Joints - Moehle c

advertisement

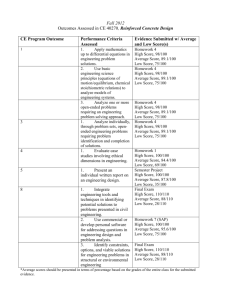

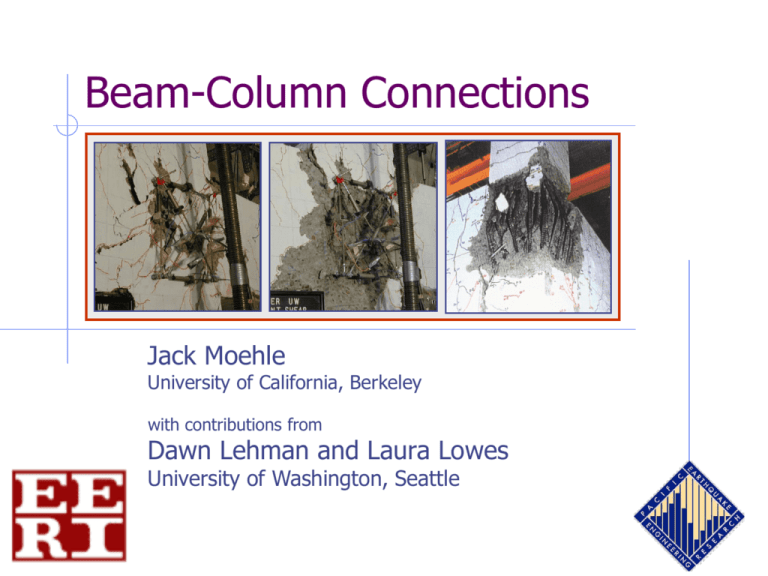

Beam-Column Connections Jack Moehle University of California, Berkeley with contributions from Dawn Lehman and Laura Lowes University of Washington, Seattle Outline design of new joints existing joint details failure of existing joints in earthquakes general response characteristics importance of including joint deformations stiffness strength deformation capacity axial failure Special Moment-Resisting Frames - Design intent Vcol Mpr For seismic design, beam yielding defines demands Mpr lc w Mpr Beam Vp Vp lnb Vcol Vp Mpr Beam Section Vcol Joint demands Ts1 = 1.25Asfy C2 = Ts2 Vb2 Vb1 C1 = Ts2 Vcol Ts2 = 1.25Asfy (b) internal stress resultants acting on joint Vcol (a) moments, shears, axial loads acting on joint Ts1 C2 Vu =Vj = Ts1 + C1 - Vcol (c) joint shear Joint geometry (ACI Committee 352) ACI 352 a) Interior A.1 b) Exterior A.2 d) Roof Interior B.1 e) Roof Exterior B.2 c) Corner A.3 f) Roof Corner B.3 Joint shear strength - code-conforming joints - Vu Vn g = 0.85 ' c f bj h Values of g (ACI 352) ACI 352 Classification /type interior exterior corner cont. column 20 15 12 Roof 15 12 8 Joint Details - Interior hcol 20db ACI 352 Joint Details - Corner ldh ACI 352 Code-conforming joints Older-type beam-column connections Survey of existing buildings Mosier Joint failures Studies of older-type joints Lehman Damage progression interior connections 80 Yield of Beam Longitudinal Reinforcement 60 Spalling of Concrete Cover Measurable residual cracks Longitudinal Column Bar Exposed Column Shear (K) 40 20 0 20% Reduction in Envelope -20 -40 -60 -80 -6 -4 -2 0 Drift % Lehman 2 4 6 Effect of load history interior connections Column Shear (k) Impulsive loading history -6 Lehman Envelope for standard cyclic history Column Bar -4 -2 0 Story Drift 2 4 6 Damage at 5% drift Standard Loading Lehman Impulsive Loading Contributions to drift interior connections 120 Column Percent Contribution 100 Beam Flexure Bar Slip 80 60 Joint Shear 40 “Joints shall be modeled as either stiff or rigid components.” (FEMA 356) 20 Specimen CD15-14 0 1 Lehman 4 7 10 13 16 19 Cycle Number 22 25 28 31 34 Evaluation of FEMA-356 Model interior connections 18 Joint Shear Factor 16 14 12 10 FEMA PEER-14 CD15-14 CD30-14 PADH-14 PEER-22 CD30-22 PADH-22 8 6 4 2 0 0 Lehman 0.005 0.01 0.015 0.02 Joint Shear Strain 0.025 0.03 Joint panel deformations Joint Deformation Joint shear stiffness Joint shear stress (MPa) interior connections Lehman Gc Gc /5 Gc /8 12 20 f c' , psi 10 8 6 10 f c' , psi 20 f c' , psi 4 2 0 0.000 0.005 0.010 0.015 0.020 Joint shear strain 0.025 0.030 Joint strength Joint Stress (psi) effect of beam yielding 1600 Yield 1200 800 400 Yield 0 0 1 2 3 4 5 Drift (%) • Joint strength closely linked to beam flexural strength • Plastic deformation capacity higher for lower joint shear Lehman 6 Joint strength interior connections - lower/upper bounds Joint failure without yielding near 25.5√f’c 0.4 0.3 Failure forced into beams between 8.5√f’c and 11√f’c Joint 0.2 Shear vj/fc’ Failure 0.1 Beam Hinging/ Beam Bar Slip 0 0 10 20 30 L Lehman 40 50 60 Joint strength interior connections Joint Stress (psi) 3500 3000 Joint Failures 2500 2000 1500 1000 10 f c' , psi 500 Beam Failures 0 0 4000 8000 12000 Concrete Strength (psi) Lehman 16000 Joint Stress (psi) Joint deformability 1600 plastic drift capacity 1200 vmax 800 0.2vmax envelope 400 0 0 1 2 3 Drift (%) 4 5 6 Plastic drift capacity interior connections v joint f c' , psi 30 25 20 15 10 5 0 0 0.01 0.02 0.03 0.04 0.05 0.06 plastic drift angle Note: the plastic drift angle includes inelastic deformations of the beams Damage progression exterior connections Pantelides, 2002 Joint behavior exterior connections v joint f c' 15 2 Clyde 6 Clyde 4 Clyde 5 Clyde 5 Pantelides 6 Pantelides 6 Hakuto Priestley longitudinal Priestley transverse , psi 10 5 0 0 1 2 3 4 Drift, % 5 6 7 bidirectional loading Plastic drift capacity v joint f ' c , psi 30 Interior Exterior 25 20 15 10 5 0 0 0.01 0.02 0.03 0.04 0.05 0.06 plastic drift angle Note: the plastic drift angle includes inelastic deformations of the beams Exterior joint hook detail hook bent into joint hook bent out of joint Interior joints with discontinuous bars Column shear, kips 40 30 20 10 0 0 Beres, 1992 1 2 3 Drift ratio, % 4 5 Unreinforced Joint Strength FEMA 356 specifies the following: Vj g joint geometry f c' bh • No new data. Probably still valid. g 4 6 8 10 12 • Assuming bars are anchored in joint, strength limited by strength of framing members, with upperbound of g 15. For 15 ≥ g ≥ 4, joint failure may occur after inelastic response. For g ≤ 4, joint unlikely to fail. • Assuming bars are anchored in joint, strength limited by strength of framing members, with upper bound of g 25. For 25 ≥ g ≥ 8, joint failure may occur after inelastic response. For g ≤ 8, joint unlikely to fail. Joint failure? sy tcr tcr t cr 6 f ' c 1 sy 6 f ' c , psi Joint failure? Lateral Load Lateral Deflection, mm Priestley, 1994 Drift at “tensile failure” Drift at “lateral failure” Drift at “axial failure” Joint test summary axial failures identified Tests with axial load failure 0.06 0.20 - 0.22 0.36 0.03 - 0.07 Drift ratio 0.08 0.10 - 0.18 0.1 } v j gf c' Range of g values Interior 0.04 Exterior, hooks bent in Exterior, hooks bent out 0.02 Corner 0 0 0.05 0.1 0.15 0.2 Axial load ratio 0.25 0.3 Suggested envelope relation interior connections with continuous beam bars 0.015 v joint f ' c 25 , psi stiffness based on effective stiffness to yield strength = beam strength but not to exceed 25 f c' , psi 20 15 8 10 5 0 0.04 0.02 Note: the plastic drift angle includes inelastic deformations of the beams Suggested envelope relation exterior connections with hooked beam bars v joint f c' , psi stiffness based on effective stiffness to yield 25 strength = beam strength but not to exceed 12 f c' , psi 20 15 0.010 connections with demand less than 4 f c' have beam-yield mechanisms and do not follow this model 10 5 0 0.02 0.01 axial-load stability unknown, especially under high axial loads Note: the plastic drift angle includes inelastic deformations of the beams Joint panel deformations Joint Deformation Methods of Repair (MOR) Method of Repair 0. Cosmetic Repair Activities Replace and repair finishes 0-2 1. Epoxy Injection Inject cracks with epoxy and 3-5 2. Patching Patch spalled concrete, epoxy inject cracks and replace finishes 6-8 3. Replace concrete Remove and replace damaged concrete, replace finishes 9-11 4. Replace joint Replace damaged reinforcing steel, remove and replace concrete, and replace finishes 12 replace finishes Pagni Damage States Probability of Requiring a MOR Interior joint fragility relations 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0.0 1.0 Cosmetic repair Epoxy MOR 0 injection MOR 1 Patching MOR 2 Replace concrete MOR 3 Replace joint MOR 4 2.0 3.0 4.0 Drift (%) 5.0 6.0 Beam-Column Connections Jack Moehle University of California, Berkeley with contributions from Dawn Lehman and Laura Lowes University of Washington, Seattle References • Clyde, C., C. Pantelides, and L. Reaveley (2000), “Performance-based evaluation of exterior reinforced concrete building joints for seismic excitation,” Report No. PEER-2000/05, Pacific Earthquake Engineering Research Center, University of California, Berkeley, 61 pp. • Pantelides, C., J. Hansen, J. Nadauld, L Reaveley (2002, “Assessment of reinforced concrete building exterior joints with substandard details,” Report No. PEER-2002/18, Pacific Earthquake Engineering Research Center, University of California, Berkeley, 103 pp. • Park, R. (2002), "A Summary of Results of Simulated Seismic Load Tests on Reinforced Concrete BeamColumn Joints, Beams and Columns with Substandard Reinforcing Details, Journal of Earthquake Engineering, Vol. 6, No. 2, pp. 147-174. • Priestley, M., and G. Hart (1994), “Seismic Behavior of “As-Built” and “As-Designed” Corner Joints,” SEQAD Report to Hart Consultant Group, Report #94-09, 93 pp. plus appendices. • Walker, S., C. Yeargin, D. Lehman, and J. Stanton (2002), “Influence of Joint Shear Stress Demand and Displacement History on the Seismic Performance of Beam-Column Joints,” Proceedings, The Third USJapan Workshop on Performance-Based Earthquake Engineering Methodology for Reinforced Concrete Building Structures, Seattle, USA, 16-18 August 2001, Report No. PEER-2002/02, Pacific Earthquake Engineering Research Center, University of California, Berkeley, pp. 349-362. • Hakuto, S., R. Park, and H. Tanaka, “Seismic Load Tests on Interior and Exterior Beam-Column Joints with Substandard Reinforcing Details,” ACI Structural Journal, Vol. 97, No. 1, January 2000, pp. 11-25. • Beres, A., R.White, and P. Gergely, “Seismic Behavior of Reinforced Concrete Frame Structures with Nonductile Details: Part I – Summary of Experimental Findings of Full Scale Beam-Column Joint Tests,” Report NCEER-92-0024, NCEER, State University of New York at Buffalo, 1992. • Pessiki, S., C. Conley, P. Gergely, and R. White, “Seismic Behavior of Lightly-Reinforced Concrete Column and Beam Column Joint Details,” Report NCEER-90-0014, NCEER, State University of New York at Buffalo, 1990. • ACI-ASCE Committee 352, Recommendations for Design of Beam-Column Connections in Monolithic Reinforced Concrete Structures,” American Concrete Institute, Farmington Hills, 2002. References (continued) • D. Lehman, University of Washington, personal communication, based on the following resources: Fragility functions: •Pagni, C.A. and L.N. Lowes (2006). “Empirical Models for Predicting Earthquake Damage and Repair Requirements for Older Reinforced Concrete Beam-Column Joints.” Earthquake Spectra. In press. Joint element: •Lowes, L.N. and A. Altoontash. “Modeling the Response of Reinforced Concrete Beam-Column Joints.” Journal of Structural Engineering, ASCE. 129(12) (2003):1686-1697. •Mitra, N. and L.N. Lowes. “Evaluation, Calibration and Verification of a Reinforced Concrete BeamColumn Joint Model.” Journal of Structural Engineering, ASCE. Submitted July 2005. •Anderson, M.R. (2003). “Analytical Modeling of Existing Reinforced Concrete Beam-Column Joints” MSCE thesis, University of Washington, Seattle, 308 p. Analyses using joint model: •Theiss, A.G. “Modeling the Response of Older Reinforced Concrete Building Joints.” M.S. Thesis. Seattle: University of Washington (2005): 209 p. Experimental Research •Walker, S.*, Yeargin, C.*, Lehman, D.E., and Stanton, J. Seismic Performance of Non-Ductile Reinforced Concrete Beam-Column Joints, Structural Journal, American Concrete Institute, accepted for publication. •Walker, S.G. (2001). “Seismic Performance of Existing Reinforced Concrete Beam-Column Joints”. MSCE Thesis, University of Washington, Seattle. 308 p. •Alire, D.A. (2002). "Seismic Evaluation of Existing Unconfined Reinforced Concrete Beam-Column Joints", MSCE thesis, University of Washington, Seattle, 250 p. •Infrastructure Review •Mosier, G. (2000). “Seismic Assessment of Reinforced Concrete Beam-Column Joints”. MSCE thesis, University of Washington, Seattle. 218 p.