CE 413 Class 3 Mix Design Slides & Lab Schedule

advertisement

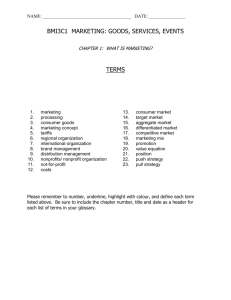

The Cathedral of Our Lady of the Angels. Los Angeles, California Rafael Moneo Form a group of 3-4 students for mix design lab next week Write all your all names on a piece of paper and turn in at the end of class Possible Group Mix Times in Structures Lab Tuesday Wednesday Thursday 8 – 10 am Friday Saturday 8 – 10 am 8 – 10 am 10 - noon 10 - noon noon - 2 pm 2 - 4 pm 4 - 6 pm 4 - 6 pm 4 - 6 pm 6 - 8 pm 6 – 8 pm 6 - 8 pm Group 1 4000 psi no AE no fiber Group 2 5000 psi no AE no fiber Group 3 6000 psi no AE no fiber Group 4 4000 psi no AE yes fiber Group 5 5000 psi no AE yes fiber 4 - 6 pm • Stiff 0-2” – massive sections, little reinforcement • Medium 2-5” – columns, beams, retaining walls • Fluid 5-7” (sometimes even 10”) – heavily reinforced section, flowable concrete Different Slumps Taipei 101 Pumping Test of HPC Steel Rebar Congestion High Slump Achieved with Superplasticizers Mix Design: Target Strength = 10,000 psi w/c = 0.31 Achieved Strength = 12,000 psi with slag & silica fume and superplasticizers ½” diameter aggregate maximum Result of Poor Concrete Placement due to Inadequate Workability of the Mix Concrete Mix Design • Design a mix that provides the required strength with minimum cement amounts, the required durability and acceptable workability/consolidation (slump) • Factors: Intended Use, Exposure, Size & Shape of Members, Strength • Minimize cement content – Use highest w/c ratio permitted – Use largest size aggregate with good gradation – Do not use too much fine aggregate – Use admixtures – fly ash, superplasticizers, etc. • Higher slump mixes require more water and therefore more cement (to keep w/c ratio constant) than lower slump mixes for the same f’c strength provided • Mixes with rounded aggregate will have a higher slump than with angular aggregate for the same w/c and air How do I design a concrete mix? Produce a trial batch w/ the ACI 211 Design Procedure: 1. 2. 3. 4. Water and air entrainment determines slump w/c determines strength (durability requirements also) Compute cement from 1 & 2. Use as much coarse aggregate as you can (compute from empirical tables). 5. Fine aggregate fills the rest of the space (compute by subtracting weights of other ingredients from estimated total weight) 6. Adjust weights of aggregate and water added based on each aggregate’s moisture content and absorption capacity Get Concrete ‘Cookies” Mix Design I Concrete for an interior column in a three-story building The desired properties are: • Slump = 3” – 4” • 28-day compressive strength, f’c = 4000 psi • No air-entrainment required (interior, not in contact with soil) • Coarse aggregate: – Nominal maximum size = 1” (max. aggregate size is 1-1/2”) – Dry-rodded bulk density = 105 lb/ft3 – Absorption capacity (AC) = 1.0% – Moisture content (MC) = 0.5% • Fine aggregate: – Fineness modulus (FM) = 2.70 – Absorption capacity (AC) = 0.7% – Moisture content (MC) = 1.5% Table 1 Table 2 Table 3 Table 4 Level of Moisture in Aggregate • Oven-dry (OD). All moisture is removed. All pores connected to the surface are empty and the aggregate is fully absorbent. • Air dry (AD). All surface moisture is removed, but internal pores connected to the surface are partially filled with water. The aggregate is somewhat absorbent. • Saturated surface dry (SSD). All pores connected to the surface are filled with water, but the surface is dry. The aggregate is neither absorbent nor does it contribute water to the concrete mix. • Wet. All internal pores connected to the surface are filled with water and there is excess moisture on the surface. The aggregate contributes water to the concrete mix. Adjustments for Aggregate Moisture & Adsorption Aggregate weights. Aggregate quantities are calculated based on oven dry (OD) unit weights, but aggregate is typically batched based on weight as-is the lab or field. The as-is lab or field aggregate may have a moisture content – have water in its pores or on its surface/ water. This moisture in the aggregate will increase its weight. Without correction for the moisture content, the batched aggregate volumes will be incorrect. Amount of mixing water. If the as-is aggregate is anything but saturated surface dry (SSD) it will: Take away (absorb) water (if oven dry (OD) or air dry (AD)) from the added mix water and away from the cement paste. or Add water (if surface water is present) to the mix water and the cement paste. This causes a change in the amount of water available in the mix and the amount of water added to the mix must be adjusted accordingly. Adjusting for Aggregate Moisture & Adsorption • The actual quantities of aggregate to be weighed out during batching of a concrete mix must allow for the specific amount of moisture present in the aggregate. • Generally, the aggregates will be moist and their dry weights should be increased by the amount of water they contain, both absorbed and surface. This is the moisture content of the aggregate. • The mixing water added to the batch must be reduced by an amount equal to the free moisture contributed by the aggregate (i.e., moisture content of the mix minus absorption capacity of aggregate, or the what is available from the surface moisture). • Remember that water absorbed into the aggregate does not become part of the available mixing water. • If the MC is less than the AC, more mix water needs to be provided because some of the mix water will be absorbed by the aggregate. • If the MC is more than the AC, then surface water is included in the mix already from the aggregate and less mix water needs to be added. Trial Batching Steps • Use Table 1 to determine the amount of water per cubic yard req’d to obtain the desired slump • Use Table 2 to determine the w/c ratio req’d to obtain the desired strength • Calculate the amount of cement • Use Table 3 to determine the amount of coarse aggregate • Calculate the amount of fine aggregate using the estimated weight of concrete from Table 4 Fine Weight = Total Weight – Coarse Weight – Cement Weight – Water Weight • Adjust the amount of coarse and fine aggregates and amount of mix water based on moisture in/on aggregate (MC) and the adsorption capacity (AC) of aggregate Mix Design II Concrete for an exterior slab of a parking deck The desired properties are: • Slump = 1” – 2” • 28-day compressive strength, f’c = 3500 psi • Air-entrainment required • Coarse aggregate: – Nominal maximum size = 3/4” – Dry-rodded bulk density = 100 lb/ft3 – Absorption capacity (AC) = 1.5% – Moisture content (MC) = 1.8% • Fine aggregate: – Fineness modulus (FM) = 2.60 – Absorption capacity (AC) = 1.0% – Moisture content (MC) = 2.0% On-Going Research Area Steel Rebar Diameters and Areas Summary Adjusting for aggregate moisture • • • • • • • • The aggregate quantities are based on OD conditions. The actual quantities of aggregate to be weighed out during batching of a concrete mix must allow for the specific amount of moisture in the aggregate. Generally, the aggregates will be moist and their dry weights should be increased by the amount of water they contain, both absorbed and surface. The mixing water added to the batch must be reduced by an amount equal to the free moisture contributed by the aggregate (i.e., moisture content of the mix minus absorption capacity of aggregate or the what is reported as the surface moisture). Thus, if the total moisture content of the sand is 5.20% and the sand absorption is reported to be 0.7 %, while the comparable values for coarse aggregate are 2.0 % and 0.5 %, you would adjust the batch weights as: For aggregates, Batch weight = Design weight * (1 + decimal equivalent of total moisture content) For water, Batch weight = Design water – coarse aggregate free moisture – fine aggregate free moisture Remember that water absorbed into the aggregate does not become part of the available mixing water, and only the surface water of the aggregate must be considered in the last step. Coarse aggregate = 1,836 x 1.020 = 1,873 lbs Fine aggregate = 1,243 x 1.052 = 1,308 lbs Water = 315 - (1,836 x .015) - (1,243 x .045) = 315 - 84 = 231 lbs WaterCementitious Materials Ratio Aggregates Water Content Cementing Materials Content Cementing Materials Content • The grading characteristics and nature of aggregate particles have an important influence on proportioning concrete mixtures because they affect the workability of the fresh concrete Bleeding and its control • Creates problems: • causes – lack of fines – poor pumpability – too much water – delays in finishing content – high w/c at the top • Remedies – poor bond – more fines between two layers – adjust grading – entrained air – reduce water content