Seminar4 39KB Sep 10 2013 04:46:45 PM

advertisement

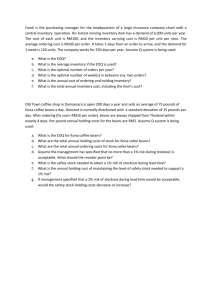

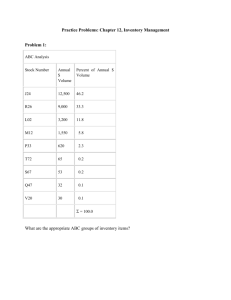

2009-11-17 Seminar 4 Purchases Video Galore Sells Information: Annual demand 13 000 packages 250 packages per week (13 000/52) 15% Purchase: delivery time 2 weeks Ordering costs: 200 per order a) Calculate the economic order quantity Carrying costs: 3.10 Required rate of return for each unit: 15%*14 (purchasing cost) = 2.1 Total of 5.20 EOQ (economic order quantity)= sqrt(2*annual demand*cost per order) = sqrt((2*13000*200)/5.2)= 1 000 b) What is the total annual cost for video tapes? Total annual cost = ((annual demand/order quantity)*cost per order) + ((order quantity/2)*annual carrying cost per unit) = (13000*200)/1000 + (1000*5.20)/2 = 2 600 + 2 600 These are always supposed to be equal. Total annual cost d) Total annual Carrying cost EOQ Cost of ordering Ordering quantety 13 000/1 000 = 13 per year Reordering point Order quantity 1 000 Demand each week 250 Purchase lead line 2 weeks 250 per week * 2 weeks = Reordering point 500 e) Safety stock units: No safety stock Demand resulting in stockouts: 600 Stockout: 600 – 500 = 100 Stockout costs: 100*4=400 Number of orders per year: 13 Probability of stockout: 0.20 Expected stockout costs: 400*13*0.20 = 1040 Carrying costs: 0 (as we had no stock)! Safety stock units: No safety stock Demand resulting in stockouts: 700 Stockout: 700 – 500 = 200 Stockout costs: 200*4=800 Number of orders per year: 13 Probability of stockout: 0.09 Expected stockout costs: 800*13*0.09 = 936 Carrying costs: 0 Safety stock units: No safety stock Demand resulting in stockouts: 800 Stockout: 800 – 500 = 300 Stockout costs: 300*4=1200 Number of orders per year: 13 Probability of stockout: 0.06 Expected stockout costs: 1200*13*0.06 = 936 Carrying costs: 0 Total annual cost: 2912 + 0 = 2912 With a safety stock of: 100 1612 200 1352 300 1560 f) Should Video Galore implement JIT purchasing? Order size with JIT is 100 instead of 1000. Current (EOQ) JIT Order cost 200*13=2600 0 (negligible) Purchasing cost 14*13000=182000 14.02*130000= 182260 Carrying cost 5.20*500=2600 15%*(100/2)*14.02= 105.15 Stockout cost 0 4*50=200 187 200 182 720.15 4479.85 in favor of JIT. EOQ is static. With JIT, you reduce stock levels (more dynamic). Change system if you need improvements. g) Sontek Purchasing price Inspection cost Carrying cost 14.02*13000=182260 0 ( not necessary) 15%*14.02*50=105.15 Denton 13.60*13000*176800 0.05*13000= 650 15%13.60*50=102 Other carrying costs 3.10*50=155 3*50=150 Stockout cost 4*50=200 360*8=2880 50*3.10=155 Customer return cost 25*(2%*13000)=6500 182720.15 187082 Better to stay with Sontek.