting quality problems Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 4 Strategic Importance of Quality • Baldridge Quality Award • ISO 9000 and ISO 14000 • Conceptual linkage between Quality and Financial Performance (Exhibit 16.1—see next slide) • Empirical evidence regarding the relationship between quality and financial performance—what do the data suggest? Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 Exhibit 16.1 Improved Quality Lower Return Sales Lower Warranty and Service Costs Lower Manufacturing Cost Higher Perceived Value Higher Prices Higher Market Share Increased Revenue Financial Performance Lower Throughput Time Faster Delivery 6 Accounting’s Role in the Management & Control of Quality • Accountants can add value to the organization by providing decision-makers with relevant financial and nonfinancial information related to quality • Such information actively supports the quality initiatives embraced by management Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 7 Basic Terminology • “Quality”— customer satisfaction with the total experience of a product or service: – Design quality (focuses on the features that customers want) – Performance quality (focuses on product/service performance) • Total quality management (TQM) – Importance of having a good measurement system to support TQM – Limitations of conventional accounting systems? Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 8 Comprehensive Framework for Managing/Controlling Quality: Exhibit 16.3 • Broad business perspective—knowledge of business processes • Paramount role of the consumer • Relevant financial data • Nonfinancial performance indicators • Feedback loops • Linkage to operations management • Breadth of the system—value-chain approach Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 9 Setting Quality-Related Expectations • Six-Sigma approach: – – – – Define Measure Analyze Improve – Control • Goalpost vs. Absolute Conformance: – Goalpost conformance – Absolute quality conformance (robust quality approach) Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 10 Goalpost Conformance Goalpost or absolute conformance assumes that the firm incurs no quality or failure cost or loss if quality measures fall with the specified limits Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 11 Absolute Conformance Absolute quality conformance requires that all products or services meet exactly the target value with no variation allowed Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 12 Financial Measures & COQ Financial information to support TQM initiatives: – Relevant cost information for decision-making (refer to concepts in Chapter 9): • Future costs and revenues that differ between decision alternatives • “Avoidable costs” vs. Sunk costs • Out-of-Pocket costs + Opportunity costs – Cost of Quality (COQ) Reporting Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 13 COQ Reports • Prevention—expenditures incurred to keep quality defects from occurring • Appraisal—costs incurred in the measurement and analysis of data to find out if products and services conform to specification/customer expectations • Internal failure—costs incurred as a result of poor quality found through appraisal prior to delivery to customers • External failure—costs incurred to rectify quality defects after unacceptable products or services reach the customer Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 14 Sample Costs of Quality Prevention: – Quality training costs – Equipment maintenance costs Appraisal: – Testing & inspection costs – Quality audits – Vendor certification – Test equipment and instruments Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 15 Sample Costs of Quality (continued) Internal failure: – Rework costs – Scrap (net of disposal value) – Lost contribution margin because of schedule disruptions External failure: – Costs to handle customer complaints & returns – Lost sales/market share (customer ill-will) – Field service/repair costs – Product liability lawsuits Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 16 Example: COQ Report Prevention costs Training $ Quality planning Other quality improvements Supplier evaluation Total Appraisal costs Testing Quality performance Supplier monitoring Customer surveys Total Internal failure costs Rework and reject Reinspection and testing Equipment failure Downtime Total External failure costs Product liability insurance Warranty repairs Customer losses Total Total quality costs $ Blocher,Stout,Cokins,Chen, Cost Management 4e 2,008 15,000 $ 8,000 6,500 3,000 32,500 2,007 14,000 8,100 6,000 2,500 30,600 % Change 7% -1% 8% 20% 6% 45,000 17,000 28,000 15,000 105,000 47,000 15,000 34,000 21,500 117,500 -4% 13% -18% -30% -11% 7,500 2,500 1,800 2,000 13,800 8,200 3,500 2,000 2,400 16,100 -9% -29% -10% -17% -14% 65,000 106,000 11,000 182,000 346,200 0% 18% 9% 11% 2% 65,000 125,000 12,000 202,000 353,300 $ ©The McGraw-Hill Companies 2008 17 Conformance and Nonconformance Costs Cost of Conformity: – Prevention Costs – Appraisal Costs Cost of Nonconformity: – Internal Failure Costs – External Failure Costs Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 18 Detecting & Correcting Poor Quality Detecting Poor Quality – Control Charts – Statistical Control Charts – Run Charts Correcting Quality Problems – Histograms – Pareto Diagrams (Charts) – “Cause-and-Effect” (“fishbone”) Diagrams Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 19 Control Charts Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 20 Control Charts (continued) The circled observations are unacceptable, that is, they suggest an out-of-control process. Management may want to investigate the underlying causes of these observations and take appropriate corrective action. Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 21 Histograms 70 60 50 40 30 20 10 0 1 1 3 5 2 3 Quality of chocolate Egg size Blending duration Blocher,Stout,Cokins,Chen, Cost Management 4e 4 2 4 6 5 6 Liqueur Blending speed Improper refrigeration ©The McGraw-Hill Companies 2008 22 Pareto Diagram Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 23 Cause-and-Effect Diagram Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 24 Chocolate Mousse Cause-and Effect Diagram Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 25 Appendix: Taguchi Loss Functions General expression of the loss function, L(x), for an observed quality characteristic, x, is: L(x) = k(x -T)2 where: x = an observed value of the quality characteristic T = the target value of the quality characteristic k = the cost coefficient, determined by the firm’s failure costs Total Quality Cost k = --------------------------------------------(Tolerance Allowed)2 Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 26 Taguchi Loss Functions (continued) Your firm has determined that no customer will accept sheet-metal deviating more than 0.05” from the target thickness (0.50”). The cost to the firm is $5,000 for each rejection by a customer. Total Quality Cost k= (Tolerance Allowed)2 $5,000 k= 0.05 2 = $2,000,000 Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 27 Taguchi Loss Functions (continued) L(x) = k(x -T) L(0.47) = $2,000,000(0.47 - 0.50)2 L(0.47) = $1,800 If the actual thickness of a unit is 0.47, then the estimated total loss for the unit is $1,800. Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 28 Chapter Summary • We specified accounting’s role in the management & control of quality • We defined “quality” and the characteristics of total quality management (TQM) • We developed and discussed comprehensive framework for the management & control of quality, and the role of accounting within this framework • We discussed two different approaches for setting quality-related goals (Six Sigma and Goalpost versus Absolute Conformance) Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008 29 Chapter Summary (continued) • We discussed two areas where financial information can be supplied by the accountant to support TQM initiatives: – Relevant cost information for decision-making purposes – Cost of Quality (COQ) Reporting • We discussed the use of nonfinancial information to support TQM initiatives • We described techniques, borrowed from operations management, that can be used for detecting & correcting quality problems Blocher,Stout,Cokins,Chen, Cost Management 4e ©The McGraw-Hill Companies 2008