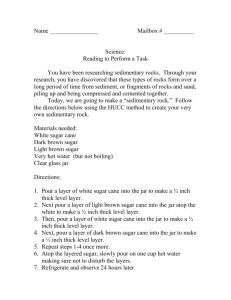

Technology mission on Sugarcane

advertisement