1 Introduction

advertisement

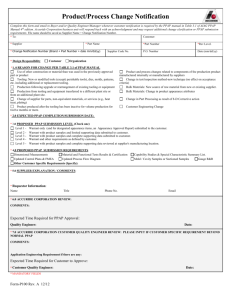

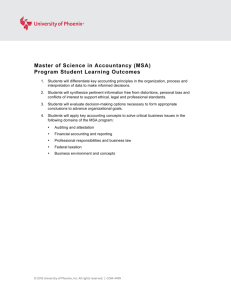

PPAP TRAINING Production Part Approval Process 4th Edition Ed van den Enden PPAP WORKBOOK TRAINING – Rev 6– dd 06/06/2014 It‘s the goal of this lecture to: • to show you the basic content and the rules of the Production Part Approval Process • and to explain the purpose and the background • but this lecture will not save you from learning how to practically use this system Notes to this lecture • this lecture was created for training purposes only; • it is not an extensive description, but • a help for getting started • view of contents, basic idea and goals • The content of this lecture shall not be used as a reference for daily work • Please make sure that you are working only with original latest level documents • This lecture does not refer to customer specific requirements, nor to special PPAP rules/requirements for bulk materials, tires, nor truck industry! What is PPAP? • Production Part Approval Process • Standard used to formally reduce risks prior to product or service release, in a team oriented manner using well established tools and techniques • Initially developed by AIAG (Auto Industry Action Group) in 1993 with input from the Big 3 - Ford, Chrysler, and GM • AIAG’s 4th edition effective June 1, 2006 is the most recent version • PPAP is part of the Donaldson Supplier Business Operating Standard (S.B.O.S.S.) Content 1. Introduction 2. Content of the „PPAP“ 1. General 2. PPAP Process Requirements 3. Customer Notification and Submission Requirements 4. Submission to Customer - Levels of Evidence 5. Part Submission Status 6. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links 1 Introduction • it is the purpose of advanced quality management to prevent that unreliable designs or processes are used in serial production • therefore it is necessary to have one extensive, strict approval process for new or changed designs or processes • inevitably this process causes some administration work • but its worth while because it reduces the production of muda! 1 Introduction Saving by taking advantage of the “Rule Of The 10”: “The cost of the remedy of a defect increases tenfold with every step, the project advances!” 1 Introduction Savings by avoiding the “7+1 muda” Design ignoring the customer‘s expectations 1 Introduction Savings by avoiding to high stock” • • • • • • • • • • take space raise assets employed require additional searching require additional administration require additional transport are a risk, because parts might exceed expiration date or become unsaleable are a risk, because parts might be damaged complicate the overview are often a consequence of a weak process cover weak process 1 Introduction Requirements for Lower “stock” • Controlled and capable processes • Total Productive Maintenance • since all kind of process problems will cause delivery stops, if the stocks are low! 1 Introduction • satisfied customers by good quality and avoided muda • no scrap, no rework • constant flow of material • low stocks possible 1 Introduction • such an extensive and strict process is an obligatory requirement • the name of this process is: Production Part Approval Process 2. Content of the „PPAP“ Customer specific requirements are not discussed in this presentation; for this please lookup SharePoint chapter “Customer Requirements” Content 1. Introduction 2. Content of the „PPAP“ 1. General 2. PPAP Process Requirements 3. Customer Notification and Submission Requirements 4. Submission to Customer - Levels of Evidence 5. Part Submission Status 6. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links PPAP is, so to speak, „the goal” of APD APD (APQP) makes sure; • that all requirements are recognized before the Product Development is started • that those “special characteristics” of the product are specified which influence these requirements • that it is verified again and again that the planned design can safely meet these requirements, if the special characteristics are within tolerance • that only those production processes are specified, which are controlled and capable according to SPC regarding these characteristics • A Readiness Review and PPAP are used to validate that all processes are under control and capable • the produced parts fulfil all requirements Purpose and Applicability It is the purpose of PPAP to • define generic requirements for production part approval • determine if all customer engineering design record and specification requirements are properly understood by the organization • determine that the manufacturing process has the potential to produce the product consistently meeting these requirements during an actual production run at the quoted production rate Applicability • PPAP shall apply to internal and external organization sites supplying production materials, sub assemblies or customer service parts. For bulk material and standard catalogue parts, PPAP is not required unless specified by the APD project-team or customer. Material certificates and dimensional reports are the minimum required documents . Submission of PPAP Before any supply to the customer the organization shall obtain full approval from the customer for: 1. Anny new serial part or serial product 2. Correction of a discrepancy or any change on previously submitted parts or part processes. 3. Product modified by an engineering change to design records specifications materials 4. Any tool or equipment change or update. Note: If there is any question concerning the need for PPAP, contact the authorized customer representative. Content 1. Introduction 2. Content 1. General of the „PPAP“ 2. PPAP Process Requirements 3. Customer Notification and Submission Requirements 4. Submission to Customer - Levels of Evidence 5. Part Submission Status 6. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links 2. PPAP Process Requirements 2.1 Significant Production Run • Products for PPAP shall be taken from a significant production run • This production run shall be from one hour to eight hours of production, and with the specific production quantity to total of minimum of 300 consecutive parts, unless otherwise specified by the authorized customer representative. • This significant production run shall be conducted at the production, at the production rate, using the production tooling, production gaging, production process, production materials, and production operators. • Parts from each unique production process, e.g. duplicate assembly line and/or work cell, each position of a multiple cavity die, mold, tool or pattern, shall be measured and representative parts tested 2. PPAP Process Requirements 2.2 PPAP Requirements • the supplier shall meet all specified requirements as listed in this handbook and all customer-specific requirements • Production parts shall meet all customer engineering design record and specification requirements including safety and regulatory requirements • If any part specification cannot be met, the organization shall document their problem-solving efforts and shall contact the authorized customer representative for concurrence in determination of appropriate corrective action. Content 1. Introduction 2. Content of the „PPAP“ 1. General 2. PPAP Process Requirements 3. Submission to Customer - Levels of Evidence 4. Part Submission Status 5. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links 3. Submission to Customer - Levels of Evidence The organization shall submit the items and/or records as specified Level 1 Warrant only (and for designated appearance items, an Appearance Approval Report) submitted to the customer. Level 2 Warrant with product samples and limited supporting data submitted to the customer. Level 3 Warrant with product samples and complete supporting data submitted to the customer. Level 4 Warrant and other requirements as defined by the customer. Level 5 Warrant with product samples and complete supporting data reviewed at the organization's manufacturing location. Level 6 Customizable by Region based on circumstances. Typically Warrant only unless noted by Donaldson on the PSW. Used for Catalog and/or commercially available product that may be of supplier-propriety design, and also low-volume limited runs. 3. Submission to Customer - Levels of Evidence Level 1 Level 2 Level 3 Level 4 Level 5 Include a copy of the current approved revision drawing with all dimensions, specifications and notes bubbled (circle with corresponding number) for reference to dimensional report. R S S * R 2. Engineering Change Documents A document that shows the detailed description of the change / ECO, if any. R S S * R 3. Customer Engineering approval Not used with Donaldson submissions. Where specified by the customer, the organization shall have evidence of customer engineering approval. --- --- --- --- --- 4. Design FMEA A copy of the Design Failure Mode and Effect Analysis, if applicable. R R S * R 5. Process Flow Diagrams A copy of the Process Flow, indicating all steps and sequence in the fabrication process, from receiving to shipping, steps must match with PFMEA and Control Plan steps. R R S * R PPAP Element Description 1. Design records 3. Submission to Customer - Levels of Evidence Level 1 Level 2 Level 3 Level 4 Level 5 A copy of the Process Failure Mode and Effect Analysis. The PFMEA follows the Process Flow steps, and indicate "what could go wrong" during the fabrication and assembly of each component. Actions required for: a) All RPN above 100 with severity ≥ 8, c)For RPN btw 100-150 need to be reviewed and preventive / corrective action taken R S S * R 7. Control Plan Control Plan provides details on how the "potential issues" are checked in the incoming material, production process and during inspections of finished products, Control Plan must match the Flow Chart and P-FMEA steps. R R S * R 8. Measurement System Analysis Studies Gage R&R studies are required for Critical/ Significant Characteristics as defined in the Control Plan and/or Donaldson drawing. R R S * R 9. Dimensional Results A list of the measurement results for all the characteristics and specifications noted on the ballooned drawing. R S S * R PPAP Element Description 6. Process FMEA 3. Submission to Customer - Levels of Evidence Level 1 Level 2 Level 3 Level 4 Level 5 Records of material certifications and/or test results for test specified on the design record or Control Plan. R S S * R 11. Initial Process Studies Process Capability Studies for the critical characteristics identified on the drawing. R R S * R 12. Qualified Laboratory Documentation Copy of certifications of the laboratories that performed the tests and measurements reported. R S S * R 13. Appearance Approval Report AAR, If a part is a designated appearance item, appearance compliance requirements will be identified via a special purchase order notification. S S S * R 14. Sample Product The organization shall provide sample product as specified by Donaldson (typically 1-3 pieces). R S S * R PPAP Element Description 10. Material Performance Test Results 3. Submission to Customer - Levels of Evidence Level 1 Level 2 Level 3 Level 4 Level 5 The suppler shall retain an identified master sample for each position of a multiple cavity die, mold, tool or pattern. R R R * R 16. Checking Aids When there are special tools for checking parts, this section shows a picture of the tool, design prints and calibration records, including dimensional report of the tool. R R R * R 17. Records of Compliance With Customer Specific Requirements Not used with Donaldson submissions. Records of all applicable customer specific requirements. --- --- --- --- --- 18. PSW Upon completion of all PPAP requirements, the organization shall complete the Part Submission Warrant. S S S S R PPAP Element Description 15. Master Sample Content 1. Introduction 2. Content of the „PPAP“ 1. General 2. PPAP Process Requirements 3. Submission to Customer - Levels of Evidence 4. Part Submission Status 5. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links 4. Part Submission Status Approved - The part meets all Donaldson requirements - Supplier is authorized to ship production quantities of the part Interim Approval - Donaldson permits shipment of part on a limited time and quantity clearly in writing defined. On Hold - SQA needs more info Rejected - The part does not meet Donaldson requirements, based on the production lot from which it was taken and/or accompanying documentation Production quantities may not be shipped before Donaldson / Customer approval Content 1. Introduction 2. Content of the „PPAP“ 1. General 2. PPAP Process Requirements 3. Submission to Customer - Levels of Evidence 4. Part Submission Status 5. Record Retention 3. Summary of the Process 4. The Documentation and its Preparation 5. Summary 6. Internet Links 5. Record Retention The start of using the PPAP workbook PPAP Submission Due Date ● Safe the “Workbook template” as an Excel Workbook. File name = Donaldson Part number followed by Donaldson Part rev number. E.g. P566611-rev8-……(+ free suffix) ● Fill out the sheet: “PPAP Submission Info” To do so, headers of other sheets are filled out automatically. ● Most of the fields can be filled out by the Donaldson PPAP team Part Name (Donaldson Part Number (Donaldson) Revision (Donaldson) Revision date (Donaldson) Supplier Part Number (optional) PPAP Assigned Quality Engineer Supplier Name Supplier Number Street Address City Postcode / Zip code Country Phone Number Supplier Contact Supplier PPAP Remarks If designated appearance part, appearance compliance will be identified via a special purchase order notification. va SC lev LEVEL 3 Requirements Part Submission Warrant Submit Appearance approval Report Submit Design records Authorized change documents Part Dimensional approval List of checking aids Part Material approval Process Flow Map Design and or Process FMEA Control Plan Submit Submit Submit Required Submit Submit Submit Submit Please execute and show evidense Process Capability Study, Cpk Calculation of capabillity Measuring System Study, Gage R&R Sample parts Master Sample (If applicable) Customer Engineering Approval Form PPAP Level 5 Checklist Submit Submit Submit Electronic Submission Requirements • Donaldson requires that all PPAPs be submitted electronically ppap.emea@donaldson.com • Submission must be received on or prior to the PPAP due date • Review and Approval Process: Donaldson will attempt to review and provide feedback within 3 business days Donaldson requires all submissions to be electronic Donaldson PPAP book • What is the Donaldson PPAP book? An Excel spreadsheet containing templates of the documents suppliers are required to submit to Donaldson. Organization formats are allowed as long these documents are providing the same. (Preferred language is English) • Why use the PPAP book? Simplifies the process for suppliers by serving as a “checklist” of what needs to be submitted to Donaldson Reduces the number of files to manage Enables the SQA / PPAP team to quickly see if anything is missing Part Submission Warrant Part Submission Warrant What is It? • Document required for all newly tooled or revised products in which the supplier confirms that inspections and tests on production parts show conformance to Donaldson requirements Objective or Purpose Used to : • document part approval • provide key information • declare that the parts meet specification When to Use It • Prior to shipping production parts Have a closer look Part Submission Warrant Product weight Enter the product weight Donaldson Part Number Engineering released finished Engineering Change Level & Date end item part number Show the change level and date of Shown on Drawing Number the Design Record The design record that specifies Additional Engineering Changes the customer part number being Safety Government Regulation List alland/or authorized Engineering Purchase Order Number submitted “Yes” if sonot indicated by the Design Record, changes yet incorporated inEnter this number as found on otherwise “No” the design record but which are the contract / purchase order Checking Aid Number, Change Level, & Date incorporated in the part Enter if requested by the customer Part Submission Warrant Supplier Manufacturing Information Show the name and code assigned to the manufacturing site on the purchase order / contract Parts Identified with Appropriate Marking Codes UL = Underwriters Laboratories safety standards CE = Conformite Europeenne (European Conformity) – Certifies that a productLocation has met European consumer Donaldson Restricted Substances Safety, health, or environmental requirements Showorthe location where Enter “Yes” “No” ISO = International for Standardization Buyer /Organization Buyer Code to parts will be shipped Enter “Yes” orEnter “No”the buyer’s name Model Name / Number and code Enter the model name and number Part Submission Warrant Reason For Submission Check the appropriate box(es) Mold / Cavity / Production Process If production parts will be produced from more than one mold, cavity, tool, die, pattern, or production process, the supplier Submission Results shall complete a dimensional evaluation on Check the appropriate boxes one part from each. The specific molds, lines, etc. shall then be identified here. Requested Submission Level Identify the submission level requested by Donaldson Part Submission Warrant Declaration Declaration Explanation / Comments Affirmation that the samples represented Entercomments the number pieces Provide any explanatory onof the by the during warrant are representative and manufactured the submission results or any deviations Supplier Authorized Signature were made by run a process that meets Donaldson’s significant production from the Declaration. Attach additional A responsible supplier official, after verifying requirements and the PPAP time (in hours) taken information as appropriate. that the results show conformance all Donaldson for the significantto production run requirements and that all required documentation is available, shall approve the declaration For Donaldson Use Only To be completed by appropriate PPAP Warrant Disposition Donaldson Supplier Quality Engineer Donaldson Approved,Signature Rejected, Other Signed by Donaldson Supplier Quality Engineer The approved Production Warrant officially warrants the parts ready for production Part Submission Warrant ●Reviewers Checklist Must be completely filled out Must be signed by the supplier and customer Part Number must match the PO Submitted at the correct revision level Submitted at the correct submission level Specify the reason for submission Report the approval / Reject to the PPAP team and the APD team Upload to the central Supplier or Customer PPAP SharePoint Site by sending to: ppap.emea@donaldson.com AUTHORIZED ENGINEERING CHANGE DOCUMENTS Authorized Engineering Change Documents ● The supplier shall provide authorized change documents for those changes not yet recorded in the design record, but incorporated in the product, part or tooling, such as: ECNs (must be approved, not pending) Specifications (ECO) Feasibility studies Supplier change requests Sub-assembly drawings Life or reliability testing requirements PROCESS FLOW DIAGRAM Process Flow Diagram What is It? Operator Separate Cutting Tags (31) Evaluate for Corrective Action Yes Operator Get Traveler and Nest from Holding Shelf (26) Operator Load Machine with Blanket (28) Operator Prints Cut Tags (27) Operator Download Cutting Infomation (2s to 2m) (29) Operator Program Command "Ready to Cut" (30) Operator Observe Cutting Operation for Errors (32) Cutting Error? (33) No Operator Remove Small Plies from the Cutting Table (36) Operator Move to Kitting Table (37) Operator Tag Small Plies (38) No Small Plies Operator Cutting Operation Complete (34) Large or Small Plies or Test Coupons? (35) Operator Tag while Laying on the Cutting Table And (39) Coupons Large Piies Operator Remove Plies from the Cutting Table (40) Operator Move Plies to Kitting Table (41) Traveler Complete? (42) Operator Stamp Traveler (43) Department/Group Project High Level Process Map Project Idea 6 Sigma Project High Level Process Map Yes Fill Out Master Form with Initial Information Get WO Assigned Begin/Work Project Follow DMAIC or DFSS process 6 Sigma Assigns Project Number Monitor Progress through Power Steering and Monthly Financial Reviews Other Required Signatures: Segment CEO Champion Process Owner BB or GB No Yes Finance Approval and Signature Finance Approval and Signature No Master Form Will Generate Contract Complete Project (Has to be fully Documented Do you have BB/GB to Assist/Work the project? Monitor Progress through BiWeekly Updates and Monthly Reviews 6 Sigma Project Does the Project Involve Only Your Group? Final Project Review Yes Department or Group Project Enter Remaining Information on Master Form Finance Approval and Signature No Does the Project Involve >2 Groups in Eng? Other Required Signatures: Champion: Dir T&E Process Owner Project Owner Dept BB or MBB No Yes Close Project Yes Follow DMAIC or DFSS process Is Hard Savings > $??? No Other Required Signatures: Champion: Dir T&E Process Owner Project Owner Dept BB or MBB Get DLN Assigned Begin/Work Project Complete Project (Has to be fully Documented) Master Form Will Generate Contract Finance Approval and Signature Complete all Documentation including a (1) Page Closeout Sheet Group Assigns Project Number Yes Yes Enter Remaining Information on Master Form Final Project Review Other Required Signatures: Champion: Process Owner Project Owner Dept GB/BB/MBB Prefer to work this project within your area? Does the Project Involve >3 Depts. outside Eng? No Close Project Complete all Documentation including a (1) Page Closeout Sheet • A visual diagram of the entire process from receiving through shipping, including outside processes and services Objective or Purpose • To help people “see” the real process. Process maps can be used to understand the following characteristics of a process: • Step-by-step process linkage • Offline activities (measurement, inspection, handling) • Rework, scrap When to Use It • To understand how a process is done • Prior to completing the PFMEA Process Flow Diagrams The process flow diagram utilizes these symbols to clearly identify each step in the process Process Flow Diagrams ●Reviewers Checklist Process Flow must identify each step in the process Should include abnormal handling processes Scrap Rework Process Flow must include all phases of the process Receiving of raw material Part manufacturing Offline inspections and checks Assembly Shipping PROCESS FMEA Process FMEA (PFMEA) CORP QEHSDOC 014 What is It? Failure Mode and Effects Analysis (Design FMEA) S ys t e m / C o m po ne nt : F M E A N um be r: P a ge P re pa re d by: F M E A D a t e ( O rig.) D e s ign R e s po ns ibilit y: of ( R e v .) C o re T e a m : Item / Process Potential Failure Mode Function Potential Effect(s) of Failure S e v Potential Cause(s)/ Mechanism (s) of Failure O c c u r Current Design Controls Prevention Current Design Controls Detection D e t e c R. P. N. Recom m ended Action(s) Responsibility & Target Com pletion Date Action Results O S c e c v u r ActionsTaken D e t e c R. P. N. • A tool used to identify and prioritize risk areas and their mitigation plans. Objective or Purpose • Identifies potential failure modes, causes, and effects. Inputs come from the process flow diagram. • Identifies key inputs which positively or negatively affect quality, reliability and safety of a product or process. When to Use It IMPORTANT! The PFMEA should be completed using a cross-functional team! • After completion of the process flow diagram. • Prior to tooling for production FMEA Origin • Created by NASA following Apollo 1 mission failure • Allows us to take a proactive approach to what can go wrong in a process and manage our risks better Process FMEA (PFMEA) This is included in the PPAP book! PFMEA - Step 1 R.P.N. Current Process Controls 8 Variables check for film thickness; Visual check for coverage 5 280 5 Variables check for film thickness; Visual check for coverage; Test spray at start-up and after idle periods and preventative maintenance program to clean heads 5 175 Detec Occur Class Potential Failure Mode Sev Process Step Potential Potential Failure Modes Cause(s)/ Effect(s) of Mechanism(s) For each Process Input, Failure of Failure determine the ways in Op 70: Manual Insufficient wax Allows integrity 7 inputManually which the can go application of coverage over breach wrong. of inner inserted spray wax inside door specified surface door panel head not panel inserter far Corroded interior enough lower door panels Using the completed Process Flow Diagram, enter the process step. Deteriorated life of door leading to: - Unsatisfactory appearance due to rust through paint over time - Impaired function of interior door hardware Spray head clogged: - Viscosity too high - Temp too low - Pressure too low TIPS • There should be at least one failure mode for each input. PFMEA - Step 2 R.P.N. Current Process Controls Detec Deteriorated life of door leading to: - Unsatisfactory appearance due to rust through paint over time - Impaired function of interior door hardware 7 Potential Cause(s)/ Mechanism(s) of Failure Occur Op 70: Manual Insufficient wax Allows integrity application of coverage over breach of inner wax inside door specified surface door panel panel Corroded interior lower door panels Class Potential Effect(s) of Failure Sev Process Step Potential Failure Mode Manually 8 Variables check 5 280 inserted spray for film head not thickness; Visual inserter far check for Potential Failure Effects enough coverage For each Failure Mode, determine what effect the specific failure Spray head 5 Variables check 5 175 could have on the clogged: for film process output. - Viscosity too thickness; Visual high - Temp too low - Pressure too low check for coverage; Test spray at start-up and after idle periods and preventative maintenance program to clean heads TIPS • There should be at least one failure effect for each failure mode. • Effects should be specific, clear, and leave no doubt to the uninformed reviewer. PFMEA - Step 3 Spray head clogged: - Viscosity too high - Temp too low - Pressure too low R.P.N. of door leading to: - Unsatisfactory appearance due to rust through paint over time - Impaired function of interior door hardware Manually inserted spray head not inserted far enough Current Process Controls 8 Variables check for film thickness; Visual check for coverage 5 280 5 Variables check for film thickness; Visual check for coverage; Test spray at start-up and after idle periods and preventative maintenance program to clean heads 5 175 Detec determine the possible cause of the failure.Deteriorated life 7 Potential Cause(s)/ Mechanism(s) of Failure Occur Op 70: Manual Insufficient wax Allows integrity application of coverage over breach of inner wax inside door specified surface door panel panel Corroded interior Potential Causes lower door For each Failure Mode,panels Class Potential Failure Mode Sev Process Step Potential Effect(s) of Failure TIPS • There should be at least one potential cause for each failure mode. PFMEA - Step 4 8 Variables check for film thickness; Visual check for coverage R.P.N. Op 70: Manual Insufficient wax Allows integrity 7 Manually application of coverage over breach of inner inserted spray wax inside door specified surface door panel head not Current Controls panel inserter far For each potential Corroded interior enough lower door cause, list the current panelsused for method Current Process Controls Detec Potential Cause(s)/ Mechanism(s) of Failure Occur Class Potential Effect(s) of Failure Sev Process Step Potential Failure Mode 5 280 Spray head preventing or detecting Deteriorated life clogged: failure. TIPS • This step in the FMEA current control plan. 5 Variables check 5 175 for film of door leading - Viscosity too thickness; Visual to: high check for - Unsatisfactory - Temp too low coverage; Test appearance due - Pressure too spray at start-up to rust through low and after idle paint over time periods and - Impaired preventative function of maintenance interior door begins to identify initial shortcomings or gaps program to clean hardware heads • If a procedure exists, enter the document number. • If no current control exists, list as “none.” in the PFMEA - Step 5 ● Assign Severity, Occurrence, and Detection ratings Manually 8 Variables check inserted spray for film headDetection not thickness; Visual Assign inserter far can the check for (How easily enough coverage cause or failure R.P.N. Current Process Controls Detec 7 Potential Cause(s)/ Mechanism(s) of Failure Occur Assign Severity Op 70: Manual Insufficient waxis the Allows integrity (How serious application effect of coverage over breach of inner if it fails?) wax inside door specified surface door panel panel Corroded interior lower door panels Class Potential Failure Mode Sev Process Step Potential Effect(s) of Failure 5 280 mode be detected?) Spray head Deteriorated life Assign Occurrence clogged: of door leading (How likely is the - Viscosity too to: cause to occur?) high - Unsatisfactory - Temp too low appearance due - Pressure too to rust through low paint over time - Impaired function of interior door hardware 5 Variables check for film thickness; Visual check for coverage; Test spray at start-up and after idle periods and preventative maintenance program to clean heads 5 175 Severity, Occurrence and Detection rating details on next slide PFMEA - Definition of Terms ● Severity (of Effect) Severity of the effect on the Customer and other stakeholders (Higher Value = Higher Severity) ● Occurrence (of Cause) Frequency with which a given Cause occurs and creates Failure Mode. (Higher Value = Higher Probability of Occurrence) ● Detection (Capability of Current Controls) - ability of current Control scheme to detect the cause before creating the failure mode and/or the failure mode before suffering the effect (Higher Value = Lower Ability to Detect) Caution: Notice the scale difference for Detection! An Example of Rating Definitions Rating High Low 10 1 Severity Occurrence Detection* Hazardous without warning Very high and almost inevitable Cannot detect or detection with very low probability Loss of primary function High repeated failures Remote or low chance of detection Loss of secondary function Moderate failures Low detection probability Minor defect Occasional failures Moderate detection probability No effect Failure unlikely Almost certain detection *If No Controls Exist, Detection = 10 Referring too 4th Edition FMEA Manual and the scales in Donaldson PPAP workbook. PFMEA - Step 6 Op 70: Manual Insufficient wax Allows integrity 7 Manually 8 Variables check application of coverage over breach of inner inserted spray for film wax inside door specified surface door panel head not thickness; Visual panel inserter far check for Calculate the Risk Priority Number Corroded interior enough coverage lower door = Severity panelsx Occurrence x Detection R.P.N. Current Process Controls Detec Potential Cause(s)/ Mechanism(s) of Failure Occur Class Potential Failure Mode Sev Process Step Potential Effect(s) of Failure 5 280 RPN TIPS • The RPN is used to FMEA. • High RPNs (100 or above) are flags to take Spray head clogged: - Viscosity too high - Temp too low - Pressure too low 5 Variables check 5 175 for film thickness; Visual check for coverage; Test spray at start-up after idle risks identifiedand in the periods and first half of the preventative maintenance program to clean effort to reduce heads the calculated risk. Deteriorated life of door leading to: - Unsatisfactory appearance due to rust through prioritize the most paint over timecritical - Impaired function of interior door hardware • Regardless of RPN, high Severity scores (>8) should be given special attention. Analyzing the PFMEA Sort by RPN to determine the most significant failure modes ? How many items should be the focus of the next steps? • Once the RPN Numbers are determined, they can be used to prioritize the most significant failure modes. • Sort the FMEA by the RPN numbers. Graphical and statistical tools can help the team select a “cut-off” RPN for the next steps. RPN Thresholds • When using an RPN threshold, DO NOT forget to address high Severity scores Pareto Chart PFMEA – Remediation Guidelines ● Severity Can only be improved by a design change to the product or process ● Occurrence Can only be reduced by a change which removes or controls a cause. Examples are redundancy, substituting a more reliable component or function or mistake-proofing. ● Detection Can be reduced by improving detection. Examples are mistakeproofing, simplification and statistically sound monitoring. In general, reducing the Occurrence is preferable to improving the Detection FMEA – Step 7 • Determine Actions Recommended to reduce High RPNs Action Results 175 Use DOE on viscosity vs. temp vs. pressure Mfg. Eng. By 5/31/10 recommended actions. Deteriorated life of door leading to: - Unsatisfactory appearance due to rust through paint over time - Impaired function of interior door hardware Mfg. Eng. By 5/25/10 R.P.N. Mfg. Eng. By 5/10/10 Det Op 70: Manual Insufficient wax Allows integrity 280 Add positive application of coverage over breach of inner depth stop to wax inside door specified surface door panel sprayer panel Automate Corroded interior spraying For the high RPN numbers, lower door determine the panels Actions Taken Occ Recommended Responsibility & Actions Target Date Sev Potential Failure Mode R.P.N. Process Step Potential Effect(s) of Failure Stop added, 7 2 5 70 sprayer checked on-line Rejected due to complexity of different doors on the same line Temp and press 7 1 5 35 limits were determined and limit controls have been installed - Control charts show process is in control Cpk = 1.85 FMEA – Steps 8 and 9 Action Results R.P.N. Op 70: Manual application of wax inside door specified surface panel Det Assign a specific person who will responsible Insufficient wax be Allows integrity 280 Add positive coverage over breach of inner depth stop to for recommended actions. Actions Taken Occ Recommended Responsibility & Actions Target Date Sev Potential Potential Failure Effect(s) of Mode (responsibility) Resp Failure R.P.N. Process Step Mfg. Eng. By 5/10/10 Stop added, 7 2 5 70 sprayer checked door panel sprayer on-line Automate Mfg. Eng. By Rejected due to Corroded interior spraying 5/25/10 complexity of Actions lower door Taken different doors on panels As actions are identified the same line 175 Use document DOE on Mfg. Eng. By Temp and press 7 1 5 35 and completed, Deteriorated life viscosity vs. 5/31/10 limits were “Actions Taken” of in doorthe leading temp vs. determined and to: column. pressure limit controls - Unsatisfactory have been appearance due installed - Control to rust through show SEV, OCC, DET,charts RPN paint over time process is in - Impaired As actions are control complete Cpk = function of 1.85 reassess Severity, interior door Occurrence, and Detection hardware • Now recalculate your RPNs based on mitigation plans. TIPS: and recalculate RPN. Continue updating the actions taken and resulting RPNs until all risks are at an acceptable level (below 100). Summary Steps To Complete a FMEA 1. For each Process Input, determine the ways in which the Process Step can go wrong (these are Failure Modes). 2. For each Failure Mode associated with the inputs, determine Effects on the outputs. 3. Identify potential Causes of each Failure Mode. 4. List the Current Controls for each Cause. 5. Assign Severity, Occurrence and Detection ratings after creating a ratings key appropriate for your project. 6. Calculate RPN. 7. Determine Recommended Actions to reduce High RPNs. 8. Take appropriate Actions and Document. 9. Recalculate RPNs. 10. Revisit steps 7 and 8 until all the significant RPNs have been addressed. Process FMEA (PFMEA) Tips and Lessons Learned • Collaborative Effort: Do not try alone, use a group • Very comprehensive: Time consuming process. Take necessary • • • • breaks. Action items are required for completion Train team ahead of time by explaining scoring criteria Proper preparation is needed for meetings Summarize often: FMEA is a living document Process FMEA (PFMEA) ●Reviewers Checklist Verify there is a system for prioritizing risk of failure such as RPN numbers of 150 or above Make sure that high RPN process concerns are carried over into the control plan Make sure that all critical failure modes are addressed Safety Form, fit, function Material concerns CONTROL PLAN Control Plan What is It? A document that describes how to control the critical inputs to continue to meet customer expectations of the output. Objective or Purpose NOTE Since processes are expected to be continuously updated and improved, the control plan is a living document! • Primary reference source for minimizing process and product variation. • Description of how teams should react to out-of-control situations. When to Use It • Implementation of new process • Following a process change Control Plan Tool Interaction Department/Group Project High Level Process Map Project Idea 6 Sigma Project High Level Process Map Process Step Fill Out Master Form with Initial Information Get WO Assigned Begin/Work Project Follow DMAIC or DFSS process 6 Sigma Assigns Project Number Other Required Signatures: Segment CEO Champion Process Owner BB or GB Monitor Progress through Power Steering and Monthly Financial Reviews Finance Approval and Signature No Finance Approval and Signature Do you have BB/GB to Assist/Work the project? Monitor Progress through BiWeekly Updates and Monthly Reviews 6 Sigma Project Final Project Review No Yes Department or Group Project Does the Project Involve >2 Groups in Eng? Finance Approval and Signature Other Required Signatures: Champion: Dir T&E Process Owner Project Owner Dept BB or MBB No Yes Yes Potential Failure Effects Receive Payment Checks Delay internal mail Identify Customer Wire Transfer reference line Information not AR balance is supplied past due AR balance does not go down Does the Project Involve >3 Depts. outside Eng? No Identify Invoice Checks Incorrect invoice supplied Identify Invoice Checks Invoice number Invoice shows not supplied outstanding (AR balance does go down) Enter Remaining Information on Master Form No Close Project Process Steps Potential Failure Mode S O E Potential Causes C V C Inadequate staffing in mail 7 room Customer or bank did not include name and/or 10 account info on wire transfer Current Controls D E T R P N None 7 5 10 490 Acct identifies problem when trying to apply payment E O C Actions Recommended Resp. Actions Investigate mail room G. Lee staffing and associated processes Added anoth clerk. Adjus schedule. Poka-Yoke wire transer N. Peart process Contacted ba established w transfer proc 2112) 5 250 Is Hard Savings > $??? Does the Project Involve Only Your Group? Other Required Signatures: Champion: Dir T&E Process Owner Project Owner Dept BB or MBB Get DLN Assigned Begin/Work Project Follow DMAIC or DFSS process Complete Project (Has to be fully Documented) Master Form Will Generate Contract Finance Approval and Signature Complete all Documentation including a (1) Page Closeout Sheet Group Assigns Project Number Yes Yes Enter Remaining Information on Master Form Final Project Review Prefer to work this project within your area? Yes No Master Form Will Generate Contract Complete Project (Has to be fully Documented Other Required Signatures: Champion: Process Owner Project Owner Dept GB/BB/MBB Key Process Input Close Project Complete all Documentation including a (1) Page Closeout Sheet New/Revised Process Steps Process Flowchart Control Plan Invoice shows outstanding (AR balance does go down) Customer error Customer might catch it when reviewing the 5 next statement 10 250 Provide payment stub A. Lifeson with statement for each invoice Revised stat include paym with each inv Customer error Acct identifies problem when trying to apply 10 payment 5 250 Provide payment stub S. Hagar with statement for each invoice Revised stat include paym with each inv 5 5 Process FMEA Control Plan This is included in the PPAP book! Control Plan 3 Distinct Phases 3 Distinct Phases 3 Distinct Phases 3 Distinct Phases Pre-Launch 3. the –Production a description – aofcomprehensive the 1. Prototype – a2.description of dimensionaland measurements documentationand of product/process dimensional measurements material and performance characteristics, tests process that controls, material and performance tests that occur after tests, Prototype and measurement and before systems that will occur duringwill Prototype build. full Production. will occur during mass production Control Plan Administrative Section Administrative Section Identifies part number and description, supplier, required approval signatures, and dates. Control Plan Process, Machine/Tools, Characteristics Part/Process Use this area to define part/process number and description. Machine/Tools Characteristics Define the characteristics of the product or process List the machine, device, jig, or tools that will be used in the manufacturing process Control Plan Specifications, Measurement, Sample Size & Frequency Sample Size What is the size of the sample you should gather data from? Specifications/Tolerance Use this area to define upper/lower spec limits for each control element. Measurement Technique For each line in the control plan, list the measurement procedure that will be used (may list R&R Gage Plan or PokaYoke). Frequency Define the frequency for which the measurement will be taken. Control Plan Control Method, Reaction Plan Control Method Method that will be used to control the process Reaction Plan Actions to be taken if controls fail Control Plan Audit Plans • Audit plans should be included in the control plan as a separate line. • Auditing is an important tool for control. • Process auditing should be a key element of the quality system of a business. • Audits generally cover: Effectiveness of controls Control plan (say) vs. what is actually done (do) • Audits should be objective (done by internal or external third parties if possible). • Audit frequencies should be based on balancing level of risk (FMEA) and cost. Control Plan Reviewer’s Checklist Use process flow diagram and PFMEA to build the control plan; keep them aligned Controls must be used to be effective. Keep it simple. Ensure that the control plan is in the document control system of the business. Good control plans address: All testing requirements - dimensional, material, and performance All product and process characteristics at every step throughout the process An periodical Audit. (Audit Frequency indicated and data stamp for next Audit given!) The control method should be based on an effective analysis of the process Such as SPC, Error Proofing, Inspection, Sampling Plan Control plans should reference other documentation Specifications, tooling, etc. MEASUREMENT SYSTEM ANALYSIS (MSA) Measurement System Analysis (MSA) Gage R&R What is It? An G R&R is a statistical tool used to determine if a measurement system is capable of precise measurement. Objective or Purpose When to Use It • On the critical inputs and outputs prior to collecting data for analysis. • For any new or modified process in order to ensure the quality of the data. Who Should be Involved Everyone that measures and makes decisions about these measurements should be involved in the MSA. • To determine how much error is in the measurement due to the measurement process itself. • Quantifies the variability added by the measurement system. • Applicable to attribute data and variable data. IMPORTANT! Measurement System Analysis is an analysis of the measurement process, not an analysis of the people!! Attribute and Variable MSA – Attribute Data Examples: Count, Pass/fail, yes/no, red/green/yellow, timekeeping buckets – Variable Data Examples: Physical measurement (length, width, area, …) Physical conditions (temperature, pressure…) Physical properties (strength, load, strain…) Continuous or non-ending Unless approved by an Donaldson SQA, attribute data is not acceptable for PPAP submission Measurement System Analysis (MSA) The observed variation in process output measurements is not simply the variation in the process itself; it is the variation in the process plus the variation in measurement that results from an inadequate measurement system. Measurement System Variation Observed Variation Process Variation Conducting an MSA reduces the likelihood of passing a bad part or rejecting a good part Measurement System Analysis (MSA) Observed Variation Measurement System Variation Observed Variation The output of the process measured by: Process Variation • Cycle time • Dimensional data • Number of defects and others Measurement System Analysis (MSA) Observed Variation Resolution Precision (Variability) Repeatability Reproducibility Measurement System Variation Linearity Accuracy Observed Variation (Central Location) Bias Stability Process Variation Calibration addresses accuracy Measurement System Analysis (MSA) Resolution Observed Variation Precision (Variability) Reproducibility Measurement System Variation Observed Variation Repeatability Accurac y (Central Location) Linearity Bias Stability Process Calibration Addresses Accuracy Variation Let’s take a closer look at Precision Measurement System Analysis (MSA) Resolution Error in Resolution The inability to detect small changes. Possible Cause Wrong measurement device selected - divisions on scale not fine enough to detect changes. Measurement System Analysis (MSA) Repeatability Error in Repeatability The inability to get the same answer from repeated measurements made of the same item under absolutely identical conditions. Possible Cause Lack of standard operating procedures (SOP), lack of training, measuring system variability. Equipment Variation Measurement System Analysis (MSA) Reproducibility Error in Reproducibility The inability to get the same answer from repeated measurements made under various conditions from different inspectors. Possible Cause Lack of SOP, lack of training. Appraiser Variation Variable MSA – Gage R&R Study • Gage R&R is the combined estimate of measurement system Repeatability and Reproducibility • Typically, a 3-person study is performed Each person randomly measures 10 marked parts per trial Each person can perform up to 3 trials • There are 3 key indicators EV or Equipment Variation AV or Appraiser Variation Overall % GRR Donaldson’s Gage R&R Form Automatically calculates EV, AV, and % GRR! Included in PPAP Playbook! Variable MSA – Gage R&R Steps Step 1 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Step 2 Step 3 Step 4 Step 5 Step 6 Step 7 Step 8 Step 9 Step 10 Select 10 items that represent the full range of long-term process variation. Identify the appraisers. If appropriate, calibrate the gage or verify that the last calibration date is valid. Open the Gage R&R worksheet in the PPAP book to record data. Have each appraiser assess each part 3 times (trials – first in order, second in reverse order, third random). Input data into the Gage R&R worksheet. Enter the number of operators, trials, samples and specification limits Analyze data in the Gage R&R worksheet. Assess MSA trust level. Take actions for improvement if necessary. Steps 1 and 2: Variable MSA - Gage R&R Step 1 Step 2 Select 10 items that represent the full range of long-term process variation. Identify the appraisers. – Should use individuals that actually do the process being tested. – Can also include other appraisers (supervisors, etc.). – Should have a minimum of 3 appraisers. Steps 3 and 4: Variable MSA – Gage R&R Step 3 Step 4 If appropriate, calibrate the gage or verify that the last calibration date is valid. Open the Gage R&R worksheet in the PPAP book to record the data Step 5: Variable MSA – Gage R&R Step 5 Have each appraiser assess each item 3 times. • Each appraiser has to work independently. • Items should be evaluated in random order. • After each appraiser completes the first evaluation of all items – repeat the process at least 2 more times. • Do not let the appraisers see any of the data during the test !! Steps 6 and 7: Variable MSA – Gage R&R Step 6 Step 7 Input data into the Gage R&R worksheet Enter the number of operators, trials, samples and specification limits Steps 8 and 9: Variable MSA – Gage R&R Step 8 Analyze data in the Gage R&R worksheet Step 9 Assess MSA Trust Level. % Tolerance* – Red: > 30% (fail) – Yellow: 10-30% (marginal) – Green: < 10% (pass) 30% 10% Step 10: Variable MSA – Gage R&R Step 10 If the Measurement System needs improvement: • Brainstorm with the team for improvement solutions. • Determine best “practical solution” (may require some experimentation). • Pilot the best solution (PDSA) • Implement best solution – train employees. • Re-run the study to verify the improvement. Variable MSA – Gage R&R Example Problem Statement • The sulfuric acid concentration in process tank 8 is measured at least once per day • Additions/deletions of chemicals and decisions to shut down the process are dependent on these results. • Based on current data, we need to do an MSA. MSA Process A Gage R&R was conducted in order to validate the process. MSA Parameters » (3) Operators » (3) Trials » (10) Samples Variable MSA – Gage R&R Example Entered the number of operators, trials, and samples Entered upper and lower process specification limits Chose 3 operators to be appraisers Had each appraiser measure each sample 3 times Results calculated automatically Selected 10 samples to be measured Variable MSA – Gage R&R Example Repeatability = (EV) Reproducibility = (AV) Equipment Variation Repeatability & Appraiser Variation Reproducibility = R&R % Tolerance* % Tolerance is > 30% MSA fails! 30% 10% Tips and Lessons Learned Important: An MSA is an analysis of the process, not an analysis of the people. If an MSA fails, the process failed. A Variable MSA provides more analysis capability than an Attribute MSA. For this and other reasons, always use variable data if possible. The involvement of people is the key to success. Involve the people that actually work the process Involve the supervision Involve the suppliers and customers of the process An MSA primarily addresses precision with limited accuracy information. MSA – Gage R&R Reviewer’s Checklist If the gage/inspection affects quality, then conduct a Gage R&R Make sure the study is recent - less than 1 year Compare the control plan gages against the Gage R&Rs If you question that gage, then −Question the technique and part sampling −Ask for additional studies DIMENSIONAL RESULTS Dimensional Results What is It? Evidence that dimensional verifications have been completed and results indicate compliance with specified requirements. Objective or Purpose • To show conformance to the customer part print on dimensions and all other noted requirements. When to Use It • For each unique manufacturing process (e.g., cells or production lines and all molds, patters, or dies Donaldson Dimensional Report (Critical) Automatically Calculates Cpk! Requires 35 data points Cpk must be greater than or equal to 1.67 This is included in the PPAP book! Acceptance Criteria Acceptance criteria for critical vs. non-critical characteristics Red (Bad) Yellow (OK) Green (Good) Critical Non-Critical <1.33 <1.00 1.33-1.67 1.00-1.33 >1.67 Decision >1.33 Cpk must be greater than or equal to 1.67 for critical processes Cpk must be greater than or equal to 1.33 for non-critical processes Donaldson Dimensional Report Example Nominal Value Tolerance Sample Data Cp & Cpk Pass / Fail Calculations Cpk > 1.33 for all non-critical dimensions = Pass! Dimensional Results Reviewer’s Checklist Thirty-five critical data points & 5 non-critical data points are required for part qualification Critical and non-critical data points must be taken from the same 35-piece sample Five parts from a production run must be shipped to Donaldson for verification of form, fit, and function The same 5 parts will be used to verify both critical and non-critical dimensions Supplier must clearly identify which of the 35 parts are being shipped Supplier should make every effort to ship 3 parts that represent both the low and high ends of the specifications for non-critical dimensions Capability must be greater than 1.67 for critical dimensions and greater than 1.33 for non-critical dimensions RECORDS OF MATERIAL / PERFORMANCE TEST RESULTS Records of Material/Performance Test Results Material Test Results The supplier shall perform tests for all parts and product materials when chemical, physical, or metallurgical requirements are specified by the design record or Control Plan For products with Donaldson-developed material specifications and/or an Donaldson-approved supplier list, the supplier shall procure materials and/or services from suppliers on that list Performance Test Results The supplier shall perform tests for all parts or product materials when performance or functional requirements are specified by the design record or Control Plan Material Results Material Results shall include: The name of the laboratory that conducted the test The type of test that was conducted The number, date, and specification to which the part was tested The actual test results Module Test Results Module Test Results shall include: The name of the laboratory that conducted the test The type of test that was conducted A description of the test The parameters tested The actual test results QUALIFIED LABORATORY DOCUMENTATION Qualified Laboratory Documentation • Inspection and testing for PPAP shall be performed by a qualified laboratory as defined by Donaldson requirements (e.g., an accredited laboratory). • The qualified laboratory (internal or external to the supplier) shall have a laboratory scope and documentation showing that the laboratory is qualified for the type of measurements or tests conducted When an external laboratory is used, the supplier shall submit the test results on the laboratory letterhead or the normal laboratory report format The name of the laboratory that performed the tests, the date(s) of the tests, and the standards used to run the tests shall be identified. APPEARANCE APPROVAL REPORT Appearance Approval Report What is It? • A report completed by the supplier containing appearance and color criteria Objective or Purpose • To demonstrate that the part has met the appearance requirements on the design record When to Use It • Prior to tooling for production IMPORTANT! Typically only applies for parts with color, grain, or surface appearance requirements Appearance Approval Report Administrative Section Supplier Sourcing & Texture Information List all first surface tools, graining Source(s), grain type(s), and grain and Gloss masters used to check part Pre-Texture Evaluation To be completed by SQE Appearance Approval Report Master Master Material Number DateType Material Source Color Suffix Enter Enter Identify alphanumeric the date first Identify on surface which firstfinish surface andand Alphanumeric or numeric master thesubstrate master identification was substrate (e.g. approved paint suppliers / ABS) color identification Color Shipping Suffix Color part number suffix or color number Color Evaluation Color Suffix Tristimulus Data Master Master Material Material Number Date Type Source DL* Da* Db* DE CMC Red Yel Tristimulus Data List numerical (colorimeter) data of submission part as compared to the customerComments: authorized master Supplier Signature Hue Phone No. Grn Blu Value Chroma Gloss Color Metallic Part Shipping Brilliance Disposition Suffix Light Dark Gray CleanHigh Low High Low Part Disposition Hue, Value, Chroma, Gloss, To and be determined by Metallic Brilliance Donaldson Visual assessment by Donaldson (approved or rejected) Date Customer Representative Signature Tristimulus data Date SAMPLE PRODUCTION PARTS Sample Production Parts What is It? Actual samples that reflect the parts documented in the PPAP. Objective or Purpose • Confirm cosmetic or functional part approval. When to Use It • Sample parts should be delivered WITH the PPAP submission Sample Production Parts • The sample parts provided should be the same parts measured for the dimensional results • Default quantity for all submissions is 3 parts unless otherwise requested Sample Production Parts ● Sample production parts MUST be properly identified • Include the following information on the part label: - Shipping date - Donaldson part number - Quantity submitted - Supplier part number (optional) - Donaldson Part name - Carrier name - Country of origin - Tracking number - Approval markings (UL, CE, etc.) where applicable See Donaldson part label examples on the next slide Part Label Example PPAP sample submission To: Shipping date Shipping quantity Country of origin Supplier Name Part Name Part Number Part revision level Sample with PPAP? Sample Parts separate submitted Shipping Carrier Tracking Number Donaldson Italia S.r.l., Via Dell’Industria 17, I46035 Ostiglia (Mantova), Italy 0 0 0 0 Yes Yes No No Name Number PPAP Workbook includes these PPAP samples submission labels. Where applicable, fields get filled out automatically by filling out the PPAP submission sheet. PPAP Summary • The Production Part Approval Process is an extensive approval process for new or changed designs or processes • It is very formalized, so it inevitably causes some administrative work • Later changes to the product or process can be expensive and time-consuming! PPAP to prevent loosing an opportunity for saving costs