original PowerPoint File

advertisement

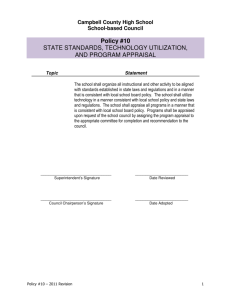

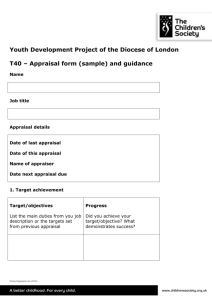

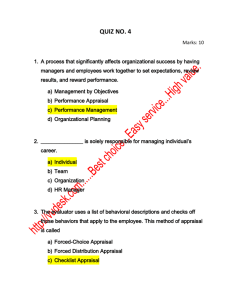

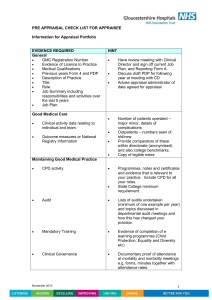

Continuing Education (CE) Credit: Participants desiring CE credit for attending this session should sign the document at the back of the room and indicate the session name on the back of the Uniform Request for Recertification Credit form. The sign-in sheet will not be available once you leave the room. Housekeeping Note: Please silence your cell phones Making Heads or Tails out of a Machinery & Equipment Appraisal Location of Subject Appraisal: Gastonia, North Carolina Machinery & Equipment Appraisal Basics USPAP Standard 7: Personal Property Appraisal, Development USPAP Standard 8: Personal Property, Reporting – Self contained – Summary – Restricted use M&E Appraisers No License required – Caveat Utilitor Machinery & Equipment Designations – PPS - International Association of Assessing Officers – ASA, AM – American Society of Appraisers – MCMEA, CMEA – NEBB Institute – CEA/ AEA - Association of Machinery & Equipment Appraisers Letter of Transmittal Appraisal Contents Appraisal Contents (Continued) Scope of Work Scope of Work (Continued) Caveat Utilitor The Subject Machine Shop Equipment Turning is a machining process in which a cutting tool, typically a nonrotary tool bit, describes a helical toolpath by moving more or less linearly while the workpiece rotates. Forming- A CNC press brake uses programs to automatically execute a series of bending operations that leads to increased productivity and flexibility. Milling is the machining process of using rotary cutters to remove material[1] from a workpiece advancing (or feeding) in a direction at an angle with the axis of the tool. Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser, by computer, at the material to be cut. Press with Bending Die & a Cutting Tool Equipment Detail Equipment Detail Equipment Detail Equipment Detail 2007 Mazak Hyper Turbo Laser Historical Cost - $570,000 FMV Per Appraisal - $440,000 Gaston County Tax Value - $467,400 Difference = (6.2%) 2007 Ermak Press Brake Historical Cost - $75,000 FMV Per Appraisal - $44,000 Gaston County Tax Value - $47,250 Difference = (7.4%) 2004 HAAS Lathe VF-4D Milling Center Historical Cost - $70,095 FMV Per Appraisal - $54,000 Gaston County Tax Value - $17,524 Difference = 68% 3 CNC Mill HAAS VF-4D 36942 2004 Good Condition 5 $54,000 $25,000 Appraisal Notes HAAS VF-4D M&E Appraisal Data Collection Form Item Number Depreciation Schedule Information Type Manufacturer Model No. Serial No. Year Condition: § Is this machine working well and at peak function? § How many hours each day in use? § Does it need anything presently (repair/maint)? § Are repairs done by staff or third party? § Has any major repair been done lately? § Is there a regular service schedule on this machine? § Have there been any upgrades made? § Have there been any special accessories added? § Electrical Specs: wattage, ampage, ohms, etc. § Capacity: ft dimensions, length, size, etc. § How easily could you sell it? § What would you ask for it? § Do you keep maintenance records? § If so can I get a copy? Comments When Purchased Purchased New or Used Amount Paid (including installation) Installation Costs Who purchased from Appraisal Contacts (Partial List) TURNER BUSINESS APPRAISERS List of contacts for M&E values Compressed Air Systems Jack Connor – assisted me on the J&L Appraisal. He provided information on Kaeser Air Compressors P: 800/626-8177 Web: www.compressedairsystems.com OSS, LLC – Scott provided me with information on the Clausing Lathe – J&L Appraisal 380 Wingo Heights Rd 4B Spartanburg, SC 29303 P: 864/585-3275 Web? Jeffreys – A division of Phillips Kip Asmuth – very helpful regarding the value of the HAAS CNC Mill & Lathe – J&L Appraisal P: 336/456-3242 Email: kasmuth@phillipscorp.com Bit Yack CAM Patrick Moonie – helpful regarding the pricing of the Cincinnatti Mill – J&L Appraisal P: 804/405-9540 Machinery Solutions Daniel Jones, Sales Manager – provided me with a second opnion on the Cincinnatti Mill and an opinion on the Doosan Lathe PO Box 130 Lexington, S.C. 29071 803/359-7000 Final Value Summary Value Reconciliation Seventh Inning Stretch Mass Appraisal Method Trend & Depreciate Making Heads or Tails out of the M&E Appraisal Compared to the Ad Valorem Appraisal Reconciliation of M&E Appraisal with County Ad Valorem Appraisal Source M&E Appraisal County Appraisal Reconciliation SS Category March 28, 2012 January 1, 2012 Difference Percent Variance Machine Shop Equipment $1,315,300 $1,084,582 $230,718 21% Shop Support and Ancillary Items $12,500 $6,912 $5,588 81% Appraised Value $1,327,800 $1,091,494 $236,306 22% Nuances Among the Appraisal Method Utilized by the M&E Appraiser vs. the Mass Appraiser The M&E appraiser often utilizes the market approach The mass appraiser is prone to exclusively utilize the cost approach When a cost approach is necessary USPAP SR-7.4 requires the M&E appraiser to calculate the accrued depreciation. The M&E appraiser must estimate the effective age of the property – Effective age can be greater than, equal to, or less than chronological age The mass appraisal cost approach utilized in most jurisdictions presume chronological age = effective age. Economic Obsolescence The Inutility Method Scale Factor 0.55 0.6 0.65 0.7 0.75 0.8 Plant Utilization (actual/capacity) Inutility Factor Inutility Factor Inutility Factor Inutility Factor Inutility Factor Inutility Factor 50% 31.7% 34.0% 36.3% 38.4% 40.5% 42.6% 60% 24.5% 26.4% 28.3% 30.1% 31.8% 33.5% 70% 17.8% 19.3% 20.7% 22.1% 23.5% 24.8% 80% 11.5% 12.5% 13.5% 14.5% 15.4% 16.3% 90% 5.6% 6.1% 6.6% 7.1% 7.6% 8.1% 100% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% Inutility formula = [(Actual Production/Design Capacity)^(scale factor)] X 100 Scale Factor:Studies indicate cost-capacity factors average .6 to .7 Note: Design Capacity < Max Capacity. It is based upon a theoretical product mix and often allows for future expansion. U.S. Capacity Utilization Rates U.S. average capacity utilization total industry 1972-2012 = 80.2% Manufacturing average capacity utilization 1972-2012 = 78.7% Source: Board of Governors of the Federal Reserve System Industrial Production and Capacity Utilization – G.17 Release Date July 16, 2013 Takeaways Obsolescence If the inutility calculation is utilized to quantify economic obsolescence remember to ask questions: – Did you Calculate the RCN for the subject M&E? – How did you calculate the effective age of the M&E? – Did the market approach corroborate the obsolescence? • Request copies of comps The source documents which depict the plant capacity and the plant utilization Perform your own analysis to determine what are customary utilization rates for the subject Company’s industry Attempt to find comparables to verify the presence of economic or functional obsolescence Takeaways M&E appraisal Caveat Utilitor – M&E appraisal is an unregulated industry – There are plenty of good M&E appraisers – Perform some due diligence to ascertain the validity of the M&E appraisal To corroborate the veracity of an M&E appraisal ask for these items: – Data collection forms or their equivalent – Conversation notes and contact information to ascertain the RCN and market approach – Ask the appraiser for the contact information of the expert who gave him/her the tour at the subject company Discussion & Questions The Finish Line!