Document

advertisement

X-Ray Microanalysis – Precision and Sensitivity

Recall…

wt.fraction I = ISiKα (unknown) / ISiKα (pure std.)

K-ratio I = [ISiKα (unknown) / ISiKα (std.)] x CF

CF relates concentration in std to pure element

K x 100 = uncorrected wt.%, and …

K (ZAF)(100) = corrected wt.%

Weight Percent?

X-ray intensities are related to mass concentration, not atom concentration

Incident electrons penetrate a constant mass of material which will differ as the

composition differs

Electrons interact with orbital electrons of target atoms

lose kinetic energy

number of electrons proportional to atomic mass

Example:

Elements A and B

B is heavier than A

Excited

volume

Pure A

Mixture of A and B

If atomic concentration of A = nA

the mass concentration is:

CA = nAAA / [nAAA+(1-nA)AB]

Where: AA = atomic weight of A

AB = atomic weight of B

# of excited atoms in pure A = Nm / AA

Where: N is Avogadro’s number

m is mass penetrated by incident electrons

In the compound:

# of A atoms excited is

= nANm / [nAAA+(1-nA)AB]

The X-ray intensity ratio (proportional to the number of excited atoms) is

then

= {nANm / [nAAA+(1-nA)AB]} / (Nm / AA)

Which is equal to the expression for CA, the mass

concentration of A

Spatial Resolution

D = 0.077 (E0 –

/ρ

ρ = density

E0 = accelerating potential

EC = excitation potential

1.5

EC1.5)

X-ray distribution from a point source…

Example:

Si in fayalite at 15keV

ρ = 4.39

X

E0 = 15 keV

EC = 1.840 keV for SiKα

d = 0.98 μm

3σ = 2.9 μm diameter

volume containing 99% of X-ray productions

Precision, Accuracy and Sensitivity (detection limits)

Precision:

Reproducibility

Analytical scatter due to nature of X-ray

measurement process

Accuracy:

Is the result correct?

Sensitivity:

How low a concentration can you expect to see?

Accuracy and Precision

Measured value

Ave

Standard deviation

Std

error

20

25

Ave

Std

error

30

35

Correct value

Wt.% Fe

Low precision, but relatively

accurate

20

25

30

Correct value

Wt.% Fe

High precision, but low

accuracy

35

Accuracy and Precision

Measured value

Ave

Standard deviation

Std

error

20

25

30

35

Correct value

Wt.% Fe

Low precision, but relatively

accurate

20

25

Ave

Ave

Std

error

Std

error

30

Correct value

Wt.% Fe

Precise

High

precision,

and accurate

but low

accuracy

35

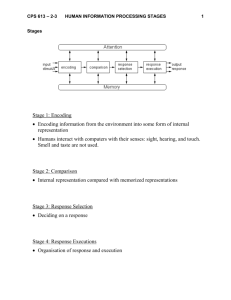

Characterizing Error

What are the basic components of error?

1) Short-term random error (data set)

Counting statistics

Instrument noise

Surface imperfections

Deviations from ideal homogeneity

2) Short-term systematic error (session to session)

Background estimation

Calibration

Variation in coating

3) Long-term systematic error (overall systematic

errors that a reproducible session-to-session)

Standards

Physical constants

Matrix correction and Interference algorithms

Dead time, current measurement, etc.

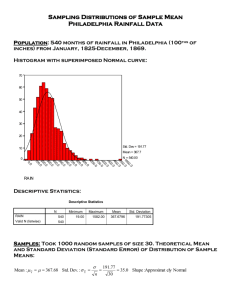

Short-Term Random Error - Basic assessment of counting statistics

X-ray production is random in time, and results in a fixed mean value – follows

Poisson statistics

At high count rates, count distribution follows a normal (Gaussian) distribution

Frequency of Xray counts

Counts

The standard deviation is:

99.7% of area

95.4% of area

68.3% of area

3σ

2σ

1σ

1σ

2σ

3σ

Variation in percentage of total counts

= (σC / N)100

6

So to obtain a result to 1% precision,

1-sigma error %

5

Must collect at least 10,000 counts

4

3

2

1

0

0

20000

40000

60000

Counts

80000

100000

Evaluation of count statistics for an analysis must take into account

the variation in all acquired intensities

Peak (sample and standard)

Background (sample and standard)

And errors propagated

Addition and subtraction

Multiplication and division

Relative std. deviation

i

Current from the Faraday cup

tp

Counting time on the peak

r+ et r-

Positive and negative offsets for the background measurement,

relative to the peak position

tb

Total counting time

t

P

Peak counts

B

Background counts

b

t

b

t

b

B B r B r

r

r

Cs

Element concentration in the standard

s

Intensity (Peak-Bkgd in cps/nA) of the element in the standard

Ce

Element concentration in the sample

e

Intensity (Peak-Bkgd in cps/nA) of the element in the sample

jp , j b

index of measurements on the peak and on the background

jpmax, jbmax

Total number of measurements on the peak and on the

background

For the calibration…

And standard

deviation…

The measured standard deviation can be compared to the

theoretical standard deviation …

Theo.Dev(%) = 100* Stheo/s

The larger of the two then represents the

useful error on the standard calibration:

²s = max ((Smeas)², or (Stheo)²)

For the sample, the variance for the

intensity can be estimated as…

where

The intensity on the sample is…

Or, in the case of a single measurement…

Pk – Bkg cps/nA

And the total count statistical error is then (3σ)…

An example

Calibration

Point

1

2

3

4

5

6

7

8

9

10

Ave, omitting pt. 7

SD

SD%

Th Ma (cps/nA)

154.6281

155.3082

154.8897

154.8656

156.4651

155.6509

156.8881

155.5401

154.8923

154.8614

155.2334889

0.577232495

0.371847917

X-Ray

Pk-Bg Mean (cps/nA)

Th Ma

155.2335

Std.Dev (%)

0.372

Theo.Dev (%)

0.136

3 Sigma (Wt%)

0.563

Pk Mean (cps)

3119.686

Bg Mean (cps)

34.455

Raw cts Mean (cts)

61657

Beam (nA)

19.87

S meas

0.57746862

Sample Th data

Wt%

curr

pk cps

pk t(sec)

6.4992

200.35

4098.57 800

bkg cps

pk-bk

285.0897

3813.483

λe (net intensity for sample)

π

(

β

(

σ

λ

σ

2

p

b

k

g

(

(

s

a

k

e

s

2

e

n

(

i

s

e

i

a

i

t

t

d

t

p

n

t

v

)

)

m

t

s

n

n

l

e

a

e

v

n

r

s

i

a

a

i

t

n

r

y

c

i

a

n

f

o

r

e

c

s

e

t

)

d

1

9

2

0

.

1

.

0

.

.

0

3

3

7

2

6

8

4

5

6

6

5

6

7

2

4

2

2

9

2

9

9

1

4

0

0

0

1

3

6

5

0

6

2

3

3

5

0

0

0

7

)

1

)

0

σe

.

3

3

5

3

5

4

.

7

0.073511882

This is a very precise number

Sensitivity and Detection Limits

Ability to distinguish two concentrations that are nearly equal (C and C’)

95% confidence approximated by:

N = average counts

NB = average background counts

n = number of analysis points

Actual standard deviation ~ 2σC, so ΔC about 2X above equation

If N >> NB, then

Sensitivity in % is then…

To achieve 1% sensitivity

Must accumulate at least 54,290 counts

As concentration decreases,

must increase count time to maintain precision

Example gradient:

Wt%

Ni

0

distance (microns)

Take 1 micron steps:

Gradient = 0.04 wt.% / step

Sensitivity at 95% confidence must be ≤ 0.04 wt.%

Must accumulate ≥ 85,000 counts / step

If take 2.5 micron steps

Gradient = 0.1 wt.% / step

Need ≥ 13,600 counts / step

So can cut count time by 6X

25