Polymers: Introduction

advertisement

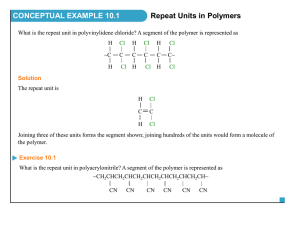

"I just want to say one word to you -- just one word -- 'plastics.'" Advice to Dustin Hoffman's character in The Graduate 1 Polymers: Introduction • Polymer: High molecular weight molecule made up of a small repeat unit (monomer). – A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A-A • Monomer: Low molecular weight compound that can be connected together to give a poymer • Oligomer: Short polymer chain • Copolymer: polymer made up of 2 or more monomers – Random copolymer: A-B-B-A-A-B-A-B-A-B-B-B-A-A-B – Alternating copolymer: A-B-A-B-A-B-A-B-A-B-A-B-A-B – Block copolymer: A-A-A-A-A-A-A-A-B-B-B-B-B-B-B-B 2 Types of Polymers • Polymer Classifications – Thermoset: cross-linked polymer that cannot be melted (tires, rubber bands) – Thermoplastic: Meltable plastic – Elastomers: Polymers that stretch and then return to their original form: often thermoset polymers – Thermoplastic elastomers: Elastic polymers that can be melted (soles of tennis shoes) • Polymer Families – Polyolefins: made from olefin (alkene) monomers – Polyesters, Amides, Urethanes, etc.: monomers linked by ester, amide, urethane or other functional groups – Natural Polymers: Polysaccharides, DNA, proteins 3 Common Polyolefins Monomer Ethylene Polymer Polyethylene CH3 H3C n Repeat unit CH3 CH3 n Polypropylene Propylene CH3 CH3 CH3 CH3 CH3 CH3 CH3 CH3 Ph n Polystyrene Ph Ph Ph Ph Ph Ph Ph Styrene CH3 Cl n Poly(vinyl chloride) Cl Cl Cl Cl Cl Cl Cl Vinyl Chloride F2C CF2 Tetrafluoroethylene F3C Poly(tetrafluoroethylene): Teflon F2 C C F2 F2 C C F2 F2 C C F2 F2 C C nF 2 F2 C C F2 F2 C C F2 CF3 4 Polyesters, Amides, and Urethanes Monomer Polymer O HO2C CO2H Terephthalic acid O OH HO Ethylene glycol Poly(ethylene terephthalate n Ester O NH2 OH H2N 4 1,6-Diaminohexane HO Nylon 6,6 O CO2H H2N HO2C NH2 1,4-Diamino benzene Terephthalic acid H2 C OCN NCO 4,4-diisocyantophenylmethane O HO H N H2 C H2 H2 O C C O H HO O HO 4 Adipic Acid O HO O 4 N H N 4 H Amide O H N H n H N H Kevlar n OH HO Spandex Ethylene glycol O H2 H2 H N O C C O H n Urethane linkage 5 Natural Polymers Polymer Monomer Isoprene Polyisoprene: Natural rubber n H OH H OH HO HO HO H H OH H H ß-D-glucose OH Poly(ß-D-glycoside): cellulose O O O R Amino Acid H3N O OH Nucleotide Base = C, G, T, A O Rn+1 O n OH Rn+2 O O O oligonucleic acid DNA n H N O P O Base OH OH H H N R1 DNA O P O O Polyamino acid: protein H H O H3N HO O HO O Base DNA 6 What Makes Polymers Unique? • Really big molecules (macromolecules) like polymers have very different properties than small molecules – Chain entanglement: Long polymer chains get entangled with each other. • When the polymer is melted, the chains can flow past each other. • Below the melting point, the chains can move, but only slowly. Thus the plastic is flexible, but cannot be easily stretched. • Below the glass transition point, the chains become locked and the polymer is rigid 7 Physical Properties Linear Polymer Stretch The chains can be stretched, which causes them to flow past each other. When released, the polymer will not return to its original form. Cross-Linked Polymer Stretch Relax The cross-links hold the chains together. When released, the polymer will return to it's original form. 8 Polymer Synthesis • There are two major classes of polymer formation mechanisms – Addition polymerization: The polymer grows by sequential addition of monomers to a reactive site • Chain growth is linear • Maximum molecular weight is obtained early in the reaction – Step-Growth polymerization: Monomers react together to make small oligomers. Small oligomers make bigger ones, and big oligomers react to give polymers. • Chain growth is exponential • Maximum molecular weight is obtained late in the reaction 9 Addition Polymerization In* A Initiation In A* A 10 Addition Polymerization Propagation In* A In A A* A Initiation 11 Addition Polymerization Propagation A In* Initiation In A A A* A 12 Addition Polymerization nA A In* In A A A A* Initiation In Propagation A A A A A* n *A A *A A A A A m A A A A m In In A A A A A A A A A A In n n A* A A A A A A A A A A n m Combination B A A A A m Chain Transfer New reactive site is produced Disproportionation Termination Reactive site is consumed MW MW 0 100 % conversion k propagation k ter mination 13 Types of Addition Polymerizations Anionic Ph C3H7 Li n Li+ C4H9 Ph Li+ C4H9 n Ph Ph Ph Radical PhCO2• Ph n Ph PhCO2 n Ph Cationic Ph Cl3Al OH2 PhCO2 Ph Ph n Ph H Ph HOAlCl3 HOAlCl3 H n Ph Ph 14 Step-Growth Polymerization Stage 1 n n Consumption of monomer Stage 2 Combination of small fragments Stage 3 Reaction of oligomers to give high molecular weight polymer 15 Step-Growth Polymerization • Because high polymer does not form until the end of the reaction, high molecular weight polymer is not obtained unless high conversion of monomer is achieved. Degree of Polymerization 1000 Xn = Degree of polymerization p = mole fraction monomer conversion Xn 1 1 p 100 10 1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Mole Fraction Conversion (p) 16 Nylon-6,6 O O O NaOH Cl 4 Cl Adipoyl chloride H2N 4 NH2 Cl O N H 4 1,6-Diaminohexane O Adipoyl chloride in hexane HO N H 4 O N H 4 4 Nylon 6,6 Diamine, NaOH, in H2O H 6 carbon diacid N H H n 6 carbon diamine Nylon-6,6 17 Nylon-6,6 Since the reactants are in different phases, they can only react at the phase boundary. Once a layer of polymer forms, no more reaction occurs. Removing the polymer allows more reaction to occur. Adipoyl chloride in hexane Nylon 6,6 Diamine, NaOH, in H2O 18 Molecular Weight of Polymers Unlike small molecules, polymers are typically a mixture of differently sized molecules. Only an average molecular weight can be defined. Mv Mn Mw # o f m o le cu le s • Measuring molecular weight • Size exclusion chromatography • Viscosity • Measurements of average molecular weight (M.W.) • Number average M.W. (Mn): Total weight of all chains divided by # of chains • Weight average M.W. (Mw): Weighted average. Always larger than Mn • Viscosity average M.W. (Mv): Average determined by viscosity measurements. Closer to Mw than Mn increasing molecular weight 19 What the Weights Mean Mn: This gives you the true average weight Let's say you had the following polymer sample: 2 chains: 1,000,000 Dalton 2,000,000 5 chains: 700,000 Dalton 3,500,000 10 chains: 400,000 Dalton 4,000,000 4 chains: 100,000 Dalton 400,000 2 chains: 50,000 Dalton 100,000 10,000,000 10,000,000/23 = 435,000 Dalton 1 Dalton = 1 g/mole 20 Weight Average Molecular Weight Mw: Since most of the polymer mass is in the heavier fractions, this gives the average molecular weight of the most abundant polymer fraction by mass. 2,000,000 0.20 1,000,000 200,000 10,000,000 3,500,000 0.35 700,000 245,000 10,000,000 4,000,000 0.40 400,000 160,000 10,000,000 400,000 0.04 100,000 4,000 10,000,000 100,000 0.01 50,000 500 10,000,000 Total 609,500 21 Polymer Microstructure Polyolefins with side chains have stereocenters on every other carbon CH3 n CH3 CH3 CH3 CH3 CH3 CH3 CH3 With so many stereocenters, the stereochemistry can be complex. There are three main stereochemical classifications for polymers. Atactic: random orientation Isotactic: All stereocenters have same orientation Syndiotactic: Alternating stereochemistry 22 How to Determine Microstructure? 13C NMR is a very powerful way to determine the microstructure of a polymer. 2 1 1 2 13C NMR shift is sensitive to the two stereocenters on either side on sptectrometers > 300 MHz. This is called pentad resolution. r m m r m r mmrm pentad m = meso (same orientation) r = racemic (opposite orientation) 13C NMR spectrum of CH3 region of atactic polypropylene 23 Why is this important? • Tacticity affects the physical properties – Atactic polymers will generally be amorphous, soft, flexible materials – Isotactic and syndiotactic polymers will be more crystalline, thus harder and less flexible • Polypropylene (PP) is a good example – Atactic PP is a low melting, gooey material – Isoatactic PP is high melting (176º), crystalline, tough material that is industrially useful – Syndiotactic PP has similar properties, but is very clear. It is harder to synthesize 24