file - EBF Groningen

advertisement

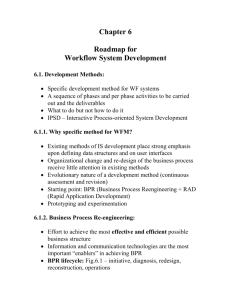

Process Improvement & Quality control – Summaries PPT Six Sigma Six Sigma is an organized, parallel-meso structure to reduce variation in organizational processes by using improvement specialists, a structured method, and performance metrics with the aim of achieving strategic objectives. Underlying assumptions are that an extra organizational structure is implemented for managing improvement projects, every organization has its own hidden factory, project-selection is customer-focused, problems should be parameterized, reduction of variation will lead to performance breakthrough, and a coherent mix of tools is applied in order to reach an unprecedented performance level. Critical to quality characteristics concerns the dimensions of product and process quality, the dimensions on which SS aims to achieve improvements. Influence factors are the vital few out of the trivial many factors that causally affect the CTQs. This program is managed by Master Black Belts. Project tracking by champions who hire black (4/5 modules of a week) and green belts (2 weeks training). Black belts execute their first project in the intermittent periods. Six sigma requires several organizational members. Champions have to define the steps, green belts measure, analyse, and improve, black belts are the project leaders in all steps, and process owners function as controller of the process. Phase’s functionality and steps are: define (problem selection and benefit analysis), measure (translation of the problem into measurable form and measurements of current situation), Analyse (identification of root causes), improve (design and implementation), and control (adjustment of process management and control system). Three propositions are relevant: (1) Organizational performance will tend to improve with the use of a parallel-meso six sigma structure to reduce variation in organization processes by using specialists, a structured methods, and performance metrics with the aim of achieving strategic objectives. (2) Higher levels of simultaneous structural control and structural exploration in Six Sigma tend to result in higher organizational performance (Ambidexterity & Structural control/exploration). (3) Six Sigma will differ from TQM practices and will tend to provide incremental benefits in customer service and financial results for organizations that have already implemented TQM. On the concept of ambidexterity, improvement seems to require stability and adaptability, control and exploration, standardization and flexibility, parallel and sequential, and additional research is required. Six Sigma could be the switching mechanism through structural control dimension (ensures proper execution) and structural exploration dimension (emphasize crossing boundaries, seeking ideas, exploring options). When discriminating Six Sigma from TQM, it can be stated that well-defined organizational structures facilitate leadership engagement, the focus is strongly on financial and business results, insistence on following the structured method and the intense training of full-time specialists, specific measures for measuring processes, and the use of a significant number of full-time specialists. Six Sigma can cover many projects and are identified through bottom-up, from customers and employees, by means of brainstorming, focus groups, and interviews. However, the selection process is a top-down process. In addition, Six Sigma focuses on double loop learning. PPT TOC The theory of constraints was developed by Goldratt, a psychiatrist. It started as a production scheduling technique but is now used as an integrated management philosophy. The main aim of the TOC is to make money now and in the future by making optimal use of bottlenecks. TOC treats any organization as a system in order to come up with unique solutions for better system performance. In order to improve performance, a firm should clarify the purpose of the organization, determine aligned measures, and manage the few things (constraints) that limit the organization’s higher performance relative to that purpose. Constraints can be physical, policy (rules and measures), and paradigm (beliefs or assumptions). There are 5 steps: (1) identify constraints, (2), exploit the constraint, (3) subordinate the system to constraint, (4) elevate the constraint, and (5) start over. A toolset is used in TOC to systematically identify root causes, develop solutions, and implement solutions: Structural aspects of improvements are that there is not much known on who does what. Moreover, other improvements are rendered useless. As such, the TOC is probably change driven, e.g., by top management. Other issues are that TOC could take a lot of time, which results in delegation to middle management which could hinder a successful implementation. Moreover, TOC thinking focuses on undesired effects. The concept may be too focused on corrective action, rather than preventive. Finally, TOC, although highly regarded, is not easily accepted. TOC cannot be easily combined with other approaches and, when focusing too much on output, hinder creativity in a company. TOC sees resistance to change as a positive aspect and even one of the constraints. Finally, it focuses mainly on getting from diagnosis to improvements, without tools for controlling the improvement. PPT – TQM Quality has been defined as quality as excellence (achieving or reaching for the highest standard as against being satisfied with the sloppy), quality is value (quality means best for certain customer conditions, being the actual use and the selling price of the product), quality is conformance to specifications (enabling the comparison of product quality for two or more periods to determine whether differences are greater than should be left to chance), and quality as meeting customer expectations (quality is whatever customers say it is and the quality of a particular product is what the customer perceives it to be). Service quality is a performance-based subjective or attitude-based measure, based on sub dimensions of quality, being interaction quality, technical quality, and physical surrounding. Finally, satisfaction concerns an evaluation of emotions, based on emotion based measures, evaluative set of measures. Total quality management can be defined as a holistic management philosophy that strives for continuous improvement in all functions of an organization, and it can be achieved only if the total quality concept is utilized from the acquisition of resources to customer service after sale. It is based on the principles of customer focus, continuous improvement, and teamwork. Different practices are core and infrastructural practices. Core practices are mechanic/processoriented/technical such as for example process management, quality information usage, and product design through benchmarking. Infrastructural practices are non-mechanic and sociobehavioral, such as top management commitment, customer relationships, supplier relationships, workforce management, and employee trust. Relevant issues in TQM are to create a quality management system that fits with the main characteristics/contingencies of an organization, develop insight in Quality management systems, detect relevant contingencies for the design of QMS, and to be able to denominate the relationship between the contingency factor and the design of the QMS or use of QM systems. A customized quality system is tailor made in adherence to the contingency approach. As such, there is doubt on the universal applicability of QM practices, since effectiveness depends on the goodness of fit between the organization and the QMS. Contingencies are for example process and product characteristics, industry type, uncertainty, manufacturing strategy, firm size, TQM duration, and unionization. Components of TQM content Customer Orientation Market Advantage Increased Revenues Product Design Efficiency Product Reliability Operations Orientation Process Efficiency Reduced Costs High uncertain environment Low uncertain environment Customer orientation Focus on market Focus on product advantage design efficiency Increase in Reduction in revenues costs Revenue loss Additional administrative costs Operations orientation Focus on product Focus on process reliability efficiency Additional Additional production costs production costs Increase in Reduction in revenues costs. There are three types of manufacturing strategies (MFS), being the niche differentiation, broad differentiator, and cost leader. The type depends on the competitive strategy of the firm, whether they are dominant order winners and qualifiers, and the MFS context (degree of product differentiation, production volume, rate of new product introduction, process typology, internal item variety, and internal run sizes. Customer focuses QM practices are customer relationship practices (partnerships, integration, direct contact), customer involvement in new product design, collecting information on customer needs (frequent, close interaction, forward looking, in-depth), and disseminating customer’s information in the organization and being responsive to that information. The main result is that the kind of customer focused QM practices are strongly influenced by a plant’s overall MFS. The degree of product customization and service differentiation are especially relevant. A further main question is how organizations create the ability of continually improving processes, which points to the ability to consistently improve current processes while learning new ones (ambidexterity). In doing this, a coherent infrastructure to coordinate and support continuous improvement, creating a culture for this, and an organizational learning perspective (theoretical lense) are essential. Infrastructure serves the function of executing CI projects, as well as coordinating and supporting the CI projects. All in all, the infrastructure for CI requires a continuous triangle balanced between purpose, process, and people. This change approach can have a practical value when the mechanisms for managing and maintaining IC initiatives are in place and you are aware of the interdependencies among the elements of the CI structure. PPT – BPR Business process reengineering is the fundamental rethinking and radically redesign of business processes to achieve dramatic improvement in critical, contemporary measures of performance such as cost, quality, service and speed or the implementation of deliberate and fundamental change in business processes to achieve breakthrough improvements in performance. BPR is enabled by IT. The essence of BPR is that the process is developed in a way to meet customer requirements and to provide the highest value for customers through emphasis on output. The theory was developed in the mid 80ies as a result of economic pressures that forced radical changes in processes, and showed real progress in many companies (followed by the bandwagon effect). For many, BPR is the only hope for breaking away from the ineffective, antiquated ways of conducting business that will otherwise destroy them. BPR objectives are to dramatically reduce costs, reduce time, improve customer service or employee quality of life, reinvent basic rules of the business, increase customer satisfaction, and stimulate organizational learning. Moreover, BPR is used for radical change in current processes, change is crossfunctional, change is envisioned for the customer, change is pulled by explosive advances in IT, and can be used both in change of current processes and starting new ones. BPR is commonly facilitated by IT in order to obtain organizational efficiency, effectiveness, and transformation. A process is a set of logically related tasks performed to achieve a defined business outcome and a collection of activities, that, taken together, create value for customers. Companies can identify their processes by looking at the current business functions and seeing what process is involved in a specific function. This way, they can locate dysfunctions (processes in deepest trouble), which ones are the most important, and the ones most flexible that can be redesigned. When embarking on BPR, you have to persuade people to embrace (or not to fight) major change, by stating a message on the case for action and a vision statement (where we are, why we can’t stay, what we want). Simple rules are to start with a clean slate, what would you change if you could start again, and how would you design it to have a transition towards horizontal, process-based departments? Moreover, be ambitious and listen to the customer. Improvement sought Starting base Magnitude TMT commitment Role of IT Risk Improvement 30-50% Existing process Incremental Low Low Low BPR 1000-10000% Clean slate Radical High High High What to change? The process that adds value to the customer. Instead of the organization being organized around the functions of the different departments, the organization should be organized around the process that adds value to the customer. How? How the organization can be changed has a lot to deal with ‘out-of-the box’ thinking, because most of the processes are institutionalized, most of the change ideas come from the top of the organization Several BPR change methodologies can be used but most of these theories are part the consultants’ intellectual property. However, most of these methods take the following six phases into account: Preparation, Process-think, Creation, Technical design, Social design and the Implementation phase (Grover et al. 1997) 7 phases of BPR are discover (current and desired state), establish redesign team, analyze and document process, innovate and rebuild, reorganize and retrain, measure performance, and continually redesign and improve afterwards. Key success factors are taking the culture of a company into account, egalitarian leadership, collaborative working environment, tmt commitment, change in management systems, and use of IT. Disadvantages of BPR are the fact that it is costly, time-consuming, 60-80% fail, only one project can be executed at a time, to avoid stress and disruption, and it can only be applied on internal processes. Classic BPR: is about radical change and a rethinking of why we do the things we do and not about tinkering with or speeding up what already is in place. The redesign of processes starts from scratch. Modern BPR: “Radical’’ is not as important as ‘‘process’’. By bringing processes to the forefront, reengineering caused managers to take a lateral rather than vertical view of organizations, process change could be radical or incremental, it could be top-down or bottom-up, it may or may not involve IT, and so on (Grover et al. 1997 ). Organisational transformation (OT) is defined as, "profound, fundamental changes in thought and actions, which create an irreversible discontinuity in the experience of a system" (Adams, 1984, p. 278). BPR involves at best transformation of a few work processes at any given time, But organizational transformation implies change in more organisational dimensions such as organisational structure, strategy, and business capabilities (Davenport and Stoddard, 1994). BPR projects frequently attempt "revolutionary" (radical) change but because of political, organizational and resource constraints, take on "evolutionary" (incremental) implementations. Rather than following universal principles, it was found that consultants tend to tailor their BPR efforts to satisfy unique situational conditions faced by their clients, this could be incremental change as well. (Kettinger et al. 1997) The greatest problem of BPR is the lack of adequate attention to the people aspect and the top-down approach without employee participation. PPT – Lean The goal of lean is to produce what is needed, when it is needed, with the minimum amount of materials, equipment, labor, and space. This way, you design out overburden and inconsistency, hereby eliminating waste. It is crucial to maintain flexibility in this process. There are different types of waste. Muda are activities that consume resources but create no value for the customer. Mura is variation in the operation of a process not caused by the end customer. Finally, muri is overburden of equipment, facilities, and people, caused by mura and muda. Lean operations improve business processes using simple practical tools to enhance quality, costs, delivery, and people contribution and exposes waste in the system. People have to change their long standing work practices and ideas and senior management have to drive lean principles forward with total commitment. It is not a bolt on technique, but more a way of life leading to a total change in culture. As such, lean is completely about culture, not part of what we do, but a part of how we think. It is an embedded culture of understanding the customer’s need, continually striving to reduce waste and optimizing the performance of processes, people, and infrastructure. At all levels, there should be a design to become better. Five principles of lean are (1) specify value, (2) identify the value stream (value stream mapping: provide optimum value to the customer through a complete value creation process with minimum waste in it. Benefits are that VSM allows you to see waste and eliminate it), (3) avoid interruptions in value flow, (4) let customers pull value (Dell’s 3 golden rules: disdain inventory, listen to consumer, sell direct), and (5) start pursuing perfection again. Value is any process that the customer would be prepared to pay for that adds value to the product. The 7 wastes of lean are overproduction, inventory, waiting, motion, transportation, rework, and over processing (and wasted potential of people). Within services, the 7 wastes are delay, duplication, unnecessary movement, unclear communication, incorrect inventory, opportunity cost, and errors. Critical remarks to lean are that there is no attention to change roles, the five principles are vaguely described, it only describes what to improve, but no structure on implementation, and could negatively affect employees’ workload and autonomy. PPT – Tutorials There are four different perspectives on change. The (1) structural-functional perspective concerns changing structures and functions and is related to systems theory and structural theory (KW: inputstransformation-output, rational arrangement of tasks, no focus on culture and power). The (2) multiple constituencies perspective concerns change by negotiation and is related to stakeholders interest (KW: manage stakeholders, pluralist conception of power, change top-down, governance, consensual negotiation, avoid conflict by participative management). The (3) organizational development perspective concerns the humanistic perspective to change and is related to interventions on several levels (KW: structural-functional perspective + HR, action research, organizational diagnosis, process consultation, personal growth, org. learning). Finally, the (4) creativity and volition perspective is a critical theory to change and is related to conflict, flux and change, to construct a grand narrative (KW: change does not emerge from consensus, people are main elements, change can’t be planned). Three general strategies for effecting planned changes in human systems are the empirical-rational strategy (rational solutions to problems, general education to diffuse knowledge, personal selection and replacement, system analysts as staff and consultants, applying research), normative-reeducative strategy (seeking collaborative learning solutions through dialogue, change of attitudes, re- education), and application of power (political and economic sanctions, moral power, hierarchical power, position power). Change follows a sequential process: Initial organization analysis, building and energizing the need for change, describing the present state and future state, define the gap, plan action and implementation, and measure change.