INTRODUCING QUIETSIDE FOR 2002

advertisement

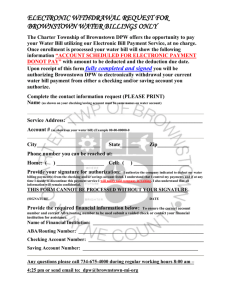

TECHNICAL QUIETSIDE DPW Dual Purpose Water Heating Season 2008/2009 QS-DPW-CT-001 DPW Condensing DPWH • Basic Model Features • 2 models 99k & 120k Btu/h inputs • Tested AFUE of 90% • Provides both Heating and Domestic Hot Water from one unit • Modulating induction fan and gas valve for complete control • Wet recuperative heat exchanger to allow condensing to reduce (<140 DegF) exhaust gas temperature allows venting in Schedule 40 PVC What is a Dual Purpose Water Heater • A Dual Purpose Water Heater is a unit that will provide both heating water for space heating and also potable domestic hot water for washing from a single unit without any additional controls required • Domestic hot water is given priority over the space heating, and is activated by flow through the domestic hot water system • DHW is “on demand” and continuous, it will be provided as long as the faucet is open • Once DHW call is completed the unit will revert to heating the house as required What is a Dual Purpose Water Heater • The Closed Loop Heating system and the Potable DHW system are COMPLETELY SEPARATED FROM EACH OTHER • No Check Valves or other Hydronic components are required for this unit to provide both heating and DHW • This makes this system a true and better alternative to taking a tankless water heater and then adding the necessary components to enable it to provide space heating What is a Dual Purpose Water Heater • It is not called a Boiler in North America unlike the rest of the world, this is because • It does not provide closed loop heating water at a temperature above 176 DegF • It does not have an ASME H stamp, therefore cannot be used in areas where this is a requirement • Internal Water Volume is less than 1 gallon • Therefore these units are certified by ANSI Z21.10.32004/CSA 4.3-2004 as a gas water heater Applications – Hydronic Heating • 1. Radiant Heating : Almost the perfect application for this unit Low water temperature adds efficiency to the system Low water volume suits these ultra low mass type of units However the only issue is not to slice the zones to thin as this can lead to short cycling of the unit when few zones are calling Applications – Hydronic Heating 2. Fan Coils : Good application For maximum efficiency ensure that return temperature is low enough to allow high efficiency operation Use an aqua stat on the air handler to allow indoor fan to cycle off when in DHW mode May need 24VAC SPST relay to interface For Air handlers (even one) with or without pumps we must use the Quietside Primary/Secondary piping arrangement Applications Hydronic Heating • 3. Baseboard : Standard US Baseboard temperature is 180 plus DegF IF baseboard is sized using these temperatures Quietside DPWH can only make 176 DegF MAXIMUM inside the unit – Typically temperature delivered into the loop is approx 165 DegF SO – We may need to add additional lengths of baseboard to the house Applications Hydronic Heating • 3. Baseboard (Cont): ∆T and Hi Flow rates can cause problems maintaining temperature in the system We recommend designing system for a loop ∆T of 20 to 25 DegF to allow the system to inject enough 160/165 DegF water into the loop to maintain temperature and comfort Return temps above 140 DegF back to the DPW significantly reduce efficiency and condensate production Therefore care is required as may not be the best possible application, especially in a true retrofit scenario Applications Hydronic Heating • 4. Cast Iron Horizontal Radiator Panels See baseboard issues regarding the water temperatures and ∆T delivered at maximum from the DPW Very high water volume when compared to a radiant or AHU application This can create flow issues and expansion tank sizing problems for the Quietside unit Return temps above 140 DegF back to the DPW significantly reduce efficiency and condensate production Therefore not a preferred application, without careful planning prior to installation Which size of DPW? HOW TO SIZE THE UNIT • 1. Size the unit to the heating load of the house THEN • 2. Size the unit to the domestic hot water usage of the household. Use the total max DHW load possible, i.e. count all of the faucets or appliances that can be used at a single time, that will be your max DHW load, e.g. Shower and faucet, Shower and Laundry etc etc etc Which size of DPW? • IT IS NOT ACCEPTABLE TO JUST PICK THE LARGEST UNIT IN THE RANGE BECAUSE OF THE DHW REQUIREMENT • We must ensure that the unit will modulate down to meet the heating load of the house, providing that the load is above minimum modulation level • Short cycling will reduce efficiency and promote component wear Sizing the DPW unit • Q : What is the MINIMUM OUTPUT capacity of a DPW? • A: DPW 099 – 47,000 Btu/h DPW 120 – 47,000 Btu/h Values based on net IBR calculations But I have small Zones? • Q : My smallest zone is 10,000 Btu/h what can I do to prevent short cycling of the unit? • A : Quietside recommends that the smallest zone on the system should be 25% of the rated unit input or 60% of the minimum output shown in the previous slide • In the above case we either need to increase the size of the zone in question or ……………….. Get a Buffer • Quietside offers a 20 Gallon buffer tank • DPW maintains the tank temperature and then system pump (field installed) acts as a primary loop pump Prevents the DPW from short cycling Sizing the DPW unit, Part 2 • DHW Production : DPW099 Sizing the DPW unit, Part 2 Sizing the DPW unit, Part 2 • Q : Still not enough DHW Production?? • A : The DPW can be used very easily in conjunction with a storage tank for an instant supply of DHW – An old electric or gas water heater works very well Use a bronze re-circ pump for temperature control in the tank OR Use the Quietside range of Storage tanks which include all of the parts required Sizing the DPW unit, Part 2 • Quietside Storage Tank • 20 Gallon • Comes complete with Bronze pump Mixing Valve Check Valves Aquastat to control pump etc But I want to use a Tankless • Homeowners want to a unit to provide between 6 and 8 GPM of DHW, without a tank • All of these units MUST have a Max Input of between 180,000 Btu/h and 240,000 Btu/h for this level of performance • DPW has a maximum Input of 120,000 Btu/h with a 90,000 Btu/h being sufficient to heat most houses I want my 8 GPM • • • • • Gas Pipe Sizing becomes an issue Standard House Construction (approx) Boiler/Furnace 135,000 Btu/h Storage Water Heater 40,000 Btu/h Range/Fireplace 30,000 Btu/h • Total 205,000 Btu/h • This requires a maximum gas pipe size in the house of 1” giving full capacity at 80ft of gas piping in the house I want my 8 GPM • Gas Pipe Sizing using a DPW with a tank • DPW (Largest) 135,000 Btu/h • No storage Water Heater required • Range/Fireplace 30,000 Btu/h • Total 165,000 Btu/h • This requires a maximum gas pipe size in the house of 1”, with ¾” through most of the house giving full capacity at 80ft of gas piping – no change needed for a retrofit I want my 8 GPM • Gas Pipe Sizing using a Tankless for DHW • • • • Water Heater Furnace or Heating unit No storage Water Heater Range/Fireplace • Total 230,000 Btu/h 135,000 Btu/h 30,000 Btu/h 365,000 Btu/h • This requires a minimum gas pipe size in the house of 1 ½” to giving full capacity at 80ft of gas piping in the house But I want to use a Tankless But I want to use a Tankless • • • • • • Added Cost Pump Taco 007 Expansion Tank Brazed Plate Flow Switch Check Valves • Plus the venting………………………. DHW & Well Systems • Pump is required in a Well application • Pressure changes during DHW use can cause flow/temperature changes of DHW from DPW • Reduce differential on well Pump to minimize OR • USE A QSDHS STORAGE TANK to prevent this Installation and Start Up Locating the DPW unit • Must be in an indoor location • Ensure that the temperature in that location does not fall below 45 DegF • Ensure that the Indoor humidity levels do not exceed 80% • Stay within the venting limitations, total equivalent length of 45feet, less elbows etc • Requires a solidly grounded dedicated 115V power supply • Ensure that a correctly sized gas pipe is available Installing the DPW • Remove unit from Carton • Unit installs on a hanging bracket mounted to studs or wall brace • CANNOT be installed on a combustible wall. Use non combustible backing plate e.g. Durarock or 24g sheet metal • Pipe condensate directly to the building drain • Comply with stated clearances to other appliances Installing the DPW – Water Connections, Left to Right Heating Water Return : ¾” Male Union DHW Cold Inlet (or tank) ½” Male Union DHW Supply to house : ½” Male Union Heating Water Supply : ¾” Male Union DO NOT OVER TORQUE!! Installing the DPW – Gas/Vent • GAS LINE SIZE MINIMUM OF 3/4”, flexible pipe to connect is acceptable providing it has a minimum capacity of 250,000 Btu/h • Drip leg required to prevent dirt entering gas valve • Venting : 3” Diameter Intake and Exhaust is standard – connections go directly to 3” PVC • PVC cement, then seal around vent connection with high temperature silicone to prevent leaks Installing the DPW EXPANSION TANK AND PRIMARY LOOP PUMP INCLUDED • Expansion Tank is equivalent to a standard 20 Gallon • Check your requirement for expansion especially if you are doing an old gravity system • Primary Loop pump, maximum flow through the Primary Loop is approximately 3.5 GPM • If you are using a higher flow on the system side it will blend down the temperature delivered in the heat emitters Installing the DPW • Manual feed valve included on the unit – no pressure setting however it does have a check valve • Always installed an approved Boiler Feed Valve on the closed loop system • Make sure that Backflow prevention is included • Taco 335 or 329 is ideal • Screw the Quietside feed valve closed and do not open it Installing the DPW • Automatic Air vent included inside unit • Air Elimination is very important with these types of units • ALSO INSTALL ADDITONAL VENT AT HIGHEST POINT – AIR REMOVAL IS SINGLE LARGEST CAUSE OF FAULT CODES Installing the DPW Note : THE PLASTIC SIPHON AT THE FRONT OF THE UNIT IT MUST BE FILLED PRIOR TO THE START UP OF THE UNIT Fill To Here Venting the DPW • When installing the venting ensure that the Exhaust Flue is sloped back to the DPW approx 1” per 2ft horizontal to allow condensate from exhaust gases to return to the unit for draining – this will also reduce the build up of ice on the termination during cold weather • Install termination snout to reduce ice build up, caulk around the snout • Install 90 Deg Elbow and birdscreen on the inlet air pipe Vertical Venting the DPW • Respect the maximum vent lengths and elbows • Always use 2 x 45 Deg Elbows on flue pipe • Use the snout that is provided with the unit for the flue pipe • 2 x Elbows are used on the Inlet pip providing they are in the same barometric plane, don’t forget the birdscreen Vertical Venting addendum to IOM available on request DPW Circulation Pump • The pump in the DPW has to overcome the head losses of the unit Heat Exchangers • Therefore the external head available to the system is much less than the gross pump curve printed, in addition the system is designed for higher ∆T’s than standard US Cast Iron boilers Unit DPW 099 Flow Rate @ 15Ft External Head 2.1 GPM DPW 120 2.2 GPM DPW Water Piping THEREFORE WE MUST PIPE THE UNIT AS FOLLOWS, NO IF’S, AND’S OR BUT’S • With a PRIMARY/SECONDARY LOOP with the unit injecting hot water into the secondary loop to be circulated by the loop pump(s) • We also have found that using additional pumps in series does not work well with the DPW • If retrofitting simply remove old unit – replace with pipe and Tees and then pipe up to DPW like this….. DPW Water Piping Cold Water Supply from House to 1/2" male connection on DPW Use 1/2" Unions Notes : When brazing always wrap valves, drains etc with a wet rag to prevent damage DPW UNIT Check system design for requirement for additional expansion tank on closed loop system Shut Off Valves to isolate both Inlet and Supply of DHW system from DPW "Boiler Drains" to allow maintenance of the DHW Plate Heat Exchanger Closed Loop Return Pressure Relief Valve (Factory Supplied) Pipe to building drain (See local codes) Boiler Feed Valve with Backflow prevention See local codes DHW Cold In DHW Hot Out Closed Loop Supply 3/4" Unions to connect to 3/4" Male Supply and Return connections on DPW Shut Off Valves to isolate both Supply & Return Boiler drain installed on Primary Loop should be below DPW Isolation valve to allow closed loop system to be filled with DPW isolated from the closed loop to protect unit A Drain can also be installed on return piping above shut off valve to drain the unit or Pressure Relief valve on the unit can be used provide a drain Anti Scald Valve MANDATORY Set for Maximum of 120DegF Air Vent at highest point House Hot Water Supply Supply to Heating zones (No detail shown) Return from Heating zones (No detail shown) 2 x 1 1/4" x 1 1/4" x 3/4" Tees Space max of 4 Pipe Dia's apart on tee centerline "Boiler Drain" - see notes System Circulation Pump Field Installed Use 1 1/4" pipe diameter for heating primary loop 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW Recommended Piping Layout, Heating & DHW Drg # : QUI-DPWP-001 Drawn : JLM 8/26/2008 Rev : 001 DPW Water Piping Cold Water Supply from House to 1/2" male connection on DPW Use 1/2" Unions Notes : When brazing always wrap valves, drains etc with a wet rag to prevent damage DPW UNIT Boiler drain installed on piping should be below DPW Isolation valve to allow closed loop system to be filled with DPW isolated from the closed loop to protect unit Shut Off Valves to isolate both Inlet and Supply of DHW system from DPW "Boiler Drains" to allow maintenance of the DHW Plate Heat Exchanger Pressure Relief Valve (Factory Supplied) Pipe to building drain (See local codes) Closed Loop Return Boiler Feed Valve with Backflow prevention See local codes DHW Cold In DHW Hot Out Closed Loop Supply 3/4" Unions to connect to 3/4" Male Supply and Return connections on DPW A Drain can also be installed on return piping above shut off valve to drain the unit or Pressure Relief valve on the unit can be used provide a drain Anti Scald Valve MANDATORY Set for Maximum of 120DegF Air Vent at highest point House Hot Water Supply Coil Inlet Shut Off Valves to isolate both Supply & Return HW Coil "Boiler Drain" - see notes AHU Unit System is designed for the Air Handler to be located no more than 10ft from the DPW and no more than 5ft above or below the DPW Air Handler should not have it's own circulator installed Disconnect pump if installed Use max ø1" pipe for Supply & Return to AHU. Max total pipe length (Supply & Return) 20ft 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW Recommended Piping Layout, AHU (No Pump) & DHW Drg # : QUI-DPWP-002 Drawn : JLM 8/26/2008 Rev : 001 DPW Water Piping Closed Loop Heating System Notes : When brazing always wrap valves, drains etc with a wet rag to prevent damage QSDHS DHW System Notes : Tank system also includes Tank Drain and P/R Valve (supplied loose) These should be installed and piped in accordance with local codes Check system design for requirement for additional expansion tank on closed loop system DPW DPWH Boiler drain installed on Supply to closed loop should be below DPW Isolation valve to allow closed loop system to be filled with DPW isolated from the closed loop to protect unit A Drain can also be installed on return piping above shut off valve to drain the unit or Pressure Relief valve on the unit can be used provide a drain House Hot Water Supply Closed Loop Return Pressure Relief Valve Pipe to building drain (See local codes) 3/4" Unions to connect to 3/4" Male Supply and Return connections on DPW Air Vent at highest point DHW Cold In DHW Hot Out Closed Loop Supply DPW DHW Inlet & Outlet connection sizes are 1/2" From DPW DHW Outlet To DPW DHW Inlet Anti Scald Valve MANDATORY Supplied with QSDHS Max Setting 120DegF ø3/4" NPT Connection "Boiler Drain" - see notes ø3/4"NPT Shut Off Valves to isolate DPW from Air Handler Use ø1 1/4" pipe for Primary Loop ø3/4"NPT QSDHS DHW STORAGE TANK SYSTEM 20 GAL CAPACITY ø1" NPT Supply to Heating zones (No detail shown) Return from Heating zones (No detail shown) Secondary or Zone Pump Taco 008 Bronze Pump c/w IFC and Shut offs Supplied with QSDHS Cold Water Inlet from House supply 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW Piping, Primary Loop Htg c/w QSDHS DHW Storage Drg # : QUI-DPWP-003 Drawn : JLM 9/18/2008 Rev : 001 DPW Water Piping Closed Loop Heating System Notes : When brazing always wrap valves, drains etc with a wet rag to prevent damage QSDHS DHW System Notes : Tank system also includes Tank Drain and P/R Valve (supplied loose) These should be installed and piped in accordance with local codes System is designed for the Air Handler to be located no more than 10ft from the DPW and no more than 5ft above or below the DPW Boiler drain installed on Supply to closed loop should be below DPW Isolation valve to allow closed loop system to be filled with DPW isolated from the closed loop to protect unit A Drain can also be installed on return piping above shut off valve to drain the unit or Pressure Relief valve on the unit can be used provide a drain DPW DPWH House Hot Water Supply Closed Loop Return Pressure Relief Valve Pipe to building drain (See local codes) 3/4" Unions to connect to 3/4" Male Supply and Return connections on DPW Air Vent at highest point DHW Cold In DHW Hot Out Closed Loop Supply To DPW DHW Inlet DPW DHW Inlet & Outlet connection sizes are 1/2" From DPW DHW Outlet Anti Scald Valve MANDATORY Supplied with QSDHS Max Setting 120DegF ø3/4" NPT Connection "Boiler Drain" - see notes ø3/4"NPT Shut Off Valves to isolate DPW from Air Handler QSDHS DHW STORAGE TANK SYSTEM 20 GAL CAPACITY Use max ø1" pipe for Supply & Return to AHU. Max total pipe length (Supply & Return) 20ft ø1" NPT HW Coil AHU Unit Taco 008 Bronze Pump c/w IFC and Shut offs Supplied with QSDHS ø3/4"NPT Cold Water Inlet from House supply 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW Piping, Close coupled AHU c/w QSDHS DHW Storage Drg # : QUI-DPWP-004 Drawn : JLM 9/18/2008 Rev : 001 Power Wiring the DPW • • • Power Wiring 115V, 15 Amp dedicated circuit is required Circuit and unit must be grounded • Unit has internal 3 Amp glass buss style fuses to protect the Microprocessor and other components • Seal around connection to prevent leakage Zone Controlling the DPW • Several ways to for zone control of the units 1. Taco/Argo style zone controller 2. SR501 switching relay 3. SPST Relays allow interface with 24VAC Thermostats – e.g. Fan Coils Zone Control Panel Wiring DSR-100F NOTES TO SET DSR-100F 1 PRESS UNIT ON/OFF BUTTON DPW DPWH 2 PRESS HEATING SET TEMP BUTTON (LHS OF ON/OFF BUTTON) YEL 3 USE UP AND DOWN ARROWS TO SELECT DESIRED HEATING WATER TEMPERATURE RANGE 122-176 DEGF YEL BRN BRN 4 PRESS DHW SET TEMP BUTTON (RHS OF ON/OFF BUTTON) 5 USE UP AND DOWN ARROWS TO SELECT DESIRED DHW WATER TEMPERATURE 98-114 DEGF, 120, 130, 140 DEGF WHEN DRY CONTACT IS CLOSED UNIT WILL START AND PROVIDE CLOSED LOOP HEATING WATER AT THE TEMPERATURE SELECTED To Secondary Pump Control e.g. Taco SR501 DHW PRIORITY WILL BE MAINTAINED WHEN THE ZONE(S) SATISFY THE UNIT WILL SHUT DOWN, DSR WILL REMAIN LIT AT ALL TIMES THIS IS THE PREFERRED METHOD TO INTEGRATE ZONE VALVES AND THE SECONDARY LOOP PUMP 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW & TACO ZVC ZONE CONTROL PANEL WIRING Drg # : QUI-ZCW-005 Drawn : JLM 10/17/2008 Rev : 001 Zone Switching Relay Wiring NOTES TO SET DSR-100F DSR-100F 1 PRESS UNIT ON/OFF BUTTON DPW DPWH 2 PRESS HEATING SET TEMPERATURE BUTTON YEL 3 USE UP AND DOWN ARROWS TO SELECT DESIRED HEATING WATER TEMPERATURE RANGE 122-176 DEGF YEL BRN BRN 4 PRESS DHW SET TEMPERATURE BUTTON 5 USE UP AND DOWN ARROWS TO SELECT DESIRED DHW WATER TEMPERATURE 98-114 DEGF, 120, 130, 140 DEGF WHEN X-X CONTACT IS CLOSED UNIT WILL START AND PROVIDE CLOSED LOOP HEATING WATER AT THE TEMPERATURE SELECTED DHW PRIORITY WILL BE MAINTAINED WHEN THE ZONE(S) SATISFY THE UNIT WILL SHUT DOWN, DSR WILL REMAIN LIT AT ALL TIMES THIS IS THE PREFERRED METHOD TO CONTROL THE SECONDARY LOOP PUMP REQUIRED IN ALL NON CLOSE COUPLED AHU & HW COIL APPLICATIONS 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW & TACO SR501 ZONE CONTROL PANEL WIRING Drg # : QUI-ZCW-003 Drawn : JLM 9/24/2008 Rev : 001 Zone Switching Relay Wiring NOTES TO SET DSR-100F DSR-100F 1 PRESS UNIT ON/OFF BUTTON DPW DPWH 2 PRESS HEATING SET TEMPERATURE BUTTON YEL 3 USE UP AND DOWN ARROWS TO SELECT DESIRED HEATING WATER TEMPERATURE RANGE 122-176 DEGF YEL BRN BRN 4 PRESS DHW SET TEMPERATURE BUTTON 5 USE UP AND DOWN ARROWS TO SELECT DESIRED DHW WATER TEMPERATURE 98-114 DEGF, 120, 130, 140 DEGF WHEN X-X CONTACT IS CLOSED UNIT WILL START AND PROVIDE CLOSED LOOP LOOP HEATING WATER AT THE TEMPERATURE SELECTED DHW PRIORITY WILL BE MAINTAINED WHEN THE ZONE(S) SATISFY THE UNIT WILL SHUT DOWN, DSR WILL REMAIN LIT AT ALL TIMES DIAGRAM SHOWS AN SR504, HOWEVER DIAGRAM CAN BE USED WITH ALL ZONE CONTROL PANELS (SR, ZV, ETC) WITH AN X - X OR 0V CONTACT 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW & TACO SR504 ZONE CONTROL PANEL WIRING Drg # : QUI-ZW-002 Drawn : JLM 9/24/2006 Rev : 001 SPST Relay Wiring NOTES WIRING DIAGRAM FOR CONTROL OF A AIR HANDLER & HW COIL, WHERE PRIMARY PUMP IN DPW IS CAPABLE OF PROVIDING FLOW TO FAN COIL DSR-100F DPW DPWH TO SET DSR-100F CONTROLLER YEL 1 PRESS UNIT ON/OFF BUTTON YEL 2 PRESS HEATING SET TEMPERATURE BUTTON BRN 3 USE UP AND DOWN ARROWS TO SELECT DESIRED HEATING WATER TEMPERATURE RANGE 122-176 DEGF BRN SPST RELAY 24V AC 4 PRESS DHW SET TEMPERATURE BUTTON 5 USE UP AND DOWN ARROWS TO SELECT DESIRED DHW WATER TEMPERATURE 98-114 DEGF, 120, 130, 140 DEGF 6 INSTALL AN AQUA STAT IN THE HTG COIL OF THE AIR HANDLER - WIRE TO FAN MOTOR TO STOP FAN OPERATION IF COIL TEMPERATURE FALLS e.g. DHW PRIORITY OR INITIAL START UP WHEN T-STAT CALLS FOR HEAT, RELAY WILL CLOSE AND DPW UNIT WILL START WHEN T-STAT IS SATISFIED RELAY WILL OPEN AND UNIT WILL STOP DSR CONTROL WILL REMAIN LIT AT ALL TIMES STD 24V AC HEAT COOL TSTAT C C W W HYDRONIC FAN COIL 8750 Pioneer Blvd, Santa Fe Springs CA 90670 Tel : 562 699 6066, Fax : 562 699 4351, Web : w w w .Quietside.com Title : DPW & SPST RELAY CONTROL WIRING Drg # : QUI-DPW-ZW-001 Drawn : JLM 9/6/2006 Rev : 001 DSR-100F Unit Controller • MUST BE USED • Will display Air Temp when first connected • Will display actual closed loop water temperature • DHW Water temperature is set from the controller • Fault Codes are displayed • DON’T ever put 24V AC to the DSR Commissioning the DPW Once unit is piped, vented and wired it can be Commissioned Fill the closed loop system with water 1. Isolate DPW from the closed loop using the shut off valves 2. Attach hose from DHW water supply to boiler drain that is open to the closed loop system 3. Fill System – add glycol if required – Only use Fernox Alphii or No Burst glycol as they do not attack the seals – Maximum Glycol 30% 4. Once system is full, open shut off valves filling the DPW Operation of the DPW • DSR – Heating Water temp was set • Call for heat : • After Call Unit will pre purge Pre Ignition Open Gas valve (Solenoids) Establish combustion at 60% capacity Modulation to load using temp sensor in DPW Post Ignition Post purge More Domestic Hot Water • DHW Temperature is controlled but you MUST INSTALL A MIXING VALVE to prevent scalding • Minimum flow rate of 0.7 GPM is required to trigger operation in DHW mode • Flow switch is normally open – closed circuit = DHW mode • DHW production is always prioritized over heating function – also unit does not need to be in heating mode to provide DHW LP Gas Conversion LP Conversion Kit Tools required Crescent wrench, Philips/Flat screwdriver, Manometer • 1. Change Gas Manifold • Then reassemble and follow set up instructions • Dip Switch #1 and 2 must be switched for LP • Gas Pressure set up is shown later Inlet Gas Pressure • Natural Gas minimum pressure 5.8” WC, Maximum 9.7” WC • LP Gas minimum pressure 9” WC, Maximum 13” WC • If unit has been set up but still is noisy check Inlet gas pressure, especially under normal start up • There is not a tapping for Inlet pressure on the gas valve Inlet Gas Pressure • ENSURE INLET GAS PRESSURE ON START UP DOES NOT CHANGE FROM THE INLET PRESSURE MEASURED WHEN UNIT IS NOT RUNNING • If this does occur a new regulator may be required Annual Maintenance Routine Maintenance is recommended Water • Check closed loop system pressure is still at 1 (15 psi) • Check for leaks at all unions and connections • Flush and clean Condensate siphon – carbon in the gas supply can give the siphon a dirty gray color, use a little washing up liquid to clean – refill with water • Check Auto Air bleed screw is loose Annual Maintenance Routine Maintenance is recommended - Electric • Check all exposed electrical connections are secure Inspect for any signs of overheating • Check Dip Switch settings • Energize heating zones to check control circuitry, make sure DSR is set correctly to required water temps and mode Annual Maintenance Routine Maintenance is recommended - Gas • Check Inlet gas piping, pressure for leaks and/or pressure deviations • Remove igniter check for carbon make sure connections to Ignition TX and flame sensor are tight • Start unit, check flame color • Switch into low fire mode check gas valve settings Re-check in High Fire mode Annual Maintenance Routine Maintenance is recommended - Vent • Check termination for any blockage, make sure any debris is thoroughly removed • Check venting for any cracks or loose joints • Check Air Pressure switch operation • Check Exhaust Duct inside unit for leaks Annual Maintenance Routine Maintenance is recommended - DHW • Isolate DHW system, then using hose bibs back flush DHW Heat Exchanger using lime away (pre mixed) or solution of ethanoic acid (Vinegar) • Repeat several times in areas of high mineral content to ensure removal of all debris Checking Components • • • • • Electrode and Flame Detector Single Electrode so no gap, check the ceramic The igniter has the pink marking Electrode Voltage – 1518kV DO NOT TOUCH! Flame Detector – Faces away from electrodes Flame Detector Voltage 200V to ground Checking Components Strainer • Closed system strainer on return side • Catches debris before passing through the pump • Held in place with a wire retainer, be careful when replacing it Technical Support • Both East And West Coast Technical Support is available • East Coast : Hours 8AM to 5PM EST Tel : 717 243 2535 (866 243 6498) • West Coast : Hours 8AM to 5:30PM PST Tel : 562 699 6066 x 3 (888 699 6067) • Website – www.Quietside.com DPW Warranty • All models, FIVE YEAR PARTS – no labor allowance • Primary and Secondary Heat Exchangers carry a 12 Year warranty • Domestic Hot Water Heat Exchanger – 12 years THANK YOU FOR ATTENDING ANY QUESTIONS??