V 2

advertisement

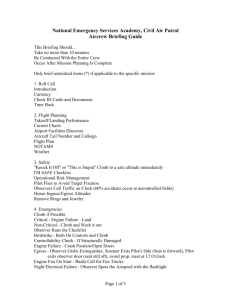

Session 04 Aircraft Accelerated Flight – 2 Session Speaker M. Sivapragasam 1 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Session Objectives At the end of this session, student will be able to: • Differentiate take off and landing requirements of different types of aircraft • Calculate the take off performance of an aircraft • Explain balanced field length requirements for aircraft take off • Calculate the landing performance of an aircraft • Calculate the climb performance of an aircraft 2 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Types of TO/L • • • • • • Conventional Short Super short Extremely short Vertical Rocket assisted 3 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Conventional TO/L • Take off using a conventional runway • Ground roll distance is determined by the requirement to clear a 50ft (35ft for commercial) obstacle • Land on a conventional runway and decelerate after clearing a 50ft obstacle • Flare is a deceleration maneuver to reduce airspeed and altitude 4 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Short TO/L • Take off and clear 50 foot obstacle in between 1000 and 1500 ft • Land and stop between 1000-1500 ft after clearing 50 foot obstacle Cessna 182 Aerostar 600 De Havilland Canada Dash 7 5 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Super Short TO/L • Take off and clear 50 foot obstacle in between 500 and 1000 ft • Land and stop between 500-1000 ft after clearing 50 foot obstacle SSTOL concept from Advanced Composites Anronov AN28 Great Lakes Sport Trainer 6 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Extremely Short TO/L • Take off and clear 50 foot obstacle in under 500 ft • Land and stop under 500 ft after clearing 50 foot obstacle • ESTOL Canaero Toucan Sherpha K650T Aeronca Champion 7 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Vertical TO/L • No need for runway or obstacle avoidance requirement • Aircraft can take off and land without the need for a runway • F35 The Harrier and V-22 Osprey Vertical Takeoff Vehicles 8 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Rocket-assisted TO/L • The use of rockets (usually solid rockets) to shorten takeoff distance • C130 • To decrease landing distance use rockets opposed to direction of flight to fall out of the sky. 9 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Take-off and Landing Take-off Field Length • The take-off field length is generally split into three sections: – Take-off Distance: The ground distance required from brakes release at the start of the runway, accelerating from rest until the aircraft reaches a 'screen' height above the runway. – Take-off Run: The ground distance required from brakes release at the start of the runway, accelerating from rest until the aircraft reaches a point between lift-off and a 'screen' height above the runway. This point can vary between different airworthiness requirements. Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences 10 Take off Field Length • Accelerate-Stop Distance: The ground distance required from brakes release till the aircraft reaches a decision speed and then the brakes are applied until the aircraft comes to a complete stop. Ground Segment V=0 Airborne Segment VLOF V2 V2 Climb Transition Air Acceleration Ground Run B A L1 L2 L3 L4 L Faculty of Engineering & Technology 11 ©M. S. Ramaiah University of Applied Sciences Take off Distance Components • The take-off distance can be split into four different phases: – Ground acceleration – Rotation phase – Transition phase – Initial climb out to screen • Typically, the aircraft take-off manoeuvres corresponding to the take-off distance phases listed above can be split as seen in figure 12 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Take off Distance Components 1. 2. 3. 4. Ground acceleration until lift-off speed Air acceleration until climb safety speed Transition to climb Climb to required altitude Speed JAR25 Decision speed (V1) V1 > VEF > Vmcg Rotation speed (VR) VR > V1 VR > 1.05Vmca Minimum take-off safety speed (V2) V2 > 1.2Vs V2 > 1.1Vmca 13 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Take off Distance Components V2 VR VLOF V1 VMCG • VMCA Before the aircraft becomes airborne – – – the aircraft is accelerating along the ground until rotation at the rotation speed (VR) transition to lift-off speed (VLOF) and climb out to achieve take-off safety speed (V2) at the screen, usually 35 ft. 14 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • To calculate the ground roll, we need to write the equations of motion for the vehicle as it moves down the runway. – See figure below 15 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • The forces that act on it are the aerodynamic forces of – Lift and Drag (L and D), the thrust force (T), – The ground normal force (R) and the ground friction force (μR), where μ is the coefficient of rolling friction. • We can now write the equations of motion along the runway and perpendicular to it. 16 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run 17 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Friction Coefficients (μ) Friction Coefficients (μ) Runway Surface CONCRETE wet dry 0.03 - 0.035 0.04 - 0.05 Grass wet dry 0.07 - 0.1 0.09 - 0.13 - 0.05 - 0.055 sand 0.2 - 0.3 Hard Snow Dry Soft Ground 18 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • Re-arranging we have 𝑇 𝑔 𝑑𝑉 𝑔 −μ − 𝐷 − μ𝐿 = 𝑊 𝑊 𝑑𝑡 𝑇 𝑔1 𝑑𝑉 2 𝑔 −μ − ρ𝑆𝑉 𝐶𝐷𝑔 − μ𝐶𝐿 𝑔 = 𝑊 𝑊2 𝑑𝑡 • During takeoff, high lift devices like Flaps, Slats etc are deployed and the landing gear is also exposed. • Here C Lg and C Dg refer to lift and drag coefficients of the aircraft in such a configuration. • Obviously both the coefficients are large 19 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • In order to be able to integrate the above equations, we need some functional relationships. We assume that Thrust T depends on V as follows 𝑇 = 𝑇0 − 𝑎𝑉 2 Where: T0 = Thrust a zero airspeed (Static Thrust) T = Thrust at airspeed V a = constant that can be positive, negative or zero • Substituting the above assumption into the equations derived earlier and collecting terms of V 2 20 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run 𝑑𝑉 𝑇0 𝑔 1 =𝑔 −μ − ρ𝑆 𝐶𝐷𝑔 − μ𝐶𝐿𝑔 + 𝑎 𝑉 2 𝑑𝑡 𝑊 𝑊 2 = 𝐴 − 𝐵𝑉 2 Here, A and B are defined as: 𝑇0 𝐴=𝑔 −μ 𝑊 𝑔 1 𝐵= ρ𝑆 𝐶𝐷𝑔 − μ𝐶𝐿𝑔 + 𝑎 𝑊 2 21 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run In the previous slide we had shown 𝑑𝑉 = 𝐴 − 𝐵𝑉 2 𝑑𝑡 Dividing both sides by V and realising V = (ds/dt) and rearranging we have 𝑑𝑉 𝑑𝑡 𝑑𝑆 𝑑𝑡 = 𝑑𝑉 𝑑𝑆 = 𝐴 −𝐵𝑉 2 𝑉 𝑑𝑆 = 𝑉𝑑𝑉 𝑐 Here if we assume A and B to be constant as a first approximation, The above equation for “ds” can be integrated between V1 and V2 22 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run 2 1 1 𝐴 − 𝐵𝑉 1 𝑉 𝑆2 − 𝑆1 = − ln 𝐴 − 𝐵𝑉 2 ǀ𝑉21 = ln 2𝐵 2𝐵 𝐴 − 𝐵𝑉22 • Here we consider the case of staring from rest then the above equation simplifies to 1 𝐴 𝑆= ln 2 2𝐵 𝐴 − 𝐵𝑉𝑇𝑂 Where, A and B are defined as: 𝑇0 𝐴=𝑔 −μ 𝑊 𝑔 1 𝐵= ρ𝑆 𝐶𝐷𝑔 − μ𝐶𝐿𝑔 + 𝑎 𝑊 2 23 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • As before we want to find the condition when S is minimum • This happens when we have – Maximum value for A which depends on Thrust/weight ratio and friction coefficient μ – Minimum value for B, here we have control only over C Lg and C Dg 𝐶𝑑𝑔 − μ𝐶𝐿𝑔 = 𝐶𝐷0𝐿𝑔 + 𝐾𝑔 𝐶𝐿2𝑔 − μ𝐶𝐿𝑔 𝐶𝐷0𝐿𝑔 Reduce this by cleaner aircraft 24 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Run • Improve C L g by better high lift devices and also higher angle of a/c during ground run – Simply making the front landing gear taller achieves this !! • We can find the optimum value by differentiating and equating to zero 𝑑(𝐶𝐷0𝐿𝑔 +𝐾𝑔 𝐶𝐿2𝑔 − 𝜇𝐶𝐿𝑔 ) 𝑑𝐶𝐿𝑔 𝐶𝐿𝑔 = 2K g CLg − μ = 0 μ = 2𝐾𝑔 25 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Takeoff : Ground Effect • When an aircraft is flying near the ground it’s efficiency improves – Because of interference between the horse-shoe vortex and ground • One of the methods for correcting for ground effect is to modify value of K 𝐾= 1 π𝐴𝑅𝑒 ϕ= ℎ 16 𝑏 by 𝐾𝑔 = ϕ𝐾 where 2 ℎ 1 + 16 𝑏 2 h = height of the wing above the ground b = wingspan e = Oswald efficiency factor 26 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Landing Run • The opposite of the takeoff procedure is the landing procedure. • Just as in the takeoff, the landing maneuver consists of two parts: – The terminal glide over a 50 ft obstacle to touchdown – The landing ground run • Some calculations include a flare from the landing glide to the touchdown. • However, for a maximum performance landing (short field landing procedure), very little flare is used. 27 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Landing Run • Here we will neglect the flare portion of landing and assume the aircraft touches down at slightly higher speed than it would after flaring. • The equations of motion governing the landing ground run are the same as those for takeoff. • However, the constants A and B can be quite different. – Thrust can be zero or even negative (reverse thrust) – The runway rolling friction can be much larger due to braking. 28 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Landing Run • The boundary conditions are different – At the beginning of the ground roll the velocity is that at touchdown, VTD – At the end of the ground run, the velocity is V2, usually zero • Differential equation of motion for the landing run is the same as that for takeoff: – Results are different For V 2 = 0, we have 29 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Balance Field Length • In order for a multi-engine commercial aircraft to takeoff from a runway, the runway must at least be as long as the Balanced Field Length (BFL). • BFL is determined by considering two options available to the pilot if an engine fails. – continue the takeoff on the remaining engines to clear the 50 ft (15m) obstacle and establish a takeoff distance – apply the brakes as soon as possible after the engine failure and to bring the aircraft to a halt in some distance. – If the two distances are the same, that distance is called the BFL Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences 30 Balanced Field Length 1. Assuming a speed (and distance along the runway) when that the engine failure occurs. 2. Continue the takeoff on the remaining engines and compute the additional distance for the vehicle to clear a 50 ft obstacle, determining the takeoff distance 3. Starting with the speed assumed in (1), assume two additional seconds go by and then • the engines are shut down, brakes applied and the ground roll to stop calculated. 31 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Balanced Field Length 4. Compare the distance in (2) with that in (3). • • • • If the distance to stop is shorter than the distance to fly over the 50 ft obstacle, increase the guess in step (1). If the distance to stop is shorter than that required to clear the 50 ft obstacle, then decrease the failure airspeed in step (1). Continue this procedure until the total takeoff distance and the total distance to stop are the same. This distance will be the balance field length, and the associated velocity found is called the critical engine failure speed 32 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Flight Test – Basics • All TO/L data recorded throughout entire flight test program • Tests devoted to TO/L done at: – Various gross weights – Clean and several “dirty” configurations – Standard to contaminated runway conditions • Must rely on statistical average of as many tests as possible – Greatly affected by factors that cannot be measured and properly accounted for • Typically delayed in flight test program b/c of amount of support and time required 33 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences High-Speed Taxi Test • Conducted prior to any TO/L tests due to: – Always present possibility of a refused takeoff in those tests – Needed to determine parameters used in TO/L tests • Parameters: – Thrust transients – Drag – Rolling Cf – Ground Handling 787 High Speed Taxi Test: Reached 100 knots first test, VR actually about 150 knots 34 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Takeoff Critical Locations Vmc = minimum control speed (OEI) V1 = critical engine failure recognition speed VR = rotate speed Vlo = liftoff speed V2 = cleared obstacle speed 35 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Rejected Takeoff Test • Rejected Takeoff Distance: The distance required for the vehicle to stop from full throttle at V1 speed for a specified altitude, weight, and configuration. • Also known as aborted or refusal takeoff 36 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Rejected Takeoff Test • To reduce risk to multi-million dollar aircraft, brakes are first tested individually in a simulated environment. 37 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Rejected Takeoff Test • Full scale aircraft test - Aircraft is accelerated to V1 at max throttle - A 3 second delay given to simulate pilot time to recognize situation - Engines are set to max reverse and brakes are applied 38 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Aircraft Steady Gliding Flight 39 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Aircraft Steady Level Flight 40 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Steady Climbing Flight 41 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Steady Climbing, Descending Turn 42 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight ε is angle between T and Centre line 43 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight small angle approximation 44 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight 45 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Max Angle of climb 46 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Max Angle of climb 47 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight R/C 48 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight R/C • For our idealized jet airplane, best rate of climb does not occur at minimum power required – Maximum rate of climb occurs at the velocity where excess power is greatest • The velocity for maximum rate of climb is determined for any aircraft as follows : – Plot power required and available versus true airspeed – Choose the velocity where the distance between the two curves is greatest. 49 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight 50 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Max R\C 51 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Effect of altitude 52 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Effect of altitude • Typical Thrust and Power change with altitude • Power required reduces as density drops hence Drag reduces with altitude • However, Power available drops faster, hence R/C decreases with altitude 53 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Propeller aircraft 54 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Climbing Flight Jet Aircraft 55 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Ceiling • The ceiling is the altitude at which R/C has reached some minimum value Absolute ceiling • Is defined as the altitude at which the R/C = 0 • Is dictated when PA is just tangent to the PR curve Service ceiling • is defined as that altitude where R/Cmax = 100 ft/min, is the practical upper limit for steady, level flight 56 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Ceiling Procedure • calculate values of R/Cmax for different altitudes, plot R/Cmax versus altitude • extrapolate this latter curve to 100 fpm and 0 fpm to get the the service and absolute ceilings 57 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Time to Height 58 Faculty ©M. S. of Ramaiah Engineering University & Technology of Applied Sciences ©M. S. Ramaiah University of Applied Sciences Example: F-15 K • Weapon launched from an F-15 fighter by a small two stage rocket, carries a heat-seeking Miniature Homing Vehicle (MHV) which destroys target by direct impact at high speed (kinetic energy weapon) • F-15 can bring ALMV under the ground track of its target, as opposed to a ground-based system, which must wait for a target satellite to overfly its launch site. 59 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Gliding Relations 60 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Gliding Relations 61 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Maximum Gliding Range 62 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Maximum Gliding Range 63 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Sink Rate 64 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Sink Rate 65 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences L/D and Velocity for min sink rate 66 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Mustang Example 67 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Example: High aspect ratio glider q To maximize range, smallest q occurs at (L/D)max A modern sailplane may have a glide ratio as high as 60:1 So q = tan-1(1/60) ~ 1° 68 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example • Use the vehicle characteristics for the very large capacity transport aircraft A380 • Estimate the rate of climb for this aircraft at two distinct points in the climb profile: – 600 meters (2,000 feet) and 210 knots - IAS – 8,000 meters (26,200 feet) and 290 knots - IAS • Estimate the thrust produced by the engines under both conditions • Find the Lift to Drag ratio for both conditions – Assume the International Standard Atmosphere applies to both aircraft states 69 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •An aircraft similar in size and performance as the Airbus A380 –Four turbofan engines each developing 34,400 kg (338,000 N) at sea level –Maximum takeoff mass is 540,000 kg. (1.188 million pounds) 70 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •Visualize the scene and sketch a free body diagram of the system –For this analysis we will ignore the second term in the Right Hand Side •(RHS) of the differential equation (acceleration term) –The pilot is interested in climbing as fast as possible –using all the engine thrust to climb 71 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •Aircraft is treated a point mass for this calculation –And we treat both start and end points 600 m 600 m 72 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example • Step 1: Estimate true airspeed using atmospheric model • Step 2: Estimate the lift coefficient needed to sustain flight using the basic lift equation • Step 3: Estimate drag coefficient • Step 4: Estimate total drag (D) • Step 5: Estimate the thrust produced by the engines at altitude (T) • Step 6: Find the rate of climb (dh/dt) 73 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •Using the standard expression to estimate the true mach number of the aircraft at altitude, –The true mach number is 0.3267, the speed of sound at 600 meters is 337.96 m/s and the density of air is 1.156 k / m3. 𝑀𝑡𝑟𝑢𝑒 = 5 ρ0 ρ 1 + 0.2 𝑉𝐼𝐴𝑆 661.5 0.286 2 3.5 −1 +1 −1 –The true airspeed (TAS) is 110.41 m/s or 214.6 knots –Use the fundamental lift equation to estimate the lift coefficient under the known flight condition 𝐿 = 𝑚𝑔 = ½ ρ𝑉2𝑆 𝐶𝐿 𝐶𝐿 = 2𝑚𝑔 ρ𝑉2𝑆 74 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •The lift coefficient need for flight is calculated •The Drag coefficient is computed using the Drag polar •CD0 is interpolated from values 75 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example •Thrust is always given with dependencies on Mach number and Altitude – Sea level and static thrust is the highest 76 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example 77 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example 78 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example 79 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example 80 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C at 8000 m 81 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C : L/D calculation 82 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Example 83 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences R/C Observations • R/C is highest at sea level and low Mach number – maximum thrust is available • Reduces non-linearly with increasing altitude – depends on density drop – tapers of to zero as it nears the service altitude • R/C is also affected by aircraft Weight and Climb speed. • Next slide shows the effect of weight on R/C 84 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Effect of Weight on R/C 85 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Effect of Temperature on R/C 86 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences Summary In this session following topics were discussed: • • • • • Take off and landing requirements of different types of aircraft Take off performance of an aircraft Balanced field length requirements for aircraft take off Landing performance of an aircraft Climb performance of an aircraft 87 Faculty of Engineering & Technology ©M. S. Ramaiah University of Applied Sciences