Environmental Health and Safety and Chemical Hygiene_Villeneuve

advertisement

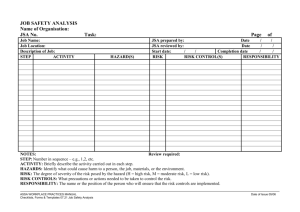

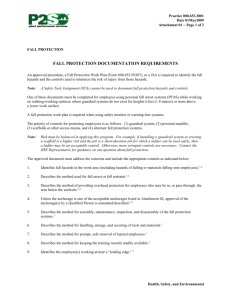

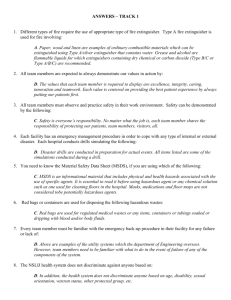

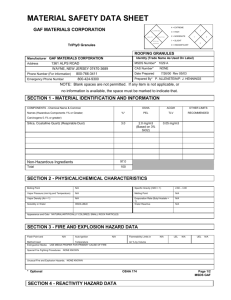

EHS and Chemical Hygiene Environment, Health and Safety Environment: • • • • • • • • Air Emissions and Ambient Air Quality Energy Conservation Wastewater and Ambient Water Quality Water Conservation Hazardous Materials Management Waste Management Noise Contaminated Land and Remediation Occupational Health and Safety • • • • • • • • • General Facility Design and Operation Communication and Training Physical Hazards Chemical Hazards Biological Hazards Radiological Hazards Personal Protective Equipment (PPE) Special Hazard Environments Monitoring Community Health and Safety: • • • • • • • Water Quality and Availability Structural Safety of Project Infrastructure Life and Fire Safety (L&FS) Traffic Safety Transport of Hazardous Materials Disease Prevention Emergency Preparedness and Response OSHA: Occupational Safety and Administration Health Act • Created within the Department of Labor – Law created in 1970 Under the OSHA act, – encourage employers and employees to reduce workplace hazards and to implement new or improve existing safety and health standards; – provide for research in occupational safety and health and develop innovative ways of dealing with occupational safety and health problems; – establish "separate but dependent responsibilities and rights" for employers and employees for the achievement of better safety and health conditions; OSHA (Cont’d) – maintain a reporting and recordkeeping system to monitor job-related injuries and illnesses; – establish training programs to increase the number and competence of occupational safety and health personnel; and, – develop mandatory job safety and health standards and enforce them effectively. How does a University Lab fall into this? General Duty Clause: The general duty clause states that each employer shall furnish "a place of employment which is free from recognized hazards that are causing or are likely to cause death or serious physical harm to [its] employees." In those cases where a specific standard does not exist, OSHA will use the general duty clause for the issuance of citations and fines. Legacy of the Past Laboratory Safety Issues • Employees - Safety governed by MIOSHA’s Chemical Hygiene Plan requirements • Students - Doctrine of Reasonable Care applies Chemical Hygiene Plan (CHP) Purpose Provide guidance and protocols for the protection of employees from safety and health effects of laboratory hazardous materials. Doctrine of Reasonable Care • Duty - What would a reasonable person of ordinary prudence do • Breach of Duty - Failure to conform to the legal duty (an act or failure to act) • Causation - Breach causes the injury – Direct act – Proximate Cause • Injury - There must be an injury Examples of “Negligence” in the Laboratory • Unclear or misunderstood instructions • Instructions do not clearly warn of impending hazards • Lack of safety equipment • Assigned experiment was unnecessarily dangerous • Instructor not adequately trained to supervise Unclear or Misunderstood Instructions “I must have misunderstood…..” “He speaks a foreign language…..” “I didn’t want to appear stupid…..” “I don’t think the instructor is good at giving directions…..” “I was in a hurry to finish…..” Instructions do not clearly warn of impending hazards “If it was so dangerous, why wasn’t I told…..” “I don’t remember things until I hear them repeated…..” “The book is unclear…..” “I was just trying to see what happens…..” “No one told me that ether fumes can spread so far…..” Safety Training Steps • Identify the safety concerns • Restate your concerns • Instructor informs you on the correct methods and safeguards • Repeat information on correct methods and safeguards to yourself. Write in lab notebook. • Check to make sure there is understanding Lack of safety equipment • “We don’t require safety glasses all the time…..” • “We do not have the resources to purchase gloves for everyone…..” • “We can’t make them wear lab coats…..” • “We have safety rules posted on the wall…..” PPE Personal Protective Equipment PPE - Personal Protective Equipment • Long pants required, no shorts. • No neckties, dangling clothes or dangling jewelry. • Long sleeve shirts recommended. • Tie-up long hair to prevent from entanglement. • Non-porous shoes, no sandals. Face Protection • Eye Protection – Glasses • side shields • Z-87 – Goggles • dusty, chemicals • Face shield Hand Protection • Cloth/Leather • Chemical Proper steps for removing gloves 1 2 3 4 5 6 How to Remove Gloves HAND WASHING • Hand washing is the single most effective way to prevent the spread of infections. – Wash your hands often and thoroughly, paying special attention to the area around and under your fingernails. – Wash Hands: • • • • Before and after eating. After using the restroom. After removing gloves. Before leaving lab at the end of the lab period. – Gloves are not a substitute for routine hand washing - rather an added protection. Respirators • Escape – 1 use or 1 year • Filtering – Fit test – Fit check • Supplied Air – SCBA Disposable Dust/Particulate Respirators Special Clothing • Aprons • Coveralls • Using Lasers – dark glasses / shield Head Protection • Hard Hats – Change liner every year – New every 5 years Safety Foot Wear • Steel Toe • Rubber or Chemical Hearing Protection • Plugs • Muffs • Custom fit Material Safety Data Sheets • When you are not sure about a material - look up the msds sheet. DEFINITIONS • Flammable: A substance having a flash point below 100 degrees Fahrenheit - easily ignited and quick burning. • Toxic: A substance which has the capacity, through chemical reaction or mixture, to produce injury or harm to the body by entry through absorption, ingestion, inhalation, or injection. • Caustic: A substance with the capability of burning, destroying or eating away organic tissue by chemical reaction - Corrosive. MATERIAL SAFETY DATA SHEETS (MSDS) • The MSDS is used by chemical manufacturers and vendors to convey hazard information to users. • MSDS’s should be obtained when a chemical is purchased. • A chemical inventory list, and MSDS, for each chemical are required. READING THE MSDS Information on the MSDS is organized in 8 sections as follows: 1 Identity The chemical name, trade name and manufacturers name, address and emergency phone number can be found here. 2 Hazardous Ingredients Hazardous ingredients are identified here. 3 Physical and Chemical Characteristics, Boiling/Melting point, vapor pressure and density, water solubility, and appearance/odor can be found here. 4 Fire Data Flash point, flammable limits, extinguishing media, unusual fire/explosion hazards, and any special fire fighting equipment are listed here. Reading the MSDS 8 Sections Continued Utube video http://www. youtube.co m/watch?v =ZcghjHu6 0K4 5 Health Data Routes of entry (inhalation, ingestion, etc…), effects from short and long term exposure, emergency and first aid procedures fall in this section. 6 Reactivity Data Stability, incompatible materials, hazardous decomposition are among the topics in this area. 7 Spill or Leak Procedures You will find clean-up procedures, waste disposal, and precautions needed when handling/storing materials here. 8 Spill Precaution Information Any personal protective equipment (PPE), ventilation, and work/hygiene practices are noted here. Risk Assessment 1. What are the harmful effects of the material or process? 2. What form is it in? 3. What other dangers are involved? 4. How do the conditions of the experiment allow the material to come in contact with me or others? Job Safety Assessment •Used to determine hazards associated with a particular experiment / procedure and to control the hazards. • Side benefit: excellent method to organize experiment and procedure prior to operation. • Can be used as an appendix in thesis. JSA – Page 1 Used to identify location of experiment. JSA – Page 1 Provide a brief verbal description of what this experiment is supposed to do. JSA – Page 1 This should summarize all the personal protective equipment required normally in the laboratory and PPE required for this particular experiment. Equipment that is required all the time (such as safety glasses) does not need to be listed on each step of the JSA. JSA – Page 1 Check all hazards that result due to this experiment. Identify the one major source of the hazard. JSA – Page 1 List the expected normal, minimum and maximum values for the temperature and pressure. JSA – Page 2 Check all special operating conditions. List all equipment available within the laboratory and their location. Show the locations on an attached floor plan. JSA – Page 2 List the location of the spill response equipment. Show location on an attached laboratory diagram. JSA – Page 2 Provide all the attachments shown, and list any additional attachments provided. JSA – Page 3 List all chemicals (including reactants and products) used for this experiment / procedure, and additional information requested. JSA – Page 3 Provide information on the chemical toxicology, regulation and disposal. List personal protective equipment specific to this chemical. JSA – Page 3 Provide information on the chemical reactions. Include the stoichiometric equation, heat of reaction, and any other information. JSA – Page 4 Need to be as detailed as possible. Refer to flow diagram of equipment and floor layout. Safety procedure should be as detailed as possible, not just “be safe” or “be careful”. JSA – Page 4 Emergency Shutdown: List a few things you can do prior to evacuating the laboratory. Start-Up Procedure: List the steps to get ready to operate the experiment. Run Time Procedure: Steps required to operate the experiment. Shut-down Procedure: Steps required to normally terminate the experiment. Clean-up / Waste Disposal: Steps required to clean the equipment and dispose of all chemical wastes. JSA – Example Need to charge 10 ml of acetic anhydride into a test cell. Acetic anhydride is stored in the flammable storage cabinet in a 1-liter container. Acetic Anhydride MSDS: OSHA PEL: 5 PPM OSHA PEL Code: M OSHA STEL: OSHA STEL Code: ACGIH TLV: 5 PPM ACGIH TLV Code: M ACGIH STEL: N/P ACGIH STEL Code: EPA Reporting Quantity: 5000 LBS DOT Reporting Quantity: 5000 LBS Ozone Depleting Chemical: N Conclusions from MSDS 1. Perform all open bottle transfer operations in hood. 2. Wear Neoprene gloves for all operations. 3. Wear face shield and safety goggles. 4. Use lab coat. 5. Wash hands thoroughly after all transfers. JSA Steps JSA Steps EXTINGUISHER D Understand the combustion process and different fire classes. Understand fire extinguisher types, operating procedures, capabilities, and limitations. Understand basic firefighting concepts: R.A.C.E. P.A.S.S. The Combustion Process THE FIRE TETRAHEDRON FUEL TEMPERATURE Fire Classes A C Trash Wood Paper • • • • • B Liquids Grease Electrical Equipment wood cloth paper rubber many plastics • • • • • • • gasoline oil grease tar oil-based paint lacquer flammable gases • COMBUSTIBLE D METALS • • • • • • energized electrical equipment magnesium sodium potassium titanium zirconium other flammable metals Fire Classes (cont.) CLASS K FIRES K Cooking Media • Recently recognized by NFPA 10. • Fires involving combustible vegetable or animal nonsaturated cooking fats in commercial cooking equipment. Fire Extinguisher Anatomy DISCHARGE LEVER DISCHARGE LOCKING PIN AND SEAL PRESSURE GAUGE (not found on CO2 extinguishers) CARRYING HANDLE DISCHARGE HOSE DATA PLATE DISCHARGE NOZZLE DISCHARGE ORIFICE BODY Fire Extinguisher Applications FIRE CLASS A EFFECTIVE EXTINGUISHER TYPES Trash Wood Paper PRESSURIZED WATER, MULTIPURPOSE DRY CHEMICAL, LARGER SIZE HALON, WET CHEMICAL B Liquids Grease MULTIPURPOSE DRY CHEMICAL, CARBON DIOXIDE, HALON C Electrical Equipment MULTIPURPOSE DRY CHEMICAL, CARBON DIOXIDE, HALON, WET CHEMICAL COMBUSTIBLE D COMBUSTIBLE METAL METALS K Cooking Media WET CHEMICAL Fire Extinguisher Types PRESSURIZED WATER • Class “A” fires only. A Trash Wood Paper A Trash Wood Paper B Liquids Grease B Liquids Grease • 2.5 gal. water at 150-175 psi (up to 1 minute discharge time). • Has pressure gauge to allow visual capacity check. • 30-40 ft. maximum effective range. C Electrical Equipment C Electrical Equipment • Can be started and stopped as necessary. • Extinguishes by cooling burning material below the ignition point. Fire Extinguisher Types (cont.) CARBON DIOXIDE (CO2) A Trash Wood Paper A Trash Wood Paper B Liquids Grease B Liquids Grease C Electrical Equipment C Electrical Equipment • Class “B” or “C” fires. • 2.5-100 lb. of CO2 gas at 150-200 psi (8-30 seconds discharge time). • Has NO pressure gauge--capacity verified by weight. • 3-8 ft. maximum effective range. • Extinguishes by smothering burning materials. • Effectiveness decreases as temperature of burning material increases. Fire Extinguisher Types (cont.) MULTIPURPOSE DRY CHEMICAL • Class “A”, “B”, or “C” fires. A Trash Wood Paper A Trash Wood Paper B Liquids Grease B Liquids Grease C Electrical Equipment C Electrical Equipment • 2.5-20 lb. dry chemical (ammonium phosphate) pressurized to 50-200 psi by nitrogen gas (8-25 seconds discharge time). • Has pressure gauge to allow visual capacity check. • 5-20 ft. maximum effective range. • Extinguishes by smothering burning materials. Fire Extinguisher Types (cont.) WET CHEMICAL A Trash Wood Paper A Trash Wood Paper C Electrical Equipment C Electrical Equipment K Cooking Media • Class “A”, “C”, and “K” fires. • 1.5 gal. of stored pressure PRX wet chemical extinguishing agent (40 sec. discharge time). • 10-12 ft. maximum effective range. • On Class “K” fires, don’t use until after fixed extinguishing system has activated. • Extinguishes by cooling and forming foam blanket to prevent reignition. Fire Extinguisher Summary EXTINGUISHER TYPE WORKS BY PRESSURIZED WATER COOLING CARBON DIOXIDE SMOTHERING MULTIPURPOSE DRY CHEMICAL SMOTHERING HALON SMOTHERING COMBUSTIBLE METAL SMOTHERING WET CHEMICAL COOLING/ SMOTHERING EFFECTIVE AGAINST D Fire Emergency Response R Rescue A Alarm C Contain E Extinguish Firefighting Decision Criteria • Know department emergency procedures and evacuation routes. • Know locations of extinguishers in your area and how to use them. • Always sound the alarm regardless of fire size. • Avoid smoky conditions. • Ensure area is evacuated. • Don’t attempt to fight unless: – Alarm is sounded. – Fire is small and contained. – You have safe egress route (can be reached without exposure to fire). – Available extinguishers are rated for size and type of fire. • If in doubt, evacuate! Fighting the Fire P Pull the pin A Aim low at the base of flames S Squeeze the handle S Sweep side to side