UD-IAC Slideshow - University of Dayton

advertisement

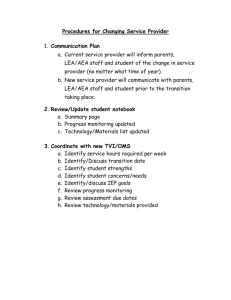

University of Dayton Industrial Assessment Center Kelly Kissock, Ph.D., P.E. Professor and Chair, Mechanical and Aerospace Engineering / Renewable and Clean Energy Director: University of Dayton Industrial Assessment Center Industrial Assessment Center Program Sponsored by U.S. Department of Energy – Program began during 1970s “energy crisis” – 26 centers at universities throughout the U.S. – 20 no-cost assessments per year for mid-sized industries Goals: – Help industry be more resource-efficient and competitive – Train new engineers in industrial best-practices Eligibility for No-Cost IAC Assessment Manufacturing facility SIC: 20 to 39 Annual energy costs: $100,000 - $2,500,000 Other Assistance to Industry from D.O.E. Save Energy Now program – http://www1.eere.energy.gov/industry/saveenergynow/ D.O.E. Software Tools – – – – – – Screening: Quick PEP Process heating: PHAST Compressed Air: Air Master Pumps: PSAT Steam: SSAT Motors: Motor Master General training on D.O.E. software tools – 1 to 3 day seminars on D.O.E. tools Energy Saving Assessments – 3-day assessment of specific energy system – Includes training on use of D.O.E. software tool IAC Assessment Gather and analyze data before visit Team of faculty and students visit plant for one day Work closely with clients to: – Reduce energy – Reduce waste – Improve productivity Write custom, confidential, independent report with specific savings suggestions Call back to see what was implemented UD Industrial Assessment Center Performed over 800 assessments since 1981 Check implementation results after one year – Half of recommendations implemented < 2 year – Average implemented savings: >$100,000 per year UD-IAC Energy Assessment Approach Develop Baseline – Billing analysis: how energy is priced – Energy balance: where energy is used – Lean energy analysis: why energy use changes Identify and Quantify Savings Opportunities – Integrated Systems and Principals Approach to Identifying Savings • • Consider relevant energy systems (elect, lights, motors, fluid flow, compressed air, steam, process heating and cooling, HVAC) Apply principals of energy efficiency (inside out, control efficiency, counter flow, etc.) – Use engineering fundamentals and fundamental-based software to quantify savings Measure and Benchmark – Measurement: extend LEA with sliding NAC and EI to measure energy efficiency improvement – Benchmarking: compare NAC and EI for inter-facility benchmarking 1,800 16,000 1,600 14,000 Actual Demand (kW) 1,400 12,000 1,200 10,000 1,000 8,000 800 6,000 600 4,000 400 2,000 200 0 1/ 24 /0 2 2/ 25 /0 2 3/ 25 /0 2 4/ 25 /0 2 5/ 24 /0 2 6/ 25 /0 2 7/ 25 /0 2 8/ 26 /0 2 9/ 25 /0 2 10 /2 4/ 02 11 /2 2/ 02 12 /2 3/ 02 1/ 24 /0 3 2/ 24 /0 3 3/ 25 /0 3 4/ 24 /0 3 5/ 23 /0 3 6/ 24 /0 3 7/ 25 /0 3 8/ 26 /0 3 0 Actual Demand (kW) Consumption (kWh/day) 140 120 100 80 60 40 20 0 3/ 6/ 02 4/ 6/ 02 5/ 6/ 02 6/ 6/ 02 7/ 6/ 02 8/ 6/ 02 9/ 6/ 0 10 2 /6 /0 11 2 /6 /0 12 2 /6 /0 2 1/ 6/ 03 2/ 6/ 03 3/ 6/ 03 4/ 6/ 03 5/ 6/ 03 6/ 6/ 03 7/ 6/ 03 8/ 6/ 03 Consumption (ccf/day) 160 Consumption (kWh/day) Baseline: Utility Bill Analysis Analyze rate schedule Verify billing amounts Check for saving opportunities: – – – – Primary/secondary Power factor correction Meter consolidation Demand reduction potential Benchmark costs Baseline: Calibrated Energy Use Breakdowns Estimated Electrical Use Breakdown Vacuum Pumps Process Blowers/Fans Lighting Dust Collectors Sanders Other Process Motors Air Compressors Process Heating Other 0% 20% 18% 17% 12% 12% 8% 6% 5% 2% 12% 24% 36% 48% 60% Baseline: Lean Energy Analysis Model energy use as functions of weather and production – E=a+bT+cP – G=a+bT+cP Use models for: – – – – – Measuring savings Budgeting LEA Breakdown Benchmarking Identifying Savings Opportunities LEA: High Independent Identifies Operating Opportunities LEA: High Scatter Identifies Control Opportunities Heating Energy Varies by 3X at Same Temp! LEA: Departure From Expected Shape Identifies Malfunctioning Economizers Air conditioning electricity use should flatten below 50 F Audit found malfunctioning economizers Energy Systems – – – – – – – – – – – Electrical Lighting Motor drive Fluid flow Compressed air Steam and hot water Process heating Process cooling Heating, ventilating and air conditioning Cogeneration Renewable Energy Principles of Energy Efficiency • • • • • • Inside Out Analysis Understand Control Efficiency Think Counter-flow Avoid Mixing Match Source Energy to End Use Whole-system, Whole-time Frame Analysis P-1: Think ‘Inside-out’ Energy Supply Conversion Distribution Use Energy Use Inside-Out Analysis Approach Result: Significant improvement at minimal cost P-2: Understand Control Efficiency Poor Energy Excellent Production (Systems sized for peak but operate at part-load) P-3: Think Counter Flow T Q Parallel Flow T x Q Counter Flow x P-4: Avoid Mixing • Availability analysis… Useful work destroyed with mixing • Examples – CAV/VAV air handlers – Separate hot and cold wells – Material reuse/recycling P-5: Match Source Energy to End Use P-6: Whole System/Timeframe Design • Dopt = 200 mm when Tot Cost = NPV(Energy)+Pipe • Dopt = 250 mm when Cost= NPV(Energy)+Pipe+Pump • Energy250 = Energy200 / 2 Integrated Systems + Principles Approach Compress Process Process Electrical Lighting Motors Fluid Flow Air Steam Heating Cooling Lean Energy Analysis Baseline Inside Out Analysis Minimum Theoretical Energy Conversion and Control Efficiency Match Source Energy to End Use Maximize Counter-flow Avoid Mixing Whole-system, Whole-time Frame Analysis Effective and Thorough HVAC CHP State of the Art Equipment Power logging Ultrasonic flow sensors Ultrasonic vibration Combustion analysis Temperature, light, pressure, air flow, etc. Lighting End Use – Turn off blocked light – Occupancy sensors – Maximize day-lighting Distribution – Add reflectors – Task Lighting – White ceilings / walls Conversion – Upgrade fixtures Motor Drive Systems End Use – Turn off when not in use Distribution – Smooth to notched V-Belts Conversion – Replace rather than rewind – Right-size motors Compressed Air Systems End Use – Eliminate inappropriate uses – Air saver nozzles Distribution – Fix leaks – Timed to demand control drains Conversion – – – – – – Reduce Pressure Efficient control Compress outdoor air Properly stage Adequate storage Reclaim heat to space Fluid Flow End Use – Decrease head – Pump slower/longer Distribution – Reduce friction Conversion – Trim impellor / slow fan – VFDs for variable flow Process Heating End Use – – – – – – Insulate hot surfaces Block radiation Minimize infiltration Reduce cooling losses Reduce conveyor losses Reduce batch losses Distribution – Counter flow heat exchange Conversion – Reduce excess combustion air – Pre-heat combustion air or load – Cascade waste heat Boiler / Steam Systems End Use – Insulate hot surfaces – Cover open tanks Distribution – Repair failed steam traps Conversion – – – – – – Reduce excess combustion air Pre-heat combustion air or feed-water Minimize steam pressure Reduce blow-down Modulation control Add O2 trim control Process Cooling End Use – Insulate cold surfaces – Increase HX effectiveness – Pinch analysis Distribution – Avoid mixing Conversion – Utilized most efficient cooling process – Properly stage chillers – VFDs on CT fans Heating Ventilating and Air Conditioning End Use – Reduce set-points – Reduce infiltration/ventilation – Insulate un-insulated envelope Distribution – Reduce temp stratification – Radiant heaters Conversion – – – – Reclaim heat from process 100% efficient MAU for ventilation Differential pressure control for MAUs Outdoor air economizers Measurement and Benchmarking Measurement – Extend LEA with sliding NAC and EI to measure energy efficiency improvement Benchmarking – Compare NAC and EI for inter-facility benchmarking Measure: Extend LEA by Calculating Sliding Normalized Annual Consumption (NAC) • AC up by 10% • NAC down by 12% Benchmark: Compare NACs of Multiple Facilities Biggest Energy Increase DNAC Smallest Energy Users Biggest Energy Users Biggest Energy Decrease NAC Institutionalize Knowledge Free Energy Analysis Software ESim HeatSim CoolSim AirSim LightSim ETracker UD-IAC Alumni McDonough-Braungart Johnson Controls Honeywell Energy Resource Solutions 2RW Consulting Select Energy Services Heapy Go Sustainable Energy And many more… Awards U.S. DOE 2003 Center of Excellence State of Ohio 2006 Governor’s Award for Excellence in Energy U.S. DOE Energy Champion Awards to UD-IAC Clients Interested? Dr. Kelly Kissock 937-229-2852 kkissock@udayton.edu Franc Sever 937-229-3343 severfrj@notes.udayton.edu http://academic.udayton.edu/kissock/http/IAC