Manufacturing Course Outline

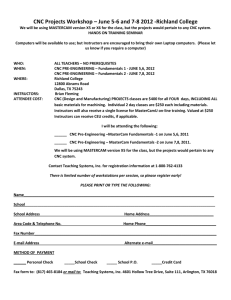

advertisement

Manufacturing Course Outline Grade: 10 – 12 Timeline: Semester Updated: 1-8-2014 Weeks Topics: Assessment/Products: Resources/Support Materials: - 2 1 - Types of Wood (review) Wood Characteristics (review) Wood recycling Recycled engineered wood products Suggested: - Wood Recycling Video - Recycle Project (Veneer Project) - MDF/OSB/Plywood All Recycled - Required: Chapters 9,10,11 Review and common assessment questions for quizzes / exams - - - 2 2-3 - General shop safety Measurement Hand Tools safety and theory (layout tools) Portable power tools safety and theory Stationary power tools safety and theory Safety test review Suggested: - Squaring Up Rough Stock (Pallet Wood bottom and sides of veneer box) - Checking and measuring for square - Designated Project Rough Cuts - Designated Project Final Cuts Required: Chapters 2, 3, 4, 5 Review and common assessment questions for quizzes / exams - Safety Test 2 2 4 - Running your own business (wood industry) Teamwork process Company Divisions Invention vs innovation Individual idea creation Suggested: - Teamwork process activities - Invention vs innovation research activity - Product research Manufacturing research methods and techniques Roles and responsibilities of officers, management, and workers Marketing and financing Suggested: - Marketing video (Wal-Mart) 5 - Required: Review and common assessment questions for quizzes / exams Required: Review and common assessment questions for quizzes / exams - - Instructor's Guide: Woodworking by Nancy MacDonald Workbook: Woodworking by Nancy MacDonald Student Edition Textbook: Woodworking by Nancy MacDonald Supplemental Book: The complete Book of Woodworking Instructor's Guide: Woodworking by Nancy MacDonald Workbook: Woodworking by Nancy MacDonald Student Edition Textbook: Woodworking by Nancy MacDonald Supplemental Book: The complete Book of Woodworking - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource Manufacturing Course Outline Grade: 10 – 12 Timeline: Semester 2 Updated: 1-8-2014 Weeks 6-7 Topics: - Prototype creation Working drawings Jig and fixture design Inspection and go/no-go design Assessment/Products: Suggested: - Prototype creation: wood, foam, rapid prototype machine, clay, ect. - AutoCAD, sketching, graph paper, Inventor drawings Required: Review and common assessment questions for quizzes / exams 2 2 2 8 - Production planning Production tooling Time study Flow process plan - Company presentations Decision making process Midterm review 9 10 Suggested: - Flow process chart and web site research Required: Review and common assessment questions for quizzes / exams Suggested: - PowerPoint, poster, technical paper, portfolio, ect. presentation Required: - Common assessment questions on the Midterm Exam - Introduction to Computer Numeric Control (CNC) CNC Equipment overview CNC Software overview (beginner level) CNC Project overview (basic level) Troubleshooting Techniques Suggested: - CNC Demo Required: - Basic CNC product Resources/Support Materials: - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - CNC Shopbot - CNC Techno-Isle Milling Machine - CNC Vertical Milling Machine - CNC Lathe Manufacturing Course Outline Grade: 10 – 12 Timeline: Semester Updated: 1-8-2014 Weeks Topics: 2 Jig and fixture creation (basic) Assembly line set-up (basic) Shop layout plan and reorganized Finalize personal and production techniques 11 Assessment/Products: Suggested: - wooden created jigs - machine modification - Shop set-up - Part / worker paths identified Required: - Student produced jigs and fixtures 2 12 - Trial run / fine tuning of assembly line Basic Continuous Production Run Deliver of product Dissolve of company Suggested: - Basic Production Run Project - Basic CNC Project Required: - Produce Basic Product 2 2 13 14 - 17 - Clamping Case joints Rail joints Housed joints Suggested: - Prepare project pieces and components - Plate jointer and / or pocket hole joinery Required: Chapters 6, 15, 17, 18 Review and common assessment questions for quizzes / exams - Computer Numeric Control (review) CNC Equipment overview (review) CNC Software overview (advanced level) Jig and fixture creation (Advanced) Assembly line set-up (Advanced) Shop layout plan and reorganized Finalize personal and production techniques Suggested: - Class Wide Production Run Project - DVD Cabinet, Folding Lawn Chair, Desk Chair, Table, ect. Required: - Finished product with CNC aspects Resources/Support Materials: - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - Technology Department Manufacturing Teaching Resource - Technology Department Manufacturing Student Activity Resource - CNC Shopbot - CNC Techno-Isle Milling Machine - CNC Vertical Milling Machine - CNC Lathe Manufacturing Course Outline Grade: 10 – 12 Timeline: Semester 2 Updated: 1-8-2014 Weeks 18 Topics: - Trial run / fine tuning of assembly line Advanced Continuous Production Run Deliver of product - Final product review Production review Final exam review Assessment/Products: Suggested: - Inspection and discussion of efficiency Required: - Common assessment questions on the Final Exam Resources/Support Materials: - Technology Department Manufacturing - Teaching Resource - Technology Department Manufacturing Student Activity Resource