view slides - AMSUS Continuing Education

advertisement

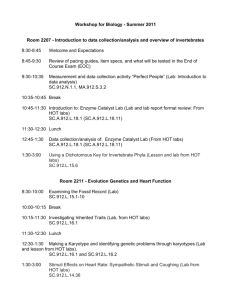

Vietnam's military clinical laboratories strengthen quality management towards ISO 15189 – SLMTA pilot in the military Supported by US DOD PEPFAR Vietnam Presenter Major Nguyen Quang Chien MD, Military Hospital 103, Military Medical University Vietnam Contributing authors 1 Maj. General Vu Quoc Binh MD, PhD; Maj. General Dang Quoc Khanh MD, PhD; Senior Colonel Le Ngoc Anh MD, PhD 2 Trinh Thi Thanh Thuy MD, MPH; Phung Thi Phuong Mai MD; Ngo Manh Hung MSc ; 3 Nguyen Thi Minh Anh MSc; 4 Major Nguyen Quang Chien MD, MSc Affiliations 1 Military Medical Department, Ministry of National Defense, Vietnam 2 US DOD PEPFAR Vietnam, Office of Defense Cooperation, US Embassy Vietnam 3 US Armed Forces Research Institute of Medical Sciences (AFRIMS) 4 Military Hospital 103, Military Medical University Vietnam Disclosures • The presenter has no financial relationships to disclose. • This continuing education activity is managed and accredited by Professional Education Services Group in cooperation with AMSUS. • Neither PESG,AMSUS, nor any accrediting organization support or endorse any product or service mentioned in this activity. • PESG and AMSUS staff has no financial interest to disclose. • Commercial support was not received for this activity. Learning objectives At the conclusion of this activity, the participant will be able to: 1. Understand the overview of program ‘Strengthening Laboratory Management Toward Accreditation’ (SLMTA), and its initiation in the military laboratory system in Vietnam including baseline assessment results. 2. Understand the overview of the SLMTA-required improvement projects and the progresses made by the participating laboratories after one year of program implementation including the lessons learned. 3. Learn of the recommendations on plans to assist the selected laboratories to achieve ISO upon graduating from the program, and expand the program to other military laboratories on a feasible roadmap using the military system's own resources. Presentation outline 1. 2. 3. 4. 5. SLMTA – What is it? SLMTA initiation in military lab system in Vietnam Results from baseline assessment of selective labs Improvement projects made towards ISO 15189 Way-forwards SLMTA – What is it? SLMTA stands for STRENGTHENING LABORATORY MANAGEMENT TOWARD ACCREDITATION SLMTA does what? PROVIDE TASK-BASED TRAINING AND POST-TRAINING MENTORING FOR LABS TO COMPLETE ALL QUALITY MANAGEMENT TASKS. … so that labs can produce improvements that are immediate and measurable, using labs’ own available (usually limited) resources … each and every improvement made, and maintained, brings labs one step closer to ISO 15189 guides steps towards ISO SLMTA – What is it? What bases are out there for SLMTA? ISO 15189 for clinical and public health laboratories WHO AFRO’s Stepwise Laboratory Improvement Process Toward Accreditation (SLIPTA) This SLIPTA checklist is used as SLMTA backbone to guide and measure improvements SLMTA – What is it? The SLMTA standard process Baseline assessment Improvement projects Training Workshop 1 Exit points Improvement projects Training Workshop 2 Improvement projects Training Workshop 3 (3 months) (3 months) (3 months) Site visits Site visits Site visits - Baseline points = SLMTA results Exit assessment SLMTA – What is it? How SLMTA measures improvements? SLIPTA Checklist - the backbone SLIPTA Score band: 0 – 258 Points SLMTA Star band: 0 – 5 Stars 3-4 Star = High potential for continuing to ISO 5 Star = Very ready for ISO application IMPORTANT: SLMTA re-assessment every 02 years 0 – 142 < 55% 143 – 165 55 – 64% 166 – 191 65 – 74% 192 – 217 75 – 84% 218 – 243 85 – 94% 244 – 258 >95% When: JULY 2009 SLMTA launching Where: Kigali, Rwanda Why: To support WHO AFRO’s Stepwise Laboratory Improvement Process Toward Accreditation (SLIPTA) Attended by 120+ experts and policy makers from 12 African countries 9 SLMTA global roll-out Yao K. et al, 2014, Evidence from 617 laboratories in 47 countries for SLMTA-driven improvement in quality management systems, http://www.ajlmonline.org , doi:10.4102/ajlm.v3i2.262 SLMTA in Vietnam – since 2012 Background: •Most labs in Vietnam are limited in human and technical resources, equipment and facilities •Before SLMTA, only few labs get ISO 15189 accreditation •Rare mutual recognition of test results between labs, making repeated testing on one same patient a must if the patient visits another hospital. Costs patients time and money Costs society additional yet unnecessary health expenditures •No official program in place that provides hands-on assistance to and closely monitors labs’ adherence to MoH regulations on lab quality management and assurance. SLMTA in Vietnam – since 2012 Government agency: Ministry of Health (MoH) Technical and funding agency: US CDC Vietnam Round 1: 12 labs, all civilian 05/2012: Baseline assessment 06/2013: Exit assessment Round 2: 14 labs, only 01 military lab 02/2014: Baseline Assessment 10/2015: Exit assessment SLMTA for Tuberculosis Labs (06 labs): on-going, NO military lab TOT/Mentors Training: 02/2012 and 05/2015 Auditors/Assessors Training: 08/2015 SLMTA in Vietnam’s military SLMTA – A priority activity by Vietnam’s Ministry of Defense, backed by US DOD PEPFAR Vietnam Objectives: •TA support to military labs to improve quality management capacity towards accreditation •TA support to build the military’s own capacity for sustained laboratory program (trainers/mentors) Coverage: •7 labs in 4 leading military hospitals (HIV lab, blood transfusion lab, general lab) •3 labs in military centers for hygiene and epidemiology (HIV lab, microbiology lab, virology lab) . SLMTA in Vietnam’s military Coordination agency: Vietnam’s Ministry of National Defense/Military Medical Department Technical focal agency: US Centers for Disease Control and Prevention Vietnam Office US Armed Forces Research Institute of Medical Sciences (AFRIMS), Bangkok, Thailand Coordination and funding agency: US DOD PEPFAR Vietnam, Office of Defense Cooperation, US Embassy Hanoi, Vietnam, via AFRIMS SLMTA in Vietnam’s military 9/2014 Baseline assessment of 15 labs Officially enrolled: 10 labs 1/2016 10/2014 Improvement projects Workshop 1 3/2015 Improvement projects 7/2015 Improvement projects Workshop 3 Workshop 2 (5 months) (4 months) (5 months) Site visits Site visits Site visits Exit assessment of 10 labs SLMTA in military – Baseline assessment results All 15 labs at “ZERO STAR” Average SLIPTA scores: 70.13 points It’s a long way to reach ISO 15189! SLMTA in military – Baseline assessment results Weaknesses found in all areas of a quality management system. Across all labs, the most outstanding areas for improvement, include: •Documents and Records, including importantly Standard Operating Procedures (SOPs) •Equipment preventative maintenance and calibration •Internal quality control and external quality assurance •Facilities and safety, including lab bio-safety SLMTA in military – THE TRAINING WORKSHOPS 10/2014 Workshop 1 Team work SLMTA in military – THE TRAINING WORKSHOPS 3/2015 Workshop 2 Creative trainer SLMTA in military – THE TRAINING WORKSHOPS 7/2015 Workshop 3 and creative trainees SLMTA in military – ON-SITE MENTORING SLMTA in the Military - Improvement Projects and Tasks Important Messages 1… Improvement projects and tasks are standardly designed for all countries. 2… Labs start at very different baseline point on each project/task 3… Most improvements can be made using labs’ own, current resources Things To Do IMMEDIATELY Nearly 40 important tasks are assigned to labs throughout the year, after each training workshop, Labs to execute these IMMEDIATELY. Example tasks include: • Floor plan and workflow rearrangement • Organizational chart • Week/Month calendar work planning • Human resources documents and records • Staff training plan and records • Work-station duty descriptions • Quality indicators monitoring and improvement • Meeting minutes • 5S + 1: Sorting/cleaning/arranging/ maintaining neatness etc. • Temperature control and log chart • Master document file list • Quality handbook drafting • And so many more … Things Completed IMMEDIATELY Workflow re-arranged at all labs: Based on logical analysis “spaghetti” mapping) Military Institute for Hygiene and Epidemiology – AIDS Center Things Completed IMMEDIATELY Org-chart & duty assignment All labs completed organizational charts to help effective communication/collaboration and enforce reporting line Daily duty assignment in place for clear accountability. Central Military Hospital 108 Things Completed IMMEDIATELY HR documents and records All labs improved on human resources documents and records to help with HR management and staff training/re-training/competency assessment planning. Military Hospital 175 – Bio-Chemistry Lab Things Completed IMMEDIATELY Work areas duty description All labs completed task: made clear which tasks in which work areas, which SOPs are to be used there. Central Military Hospital 108 – Immunology Lab Things Completed IMMEDIATELY Quality indicators monitoring All labs started monitoring quality indicators (not the case before), including test TurnAround-Time, rate of rejected specimen, etc… Meeting minute/Quality management progress minute All labs started using meeting minutes routinely as records for quality management tasks. Things Completed IMMEDIATELY Clean and tidy work-space: 5S + 1 All labs maintained clean and tidy work space (much better than before project) Military Institute for Hygiene and Epidemiology – AIDS Center Things Completed IMMEDIATELY … and many many other tasks have been completed. Improvement project 1: Analyze tests’ Turn-Around-Time (TAT), and shorten it What is it: • Aimed to return verified test results earlier and no later than policy required. • Based on process mapping technique, labs to analyze TAT, and find ways to shorten TAT if must be (or if need be). Baseline status: • All labs have long TAT (beyond desired/established timeframe). • Benchmark not yet available at some labs for some tests Current progress: • 100% labs completed project on one test/procedure ONLY TAT improved significantly • Work needed on a lot more tests. Military Hospital 354 Project target: 90% of out-patient tests are returned within 80 minutes. Pre-project: 82.5% - No patient strict queuing - Lab technical work areas are NOT arranged one-way Post-project: 91.8% - Patients take numbers and queue - One-way arrangement of technical areas Improvement project 1: Analyze tests’ Turn-Around-Time (TAT), and shorten it Main challenges: • Changing ‘old’ practices of not documenting all time points especially when involving other department staff; • Work-flow arrangement within labs may not be optimum • Availability of test results verifiers (on-duty doctors, particularly during night shift). • TAT project underway for selective tests only. Labs should roll out on all tests. Improvement project 2: Standard Operating Procedures (SOPs) What is it: • Aimed to issue all needed SOPs (technical and management SOPs) that reflect labs' current resources, and ensure adherence to SOPs. Baseline status: • All labs do not have lab-issued SOPs in place. Few have some. • Long-standing practice of doing things from memories/verbal instructions/ peer coaching. Current progress: • 9/10 labs completed at least 50% of SOPs required • No lab has fully completed this task due to the sheer number of SOPs needed • “SOPs atmosphere” spreading all over labs; attitude have changed dramatically. Southern Preventive Medicine Center – HIV Lab Project target: Complete and issue 50% of SOPs after 3 months (Achieved) Improvement project 2: Standard Operating Procedures (SOPs) Main challenges: • Labs vary in testing menu vary in technical SOPs required. • SOPs are all about “Write what you do!” • A daunting task for all labs. Staff not familiar with writing SOPs needs training/assistance. • Available time of staff to write • And “Do what you write!” • Adherence to SOPs is critical to ensure testing quality • Availability of chief technician/QA manager to supervise adherence to SOPs (well linked to staff competency assessment, Project 5) Improvement project 3: Lab facilities and safety What is it: • Labs to improve all aspects of their lab safety according to ISO standards. Baseline status: • Safety manual not available at all labs to develop • All safety aspects need improvement: • • • • • arrangement of lab sections, access to sterilized vs non-sterilized areas, sorting normal and medical waste, fire and electricity safety equipment/device, PPE, staff vaccination, etc… Current progress: • 100% labs completed improvements within reach. Other improvements pending, including due to funding. • This project proved among the most challenging Military Hospital 103 – Blood Bank Re-arranged/new safety notices Military Hospital 103 – Blood Bank Re-arranged/new safety notices Military Hospital 103 – Blood Bank Waste categorizing protocol, and respective bins right down Improvement project 3: Lab facilities and safety Main challenges: • Change management, funding request, intra-lab and inter-department coordination • Most tasks can be completed with some internal re-arrangements, some require supplies/funds but minimal including sending staff to bio-safety training. Improvement project 4: Store/inventory management What is it: • Labs to improve all aspects of their store and inventory management practices including importantly quality control of test kits/reagents Baseline status: • All labs have non-standardized store and inventory management practices, various areas not meeting basic management principles. • Example of most challenging areas: • forecasting testing reagents supply and budget: labs may forecast, but can not be on top of ordering and procurement process • placing and tracking purchase orders, inventory stocktaking and consumption; storage facilities: in charge of by procuring department • reviewing suppliers including accredited and reliable suppliers: not possible, may or may not happen at procuring department. • etc. Improvement project 4: Store/inventory management Current progress: • 100% labs made improvement in areas within reach (storage, stocktaking etc). • Some areas suffer delays or are difficult (under management by other departments, e.g. suppliers management, purchasing) Main challenges: • Changing old practices at labs • Inter-department coordination for areas outside of labs’ scope Military Hospital 103 – Bio-Chemistry Lab Follow storage standards; List of items attached. Military Hospital 103 – Bio-Chemistry Lab Refrigerator temperature log in place post-project Improvement project 5: Staff competency assessment What is it: • Labs to develop roadmap and work-plan to perform regular assessment of staff competency in their all areas of assignments. • Assessment tasks include developing competency assessment SOP by, question bank, assessment checklists (based on approved SOPs), and direct observation of test demonstration. Baseline status: • All labs practice some sort of staff competency assessment annually, but not as requirements by ISO. • Must plan for staff assessment the way ISO required (more substantial assessment) Improvement project 5: Staff competency assessment Current progress: • 2/10 labs have yet completed any steps. • 8/10 labs issued staff competency assessment SOP and conducted assessment on one or two technical protocols for which SOPs are available. • Further SOPs and associated assessments to be completed. Main challenges: • Not all SOPs have been issued task completion delayed; • Some labs are yet to issue competency assessment SOP. • Time availability to conduct assessment across the board • Staff part-time in different areas including technical large scope of assessment required on any single staff Improvement project 6: Equipment management What is it: • Labs to improve all aspects of their equipment management including importantly making available a plan for and regular conduct of equipment preventative maintenance. Baseline status: • All labs rely on equipment suppliers and/or equipment departments on preventative maintenance, repair and calibration. Very little or no self maintenance in place. • Very limited or no funding for regular maintenance; repair/replacement (by equipment departments) take times (limited funds among the reasons). Improvement project 6: Equipment management Current progress: • All labs have been working on various related tasks: • planning for equipment quality control • requesting directorship for funding for regular conduct of preventative maintenance and regular equipment/devices calibration, spare parts availability, • planning of actions on out-of-work or obsolete items including related SOPs, • etc. • Some labs receive regular maintenance services provided by PEPFAR via AFRIMS Military Hospital 103 – Blood Bank Equipment management SOP Military Hospital 103 – Blood Bank Numbering and tagging all equipment/device Improvement project 6: Equipment management Main challenges: • Preventative maintenance/calibration after end of vendors’ service period rather costly • In some sites: limited awareness by directorship/lab management of equipment preventative maintenance towards general medical quality • Limited available funding; • “other priorities” tend to get funding • Coordination with equipment departments challenging at times • Using certified service providers not yet a practice in Vietnam • Hospitals directorship and/or Ministry of Defense to provide further directions Improvement project 7: Reduce rate of rejected specimens What is it: • Labs to monitor and find solutions to reduce rate of rejected specimens received from clinical departments (for both in-patient and out-patient). Baseline status: • Most labs yet to issue specimen collection manual providing guidance and standards. Training on standards to other departments not yet in place. • At some sites, guidance in place but adherence not strictly re-enforced. Military Hospital 103 – Blood Bank Register Samples for Testing Improvement project 7: Reduce rate of rejected specimens Current progress: • Project assigned in August 2015. Guidance provided. • Preparation for execution in progress. • Survey information to include number and types of specimen rejected, for which tests, from which department etc. (for both in-patient and out-patient). Main challenges: • Approve and issue Specimen Collection Manual • Enforcing adherence to manual by all clinical departments essential to success of project intra-hospital collaboration critical. Improvement project 8: Client-satisfaction survey What is it: • Labs to conduct satisfaction survey on all their client categories: clinical doctors, patients, others as appropriate. Baseline status: • Current practice: Complaints verbally informed to labs without records uncertain to trigger corrective actions and future improvement • Complaint telephone hot-line currently available at some hospitals: Strict actions NOT always certain. Improvement project 8: Client-satisfaction survey Current progress: • Project assigned in August 2015. Guidance provided. • Preparation for execution in progress. Main challenges: • Serious partaking of all client categories critical for ultimately improving overall hospital quality of services. … for each and every improvement made, labs take one step closer to ISO 15189. … most improvements can be made using labs’ own, current resources, and only if all lab leaders and staff join in actions. guides steps towards ISO SLMTA – What is the biggest challenge??? … SLMTA/QMS is a new concept compared to the established practices. … Therefore, it will take time and efforts to get realized SLMTA in military – Common challenges and lessons learned • • • • • Lab space and facilities: Not all labs have decent and well-designed workspace in the first place re-arranging/changes not easy Lab workload: High, particularly at labs in big hospitals SLMTA suffers delays Lab staffing: Under-staffing compared to workload at busy labs Staff training: Not all staff are professionally trained to the tasks assigned QMS staff: Few staff trained on quality management system and possess a QMS mindset it takes time to spread QMS out, and change the ‘old, inefficient’ practices SLMTA in military – Common challenges and lessons learned • • • Intra-lab communication and coordination: Team-work and resultoriented attitude most critical, but need improvement Inter-department coordination: Other departments are involved, and in control for facilities, equipment management, procurement, and storage, etc. Coordination and collaboration with related departments essential. Centrally-managed and funded mechanism: Complicated funds request procedures, QMS-related requests may not be given the needed priority SLMTA suffers SLMTA in military – Recommendations and way-ahead • • • • • • Military Medical Department – MMD/MOD to issue policy and guidance in facilitating SLMTA implementation that also address challenges (some beyond labs’ authority). SLMTA promotes improvements based on current, available resources labs to address all internal challenges observed Exit assessment expectations: 2-3 labs scored at 3 STARS. Recommend MMD to select some highest scored labs at exit for intensive assistance towards ISO. Others may remain on a regular assistance plan to build up SLMTA momentum and maintain improvements made. MMD to facilitate QMS and SLMTA capacity building for more military staff, particularly those trained as trainers. To use military own SLMTA trainers to support system. SLMTA expansion roadmap need be feasible, considering available expert resources including military own resources. Vietnam's military clinical laboratories strengthen quality management towards ISO 15189 – SLMTA pilot in the military Supported by PEPFAR via US Department of Defense Contributing authors 1 Maj. General Vu Quoc Binh MD, PhD; Maj. General Dr. Dang Quoc Khanh MD, PhD; Senior Colonel Le Ngoc Anh MD, PhD 2 Trinh Thi Thanh Thuy MD, MPH; Phung Thi Phuong Mai MD; Ngo Manh Hung MSc ; 3 Nguyen Thi Minh Anh MSc; 4 Major Nguyen Quang Chien MD, MSc THANK YOU AND QUESTIONS? Obtaining CME/CE Credit If you would like to receive continuing education credit for this activity, please visit: http://amsus.cds.pesgce.com