Inventors: Dan Pastrick, et al

advertisement

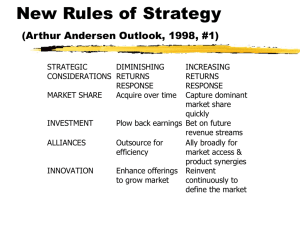

Executive Resume Dan L. Pastrick St. Joseph, Michigan 49085 Phone: (205) 789-8420 Email: dnpastrick@gmail.com Expertise Engineering and Operations Management, Leadership and Team Building, Lean Quick Response Manufacturing, Supply Chain Management, Inventory Management, Capital Equipment, Budgeting and Project Management. Leadership Profile Proven senior executive and VP of operations, engineering, and manufacturing in a demanding field (medical device design and manufacturing,) with a history of dramatic company turnarounds and six patents to his name. Six Sigma Certified and Lean Sigma leader for manufacturing and operations, excels at motivating coworkers and building dynamic teams that are invested in their missions. Highly intuitive, able to anticipate market trends and prioritize product designs accordingly to maximize their impact. Focused and persistent. Strong understanding of public relations in the globally-wired marketplace. His rare insight into developing trends is exemplified in this infographic: Professional Experience Medtronic (Formerly Osteotech), Eatontown, NJ 2011 to 2014 Senior Engineering Manager: Directed resources and continuous improvement projects as they underwent process optimization and completion of validation activities. Oversaw the execution process of new projects to ensure they would meet their timing, budget, and product quality requirements. Developed budgets, capital justifications, and implementation plans. Responsible for ~$1.5M operating budget, 6, direct reports, and 1 indirect report. Championed a custom fiber mill design while leading a major cost reduction project, saving $1,000,000+ annually. Defined and implemented new processes with an eye toward emerging products, resulting in improve quality, throughput, and capacity. Executed Policy Deployment initiatives via Manufacturing Engineering / Cross Functional Teams Defined and implemented solutions for all medical device product lines for process opportunities to improve quality, throughput, and capacity Drove production support via timely completions of Non-Conformance Reports and CAPA's utilizing Six Sigma tools (DMAIC) and techniques. Organized a variety of strategic improvements in processing which set the stage for production growth across all lines. Osteotech,Eatontown, NJ 2009 to 2011 Strategic Business Unit Director: Led the strategic and technical efforts to aseptically manufacture the latest bone fusion product line. Directed the production scale-up, and achieved the lowest failure rate for any aseptic biologic product ever made on site. Budget accountability for three cost centers. Responsible for 6 direct reports. Organized and directed a major aseptic bone tissue project through production release, successful aseptic validations and monthly production builds – all while decreasing production time and increasing yields. Accelerated the new product transfer process which enabled release of five new sizes of Magnafuse products on time in the first year of launch. Defined and implemented solutions for processing opportunities for emerging products to improve quality and output. Secured an 18-month continuous production of the most difficult product line to date, experiencing no sterility failures in the process. Biohorizons Implant Systems, Inc., Birmingham, AL 2007 to 2008 VP of Manufacturing: Directed the manufacturing strategy for a dental implant company. Planned and completed the floor build-outs for manufacturing – including a controlled environment for final cleaning and packaging – plus assembly, receiving, and warehousing. Developed budgets and capital equipment justifications to support the initiative. Established priorities and allocated necessary resources. Managed manufacturing, purchasing, receiving, packaging, and maintenance. Oversaw ~$1.25M operating budget, 7 direct reports. Convinced top management the equipment from a newly acquired competitor would establish the company’s first in-house manufacturing capabilities and saved $1,000,000 in capital appropriations. Instituted the in-house manufacturing process. Identified and acquired all manufacturing capital and support equipment, and completed build-outs for the Machine Shop and controlled environment Packaging room. Developed and implemented the launch strategy for the company’s first Enterprise Resource Planning (ERP) and manufacturing system, providing accurate documentation of the processes, material and labor costs, shop floor reporting, and receiving functions. Revised Standard Operation Procedures (SOP) for Manufacturing, and streamlined existing Work Instructions to increase throughput and reduce non-value added labor. Helix Medical, LLC / Freudenberg NOK, Carpinteria, CA 2002 to 2007 VP of Operations: Led manufacturing, engineering and operations for the silicone rubber medical manufacturer, specializing in molded, extruded, and assembled medical products for Custom / OEM markets, as well as the silicone and plastic products used in InHealth’s voice restoration prosthetics worldwide. Drove performance-improvement efforts across all operations. Managed budget and profitability across manufacturing, manufacturing engineering, quality, supply chain, facilities, machine shop, shipping and receiving. Responsible for ~$8.5M operating budget, 8 direct reports and 110 indirect reports. Increased operating income on average 28% year over year for three consecutive years Improved gross margins on an average 16% per year with continuous process improvements. Reduced department work center overhead rates 9% for three consecutive years. Introduced shop floor reporting which led directly to improved variance targeting, and greatly reduced fluctuations in cost for silicone and plastics products. VP of Engineering / Engineering Manager: Reorganized engineering and manufacturing operations utilizing Lean Manufacturing methods to reduce labor and material costs. Created Standard Work processes for mold machine set-ups, quoting, parts cleaning, and deflashing. Assisted in real-time measurements of silicone extrusions and supported New Product Introductions (NPI) for InHealth and Original Equipment Manufacturer (OEM) products. Led Manufacturing Engineering, Machine Shop, and Facilities manufacturing support and budget oversight. Responsible for 7 direct reports and 2 indirect reports. Re-engineered and re-tooled InHealth’s flagship product – adding eight product improvements and five process improvements to the multipart, molded, plastic / silicone assembly – and re-introduced it to the market on time. Directed a continuous-improvement program for OEM, Catalog, and Voice Restoration businesses utilizing cross-functional teams to increase throughput, reduce costs, and increase capacity. Standardized and oversaw quote and costing process for OEM (FDA regulated) products Created a Master Mold System for liquid silicone molding which reduced customer tooling costs, reduced build times, reduced part cost, and increased molding throughput. Identified and secured the significant capital equipment needed to upgrade productivity. Responsible for facility, equipment repairs, PM's, safety, and identification of capital equipment Alphatec Manufacturing, Inc., Palm Desert, CA 1996 to 2001 VP / Director of Operations: Led an eight-person staff responsible for manufacturing, quality control, purchasing, planning, receiving, shipping, warehouse, product development, and regulatory compliance. Established the new processes and tooling needed to effectively manufacture new and existing products. Drove cost reductions on core business products. Coordinated with marketing and product development on new product releases. Supported the research and development of new products and markets. Responsible for ~$3.5 operations budget, 8 direct reports and 50 indirect reports. Initiated continuous quality improvement activities for FDA-regulated medical devices and led regulatory compliance efforts with both national and international regulating agencies. Promoted process and product cost reduction programs via Lean Manufacturing techniques Supported R&D / Marketing New Product Introduction initiatives Introduced capital equipment that increased production speed, quality, and capacity, while reducing both process and product cost through Lean Manufacturing techniques. Successfully completed two FDA audits, three ISO 9001 audits, and one state medical device audit. Director of Product Development (Regulatory Affairs/Quality Assurance): Defined and supervised product development, focusing on improved designs for manufacture and surgeon/patient use. Coordinated new product introductions (NPI) and patent applications. Filed 510(k) premarket approval applications with the FDA as required. Responsible for 9 direct reports and 3 indirect reports. Upgraded all company processes related to product development, quality assurance and regulatory compliance. Coordinated product development activities for a range of medical devices, and led new product introductions past national and international regulatory hurdles. Drove a major product specifications upgrade program for the first year. Initiated 510(k)s for new product submissions to the FDA, and design control updates for the ISO 9001 quality system. Education Bachelor of Science, Mechanical Engineering Technology Western Michigan University Kalamazoo, MI. Continued Education/Professional Development Certified Six Sigma Green Belt (CSSGB) Villanova University Lean Six Sigma Certificate (LSSC) Villanova University 5S Auditor Training Certificate (5SATC) Medtronic Specialized Computer Skills ERP/MRP System Knowledge: QAD MFG Pro, SAP, MS Dynamics GP, DBA Manufacturing, Fourth Shift Specialty Business Software: MS Project • Agile • Trackwise • Saba Patents Anterior Cervical Plate and Fixation System United States Patent 6,258,089 Inventors: Dan Pastrick, et al Alphatec Manufacturing, Inc. Endoscopic Coupler Device United States Patent 4,844,071 Inventors: Dan Pastrick, et al Baxter, Edwards L.I.S. Division Endoscope Having a Reusable Eyepiece and a Disposable Distal Section United States Patent 4,624,246 Inventors: Dan Pastrick, et al Baxter, Edwards L.I.S. Division Prosthetic Joint United States Patent 4,624,662 Inventors: Dan Pastrick Zimmer Talar Surface Gage United States Patent 255,490 Inventors: Dan Pastrick Zimmer Rotational Offset Knee Prosthesis United States Patent 4,136,405 Inventors: Dan Pastrick, et al Zimmer Key Accomplishments ___________________________ Last Minute Save of a Major New Product Introduction Situation: I was hired to manufacture the company’s newest product line, which was saddled with the most technically challenging aseptic process in the company’s history. The launch date was late and no one could say why or how long they expected it to last. Meanwhile, the company was waiting to use the sales from this product line as evidence of growth to their stock holders, who were growing increasing concerned about expiring legacy patents. There was also a confidential effort underway to sell the company, the value of which could be leveraged by sales of this new product. Action Plan: Prioritize the ‘To Do’ list and attack the ‘A’ items needed for launch. Prepare a timeline for all issues noted. Update the President daily. Assemble task groups and assign team members to complete specific action items. Identify facility needs and complete the buildout for the three designated production rooms. Complete the new in-house Aseptic Validation requirement that tests 100% of sample parts for sterility testing, and allows zero failures. Prove the integrity of the finished production process by successfully completing three production lots, manufactured in a row, with zero failures per the validation document. Results: Four months after I arrived, the first production order was released to ship. Under my direction, the production team went on to complete 18 months of consecutive builds with zero sterility failures – something no other current or prior product line had ever achieved. In the midst of this unprecedented achievement the company was sold, but the product line continued to grow. Within 5 years it had grown to over $50 million in sales, more than offsetting the legacy market shares lost through expiration of older patents. Net Profit Doldrums Situation: After being in business for over ten years, two owners of a private medical device company that made custom silicone rubber components were frustrated that their profit margins were not in line with comparable medical device companies. The Continuous Improvement (CI) team they had in place was floundering. The firm needed a top-down reorganization of their manufacturing process if they ever hoped to achieve the results they wanted. I was hired to replace the outgoing VP of Engineering and asked to take over leadership of the CI team. Action Plan: Meet with the manufacturing engineers as well as all their internal customers (manufacturing, quality, regulatory compliance and finance) to get everyone’s needs and issues on the table. Initiate standardization processes for OEM-customer quoting, mold setup and post-molding tool assessments. Begin tracking low profits and variance issues and prioritize part numbers by dollar loss. Meet regularly to discuss progress, close out tasks, identify what issue the CI team should address next and develop plans for doing so. Initiate Lean Six Sigma techniques to eliminate waiting, defects, overproduction and extra processing, and to remove waste in motion, inventory and transportation. Results: By every measure, our efforts were a resounding success. In the first three years, operating income grew an average of 28% annually. Gross margins improved by an average of 16% per year. Department work-center overhead rates fell 9% a year for three consecutive years. Key Accomplishments __________________________ VC Owners Require ERP System Now! Situation: Upon acquiring a medical device company, a venture capital group asked it to implement the MS Dynamics GP Enterprise Resource Planning (ERP) system so they could analyze how the company was doing and addresses the weaknesses in its business structure that had plagued it prior to their purchase. An ERP specialist was brought on to handle the project, but as the deadline approached, the owners found the project to be in complete disarray. I was quickly invited to take over this project while simultaneously bringing manufacturing capabilities in-house. Action Plan: Identify my IT counterpart as well as the other members of what became the ERP Team. Gave this team a crash course on ERP integration, how it would affect each department, what disruptions to expect, and what benefits it might generate beyond those currently anticipated. Create a wish list of additional features and work through how they might be integrated into the system. Create new routers for in-house assembly, packaging, and inspection of products. Incorporate a bar coding system into the bill of materials, purchase order receipts, labor time reporting, and shop order floor tracking. Hire a certified MS Dynamics GP ERP system consultant for company-wide training and launch preparations. Results: The new ERP system was successfully launched on schedule. The automated documentation allowed all departments to process their work faster and with fewer mistakes. Receiving errors were greatly reduced with the bar coding feature, and for the first time, product moved correctly from receipt to quarantine until released by Quality. More importantly, the new owners were able to see the company’s strengths, areas of potential improvement, and overall value using data directly from the ERP system for the first time since the acquisition. Development Indifference vs Persistence Situation: While working in product development for a major orthopedic company, I was given an implant project by another engineer who had long considered it to be a concept unworthy of further development. With one look, I knew this product idea was a potential game changer — not just for the company, but for the trauma market and for how the rest of the world repairs a broken hip. The company, however, remained unimpressed for two more years, and gave the project neither priority nor budget. My team and I were on our own. Action Plan: Set up a trip to discuss the implant project with the chief surgeon of the prestigious hospital. Create the project’s scope of work and plan out the feasibility phase. Partner with this hospital to present the product prototype to the American Academy of Orthopedic Surgeons (AAOS). Propose design changes based on AAOS feedback. Review these changes with the manufacturing department and plan the pre-production phase. Review all final implant and instrument changes with the chief surgeon for approval. Establish a system for production. Work with marketing to ramp up press coverage and advertising in advance of the release. Production release. Results: This product line did turn out to be a worldwide game changer. Due to the easier surgical method and successful bone healing for the patients, 80% of the world market now uses this type of product for their common hip/neck fractures. Key Accomplishments __________________________ Development Indifference vs Persistence Industry Insights __________________________________ Design for Manufacturing Early Most companies claim to have a ‘Great Product Development Program,’ but it’s rare to find a company that actually does. Those that do all have one thing in common: They bring their Manufacturing and Quality team members to the table in the Feasibility stage. Problems that will put a drag on production or prove impossible to work around can be eliminated, sometimes before they’re even designed into your product. “Why Do I Have to Change My Process? I’ve Always Done It Like This!” Whenever you hear this line uttered, stop, because you just found gold. Here is where your company will begin to increase cost competitiveness, reduce scrap, improve processing time and reclaim lost capacity. Grab your Continuous Improvement Program team and go to work. Manpower Support Needs vs Everyone Else’s Wants Employee morale is important to the success of any company. But when you are choosing the projects your company will tackle, morale considerations should be off the table. The biggest problem I’ve seen in my years in this business occurs when companies clog the production pipeline with too many projects. They seem to think in terms of “How many projects can we have open this year,” when they should think, “How many projects can we close this year?” Building on Core Competencies Successful companies reach plateaus that call for new growth strategies. It’s a moment of great opportunity, but real peril as well. Growth plans that impede or disrupt a company’s core competencies are doomed to fail and could even put the company’s survival in jeopardy. If, however, new capabilities, products and marketing programs are developed in symbiosis with core competencies, the chances for ongoing growth and success improve dramatically. Providing Added Value You are the lone producer of a high-demand product that’s selling at an unbeatable price-point. Tomorrow, a new spin on your product will be introduced by a competitor that will render your offering obsolete. Count on it. Your best move is to beat your competitor to the punch. The Imperative of Added Value sustains all markets and drives them forward. If you stand in place, the market will run right over you. Penetrating New Markets As the company tools up for its next big market push, remember these two little words: Niche market. Companies working in niche markets have fewer competitors to battle, so they can focus more of their attention on their customers’ needs. Not only is this likely to inspire new products and features, but it sets the stage for future cross-selling, up-selling and service programs that are likely to forge long-term customer loyalty. Your Reputation is as Important as Your Product Public scrutiny on companies and individuals, by both news media and social media, has never been more intense. Companies must train themselves to spot an important PR wave in their industry early in its development. It’s the only way to get out in front of the wave and control the company’s position. Your company’s public image is an asset which, once spent, can be very slow to regenerate. Guard it well by investing in quality, individuals, programs, and tools it needs. What to Do with Lumbering Processes and Low Yields Legacy products don’t always get the attention they need until backorders begin building up. Sometimes the sale of a product simply outpaces the company’s projections, and manufacturing can no longer keep up. In either case, the issue of strangled production becomes suddenly urgent. Before you make changes to your processes or equipment, two things need to happen: 1) take a gemba walk to the production site with the supervisor and speak with the associates to get their perspective on the issue(s) 2) get with the planning group to identify any substantial sustained increase of products in the demand forecasts. Implement the appropriate changes as required.