AFM

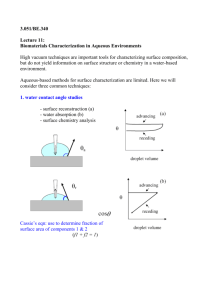

advertisement

Atomic Force Microscopy Robyn Snow 1 https://www.pinterest.com/lictorn/gary-larson-the-far-side 2 Brief History of Microscopes • 1590’s – Zacharias Jansen and father • Several lenses in a tube – Enlarged objects only ~9X http://www.history-of-the-microscope.org/history-of-the-microscope-who-invented-the-microscope.php 3 Brief History of Microscopes • Anton van Leeuwenhoek (1632-1723) – 1st to make a “real” microscope – 1st to see and describe bacteria, yeast plants… – Developed superior lenses • 270X magnifying power • Robert Hooke (1635-1703) – Verified van Leeuwenhoek’s work – Published Micrographia, 1665 • Observed pores in cork, called them “cells” – Hooke’s Law 4 IMAGE: http://www.nlm.nih.gov/exhibition/hooke/hookesbooks.html Brief History of Microscopes • Nobel Prize in Physics, 1986 – Ernst Ruska • German physicist – Fundamental work in electron optics – Designed 1st electron microscope – Gerd Binnig , Heinrich Rohrer • IBM Zurich Research Lab – Design of scanning tunneling microscope 5 http://ernst.ruska.de/daten_e/library/documents/999.nobellecture/lecture.html General Overview of AFM • Surface analysis technique – Surface topography – Elasticity – Friction – Magnetic forces – Electrostatic forces 6 General Operation – Small probe is scanned across surface – Data from interaction with surface is stored for each point – Image is displayed as an intensity map, I(x,y) ; I = parameter sensed by the probe • For AFM, the height of the surface is sensed • LFM, friction • MFM, magnetic fields 7 Change of the surface properties along the scan line Interaction force between probe and sample Deflection of cantilever Changes of the laser signal to the photosensitive position detector Electric signal Signal processing to generate image 8 Atomic Force Microscopy • Advantages: – – – – Minimal to no surface prep Non-destructive imaging Atmospheric conditions Sample not required to be conductive • Polymers, ceramics, glass • Metals • Biological samples • Obtain image at or near atomic resolution 9 Surface Preparation -Depends on sample, generally: 1. Clean substrate 2. Sample must be adhered to the surface of substrate – Mica, glass, gold – HOPG (highly ordered pyrolitic graphite) 3. Rigidly mount sample to the stage – No vibration • If contamination layer present, use contact mode or UHV 10 Resolution • Lateral resolution ~30nm • Vertical resolution ~0.1nm • Limited to scan areas of 100μm • • • • • Vertical Resolution: Laser intensity noise Photodiodes noise Thermal noise of cantilever Vertical scanner resolution <1Å(0.1nm) Noise: electrical, mechanical, acoustic Lateral Resolution • Tip sharpness / shape • Scanner resolution in X,Y • Pixelization – EX: 50μmX 50μm image – Samples/line @512 – Pixel size=0.098 μm =>cannot resolve features smaller than 98nm with 50μm scan size 11 Gold Nanoparticles http://www.afmworkshop.com/products-main/imagegallery.html#!gold_nanoparticles_100_nm_pm http://www.afmworkshop.com/productsmain/image-gallery.html#!nanotriangle_pm 12 Diagram of Instrument Probe 13 Probe • Probe: Si or Si3N4 • Only part that contacts sample – Like the “eye” of the instrument – > shape is critical! -> Resolution depends on it 14 Probe Tip • Conical Probe • more preferable • higher resolution image • Pyramidal Probe • can see distortion of image • High Radius of Curvature Artifact seen in image 15 Fat-tip Effect: apparent width measured by large tip 𝑥2 = 𝑅𝑡𝑖𝑝 + 𝑅𝑠𝑎𝑚𝑝𝑙𝑒 2 − 𝑅𝑡𝑖𝑝 − 𝑅𝑠𝑎𝑚𝑝𝑙𝑒 𝑥 = 2 𝑅𝑡𝑖𝑝 𝑅𝑠𝑎𝑚𝑝𝑙𝑒 𝑤 = 2𝑥 = 4 𝑅𝑡𝑖𝑝 𝑅𝑠𝑎𝑚𝑝𝑙𝑒 2 Rtip x w RSample •When Rtip ~ ¼ Rsample, measured width = 2Rsample •Normal tip size, ~ 20 nm or larger. 16 SEM images of probes Si3N4 Tip Atomic Force Microscopy: Theory, Practice , Applications Paul E. West, Ph.D. Diamond Coated tip 17 Conical Tip and Cantilever Silicon Cantilever Length (µm): 225 Res. Frequency (kHz): 28 Spring Constant (N/m): 0.1 Tip Radius ~8nm http://store.nanoscience.com/store/pc/viewPrd.asp?idproduct=2556&idcategory=4 18 Cantilever and Probe • Spring system/Force Sensor • Bends in presence of attractive/repulsive forces • Cantilever deflection converted to force using: – Hooke’s Law! 𝐹 = 𝑘𝑠 s : deflection k : spring constant 19 Hooke’s Law Fe : Restorative force due to spring F : force due to sample s : springs displacement from equilibrium IMAGE FROM : http://www.physics.usyd.edu.au/teach_res/jp/waves/hwaves1001.htm 20 Ideal Spring System • Max deflection for given force – Spring as soft as possible (small k) • Minimize interference due to vibrations of building (~100Hz) – Stiff spring with high natural frequency(𝑓0 ) Natural Frequency of spring(𝑓0 ): 1 𝑓0 = 2𝜋 𝑘 𝑚0 1 2 To achieve high frequency and max deflection: ↓k and ↓m0 k = spring constant m0 = mass of spring 21 Spring Constant, k • For a rectangular cantilever: 𝐸𝑤𝑡 3 𝑘= 4𝑙 3 𝑤 𝑡 • E = Young’s modulus • Measure of stiffness • For Si, E = 1.3*1011N/m2 𝑙 • Typical values for k : 0.001 to 100 N/m • ~100microns in length , a few microns thick 22 Piezoelectric Scanner • Piezoelectric material – Typically (PZT) lead zirconate titanate (Pb(ZrTi)O3) • Piezoelectric effect – Expand or contract in presence of potential difference – Develop potential in response to mechanical pressure • Allows for ability to precisely manipulate movement of sample or probe 23 Piezoelectricity • Polarization in one direction occurs due to applied electric field – Change in length ∝ field strength • ~0.1nm per applied Volt http://www.ytca.com/lead_free_piezoelectric_ceramics 24 25 Light Lever Sensor • Force Sensor – Detects changes in height/ deflection based on angle of reflected light 26 Photodetector A B D C • Photosensitive elements (photodiodes) • Photocurrent is produced upon illumination for each quadrant • The ratio between the photocurrent from each quadrant determines the relative position of the laser beam 𝐴+𝐷 − 𝐵+𝐶 X−Position = 𝐴+𝐵+𝐶+𝐷 𝐴+𝐵 − 𝐷+𝐶 Y−Position = 𝐴+𝐵+𝐶+𝐷 27 Probe-Surface Interaction • Interaction between probe tip and surface =>Atomic Forces – Creates potential energy(PE) Attractive forces- takes minimal energy to bring atoms closer together at distance Equilibrium : distance when potential energy minimized • + PE : repulsive forces , atoms very close • - PE : attractive forces, van der waals, Repulsive forces- very small r, takes a lot of atoms further away energy to bring atoms closer together>repulsive forces dominant 28 Lennard-Jones Potential (LJP) • Empirical Model, describes potential energy (V) of interaction between outermost atom of tip and surface atoms 𝑉 𝑟 =4∈ 𝜎 𝑟 12 𝜎 − 𝑟 6 ∈ : well depth- measure of strength of attraction 𝜎 : distance at which V is zero (equilibrium) r : distance of separation 29 n 30 http://chemwiki.ucdavis.edu/@api/deki/files/8914/Figure_B.jpg Van der Waals Forces 𝑉 𝑟 =4∈ 𝜎 𝑟 12 𝜎 − 𝑟 6 𝜎 𝑟 𝜎 𝑟 12 6 31 Modes of Imaging Repulsive Tapping Mode Attractive Non-Contact Mode Contact Mode http://virtual.itg.uiuc.edu/training/AFM_tutorial/ 32 Contact Mode • Tip is in very close contact with surface <0.5nm -> Repulsive forces – Cantilever bends 𝐹 = 𝑘𝑠 s : displacement of cantilever ->height/Force measure – Force varies dramatically based on distance between tip and sample • Two types of contact mode: 1. Constant Height 2. Constant Force 33 Constant Height Contact Mode • Maintain constant height of sampler – Variations of deflection of lever are recorded as topography • Deflection ↑ as height of sample ↑ • Deflection ↓ as height of sample ↓ • Advantages – Higher scanning speeds – High resolution 34 Fig. 1 STM and AFM imaging of pentacene on Cu(111). A: Ball-and-stick model B: Constant current STM C,D : Constant height AFM images Leo Gross et al. Science 2009;325:1110-1114 Published by AAAS http://www.sciencemag.org/content/325/5944/1110.full Constant Force Contact Mode • Maintain constant force between tip and sample – Regulate height of sample relative to the tip • Feedback loop : photodetector and piezoelectric scanner – Height of sample ↑ , Force ↑, lower height of sample to maintain constant force • Slower scan speeds • Advantage: – Can simultaneously measure other characteristics/forces 36 Lateral Force Microscopy • In constant force mode: – Scan perpendicular to longitudinal axis of cantilever – Measures surface friction – Friction-force map • Four quadrant photodiode detector – Difference between left and right segments ∝ friction 37 Lateral Deflection • Magnitude depends on: – Frictional coefficient of the sample – Topography of sample surface – Cantilevers lateral spring constant 38 Lateral Force Spring Constant • Lateral spring constant: 𝐺𝑤𝑡 3 𝑘𝑡 = 3𝑙𝑟 2 G : shear modulus-measure of elasticity r : length of tip ∆s 𝒍 Force 𝒕 𝒘 39 Lateral Force Calibration • Calibration of : – normal and lateral forces, F – Photodiode sensitivity, S • • • • Using reference sample 𝐹𝑁 = 𝑘𝑁 𝑆𝑁 ∆𝑉𝑁 Normal Force 𝐹𝐿 = 𝑘𝐿 𝑆𝐿 ∆𝑉𝐿 = 𝛼∆𝑉𝐿 Lateral Force 𝛼 = lateral calibration factor – Transforms lateral ΔV ->Friction Force (nN) 40 Human Hair Image : AFM vs LFM a) AFM image of topography b) LFM image http://www.parkafm.com/images/spmmodes/standard/Lateral-Force-Microscopy-(LFM).pdf 41 LFM Image Topography LFM image 2μm x 2 μm of Nickel CD stamper matrix T.Göddenhenrich, S.Müller and C.Heiden, Rev. Sci. Instrum. 65, (1994) 2870 42 Contact Mode: pros and cons Advantages • High resolution >50nm • Fastest • No problem with surface pollution – Can image in air or liquid Disadvantages • High contact pressure – Can damage/ not analyze soft samples • Probe and sample experience lateral forces • Lateral resolution limited by tip sharpness • Lowers lifetime of tip 43 Non-contact Mode • Lever(spring) oscillates close to its resonance frequency from driving piezo – => Use z-piezo to vibrate the cantilever near its resonant frequency • Forces shift this oscillation tip-sample distance of ~5-10nm 44 Z-drive Piezo for Non-contact AFM • Informs feedback loop of motion of tip/cantilever: • Frequency • Amplitude • Allows for frequency modulation(FM-AFM) or amplitude modulation (AM-AFM/tapping mode) 45 Frequency Modulation • Excitation Amplitude constant • Tip-sample interaction-> frequency ↓ • Attractive forces Tip-sample interaction-> natural frequency shift ∆f Natural frequency, no interaction 46 Frequency Modulation • ∆f : info about tip-sample interaction • Feedback loop : adjusts tip-sample distance to achieve constant Amplitude 47 Non-contact AFM of C60 STM image A : model B to E : AFM showing Δf at differing tip heights F : image used for measure of bond length • measured bond lengths are Lh = 1.38Å • Lp = 1.454 Å http://www.sciencemag.org/content/337/6100/1326.figures-only 48 “h” “p” "C60a" by Original uploader was Mstroeck at en.wikipedia Later versions were uploaded by Bryn C at en.wikipedia. - Originally from en.wikipedia; description page is/was here.. Licensed under CC BY-SA 3.0 via Wikimedia Commons - http://commons.wikimedia.org/wiki/File:C60a.png#/media/File:C60a.png 49 Amplitude Modulation/ Tapping Mode • Cantilever excited to resonance frequency • Tip-sample distance ↓ , amplitude (A)↓ • A reaches set point, below resonance A -> height is measured • Feedback loop adjusts height to maintain set A as sample is scanned 50 Set-point 51 Tapping mode pros and cons Advantages • Reduced forces on surface – Good for soft materials • No friction forces – Can use sharper tips • Can be in air or liquid • Improved lateral resolution Disadvantages • Slower than contact mode – Up to20 minutes per scan • Tip is damaged after several scans – ~5nm 52 Tapping mode image DNA deposited on mica 2.5μm scan size http://www.veeco.com/pdfs/database_pdfs/B54_Rev_A1_Caliber_300.pdf 53 High Resolution Image of muscovite mica in water High-resolution dynamic atomic force microscopy in liquids with different feedback architectures John Melcher, David Martínez-Martín, Miriam Jaafar, Julio Gómez-Herrero, Arvind Raman Beilstein J. Nanotechnol. 2013, 4, 153–163. Blue : Oxygen Green : Silicon Unit Cell: 5.199Å 9.7Å http://www.beilstein-journals.org/bjnano/single/articleFullText.htm?publicId=2190-4286-4-15 54 Force Modulation Microscopy(FMM) • Tip in contact with the sample • z feedback loop maintains a constant cantilever deflection • A periodic vertical oscillation signal is applied to either the tip or the sample. • The amplitude varies according to the elastic properties of the sample. • the system generates a force modulation image --- a map of the sample's elastic properties 55 FMM 56 FMM vs AFM Carbon fiber/polymer Composite Collected Simultaneously (5μm) FMM AFM FMM gives more detailed information about the composition and distribution of the two components --- soft polymer (dark area) and hard carbon fiber. 57 2-phase block copolymer AFM FMM The softer, more compliant component of the polymer maps in black. 900nm scans. Veeco. 58 Magnetic Force Microscopy (MFM) • Tip is coated with a ferromagnetic film(Ni, Fe, Co) • Scanned in non contact mode • Provides high resolution image of magnetic patterns • Strength of local magnetic interaction determines the vertical motion of the tip • Detectable magnetic field ~0.1 gauss (10 microteslas) 59 Magnetic Force • Described as: 𝐹 = 𝜇0 𝑚𝛻 𝐵 𝜇0 : magnetic permeability of free space (4π 10-7 WbA-1m-1) 𝑚: magnetic moment of the tip 𝐵:strength of magnetic field from sample 60 MFM Limitations • Type of tip and magnetic coating affect image • Interaction of magnetic field of tip and sample can alter each others field • Highly dependent on scan height • Inner and surface magnetic charges not able to be deconstructed 61 MFM Image magnetic disk; 40 µm x 40 µm http://www.afmworkshop.com/products-main/image-gallery.html#! 62 MFM Image 3.2GB hard drive 30GB hard drive http://commons.wikimedia.org/wiki/File:MFM_AFM_JANUSZ_REBIS_INFOCENTRE_PL_HDD_MAGNETIC_MEMORY_EVOLUTION.png#/media/ 63 File:MFM_AFM_JANUSZ_REBIS_INFOCENTRE_PL_HDD_MAGNETIC_MEMORY_EVOLUTION.png Electric Force Microscopy(EFM) • Measures electric field gradient distribution on sample surface • Tip : electrically conducting coating • applied Voltage between tip and sample • Deflection of cantilever 𝛼 charge density of sample • Use photo-diode detector 64 EFM 65 Applications of EFM • characterizing surface electrical properties • Interfacial charge transport and separation for organic/electrode devices (conducting polymer, organic semiconductors, etc.) • detecting defects of an integrated circuit (silicon surface) • measuring the distribution of a particular material on a composite surface. 66 Bio Applications • • • • • • Imaging Ligand-receptor binding sites Antibody-antigen binding sites Proteins-folding/unfolding Structural analysis – SMRFM *need special surface preparation for bio samples – Absorb sample onto a supported cationic bilayer (mica) surface and imaged with AFM in aqueous buffers 67 DNA on multiple mica layers 2 μm X 2 μm http://www.afmworkshop.com/products-main/image-gallery.html#!AFM_scan_DNA_mica_pm 68 Red Blood Cells, 30μm X 30μm http://www.afmworkshop.com/products-main/image-gallery.html#!07_img_blood_cells_01_big 69 Single-Molecule Recognition Force Microscopy (SMRFM) • Couple a “ligand” molecule to the tip – Thin PEG chain • Ligand recognizes complementary receptor site in sample – Causes deflection of cantilever / change in oscillation frequency => maps recognition sites 70 SMRFM 1. NH2 on tip reacts with NHS ester of PEG linker 2. Protein attached to free end of PEG (amine-aldehyde linkage) http://www.jku.at/biophysics/content/e54633/e54706/e54710/#fig171 How cell membranes respond to their environment Light harvesting Complex Reaction centers • Membrane organization in photosynthetic bacteria • –Rsp. Photometricum • (exposed to strong light) AFM Image Simon Scheuring , Thomas Boudier , James N. Sturgis http://www.innovations-report.com/html/reports/life-sciences/report-47236.html 72 Questions • THANK YOU!! 73