Sample paper

advertisement

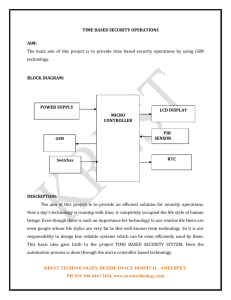

Embedded System Based Industrial Process Automation and Remote Data Logging Using GSM with Web Technology 1 S.V. Tresa Sangeetha, 2Dr. S. Ravi and 3Dr. S. Radha Rammohan 1 Lecturer- Department of Electrical Power, Al Musanna College of Technology, Ministry of Manpower, Sultanate of Oman 2.HOD- Department of ECE, Dr.MGR University, Chennai, India. 3. Assistant Professor - IT Department, Ministry of Higher Education, Sultanate of Oman. level of success in terms of implementation, cost effectiveness and reliability. The aim of this paper is to propose a simple and cost effective Abstract Embedded ARM system implementation of Remote Industrial This paper proposes a wireless Automation system for Process Monitoring, Controlling and Logging system using minimum human intervention industrial critical process, in GSM and Web Technology. Using this concept, the analog which automation of process control need to be remotely monitored and reconfigured by the plant operator using GSM/ parameters can be efficiently logged in the local memory and SMS communication. The system proposed here makes the file uploaded at regular intervals to a common server Automation process more flexible by having an option for the through GPRS commands. The data uploaded can be accesses at anytime and from anywhere through internet. To deliver operator to take runtime decision to override the set values in Automation. The system uses GSM/SMS between the data direct from field sites to a web server, the GSM Automation Process and the Operator thereby extending the technology utilizes the GSM cell phone network. The mobility of the operator. This system utilizes the Analog technology may prove very cost effective and practical in areas sensors, STM32V ARM development board with SD Card and served by cell phone data services. To eliminate the need for GSM900 A Modem with GPRS activated. An SD card linked complex radio based telemetry networks and in-field data with the STM32V enables logging and uploading of plant recorders, here we have used the GPRS technology. PC is parameters in a server for later reference and study. Thus a turned into a 'virtual' data recorder whenever data is sent direct ubiquitous system using GSM and GPRS based Web from field sites to the internet. Technology is suggested for continuous monitoring and control of Industrial process. 2. Literature Review Keywords: ARM processor, GSM Modem, GPRS, Remote The system proposed in [1]monitors and controls the humidity from the remote location and whenever it crosses the set limit Monitoring and Control, SD Card File system. the LPC2148 ARM processor used for implementation will send an SMS to a concerned plant authority(s) mobile phone 1. Introduction With the growth and widespread reach of cellular network and via GSM network. The concerned authority can control the Web Technology, its application has extended to process plant system through his mobile phone by sending AT Commands to control. Industrial Automation is an ideal solution for cost GSM MODEM and in turn to processor. Also the system effective Process Parameter monitoring and control since it provides password security against operator misuse/abuse. The requires minimum human presence in the vicinity of the system uses GSM technology for informing critical condition. process set up. But there are instances where critical human he system in [4] proposes a light controller and remote decision is required to control the process and also logging of monitoring system is based on GSM-Bluetooth. This system data required for later reference. This paper suggests a control has simple features designed with the objective of minimum system that addresses these requirements in which GSM/SMS power consumption using infrared sensor for controlling lights, is used for data reading and control and GPRS is used for fans and other appliances which are controlled using a GSM remote data logging, thus giving the flexibility for the operator module via SMS. The main microcontroller chip interfaced to be available anywhere away from the vicinity of the process. with a Bluetooth module. If the application is in a limited This system suggested in this paper which can be a supplement range (some meters) then this Bluetooth module removes the or even alternative to SCADA is tested for reading usage charges by communicating with the appliances by means Temperature and Pressure which are common analog of Bluetooth. The system will inform to the user about any abnormal conditions like intrusion detection by means of SMS parameters in process Industry. Mobile phone usage has grown exponentially over the last from the GSM module or by Bluetooth module to the user’s 2 decades. To support the increasing demands of the users, the mobile and actions are taken accordingly by the user. The infrastructure is set up to reach remote rural areas.GSM is the project in [3] develops network utilities which are required to dominant global mobile phone network which allows exchange effectively monitor a LAN network by developing an integrated software solution that allows a network of short text messages economically. administrator to remotely monitor a LAN by his cell. In a In Remote Monitoring and Control application, various concern, the computers which are grouped together to form a methods have been employed and each method has its own network are easy to manage and control while the administrator is in office. This paper[3] proposes a system to monitor and control a network using a cell away from office. one can always have our cell phone Instead of depending on third party information . This project[3] provides maximum details about the network to the administrator on their mobile phone, when administrator is away from office/goes out station. The system proposed in [2] designs a home automation and security system using Android ADK. The implementation is based on a standalone embedded system board Android ADK (Accessory Development Kit) at home. Home appliances are connected to the ADK and communication is established between the ADK and Android mobile device or tablet. The home appliances are connected to the input/output ports of the embedded system board and their status is passed to the ADK. An authentication system is also developed for authorized person to access home appliances. The device with low cost and scalable to less modification to the core is much important. This paper[2] presents the design and implementation of automation system that can monitor and control home appliances via android phone or tablet. The Entire system Block Diagram is shown in fig. 1. The Block diagram consists of Temperature Sensor, STM32V ARM Processor (shown in Fig. 2), GSM/GPRS MODEM SIM900A (shown in Fig. 3), Plant Control circuit, SD card and Mobile phone. The system proposed in this paper ensures that the Industrial Plant Parameters are within the safe operating limits by sending SMS text message by the plant operator and also the read plant parameters are stored in the SD card interfaced with the ARM board. Fig. 2: HY-Mini STM32V development board and SIM900-TTL MODEM. 3. Proposed System The system proposed in this paper uses the GSM technology 4. Hardware Implementation and Description The for remote monitoring as in [1],[4] and uses GPRS based web Interface Diagram of Temperature and Pressure sensors with technology for logging the monitored data. STM32 core is shown in Fig. 3. The features of the proposed system are: No need of human operator in the vicinity of process plant. System can be made scalable and reconfigurable using ARM modules. Data communication done by low cost SMS. Usage of existing GSM network reduces initial set up cost. Mobility of the operator is not restricted as the GSM technology works for mobile handsets. No need for a dedicated PC in the vicinity of the plant as the data is logged in remote server through GPRS. Fig. 3: Interface between HY-Mini STM and peripherals. 5. Software Implementation and Description The software is developed in Embedded C for the system using Keil and the program is cross compiled and embedded in the STM32V ARM processor board. The flowchart depicting Monitoring, Control and Logging of Plant Parameters are shown with subroutine description in Fig. 5 and the Block diagram for GPRS based web access by field sensor is shown in Fig. 4. Fig. 1: Block Diagram of STM32V based Remote Monitoring system. Algorithm 1. Read the Analog value from sensor. 2. Convert Analog to Digital value. 3. If the value is more than the Threshold Send signal to Actuator control Send SMS to the operator mobile. Save values in SD card. Go to step 1. 4. If the value is less than Threshold, Check if any SMS received from operator. If SMS not received go to step1. If SMS received, Read AT Commands from GSM Modem Decode the AT Commands Send Control action to Actuator, Go to step1. Start Initialise STM32V processor, Flush I/O ports Call LCD_Initializtion Subroutines to configure the ports connected to LCD Display Call USART1_Configuration Subroutines to set Ports (PA3, PA4), Baudrate (11500), and Parity information for serial data transfer between processor and GSM Modem. Steps to Set up TCP Connection using GPRS Network Call ADC_Configuration and ActuatorConfig Subroutines to configure PC1 to read Analog Parameter data and PC2 to control Actuator Call ADC_ Software StartConvCmd to start Reading the Analog input voltage from PC1 Call ADC_GetConversionValue () to convert the read analog voltage into digital value. Fig. 4: Establishing TCP Connection using GPRS. Step 1.Query GPRS network by sending AT Commands AT+CREG AT+CGATT to GSM/ GPRS Network. Step 2.Acknowledgement received if modem is attached to GPRS Service. Step 3.Send AT Command (AT+CIPSTART,”TCP”, IP Address of Server”, Port Address). Step 4.TCP Connection is established between the SIM 900 Module and server. Step 5.Open file from SD card Step 6 Read a string of data. Step 7 Send AT Command to GSM Modem to send the packets to Server. Call GUIText() to Display value read. Call GUI_ADCColor(Val,red) to display value as bar graph. Y ES Is Value> Theshold N0 Call datalog() subroutine that appends value to the file in SD Card with Control Action Taken Call sendSMS subroutine that sends ATCommands (for sending SMS) to GSM Modem in the USART1 PA3(TXD) Fig. 5: Flowchart depicting sending and receiving SMS YES Is there any SMSInterrupt from GSM Modem NO Call ReadSMS() Subroutine to read and deccode ATCommands received as ASCII from PA4(RXD) from GSM Modem. Call ActuatorControl() Subroutine to send control signal to the actuator according to the command 6. Results and Discussion In this section, the proposed system results have been discussed. Fig. 6 shows the measurement and display of Plant Parameters’ Instantaneous values in the bar diagram. Call ActuatorControl() subroutine to reduce control signal to PC4 connected to actuator Fig. 8: SMS received from GSM Modem to operator mobile. Fig. 6: STM32V with GUI Display of Analog input. The system is designed to send control signals to the actuator when process value reaches a set threshold using SMS. The system is designed to inform the operator the Plant Parameter status when it crosses the threshold value by sending SMS and execute appropriate command sent by operator through SMS. Message sent and received from GSM Modem is simulated in HyperTerminal of a computer in the plant premises and shown in Fig. 8 and 9 and the SMS sent and received in the operator Mobile phone is shown in Fig. 7 and 10. Fig. 7: Message sent from Computer to operator Mobile Phone through Hyperterminal. Fig. 9: SMS sent from operator to take necessary control action. Fig. 10: Message Received from operator mobile to computer in plant through HyperTerminal. The Process value is also logged in the SD Card available in the STM32V development board and can be uploaded at regular interval in the common server Which are shown in Fig. 11, Figure12, and Fig. 13. of the cellular network that reduces the initial set up time and cost (iii)Extending the mobility of the operator as the GSM Network is accessible even to remote locations.(iv)SMS cost has reduced drastically and thus system can be operated with less communication cost. The concern in this system is the unpredictable delay in message transfer between the operator and the control unit. Voice call can be used in such conditions and thus this becomes a more feasible, simple, flexible solution for Industrial Process automation with remote human intervention. Fig. 11: Starting of Server. Fig. 12: Pinging the server. Fig. 13: Server webpage showing analog Parameters. 7. Conclusion The proposed system is tested as a standalone embedded system using STM32V ARM Processor board, GSM module, Sensors and actuators for Industrial process control. This is a low cost, wireless control system which can be customized and extended for different Analog sensors and actuators. The advantages of this system is (i) Enabling run time change of control commands for critical situations by an operator in an automation process(ii)Establishing wireless link between the control unit and the operator using the existing infrastructure References [1] Development of a Low-Cost GSM SMS-Based Humidity Remote Monitoring and Control system for Industrial Applications,(IJACSA) International Journal of Advanced Computer Science and Applications, Vol. 1, No. 4(October 2010) [2] Home Automation and Security System Using Android ADK, International Journal of Electronics Communication and Computer Technology (IJECCT) Volume 3 Issue 2 (March 2013) [3] GSM Based LAN Monitoring and Controlling, International Journal of Modern Engineering Research (IJMER), Vol.2, Issue.2,(Mar-Apr 2012) [4] GSM-Bluetooth based Remote Monitoring and Control System with Automatic Light Control, International Journal of Computer Applications (IJCA) Volume 46– No.1 (May 2012) [5] Improvement of a data logger system for renewable energy. As. J. Energy Env. (2009) [6] GPS and GPRS Based Cost Effective Human Tracking System Using Mobile Phones. VIEWPOINT Volume 2 , No. 1, January-June 2011 [7] Remote Data Acquisition Using Wireless - Scada System-International Journal of Engineering (IJE), Volume (3): Issue (1)(2010) [8] Design and Development of GSM based Energy Meter International Journal of Computer Applications Volume 47– No.12, June 2012 [9] Remote monitoring system for oil wells based on GPRS technology, Computer Engineering and Technology (ICCET), 2010 2nd International Conference on (Volume:7) [10] A Mobile GPRS-Sensors Array for Air pollution Monitoring-IEEE SENSORS JOURNAL, VOL. 10, NO. 10, OCTOBER 2010. [11] GPRS-Modem Technology. [Online]. Available: http://www.comtechm2m.com/gprsmodem/gsm-gprsmodem.htm [12] Performance of IP-Based Services over GPRS, IEEE TRANSACTIONS ON COMPUTERS, VOL. 52, NO. 6, JUNE 2003.