leitat

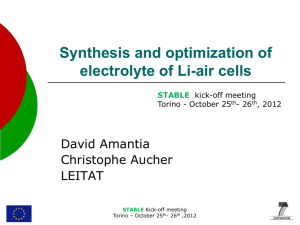

advertisement

Synthesis and optimization of electrolyte of Li-air cells STABLE WP3 organization January, 2013 David Amantia Christophe Aucher LEITAT STABLE Description WP3 LEITAT– January ,2013 Overview Information available from page 6 to 51 of Annex I Work package number WP 3 Start date or starting event: M32 Work package title Synthesis and optimization of electrolyte of Li-air cells Activity Type RTD LEITAT LUREDERRA IVF UCC SAU CEGASA ELAPHE Person-months per beneficiary: POLITO Participant id 14 20 6 0 0 8 6 2 Start date or starting event: End date: STABLE Description WP3 LEITAT– January ,2013 M1 M32 Overall goals Information available from page 6 to 51 of Annex I Objectives - Synthesis and characterization of stable electrolyte with low viscosity and high oxygen solubility to increase the discharge current density. Synthesis, characterization and evaluation of the performance of the electrolyte with different additives in terms of their effect to volatility, viscosity and conductivity of electrolyte. - Determination of the most suitable lithium air battery materials and technology for the use in EVs. STABLE Description WP3 LEITAT– January ,2013 Objective Work will be focused on: -the preparation/characterization of IL/solvent/additives/salt melts -studies on SEI -Optimization of PC/EC/DEC/DMC melts -Build new ILs by ions exchange from conventional RTILs or other precursors. -Additives for by-products and oxygen solubility Challenge = reach the best ratio between: Conductivity (& viscosity, temperature) ↑ Solvent evaporation ↓ Electrolyte quantity Oxygen & by-product solubility ↑ Water content ↓, Hydrophobicity ↑ Electrochemical windows ↑ Stability (cycling) ↑ Safety ↑ STABLE Description WP3 LEITAT– January ,2013 Objective Commercial solution New Electrolyte Byproduct solubility Filling amount Solvent Evapor ation Safety Most of these parameters could be evaluated by a simple survey of the previous works or by comparison of the technical data sheets for the commercial products. Will we be able to upscale the quantity? yes Candidates No E Viscosity Stability Conduc tivity Bibliographic survey Oxygen solubility Water content Price Physical and chemical characterization yes Candidates There is an interest to not use a commercial solution ? STABLE Description WP3 LEITAT– January ,2013 No Electrochemical characterization Final confrontation between commercial and innovative solution (performances) Workplan Information available from page 6 to 51 of Annex I Task 3.1: Synthesis and optimization of room temperature ionic liquids (RTILs) or combinations solvents properties for the aim of obtaining good performance electrolyte solvents (Month 1- Month 32, POLITO (14 MM), LEITAT (12 MM) and CEG (6 MM)). Task 3.2: Investigation on influence of aprotic additives to RTILs on properties and oxygen solubility etc. (Month1- Month 32, 8MM, SAU). Task 3.3: Investigation and evaluation of physical properties of RTILs and the optimum filling amount of electrolyte. Material and production techniques analysis including LCA (Month 1- Month 32, LEITAT (8MM), LUREDERRA (6MM), Elaphe (2MM)) Milestones (M7, M8, M9) Deliverables (D3.1, D3.2, D3.3) STABLE Description WP3 LEITAT– January ,2013 Organization (proposition) Melts Preparation. To complete a database by studying always the same parameters. Exchange between partners to lead to the complete evaluation of the samples depending of the skill/equipment availabilities. (dry/glove box, potentiostat, karl fisher, ionic chromatography, reference cell, cell pack…) Database Synthese & Physical/Chemical Characterizations Battery EV 1) electrolyte 2) LISICON modification M12 M7 M7 Additives ? ? Lab scale M12 RTILs M24 Cegasa, Polito, Leitat (melts preparation) Task 3.2 M24 PC/DEC/EC M12 Task 3.1 Lab scale (characterization) M7 RTILs M7 Task 3.3 Feedback Samples transfert Additives Input (Material, production, Power&Energy needs…) Repport (template proposed: (1) State of the art SoA, (2) Beyond SoA, (3) Table comparative) All technical data (numbers), Price, Safety, Other… Samples Electrochemical windows, Capacity, EIS, rate of charge/discharge, energy & power density, Stability (cycling), By-product solubility, WP3 Filling amount, gas (nature, flow), Price, SEI, Other… ,2013 water content, purity (ions contents), conductivity, thermal properties (volatility, degradation, Mp, Bp…), O2 solubility, viscosity, Other… STABLE Description LEITAT– January SamplesUp scaling Deliverables Information available from page 6 to 51 of Annex I D3.1) Electrolyte solvent synthesis and optimization (I): Report on description of preparation and characterization of lithium air battery electrolytes: 1) Preparation and characterization of salt and different compositions of ionic liquids with physical and chemical specifications; 2) Preparation and characterization of suitable additives or fillers to RTILs; 3) Investigation of suitable conditions for electrolyte such as filling amount and environment impact specifications such as temperature and pressure etc. [month 12] D3.2) Electrolyte solvent synthesis and optimization (II): Report on description of improvement on performance of produced lithium air battery electrolytes: 1) Optimization of the physical properties and electrochemical performance of the produced electrolytes such as viscosity and ion conductivity through adding suitable additives. Electrolyte will be analyzed by Raman spectroscopy after subjecting the anode to the electrolyte with different times, oxygen solubility will also be tested; 2) Optimization of the salt and different compositions for ionic liquids; 3) Determination of suitable conditions for electrolyte such as filling amount and environment impact specifications such as temperature and pressure etc. [month 24] D3.3) Conclusion on electrolyte solvent synthesis and optimization: Report on description of assessment on the prepared electrolytes in terms of physical and electrochemical performances: 1) Selection of optimum additives for electrolyte; 2) Selection of optimum electrolyte compositions with good physical specification (i.e. conductivity versus temperature, electrochemical windows, viscosity versus temperature); 3) Obtaining the optimum physical conditions for electrolyte. [month 32] STABLE Description WP3 LEITAT– January ,2013 Deliverables Information available from page 6 to 51 of Annex I D1.1 Title Description Date Electrolyte solvent synthesis and optimization (I): Report on description of preparation and characterization of lithium air battery electrolytes: 1) Preparation and characterization of salt and different compositions of ionic liquids with physical and chemical specifications M12 2) Preparation and characterization of suitable additives or fillers to RTILs 3) Investigation of suitable conditions for electrolyte such as filling amount and environment impact specifications such as temperature and pressure etc. STABLE Description WP3 LEITAT– January ,2013 Proposed deadlines M7 – April 2013: Reports (SaO, specifications, parameters...) First synthesis or melts preparation First characterizations (chemical, physical) M12 – September 2013: First complete experimental specifications (e.g. All: chemical, physical and electrochemical tests) M24 – septembre 2014: First pack cells STABLE Description WP3 LEITAT– January ,2013 Thank you for your attention STABLE Description WP3 LEITAT– January ,2013 Synthesis and optimization of electrolyte of Li-air cells Designation Glove box IC Potentiostat / Galvanostat TGA DSC FTIR Conductimeter Leitat Toolbox Karl Fisher Viscosimeter Utility Rate of O2 and H2O > 0.1 ppm 1) Preparation of the electrolyte (i.e. salt of lithium+ solvent.) 2) Assembly of the electrochemical cell 3) Electrochemical test inside the glove box (Electrolyte electrochemical Windows) Ionic Chromatography Cl-, BF4-, TFSI-, TFO-, PF6-, NO3-, CH3COO-, NH3-… (detection limit = 0,1 ppm – 10 ppm) Equipment Glove Box UNILAB (4 gloves) High precision for the determination of the water content. 10 – 1000 µg, ± 3 µg 2 potentiostat / galvanostat are available for testing, (1) electrolyte (conductivity, O2 reduction, potentials windows) and (2) complete cell in a Swagelok system where the purity and gas pressure could be controlled. Coulometer KF 831 Dionnex ics 300 Sample charger As-DV VMP3 Autolab Thermal Gravimetric Analyze TGA Q500 Conventional method for determining the temperature of the degradation of the solvent and the water content. Differential Scanning Calorimeter DSC Q20 Conventional method for determining the physical properties of the solvent (melting, freezing points…) Fourier Transform InfraRed spectrophotometer IRAffinity-1 Conventional method for determining the nature of the different bonds. Conventional method for determining the conductivity of the solvent and electrolyte. Possibility for checking the conductivity at different temperature. Conventional method for determining the viscosity of the solvent and electrolyte. Possibility for checking the viscosity at different temperature. STABLE Description WP3 LEITAT– January ,2013 Ec-Meter Basic 30+ Titanium cell for viscous liquid and Platinum cell for conventional liquid. Brookfield LV DV-E Vicometer LV spindle set (from 61 to 64)