R8 DRAFT CT Central AC Full Report_053013[1]

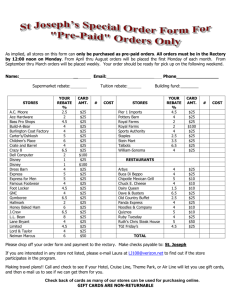

advertisement

![R8 DRAFT CT Central AC Full Report_053013[1]](http://s3.studylib.net/store/data/009417773_1-d4b93445c0d264c88d5e64da80808d78-768x994.png)