Tapping mode AFM

advertisement

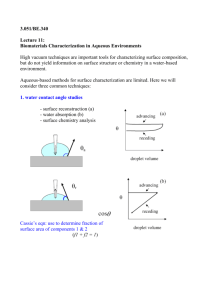

Wenqi Deng Supervisors: Guang-Ming Zhang,Dave Harvey, Francis Lilley Outline Background of AFM Simulation and results Experiment and results Discussion Project plan What is AFM? •Image topography •Mechanical, electrical, and magnetic properties of surfaces •First atomic force microscope was invented in 1986 by Binnig. How AFM works? •The x and y-piezos provide lateral scanning(up to 19um), while the z-piezo extends and retracts to follow the surface topography(up to 12um) . Image mode Tapping mode •The cantilever is vibrated at its resonant frequency •Intermittent contact with sample • Reduce sample destruction Phase imaging •Measure the phase lag of the cantilever oscillation (solid wave) relative to the phase of the piezo drive (dashed wave). •The amplitude signal is used simultaneously by the controller for Tapping Mode feedback. • Spatial variations in sample properties cause shifts in the cantilever phase (bottom) Why phase image provides more information of structure? Topography (left) & phase (right) images of a composite polymer •Higher spots in the AFM topography images should correspond to the hard phase polymer? •Brighter areas correspond to harder materials? •We don’t have an agreement yet. Simulation model The cantilever is treated to be a massless spring of stiffness k having an effective mass at the end and equivalent damping c. 1D Lumped model of tapping mode AFM The tip–sample forces are modeled by three springs with spring constants kN and kS for vertical and lateral contact stiffness, respectively. 3D model tapping mode AFM Geometry Type AC mode air Spring k (N/m) 2.8 (0.5 - 9.5) Freq (kHz) 75 (45 - 115) Length (µm) 225 (215 - 235) Width (µm) 28 (20 - 35) Thickness (µm) Shape 3.0 (2.0 - 4.0) rectangular Material Silicon Reflex Coating (nm) none A piezo (red) is attached behind the end of the cantilever. A voltage of sin(2*pi*f*t)*4 is applied to the piezo to cause the vibration of the cantilever. The free vibration amplitude is about 28nm. Eigenfrequency study Resonant frequency : 65208.9 Hz Contact model •Equilibrium position, the initial tip sample separation •Cantilever, tip and sample are defined as elastic deformation model Time dependent study Initial tip sample separation: 19 nm(green line) Displacement curve Experiment results Discussion Limitation of simulation and experiment The simulation just provides the first cycle vibration, which means it has not reached steady state yet. It may take hundreds of cycles to reach steady state, hence, based on the simulation time, it is not realistic to carry out a simulation until the steady state. However, due to the limitation of experiment, the AFM data is captured under the steady state, and it is difficult to determine the contact time. It seems a challenge to identify the bouncing effect. Project Plan Future work Set up a different experiment to determine the contact time from the deflection data. Modify the simulation model. Simulate tapping mode AFM separately. Calculate the contact stiffness between tip and sample using the model below. Tip-sample model Investigate what parameters affect contact stiffness, such as the radius of the tip, deformation of the sample, indentation force, young’s modulus of tip and sample. In real experiment, the sample surface is not always flat. The tip may not indent normally to the surface. Especially, the tip scans across the sidewall. It is worthwhile to study how forces from different direction affect contact stiffness. The calculated contact stiffness can be applied to the tip. Phase vs contact stiffness curve Might help to select what kind of cantilevers(soft or stiff?) for phase imaging Cantilever-tip model While using cantilever-tip model, computation time is reduced. It is possible to simulate tapping mode until it becomes steady. Calculate the steady time, then we might be able to see how scan rate affects phase imaging. Thank you!!! Any Questions?