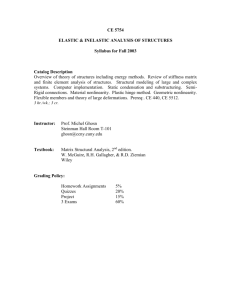

analysis for performance evaluation

advertisement