Late Phase Solubility

advertisement

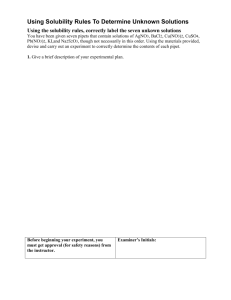

Late Phase Solubility: an Advanced Automated Workflow to Support Crystallization Development Jun Qiu and Benjamin Cohen Late Phase Chemical Development Bristol-Myers Squibb New Brunswick, NJ Outline Motivation Gaps Historical perspective Major automation challenges How we solved these challenges Case study Jun Qiu, Bristol-Myers Squibb Chemical Development Major operations in a chemical synthesis step: 1. Charging 2. Reaction 3. Quenching 4. Crystallization Jun Qiu, Bristol-Myers Squibb Value of Solubility Datasets Combination of empirical data and solubility model Enables decision making in crystallization development Key decisions Solvent & anti-solvent volumes Heating temp Seeding point Filtration temp Impact Yield Purity Powder property Process robustness Cycle time Cost of goods Jun Qiu, Bristol-Myers Squibb Solubility Dataset and Crystallization Development 1) Heat batch to dissolve crystalliz ation scenario 80.0 64.0 2) Cool to reach seeding point Solution.Temperature (C) heptane vol % (%) solubility (wt%) (%) 3) Add seeds to begin crystallization 5) Cool for isolation 48.0 4) Add heptane (anti-solvent) 32.0 Extensive solubility data set and regression enables modeling solubility as conditions change in crystallization process 16.0 0.0 0.0 115.22 230.44 345.66 Time (min) 460.88 576.1 Late Phase Solubility and DynoChem Modeling Initial Solubility Screen Crystallization Selection for Late Phase Late Phase Solubility Study Design Late Phase Solubility Study Execution DynoChem Model for Crystallization Development ab initio Simulation Gaps for Late Phase Solubility High resolution solubility map Extensive solubility data in defined list of solvent mixtures, at range of temperatures Engineers typically conduct manual late phase solubility measurements Challenges with manual method: • Sampling at temperatures other than RT • Variability in techniques • Time-consuming and labor intensive Empirical solubility model fitting is not always achievable with existing tools • DynoChem tool can only model one or two solvent systems • Crystallization systems with three or more solvents are common in manufacturing Jun Qiu, Bristol-Myers Squibb Historical Automation Perspective Automated solubility screening workflow has been in place for 9 years Hundreds of studies per year Large number of empirical solubility data collected Solubility in solvent mixtures Solubility in the presence of additives including impurities Solubility at temperatures other than RT Accurate and consistent solubility data Jun Qiu, Bristol-Myers Squibb Thermodynamic Solubility: Shake Flask Method Add compound Add solvents Incubation Filtration Dilution APIs, intermediates, reagents, by-products, impurities Organic and aqueous solutions Various temperatures Jun Qiu, Bristol-Myers Squibb HPLC Automated Workflow – Hardware Examples Freeslate batch reactor and filter plate (isothermal) Freeslate Liquid Handler with: • Temperature controlled zones • On-deck stirring • Heated needle (22 gauge) Powder Dispenser Jun Qiu, Bristol-Myers Squibb Automated Workflow – Software Examples Freeslate Library Studio enables comprehensive parallel experiment design. Freeslate Automation Studio executes experiment designs. Pictures courtesy of Freeslate Jun Qiu, Bristol-Myers Squibb Major Automation Challenges 1. 2. 3. 4. Solubility in mass fraction (wt%) instead of mg/ml Filtration of saturated solutions at high concentration and at high temperature (e.g. 20 wt% and 90 ºC) High resolution of solubility map (especially solubility vs. temperature) Understanding of accuracy and consistency Jun Qiu, Bristol-Myers Squibb Solving Mass Fraction Challenge Solubility in mass fraction (wt%) instead of mg/ml Use an internal standard to quantitate final solution volume Creative reuse of common unit operations More streamlined compared to alternative approaches No new technology/instrument required Jun Qiu, Bristol-Myers Squibb Solving Mass Fraction Challenge Starts with a familiarization experiment Confirms the use of internal standard has no impact on solubility Jun Qiu, Bristol-Myers Squibb Solving Mass Fraction Challenge 1. 2. 3. 4. Prepare major component solvents with the same concentration of internal standard (IS). X IS = mg IS / mg solvent Carry out the shake flask method. Get compound and IS concentrations in mg/mL by HPLC (may require two injections of different dilutions to quantitate both concentrations). Calculate wt% solubility (i.e. mg/mg) substrate: Csubstrate[mg Sub/mg Solv ] Csubstrate[mg Sub/mL Soln ] X IS [mg IS/mg Solv ] C IS [mg IS/mL Soln ] Csusbtrate[mg Sub/mg Soln] Csubstrate[mgSub / mgSolv ] 1 C substrate[mgSub / mgSolv] Jun Qiu, Bristol-Myers Squibb Solving Filtration Challenges Filtration of saturated solutions at high concentration and at high temperature (e.g. 20 wt% and 90 ºC) Optimize critical unit operations Pushing instruments to the limit Leveraging Freeslate hardware and software’s flexibility Jun Qiu, Bristol-Myers Squibb Solving High Resolution Challenges High resolution of solubility map (especially solubility vs. temperature) Increase experiment scale Taking multiple samples from the same vial Leveraging Freeslate hardware and software’s flexibility Jun Qiu, Bristol-Myers Squibb Solving Accuracy Challenges Understanding of accuracy and consistency Collect large amount of data (unit operations and whole workflow) Compare manual and automated measurements Compare empirical data and model predictions Results will be discussed in Case Study Jun Qiu, Bristol-Myers Squibb Case Study Detailed solubility map of API with the following parameters: MeOH, EtOH, heptane ratios Amount of DBU Amount of methyl benzoate Temperature Key decisions Solvent & anti-solvent volumes Heating temp Seeding point Filtration temp Jun Qiu, Bristol-Myers Squibb Empirical Data Collected from the Automated Workflow • Data collection was contextualized to the process • T data was obtained without (or low) n-Heptane • n-Heptane impact on solubility was obtained at the addition temperature Jun Qiu, Bristol-Myers Squibb Modeled Solubility at Seeding Point Jun Qiu, Bristol-Myers Squibb Modeled Solubility During Heptane Addition Jun Qiu, Bristol-Myers Squibb Solubility Dataset and Crystallization Development crystalliz ation scenario 100.0 Solution.Temperature (C) heptane_vol_perc (%) C_wt_perc (%) 80.0 60.0 40.0 20.0 0.0 0.0 115.22 230.44 crystallization scenario 345.66 460.88 576.1 Time (min) 100.0 yield (%) 80.0 Yield (%) 60.0 40.0 20.0 0.0 crystalliz 0.0 ation scenario 115.22 230.44 0.9 0.72 345.66 460.88 576.1 Time (min) Theoretical rate of crystallization(% / min) 0.54 0.36 0.18 0.0 0.0 115.22 230.44 345.66 Time (min) 460.88 576.1 Modeling the crystallization process can help identify potential issues (e.g. rapid mass deposition leading to undesirable powder properties, mass_dep_rate_perc (%/min) impurity occlusion) and for process optimization (yield, volumes, cycle time) Automated Workflow and Model Accuracy manual automated Manual and automated data agree well Empirical and model predicted data also agree well Conclusion Automated Late Phase Solubility workflow capable of delivering large datasets Wt% Multiple temperatures High Accuracy and consistency Enhanced DynoChem tool capable of modeling complex systems Crystallization systems with more than two solvents Datasets provided by the combined forces of automation and modeling lead to comprehensive understanding of the crystallization process and enable rapid and optimal decision making Jun Qiu, Bristol-Myers Squibb Acknowledgements Erik Rubin Jose Tabora Michelle Mahoney Amit Joshi Masano Sugiyama Keming Zhu Jun Qiu, Bristol-Myers Squibb