The Fukushima earthquake and tdalevere natural events

advertisement

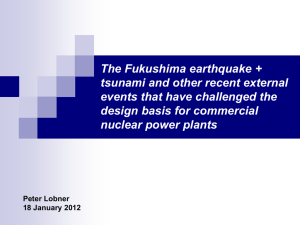

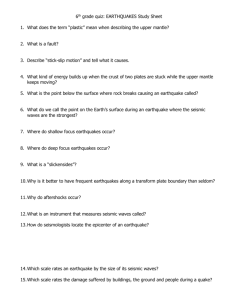

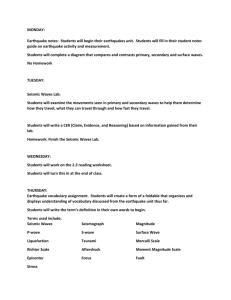

The Fukushima earthquake + tsunami and other recent external events that have challenged the design basis for commercial nuclear power plants Peter Lobner 18 January 2012 Agenda Definition of “design basis” BWR mitigating systems and system dependencies Earthquake Niigata Chuetsu-oki, Japan, magnitude 6.8,16 July 2007 Great East Japan, magnitude 9.0, 11 March 2011 Tsunami Fukushima Daiichi, 11 March 2011 Fukushima Daiichi plant responses to the 11 March 2011 earthquake + tsunami International Response to the events at Fukushima Daiichi Recent external event challenges to U.S. NPPs Missouri River flooding, July – August 2011 Northern VA earthquake, magnitude 5.8, 23 August 2011 Hurricanes Conclusions Definition of design basis Design bases: that information which identifies the specific functions to be performed by a structure, system, or component (SSC) of a facility, and the specific values or ranges of values chosen for controlling parameters as reference bounds for design. These values may be: (1) restraints derived from generally accepted "state of the art" practices for achieving functional goals, or (2) requirements derived from analysis (based on calculation and/or experiments) of the effects of a postulated accident for which an SSC must meet its functional goals. Source: 10CFR50.2 Safety design basis and safety functions Safety design basis focuses on assuring that nuclear power plant (NPP) safety functions defined in 10CFR50 Appendix A, General Design Criteria, can be accomplished when required to protect the integrity of multiple fission product barriers: Accomplish reactor shutdown (GDC 20, 29) Maintain primary system integrity (GDC 14, 15, 31) Maintain reactor core cooling (GDC 33 – 37) Maintain containment integrity (GDC 16, 38-43, 50, 51, 52-57) Maintain the cooling water heat transport path to the ultimate heat sink (GDC 44-46) Prevent an uncontrolled release of radioactive material to the environment from fuel and waste systems (GDC 60-64) Safety design basis for protection against severe natural phenomena GDC 2, Design bases for protection against natural phenomena. SSCs important to safety shall be designed to withstand the effects of natural phenomena such as earthquakes, tornadoes, hurricanes, floods, tsunami, and seiches without loss of capability to perform their safety functions. The design bases for these SSCs shall reflect: Most severe … historically reported for the site and surrounding area, with sufficient margin Combinations of the effects of normal and accident conditions with the effects of the natural phenomena, and The importance of the safety functions to be performed. Generic Letter 88-20, Supplement 4, Individual Plant Evaluation of External Events (IPEEE) for Severe Accident Vulnerabilities Licensees requested to perform analyses to determine vulnerabilities to beyond-design-basis external events and determine if any improvements are needed. SSCs were examined to estimate their “high-confidence-of-low-probability-offailure” (HCLPF) level. Source: 10CFR50 Appendix A, General Design Criterion 2 The design basis is not static 10CFR50.54,Conditions of License, paragraph (f): Value / impact ratio used for prioritizing safety issue resolution is determined using the conversion factor of $2,000/person-rem, which was approved by the Commission in September 1995. Resolving generic safety issues may require utilities to implement changes. For example: The licensee shall at any time before expiration of the license, upon request of the Commission, submit, as specified in § 50.4, written statements, signed under oath or affirmation, to enable the Commission to determine whether or not the license should be modified, suspended, or revoked. Except for information sought to verify licensee compliance with the current licensing basis for that facility, the NRC must prepare the reason or reasons for each information request prior to issuance to ensure that the burden to be imposed on respondents is justified in view of the potential safety significance of the issue to be addressed in the requested information. Station blackout rule (SBO) (10CFR50.63, 1988) Mark I containment hard vents (Generic Ltr 89-16, 1989) Utilities may choose to improve NPP operating capability. Longer operating cycles between refueling Power increase Station blackout rule (SBO) 10CFR50.63: Loss of all alternating current power, requires that each NPP be able to cope with and recover from an SBO event of specified duration 44 U.S. NPP implemented AC-independent solutions Batteries only Maximum coping duration 4 hours 60 U.S. NPPs implemented alternate AC power sources. For example: “Cope” means that the core is cooled and appropriate containment integrity is maintained in the event of a station blackout for the specified duration. Implemented by Regulatory Guide 1.155 and industry document NUMARC 87-00. Emergency diesel generator from an adjacent unit Gas turbine or other diesel generators, hydro generator. Coping duration 4 – 16 hours Non-electric driven pumps (steam, diesel) provide important capabilities for operating cooling and makeup systems during SBO. BWR mitigating systems and system dependencies Key mitigating systems available at the Fukushima Daiichi units BWR Mark-I containment steel shell BWR Mark-I containment arrangement within the reactor building BWR Mark I containment performance improvement (CPI) program Resolution of Generic Safety Issue 157, Containment Performance, resulted in significant modifications to BWR Mark 1 containments. In Generic Letter 89-16 (1989), NRC requested each licensee to provide cost estimates for implementation of a hardened vent. All affected BWRs had in place emergency procedures directing the operator to vent via the non-pressure bearing Standby Gas Treatment System (SGTS) ducting under certain circumstances (primarily to avoid exceeding the primary containment pressure limit). A hard pipe vent path bypassing the SGTS and capable of withstanding the anticipated severe accident pressure loadings would eliminate the problems with venting the containment wetwell during a severe accident. The vent isolation valves should be remotely operable from the control room and should be provided with a power supply independent of normal or emergency AC power (i.e., operable during SBO). GE reports that US operators installed hardened vents in their Mark I BWRs. In 1992, Japan's Nuclear Safety Commission rejected establishing a regulatory requirement for a hardened wetwell vent for Mark 1 BWR containments, leaving it to the NPP operators to decide to install a hardened vent. GE reports that Japanese operators, including TEPCO, installed hardened vents in their Mark I BWRs. BWR Mark-I containment refueling floor arrangement Isolation Condenser (IC) System System Dependencies Automatic start on reactor vessel high pressure or low water level, or remote manual, DC power to open the normally closed valve in the condensate return line AC power to operate normally open valves in the steam supply and condensate return lines Steam supply from main steam line to isolation condenser Periodic water supply to the secondary-side of the isolation condenser to make up for evaporation to the environment Periodic makeup to the primary system to make up for coolant shrinkage during cooldown Source: NUREG/CR-5640 Reactor Core Isolation Cooling (RCIC) System System Dependencies Automatic start on reactor vessel low water level, or remote manual, DC power to open RCIC turbine steam supply valves, injection valve, wetwell suction valves (when needed) Steam from main steam line Turbine exhaust path to wetwell and wetwell pressure < turbine backpressure trip setpoint. Water supply from condensate storage tank or wetwell. Automatic pump suction realignment on CST low level Pump room cooling by service water No cooling for the pump itself. Source: NRC BWR Concepts Manual High-Pressure Coolant Injection (HPCI) System System Dependencies Automatic actuation on reactor vessel low water level or drywell high pressure, or remotemanual DC power to open HPCI turbine steam supply valves, injection valve, wetwell suction valves (when needed) and operate the aux lube oil pump during startup Steam from main steam line Turbine exhaust path to wetwell and wetwell pressure < turbine backpressure trip setpoint. Water supply from condensate storage tank or wetwell. Automatic pump suction realignment on CST low level Pump room cooling by service water No cooling for the pump itself. Source: NRC BWR Concepts Manual Low-Pressure ECCS and Residual Heat Removal (RHR) System Dependencies Automatic pump actuation on reactor vessel low water level or drywell high pressure, or remotemanual Automatic Depressurization System (ADS) actuation on low vessel level + high drywell level + LP ECCS pump running AC power for LPCS and LPCI (RHR) pumps & valves DC power to open ADS valves Water supply from wetwell. Pump room cooling by service water RHR pump cooling by service water Source: NRC BWR Concepts Manual Niigata Chuetsu-Oki Earthquake (NCOE), Japan, magnitude 6.8, 16 July 2007 Niigata Chuetsu-Oki Earthquake (NCOE), Japan, magnitude 6.8, 16 July 2007 Source: TEPCO Source: EQECAT Inc Kashiwazaki-Kariwa NPP World’s largest nuclear power facility: 7,965 MWe net from 7 BWR units. U1 – 5: BWR, 1067 MWe U6 & 7: ABWR, 1315 MWe During NCOE: 3 operating at rated power (U3, U4 & U7) 1 starting up (U2) 3 shutdown for periodic inspection (U1, 5 & U6) 16 km from NCOE epicenter. No tsunami. Kashiwazaki-Kariwa NPP Source: TEPCO NCOE observed seismic data The observed seismic accelerations largely exceeded the design basis values. Source: TEPCO NPP response to NCOE (1/2) Units operating (Units 3, 4 & 7) and being started up (Unit 2) automatically scrammed on detection of large seismic acceleration. Off-site power remained available during and after NCOE. Reactor vessel water level maintained in all units. Reactor cooldown and depressurization accomplished. Reactor coolant at all units cooled to below 100ºC. Reactor pressure in each unit reduced to atmospheric pressure Stable cold shutdown condition achieved by 17 July. In spite of significantly exceeding the original seismic design basis, the safety-related structures, systems and components at all seven units demonstrated good performance and accomplished their intended safety functions. NPP response to NCOE (2/2) No change in fission product concentration in reactor coolant and spent fuel water, indicating that fuel in all units was sound. Minor releases of radioactive material: Some water sloshed out of the Unit 6 spent fuel pool. Many containers of LLW overturned, some lids came off. Minor release via main stack detected on 17 July at Unit 7. Relatively minor physical damage, mainly to non-safetyrelated items. Mechanical: anchorages, ducting to main stacks, various water, oil & air leaks Structural: wall & embankment cracking Ground deformations, with potential to damage underground tunnels & pipeways and surface roads & drainage paths. Transformer fire Improved understanding of site seismicity The NCOE seismic intensity exceeded the original seismic design basis for all NPP units. The NCOE seismic intensity also exceeded the seismic intensity estimated from an empirical evaluation of a magnitude 6.8 earthquake. Japan’s newer (2006) seismic design guidelines redefine “active faults” and the process for defining a Standard Seismic Ground Motion (SSGM) to be used in design. Post-NCOE seismic study findings: New and extended fault lines. Geologic structure amplifies seismic motion from sea-side. Differences between the Unit 1-4 and Unit 5-7 sites, which are 1 km apart. Source: TEPCO Standard seismic ground motion (SSGM) defined for Kashiwazaki-Kariwa NPPs. Post-NCOE seismic hazard studies yielded the largest values for ground motion ever considered for a nuclear power plant site. Source: TEPCO Post-NCOE safety actions Install seismic reinforcements to tolerate seismic motion of 1000 Gal (~1.5 times NCOE max) Perform facility integrity evaluation Add more pipe snubbers & pipe supports Reinforce reactor building roof truss structure Reinforce reactor building overhead crane, including derailment prevention Reinforce refueling machinery, including derailment prevention Add vibration control device for stacks Confirm NCOE loads on each equipment was within applicable elastic limits. Perform equipment, system & plant-level functional inspections & tests EPRI supporting evaluation of “hidden damage” Improve the spent fuel storage pool structure to prevent radioactive water overflow (from seismic-induced sloshing) by Sep 2012. Re-start status May 2009: Unit 7 re-started (22 mos) August 2009: Unit 6 re-started (25 mos) May 2010: Unit 1 re-started (34 mos) November 2010: Unit 5 restarted (40 mos) Units 2 – 4: investigations, modifications & tests in-progress. Unit 3 likely to be next unit restarted. Great East Japan Earthquake, magnitude 9.0, 11 March 2011 Great East Japan Earthquake, magnitude 9.0, 11 March 2011, 14:46 JST Source: EQECAT Inc Source: USGS • An earthquake of this magnitude is unprecedented in this region. • Megathrust rupture on the Japan Trench subduction zone • Earthquake lasted about 2 -2.3 minutes • 11 aftershocks on 11 March, ranging from 6.0 to 7.4. Fukushima Daiichi NPP One of Japan’s larger nuclear power facilities: 4,696 MWe net from 6 BWR units. U1 = BWR 3 U2 – 5 = BWR 4 U6 = BWR 5 During earthquake: 3 operating at rated power (U1, 2 & 3) 3 shutdown for periodic inspection (U4, 5 & 6) 112 miles from epicenter. Design basis tsunami: 18.8’ (5.7m) Fukushima Daiichi Site Arrangement Source: INPO Observed seismic data at Fukushima Daiichi • Design Basis Earthquake maximum acceleration exceeded at Units 2, 3 and 5. • The power lines connecting the site to the off-site transmission grid were damaged during the earthquake, resulting in a loss of all off-site power. • All reactor safety functions were successfully performed after the earthquake and all units were in a safe state prior to the arrival of the tsunami. Tsunami following the Great East Japan Earthquake, 11 March 2011 Tsunami timeline at Fukushima Daiichi 15:27: First of seven tsunami waves arrived. Height about 13’ (4 m) was less than the design basis tsunami and was mitigated by the breakwater. 15:35: Second tsunami wave arrived. Height unknown. Tidal gauge failed. Five more tsunami waves. At least one of the waves measured 46’ – 49’ (14 – 15 m) high based on water level indications on the buildings. Unit 1 – 4 site area inundated to a depth of 13’ – 16’ (4 – 5 m) above grade. Grade level at the Unit 5 & 6 site area is 3 m higher, so inundation there was less. Tsunami wave arrives at Fukushima Daiichi Tsunami wave arrives at Fukushima Daiichi Site inundation Site inundation Site inundation Tsunami effects on storage tank Fukushima Daiichi site inundation Source: IAEA Fukushima Daiichi Units 1 – 4 inundation Source: INPO Flooding resulted in common cause failure and loss of the ability to perform key safety functions: Intake structure, pumps, and flow paths to the ultimate heat sink (the ocean) at Units 1 - 6. Most main and safety-related AC and DC electric power sources and distribution rooms / areas needed to support active safety systems at Units 1 - 5. DC in Units 3, 5 & 6 survived. Fukushima Daiichi plant responses to the 11 March 2011 earthquake + tsunami Decay heat – reactor units 1, 2, 3 Source: MIT Decay heat – spent fuel pools Fuel response to severe accident progression Unit 1 sequence of events Adapted from INPO Unit 1 sequence of events (continued) Adapted from INPO Unit 1 Hydrogen Explosion, 12 March 2011 Loss if lighting in the control room Source: TEPCO Unit 2 sequence of events Adapted from INPO Unit 2 sequence of events (continued) Adapted from INPO Unit 3 sequence of events Adapted from INPO Unit 3 sequence of events (continued) Adapted from INPO Unit 3 Hydrogen Explosion, 14 March 2011 Unit 4 sequence of events Adapted from INPO Unit 4 after hydrogen explosion Possible hydrogen leak path to Unit 4 Source: INPO Units 1-4 before the tsunami & explosion Units 1-4 after the explosion Unit 5 & 6 sequence of events Source: SECY-11-0093 Severe accident response issues TEPCO confirmed that adverse conditions in the drywell may have resulted in boiling of the reference legs of the reactor vessel water level instruments, causing indicated water level to be higher than actual level. TEPCO severe accident procedures provided guidance for venting containment: If core damage has not occurred, vent at containment maximum operating pressure: 62.4 psig for U1, 55.1 psig for U2 – U5 If core damage has occurred, delay venting until pressure approaches twice the maximum operating pressure. In Units 1, 2, and 3, the extended duration of high temperature and pressure conditions inside containment may have damaged the drywell head seals, contributing to: Hydrogen leaks into the upper level of the reactor building and the subsequent explosions, and Ground-level radiation releases Severe accident response issues Was there a re-criticality at Unit 2? While examining gases taken from the reactor, short-lived fission product Xe-133 was detected on 2 November 2011 Boric acid water injected TEPCO general manager: "Given the signs, it's certain that fission is occurring." The next day, TEPCO spokesman: "Analysis suggests that it was not a criticality” Protective actions Source: SECY-11-0093 Cleanup and Decommissioning Plan December 2011: TEPCO released its 40-year plan to decommission the plan: Phase 1: Post cold shutdown stabilization and planning Phase 2: Removal of fuel from the spent fuel pools Maintain stable reactor & site conditions Conduct R&D for later phases Complete within 2 years (by end of 2013) Remove fuel from spent fuel pools in all units Process accumulated water Conduct R&D for later phase Complete within 10 years (by end of 2021) Phase 3: Removal of fuel debris through final decommissioning & cleanup Fuel debris removal in U1, 2 and 3 Decommissioning and site cleanup Complete in 30-40 years (by 2041 – 2051) International Response to the Fukushima Daiichi Accident USA Aug 2011: NRC released the results of its 90-day review of Fukushima lessons learned No "imminent threat“, but some issues require immediate action: Ability to withstand prolonged loss of AC power Ability to respond to earthquakes and flooding, and Ability to monitor the condition of spent fuel pools. Sep 2011: NRC issues, “Recommendations for Enhancing Reactor Safety in the 21st Century”, with 12 recommendations, including Balance “defense in depth” and risk considerations As needed, upgrade design basis seismic and flood protection Strengthen prolonged station blackout mitigation Study adequacy of hydrogen control Enhance spent fuel makeup capability and instrumentation Strengthen on-site emergency response & accident management USA Nov 2011: Proposed ballot initiative in California calls for immediate shutdown of PG&E’s Diablo Canyon and SCE’s San Onofre NPPs, which generate 16% of California's power. Dec 2011: NRC approved the Westinghouse AP1000 standard plant design 13 Jan 2012: Industry – NRC meeting to recommend an approach for post-Fukushima improvements Diverse and flexible coping strategy (FLEX) for preventing fuel damage. FLEX differs from Severe Accident Management Guidelines (SAMGs), which come into play after core damage. FLEX is designed to expand the margin of safety at nuclear energy facilities and ensure they can cope with extended loss of power using pre-staged backup equipment and supplies—such as fresh water and diesel fuel that are available on-site—supplemented by off-site resources established for this purpose. Approach builds on concepts used to provide additional contingency at U.S. nuclear facilities after the 9/11 attacks. European Union (EU) “stress test” The European Council of 24-25 March 2011 requested that the safety of all EU NPPs be reviewed on the basis of a “stress test“. A reassessment of NPP safety margins in the light of the events that occurred at Fukushima Extreme natural events challenging the plant safety functions and leading to a severe accident. A deterministic sequential loss of lines of defense is assumed, irrespective of the probability of the loss. The final country-specific reports were due to be submitted to the European Nuclear Safety Regulators Group (ENSREG) by December 31, 2011. The next stage is a peer review of the country-specific reports, to be completed by April 30, 2012 A consolidated EU report will be issued in June 2012. These reports are publically available on the ENSREG web site: http://www.ensreg.eu/ France Current fleet of 58 NPPs has a generating capacity of 63,130 MWe and produce >75% of France’s electricity. One new 1600 MWe EPR unit is under construction and one more committed in Nov 2011. Nov 2011: Green and Socialist parties call for shutting down 24 NPPs across France by 2024. President Sarkozy said the proposal would cost French consumers €5 B ($6.63 B) a year. Dec 2011: First phase of EU “stress test” completed. Jan 2012: French Nuclear Safety Authority (ASN) stated that current NPPs have a “sufficient” safety level, but called for significant safety investment from EDF; on the order of €10 B (about $13.5 B) over 10 years. Identified safety improvements include: Flood-proof diesel generators, and Bunkered remote back-up control rooms Nuclear Fast Response Force available to support an NPP site within 24 hours EDF is planning to operate its fleet of PWRs for 60 years. Germany Current fleet of 17 NPPs has a generating capacity of 20,429 MWe and produce about 23% of Germany’s electricity. 30 June 2011: the country's parliament voted to phase out Germany's nuclear fleet The 8 oldest reactors (> 8,000 MWe) already have been disconnected from the grid The remaining 9 reactors will be retired by 2022 Sep 2011: International Energy Agency warns German government of risky phase-out strategy Switzerland Current fleet of 5 NPPs has a generating capacity of 3,220 MWe and produce about 38% of Switzerland’s electricity Parliament approved nuclear phase-out in 2011. Preliminary phase-out plan: Beznau I in 2019 (365 MWe) Beznau II and Muehleberg in 2022 (720 MWe combined), Goesgen in 2029 (970 MWe) Leibstadt in 2034 (1165 MWe) Sources of replacement power It has been estimated that the cost of reshaping the country's energy resources, offset by measures to cut consumption, would cost the country between 0.4 - 0.7 % of gross domestic product per year. Development of hydro-electric plants and other renewable energy Possibly importing electricity. If necessary the country could also fall back on electricity produced by fossil fuels. 2010 GDP was $524 B, so phase-out costs $2.1 – 3.7 B / year Swiss nuclear safety authority ENSI requires EU “stress tests” applied to Swiss NPPs. Belgium Current fleet of 7 NPPs has a generating capacity of 5,885 MWe, which represents 92% of domestic energy generation and 22% of domestic energy consumption. Belgium imports most of its energy. In October 2011, the Belgian government committed to implementing the nuclear exit law of 2003. The plan calls for the following shutdown schedule: The three oldest NPPs by 2015 (1787 MWe) The remaining four NPPs by 2025 (4098 MWe) This plan is conditional on finding enough energy from alternative sources to prevent electric supply shortages and significant change in the price of electricity. Elsewhere in Europe Italy: Lithuania: July 2011: GE-Hitachi was selected to build a new BWR NPP to replace the Ignalina NPP, which is being decommissioned Will reduce Baltic state’s energy dependence on Russia. Finland: Italy has no NPPs In a 12-13 June 2011 referendum, voters rejected government plans to build new nuclear plants. October 2011: First in Europe to approve a new green-field NPP site since the Fukushima Daiichi accident. Poland: Still moving ahead to select NPP supplier in 2013, with initial operation of Poland’s first NPP in 2020. Japan In 2010, the Japanese government approved a plan to build 14 new NPPs and increase reliance on nuclear energy. Current fleet of 48 NPPs (excluding 6 units at Fukushima Daiichi) has a generating capacity of 42,300 MWe and produce about 25% of Japan’s electricity. Since the Fukushima Daiichi accident, all reactors that have been shut for regular maintenance have been kept offline as part of efforts to assuage public concerns about nuclear safety. Only 6 NPPs operating in Japan at the end of 2011. July 2011: Japanese Prime Minister states the country must eliminate dependence on nuclear power. Japan Tepco proposed to install a system of tide barriers with watertight doors at Kashiwazaki Kariwa units 1 to 4. In addition, TEPCO has installed facilities on the upland part of the site to provide backup power and water injection to the reactors and spent fuel pools, and taken measures to ensure cooling functions in the event of tsunamis flooding the reactor buildings Japan Oct 2011: Nuclear Safety Commission will mandate that Japan’s utilities install “reinforced sources of electric power” at all NPPs Kansai Electric submit the results of the “stress test” for Ohi Unit 3 to the Nuclear and Industrial Safety Agency (NISA). Dec 2011: First stress test to be reported to NISA for consideration on restarting a shutdown reactor. New nuclear safety agency is being formed under the Environment Ministry from the merger of the Nuclear and Industrial Safety Agency of the Ministry of Economy Trade and Industry and the Nuclear Safety Commission of Japan Parliament appoints an independent panel formed to investigate the Fukushima Daiichi incident Jan 2012: Japanese Prime vowed to revive the region surrounding the Fukushima Daiichi nuclear plant Amendment proposed to Japan’s Nuclear Plant Operations Law to limit NPP operating life to 40 years China Japan's Fukushima nuclear disaster in March led China to delay all nuclear project approvals. Dec 2011: China has approved a five-year nuclear safety plan, which is a prelude to their nuclear development plan that is expected to reduce the 2020 nuclear capacity target by about 10%. Northern VA earthquake magnitude 5.8 23 August 2011 U.S seismic design basis Licensing bases for existing NPPs considers historical data at each site. Data are used to determine design basis loads from the area’s maximum credible earthquake, with an additional margin included. In Generic Letter 88-20, the NRC required existing NPPs to assess their potential vulnerability to earthquake events, including those that might exceed the design basis. Following the events of September 11, 2001, NRC required all nuclear plant licensees to take additional steps to protect public health and safety in the event of a large fire or explosion. If needed, these additional steps could also be used to mitigate severe natural phenomena. The NRC examined new Central & Eastern US (CEUS) earthquake hazard information under Generic Issues GI-199 and completed a limited scope screening analysis for the seismic issue in December 2007. New CEUS seismic data were compared with earlier seismic evaluations. This analysis confirmed that operating nuclear power plants remain safe with no need for immediate action. Northern VA earthquake magnitude 5.8, 23 August 2011 • Very short duration peak acceleration (1 – 3 sec). • No fault associated with the earthquake epicenter and aftershocks. • No surface ruptures during the earthquake. • NRC classifies as “blind reverse fault”. Northern VA earthquake magnitude 5.8, 23 August 2011 Although the U.S. east of the Rockies has fewer and generally smaller earthquakes than the West, due to geologic differences, eastern earthquakes affect areas 10 time than western ones of the same magnitude. (ref: NJ Geologic Survey) Hard ground and fewer faults Effective in conducting seismic waves over long distances. USGS estimated the earthquake produced a peak ground acceleration of 0.26g at the North Anna NPP First time that an earthquake has exceeded the design basis for a U.S. NPP. North Anna NPP Seismic design basis: DBE, structures on rock: 0.12g horiz, 0.08 g vert DBE, structures on soil: 0.18g horiz, 0.12g vert OBE = ½ DBE 2 unit Westinghouse PWRs Net 1,806 MWe Both operating at 100% power when earthquake occurred Site includes an independent spent fuel storage installation 11 miles from epicenter Plant response to the earthquake Reactor tripped automatically Reactor trip system does not include an automatic seismic scram. Direct cause for both Units 1 & 2 reactor trip was detection of high rate of change of neutron flux (decreasing) in the power range nuclear instruments (>5% change in 2.5 seconds). Root cause is believed to be a synergistic combination of seismicallyinduced conditions: Core barrel, core & detector movement. Momentary change in thermal boundary layer conditions along the fuel rods. Momentarily under-moderated core with oscillatory but overall decreasing flux. Turbine tripped automatically and offsite power lost Main turbines tripped because of main transformer “lockout”, which interrupted the connection to the off-site grid. The earthquake caused multiple transformers to lockout due to activation of sudden pressure relays, which operated as designed due to earthquake-induced pressure pulses within the transformer, not due to an electrical fault. NPP connection to offsite power restored about 7 hours later. Mitigating systems started automatically Reactor power during earthquake, before scram Scram North Anna earthquake timeline Date Time Events at North Anna NPP 23 Aug 2011 1351 5.8 magnituide earthquake Automatic reactor trip Loss of offsite power and automatic main turbine trip Automatic actuation of auxiliary feedwater system, charging system, emergency diesel generators, and service water system 1403 Alert declared. Operators focus on stabilizing each unit and restoring offsite power. 2055 NPP connection to offsite power restored 24 Aug Unit 1 cooldown to cold shutdown started. Unit 2 cooldown started after Unit 1 cooldown completed 26 Aug Review of seismic data determined that seismic acceleration potentially exceeded the Design Basis Earthquake at frequencies above 5 Hz. Aug - Oct Plant walkdowns, inspections, tests and analysis do not reveal any significant physical or functional damage to safety-related structures, systems or components, and only limited damage to non-safety, non-seismic SSC. 1 Nov Public meeting with NRC to address readiness to re-start 11 Nov NRC approves re-start 18 Nov Unit 1 back at 100% power 21 Nov Unit 2 back at 100% power U.S. restart requirements and guidance Appendix A to 10CFR100—Paragraph V(a)(2): “If vibratory ground motion exceeding that of the Operating Basis Earthquake occurs, shutdown of the nuclear power plant will be required. Prior to resuming operations, the licensee will be required to demonstrate to the Commission that no functional damage occurred to those features necessary for continued operation without undue risk to the health and safety of the public.” Regulatory Guide 1.166, Pre-earthquake planning and immediate NPP Operator Post-earthquake Actions” (1997) Cumulative Absolute Velocity (CAV) is a measure of the damage potential of earthquake ground motion NRC, EPRI and industry agree on a CAV threshold If CAV calculation > 0.16 g-sec, then OBE exceeded Regulatory Guide 1.167, “Restart of Nuclear Power Plant Shut Down by a Seismic Event” (1997) EPRI NP-6695, “Guidelines for Nuclear Power Plant Response to an Earthquake” (1990) Dominion report of readiness to re-start Acceleration criteria were briefly exceeded in certain directions and frequencies by a strong, but very short duration earthquake Previous IPEEE evaluations establish that safe shutdown systems, structures and components can handle peak accelerations above design basis No safety-related systems, structures or components required repair due to the earthquake No significant damage was found or should have been expected and results of expanded tests and inspections have confirmed expectations Commitments: By February 2012: With Westinghouse, develop a plan for additional evaluations or inspections to assure long-term reliability of reactor internals. By December 2012: Improve seismic monitoring equipment. By March 2013: Reevaluate equipment identified in the Individual Plant Evaluation of External Events (IPEEE) with a high-confidence-of-lowprobability-of-failure (HCLPF) capacity of <0.3g and recommend potential improvements Source: Dominion 31 Oct 2011 letter to NRC and 1 Nov 11 presentation Basis for post-earthquake integrity of North Anna structures, systems & components 0.16 g-sec ------- Source: Dominion 1 Nov 11 presentation to NRC Missouri River Flooding Fort Calhoun NPP June – August 2011 U.S. design basis flood and flood protection A design-basis flood is a flood caused by one or an appropriate combination of several hydrometeorological, geoseimic, or structuralfailure phenomena, which results in the most severe hazards to structures, systems, and components (SSCs) important to the safety of a nuclear power plant (NUREG/CR-7046). Sources of requirements & guidance: USNRC Regulatory Guide 1.59, “Design Basis Floods for NPPs” (1977) USNRC Regulatory Guide 1.102 (R1), “Flood Protection for NPPs” (1976) Standard Review Plan 3.4.1, R2, “Flood Protection” (1981) NUREG/CR-7046, Design-Basis Flood Estimation for Site Characterization at Nuclear Power Plants in the United States of America (Nov 2011) Temporary flood barriers, such as sandbags, plastic sheeting, portable panels, etc., which must be installed prior to the advent of the DBFL, are not acceptable for issuance of a construction permit. However, unusual circumstances could arise after construction that would warrant consideration of such barriers. One example of unusual circumstances that might justify use of temporary barriers is a post-construction change in the flood-producing characteristics of the drainage area….. In such circumstances, and with strong justification, the staff may accept temporary barriers (RG 1.102) Fort Calhoun NPP site Source: ORNL-NSIC-55, V1 Missouri River floods Fort Calhoun NPP site • Site grade elevation: 1004’ MSL, includes an independent spent fuel storage installation • Alert level: 1006’ MSL • Auxiliary building ground floor level: 1007’ MSL • Tech Spec reactor shutdown level:1009’ MSL • Current design basis flood level: 1014’ MSL with NPP main buildings & switchyard protected by temporary barrier (AquaDam®) Missouri River floods Fort Calhoun NPP site AquaDam® temporary barrier OPPD refers to the water-filled AquaDam® as a supplemental flood protection measure that provides protection up to 1014’ MSL. Equipment at or below grade in the auxiliary building that must be protected from flooding 1007’ level: Both divisions of AC and DC power Alternate shutdown panel New fuel storage 989’ level: Diesel generators Batteries 4160 VAC, 480 VAC and 125 VDC electric panels Emergency feedwater pumps 480 v Class 1E panels 971’ level: High pressure safety injection (ECCS) pumps Low pressure safety injection / shutdown cooling pumps Fort Calhoun flood timeline Date Events at Fort Calhoun NPP 9 Apr 2011 NPP in cold shutdown for routing refueling 6 Jun Notice of Unusual Event (NOUE) due to high river level 8 Jun Fire in switchgear temporarily disables spent fuel pool cooling 17 Jun NRC implements 24 hr/day augmented coverage 26 Jun Worker punctures AquaDam® with bobcat. Plant temporarily disconnected from offsite power to protect switchyard equipment that might become flooded. NPP loads supplied from the diesel generators. 29 Jun Missouri river crests at Blair 11 Jul Re-installation of AquaDam® complete, water within the confines of the dam perimeter removed. 23 Jul Second Missouri river crest at Blair 29-30 Jul NOUE rescinded, NRC suspends 24 hr/day augmented coverage. 10 Aug OPPD issues post-flood recovery plan. Updated 30 Aug. 6 Oct NRC issues finding of inadequate flood protection strategies. 14 Dec NRC delays plans to restart Fort Calhoun at least to 2012 Q2. 17 Dec OPPD issues LER for inadequate flood protection for intake structure and auxiliary building due to unsealed wall and ceiling/floor penetrations and other reasons. Hurricanes Hurricane Andrew - 1992 Category 4 Hurricane Andrew – 1993 First time a hurricane significantly affected a U.S. NPP Hurricane passed over 2-unit Turkey Point NPP, which was shut down 4 hours prior to the onset of hurricane strength winds 145 mph winds, gusts to 175 mph The onsite damage included loss of all offsite power for more than 5 days, complete loss of communication systems, closing of the access road, and damage to the fire protection and security systems and warehouse facilities. No damage to the safety-related systems except for minor water intrusion. There was no radioactive release to the environment. Hurricane Andrew - 1992 Hurricane Irene - 2011 Category 3 Hurricane Irene – 2011 Only two NPPs in the hurricane’s track were shut down: All In Maryland, one reactor at the Calvert Cliffs plant automatically went off-line when wind blew a piece of aluminum siding into the unit’s main transformer in the switchyard. The second unit remained online In New Jersey, the Oyster Creek NPP was taken offline as a precaution ahead of expected high winds and storm surge. others remained on-line throughout the storm. Hurricane Irene - 2011 Conclusions NPPs have demonstrated their robustness and ability to withstand some beyond design basis severe natural events and then be able to return to operation. The magnitude of some beyond design basis severe natural events were much greater than expected based on pre-event knowledge of historical events and site characteristics. The common cause failure potential for some beyond design basis severe natural events has been grossly underestimated. It is time to redefine the nuclear regulatory process and develop a more effective approach for assuring that nuclear safety functions can be accomplished when required so nuclear power plants can cope with events and combinations of events that exceed the traditional design basis.